In any building, ensuring the safety and quick evacuation of occupants during an emergency is a primary concern. Specialized mechanisms are employed to facilitate fast and secure exits, especially in high-traffic or high-risk environments. These systems are designed to be intuitive, reliable, and easy to operate, even under stressful conditions.

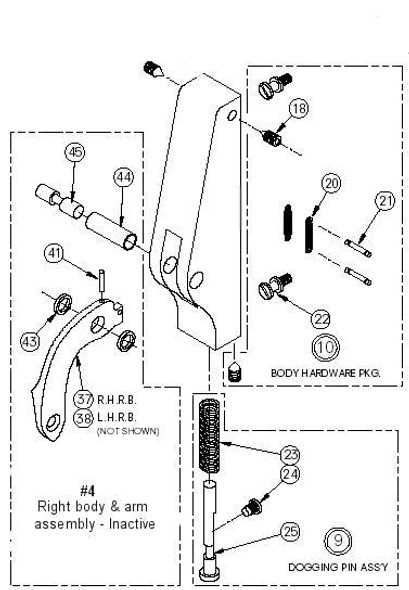

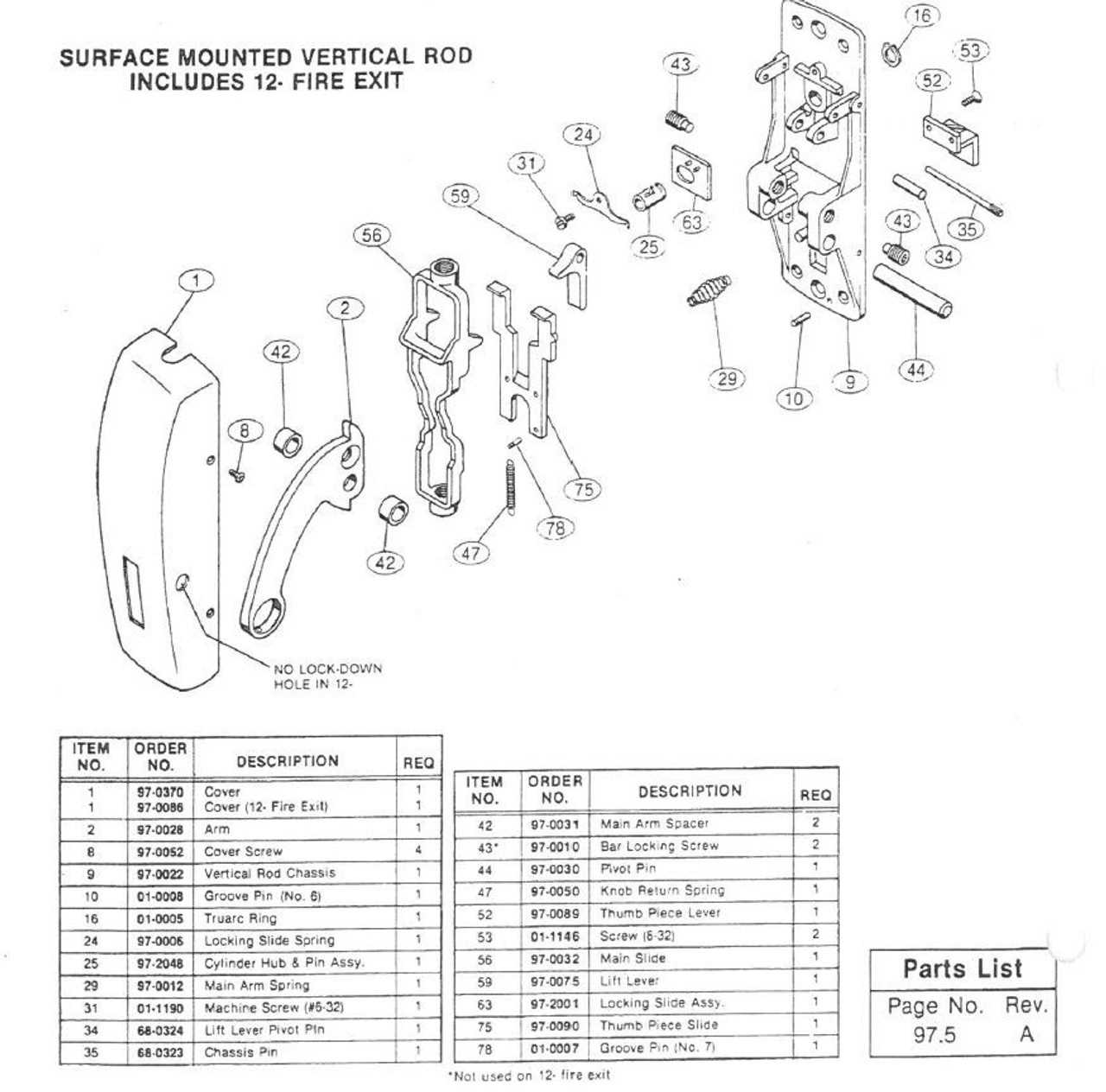

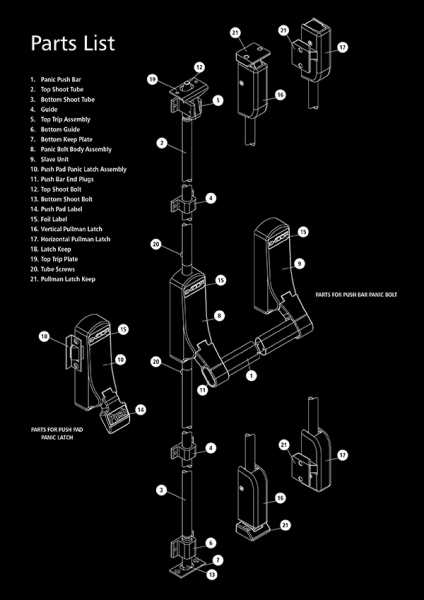

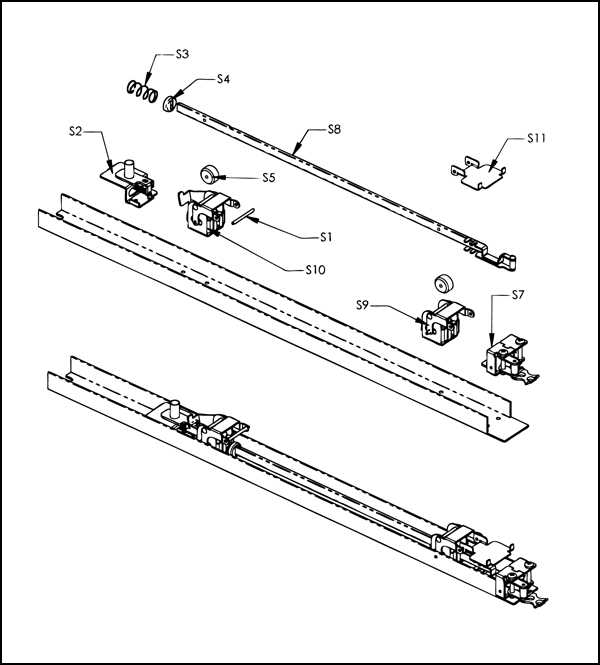

Understanding the individual elements that make up these exit devices is crucial for anyone responsible for the design, installation, or maintenance of such systems. Each component plays a specific role in ensuring the overall functionality and effectiveness of the mechanism, particularly in critical moments when every second counts.

To maintain compliance with safety regulations and ensure the longevity of these systems, it’s important to have a clear grasp of how each part interacts within the larger setup. Detailed insights into the configuration of these elements can guide professionals in selecting, installing, and servicing the systems to provide maximum security and efficiency.

Understanding Panic Bar Mechanisms

In emergency situations, quick and efficient exit from a building is essential. Specialized mechanisms are designed to facilitate swift evacuation while maintaining security when the door is not in use. These systems allow people to open doors with minimal effort, ensuring safety without compromising the integrity of the structure.

How the Mechanism Functions

The mechanism typically relies on a simple but effective design. When pressure is applied to a specific area of the device, it disengages the locking mechanism, enabling the door to swing open. This is crucial in settings where rapid clearance is necessary, such as during fire drills or actual emergencies.

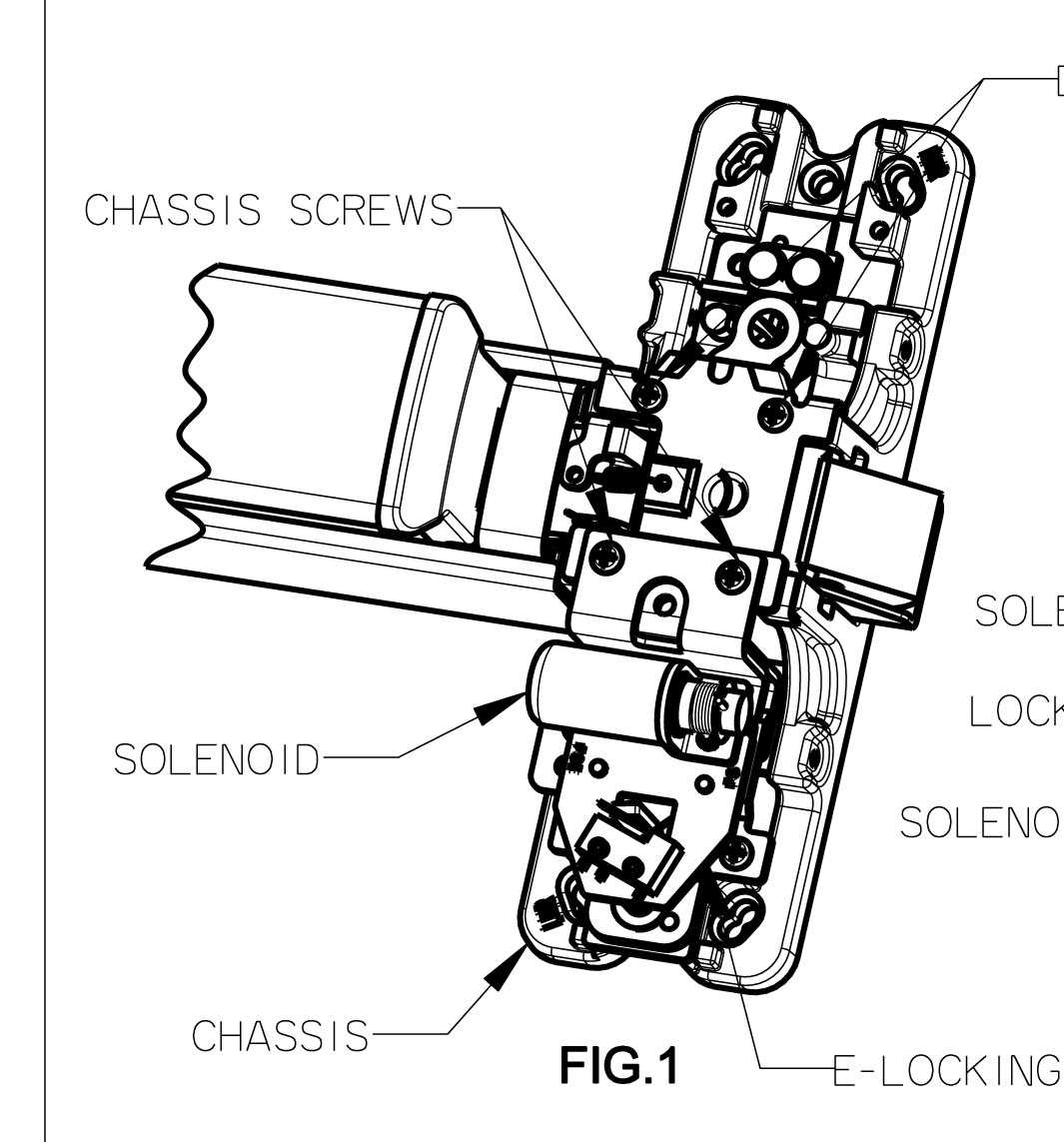

Key Components and Their Roles

Several components work together to ensure smooth operation. Locking latches hold the door in place until they are triggered by the pressure mechanism. Actuation rods transfer the pressure applied by the user to release the locks. The pivot points allow for seamless motion of the door, ensuring it opens quickly and with minimal resistance.

Essential Components of Panic Bar Systems

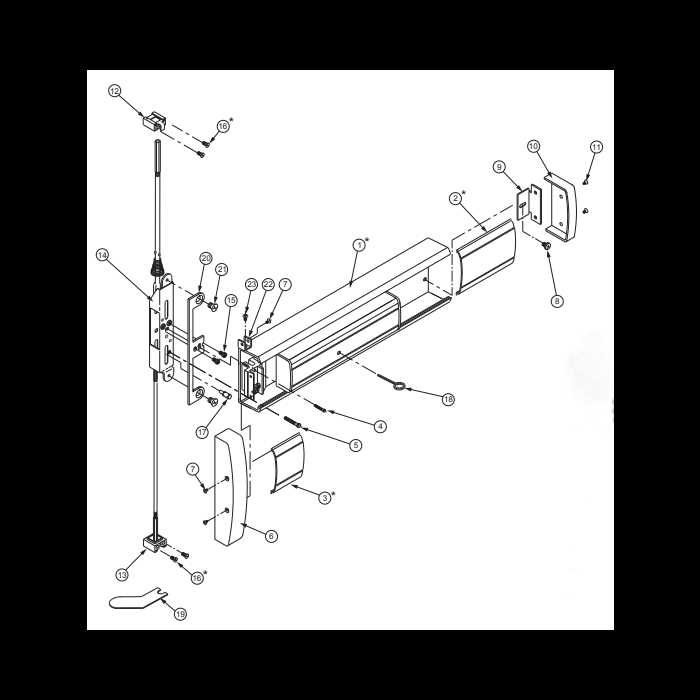

The safety mechanisms used to secure entryways while allowing for quick and efficient exit in emergencies consist of several key elements. These systems are designed to provide ease of use and durability under stressful conditions, ensuring that individuals can exit a building swiftly and without obstruction. Understanding these components is crucial for both installation and maintenance.

Here are the main elements that make up these exit control systems:

- Exit Device: The core mechanism that enables the door to open easily under pressure when activated by a simple push.

- Trims and Handles: Auxiliary controls that help in unlocking or securing the door. They typically include levers or knobs that complement the primary exit device.

- Deadbolt: A security feature that helps to keep the door closed when necessary, adding an additional layer of protection.

- Strike Plate: A metal plate on the door frame where the latch or bolt locks into place, ensuring that the door stays secure.

- Mounting Plate: The structural base that supports and holds the exit device in position on the door.

- Electromechanical Components: These may include motors or sensors that allow for automatic unlocking and door release in certain systems.

- Threshold and Seals: These parts help to prevent drafts and ensure that the door remains sealed when closed, contributing to the building’s overall security and energy efficiency.

Each component plays an integral role in providing a safe and reliable means of exit in critical situations, while also ensuring the door is secure during normal operation.

How Panic Bars Enhance Building Safety

Emergency exit systems play a crucial role in ensuring the safety of occupants in various types of buildings. These mechanisms are designed to allow quick and effortless evacuation during critical situations. They provide a means of escape without the need for traditional handles or complicated unlocking processes, significantly reducing the risk of injury or entrapment during emergencies.

In addition to their practical function, these systems are often easy to operate under pressure, ensuring that people can exit rapidly even in crowded or stressful conditions. The design of these devices ensures that doors open instantly with minimal force, which is particularly important in situations where every second counts. Their ability to provide quick access to exits helps prevent bottlenecks and overcrowding, which can lead to dangerous scenarios in emergency evacuations.

Furthermore, these systems contribute to compliance with building codes and safety regulations. They are often a mandatory feature in structures where large groups of people gather, such as schools, offices, and public venues. By integrating these systems, buildings can provide a safer environment for all occupants, helping to mitigate risks during fires, natural disasters, or other urgent situations.

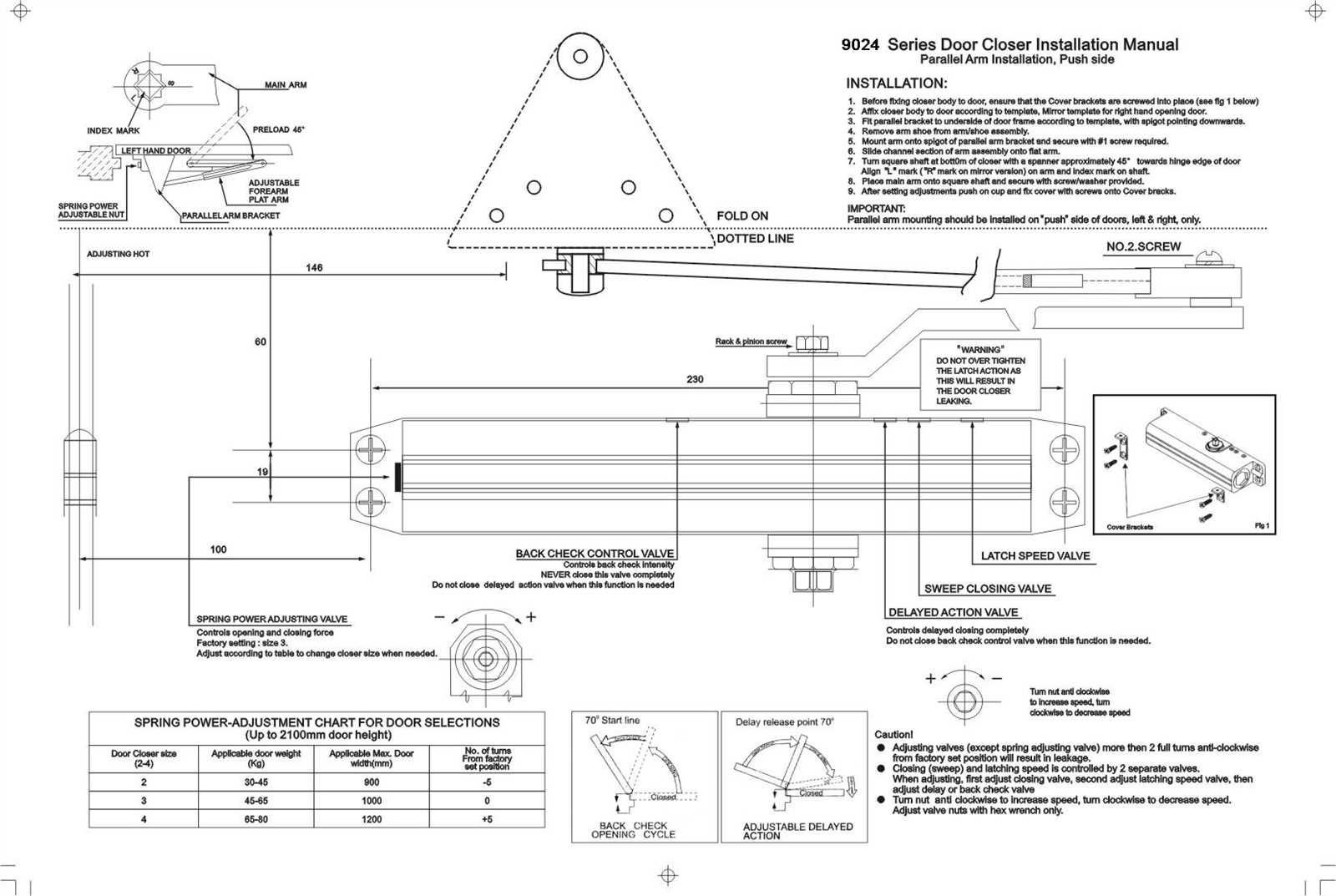

Step-by-Step Panic Bar Installation Guide

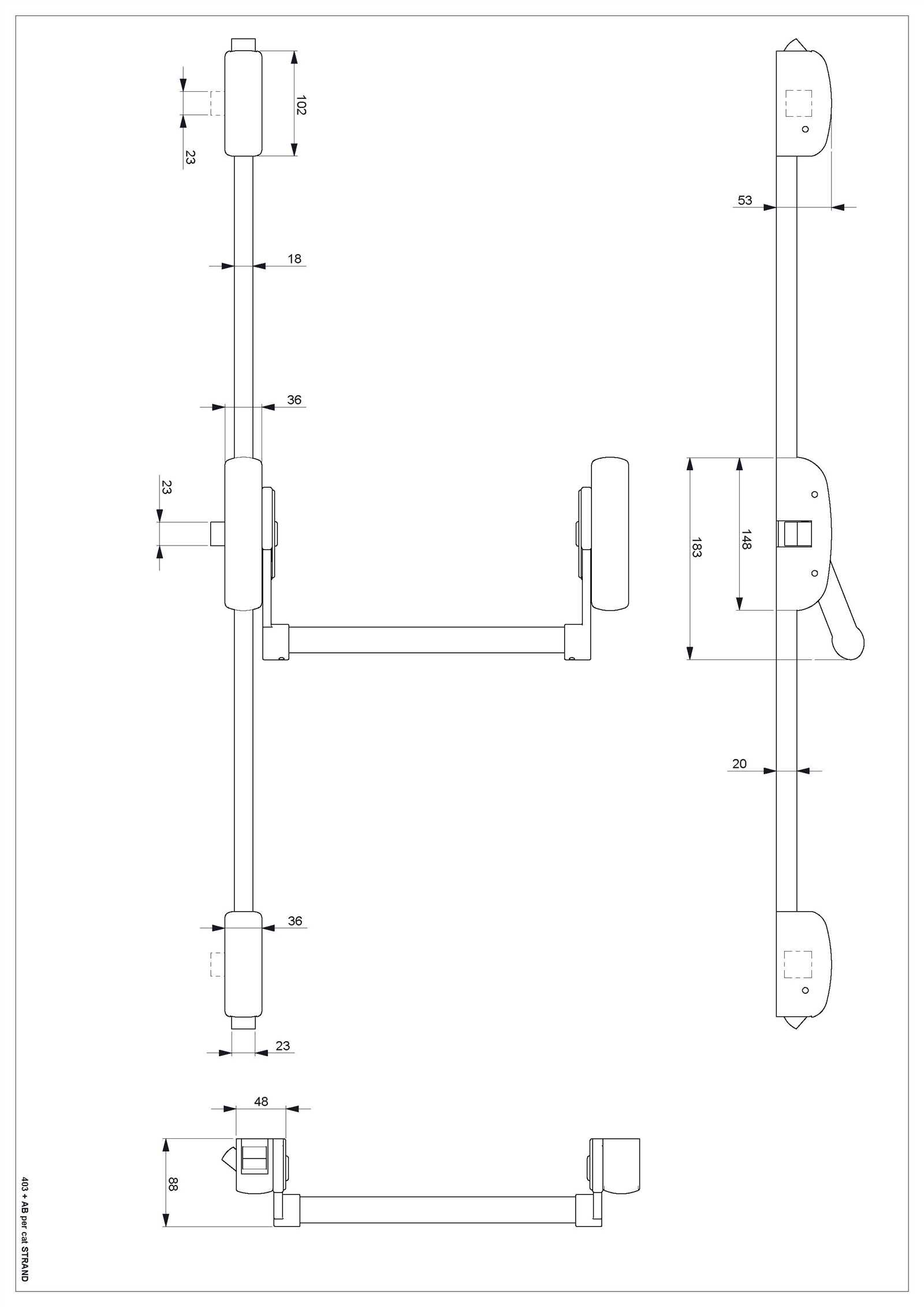

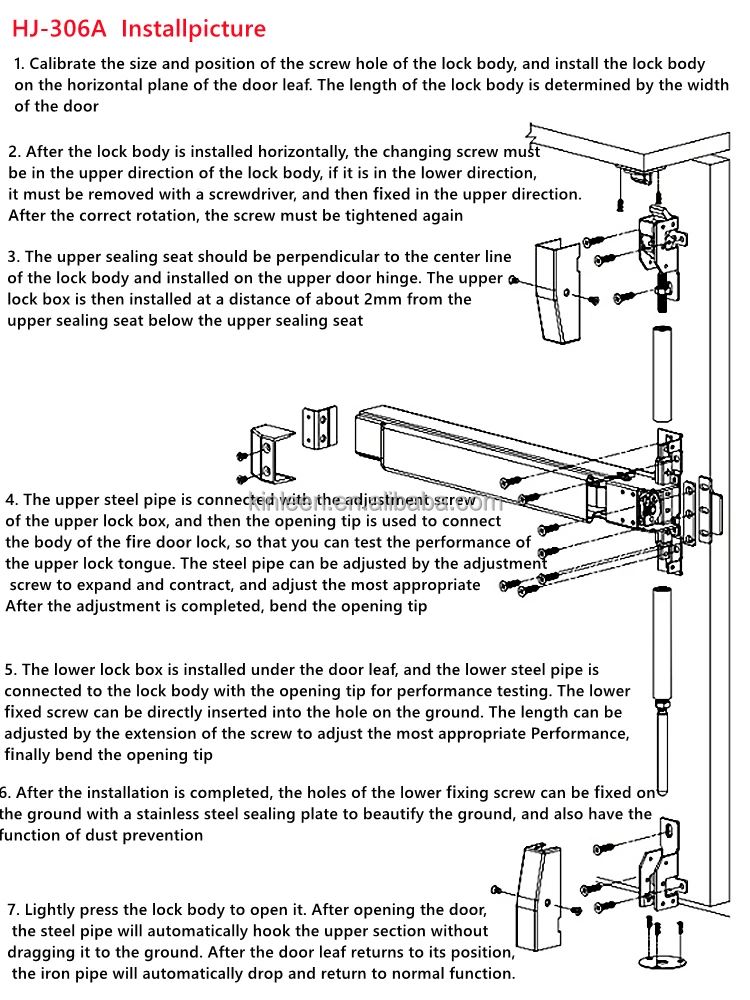

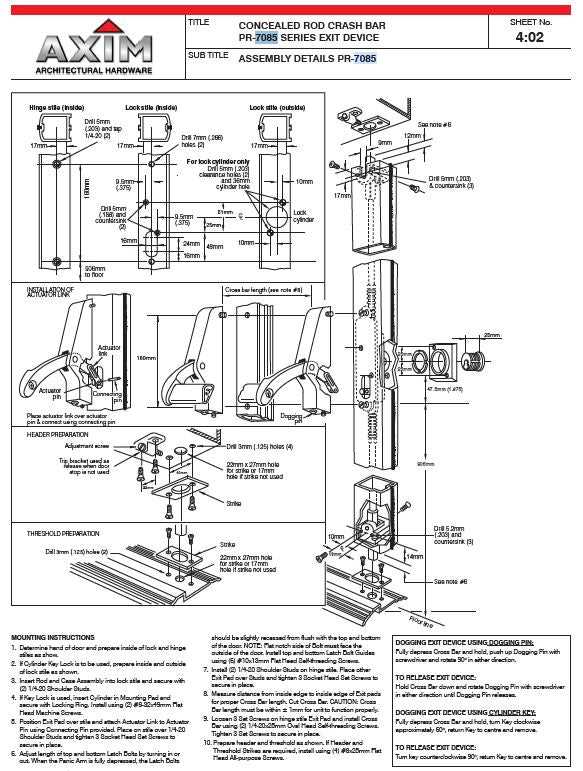

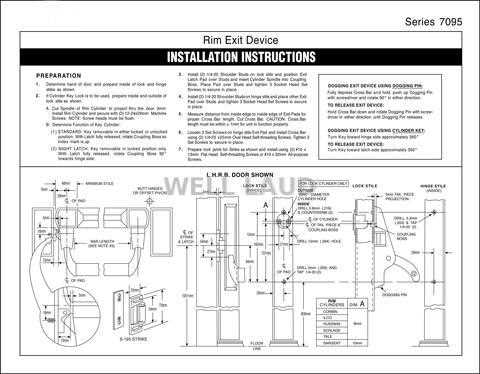

Proper installation of emergency exit devices is crucial for ensuring safe and efficient evacuation in critical situations. This guide will walk you through the necessary steps to correctly fit such a system, ensuring that it functions reliably and meets safety standards. Whether you’re installing a new unit or replacing an old one, following these instructions will help you achieve optimal results.

1. Preparation and Tools

Before starting the installation, gather all necessary tools, including a screwdriver, measuring tape, drill, and level. Ensure the door is properly aligned and free from any obstructions. Also, make sure you have the correct device model and that all components are present in the package.

2. Marking the Placement

Carefully measure and mark the ideal location for the unit on the door. The center of the device should be positioned at a height that is accessible and comfortable for all users, typically around 40-48 inches from the floor. Use a level to ensure the marks are straight and aligned.

3. Drilling the Holes

Once the placement is marked, drill the necessary holes for mounting screws and any other required fittings. Make sure the holes align with the mounting brackets and that they are drilled to the correct depth for the screws provided. If needed, use a wood or metal drill bit depending on your door material.

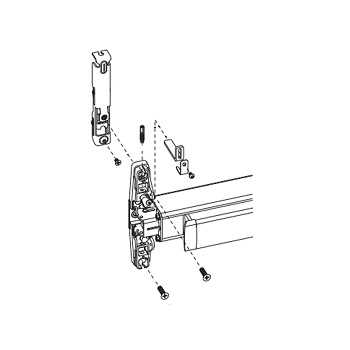

4. Installing the Device

Secure the device to the door by aligning it with the drilled holes. Attach the mounting hardware and tighten the screws firmly, ensuring the system is securely fastened. Double-check the alignment before moving on to the next step.

5. Testing the Mechanism

Once installed, test the mechanism to confirm it operates smoothly. Push the release mechanism to ensure the door opens easily without resistance. Verify that the device returns to its normal position after use and that the door closes properly.

6. Final Adjustments

If necessary, make any final adjustments to the tension or alignment of the device. This will ensure long-term durability and reliability in emergency situations. Afterward, clean the area and check the unit for any loose components.

Common Issues with Panic Bar Systems

Exit systems designed for quick release and ease of access can encounter a range of operational problems. These issues, if left unaddressed, can compromise the safety and functionality of the exit mechanism. Understanding the common challenges associated with these systems is crucial for ensuring they perform as intended during an emergency.

One of the most frequent problems is the misalignment of the mechanism, which can prevent the door from opening smoothly. This can be caused by wear and tear, improper installation, or external factors like shifts in the building structure. Another issue is the malfunction of the locking mechanism, which may fail to disengage when needed. Corrosion or rust, particularly in high-humidity environments, can also affect the system’s performance, leading to sluggish operation or complete failure.

In addition, regular maintenance is often neglected, which increases the likelihood of obstructions or damage. Accumulation of dirt, debris, or even loose components can interfere with the proper functioning of the release system. Lastly, some systems may be outdated or improperly fitted to the door, causing compatibility issues and reducing their effectiveness in a critical situation.

Repairing and Maintaining Emergency Exit Mechanisms

Regular maintenance and prompt repair of emergency exit devices are crucial for ensuring the safety and efficiency of building evacuation systems. These systems must be kept in optimal working condition to provide quick and easy access in times of need. Neglecting these components can lead to malfunctions or failures, posing serious risks during emergencies.

To maintain these systems effectively, routine inspections should be carried out, and any worn or damaged components should be promptly addressed. Understanding the core elements and mechanisms involved allows for better decision-making during the repair process and prolongs the lifespan of the system.

| Common Issues | Solution |

|---|---|

| Sticky or hard-to-press mechanism | Lubricate the moving parts to ensure smooth operation. If the issue persists, check for misalignment or obstruction. |

| Loose or damaged frame | Check for loose screws or bolts, and tighten them. Replace any broken or worn-out parts. |

| System not functioning correctly during emergencies | Inspect the spring-loaded mechanism and ensure all components are in place. Test the device regularly for functionality. |

| Rust or corrosion | Clean and apply rust-proofing treatments to affected areas. Replace severely corroded parts if necessary. |

Regular servicing, along with using high-quality replacement components, will help keep emergency exit systems in peak working condition, safeguarding the building’s occupants and ensuring compliance with safety regulations.

Choosing the Right Panic Bar for Your Door

When it comes to securing your space while ensuring quick and safe exit in emergencies, selecting the proper exit hardware is crucial. The right system can offer both reliability and ease of use, providing peace of mind in high-traffic areas or places where safety is a top priority. This guide will help you understand the key factors to consider when choosing the appropriate solution for your door.

Consider Door Functionality and Traffic Flow

The first step in making an informed choice is to assess the functionality of your door. Consider how often the door is used and the volume of foot traffic that passes through it. If the door is located in a busy area or serves as a primary exit point, you’ll need a durable and easy-to-operate system. For less frequent use, simpler models may suffice.

Safety Standards and Compliance

Another important factor is ensuring the hardware meets local safety codes and regulations. Compliance with these standards is necessary for both functionality and legal reasons. Make sure the system you choose is designed to provide quick and effective release in emergencies, allowing people to exit with minimal effort.

By taking these considerations into account, you’ll be able to find the right solution that balances security, convenience, and safety for your specific needs.

Panic Bar Compliance with Safety Standards

Ensuring the proper functioning of exit mechanisms in buildings is essential for meeting safety regulations. These systems play a crucial role in facilitating swift and safe evacuations during emergencies. Compliance with established safety codes is mandatory to prevent hindrances in life-threatening situations, ensuring that occupants can exit the building efficiently and without obstruction. Meeting these standards requires not only correct installation but also regular maintenance and testing.

Various regulatory bodies, such as the National Fire Protection Association (NFPA) and Americans with Disabilities Act (ADA), set forth specific criteria that these systems must adhere to. These regulations address factors like accessibility, ease of operation, and durability. Devices must allow for easy exit under pressure, including for individuals with disabilities, and must function properly even under extreme conditions. Non-compliance can lead to serious safety risks and legal consequences.

To maintain adherence to these standards, manufacturers and building owners must carefully select and install components that meet the required specifications. Regular inspections and updates ensure that the systems remain functional and compliant with evolving safety protocols. This attention to detail ultimately safeguards the well-being of all building occupants during emergencies.

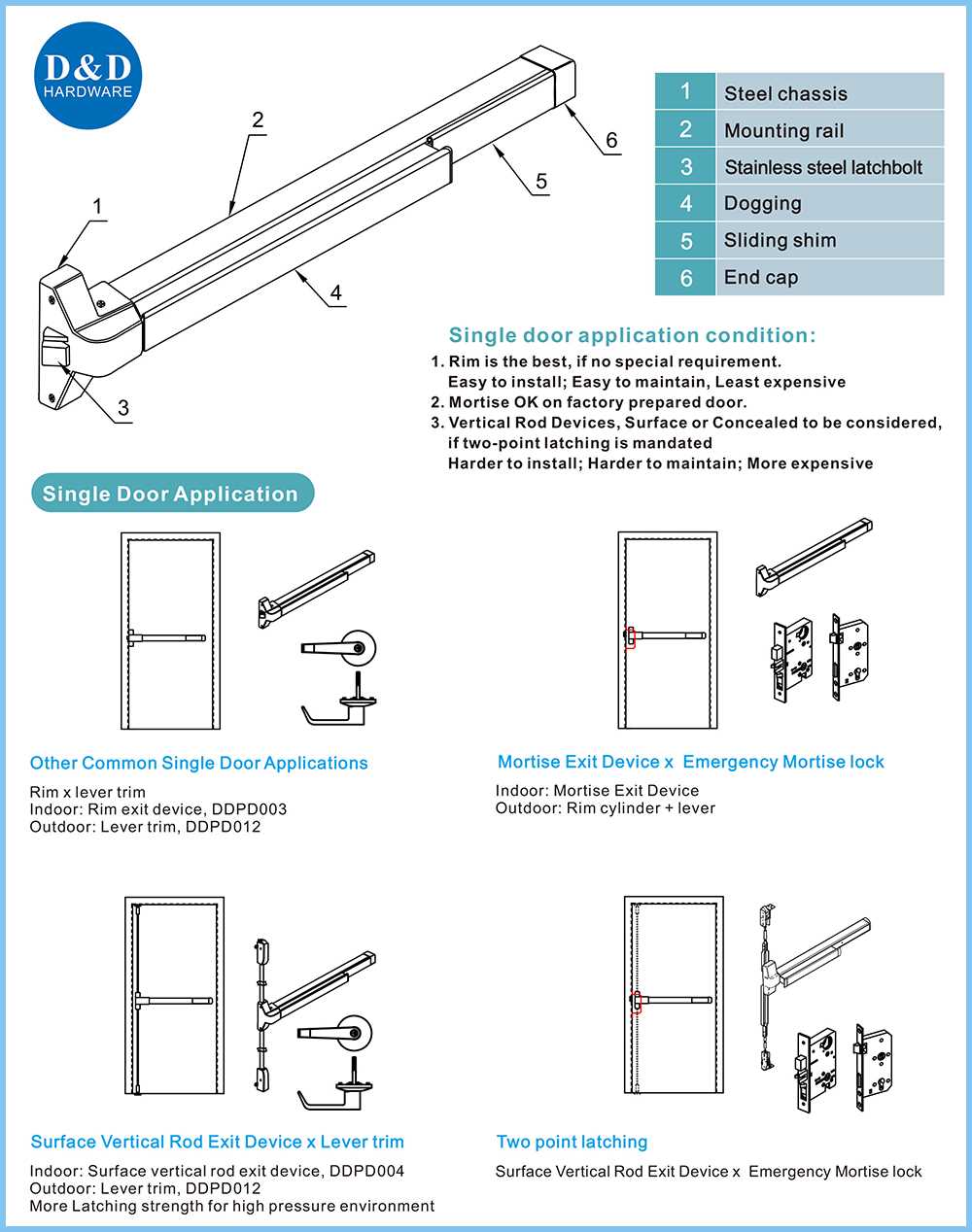

Different Types of Panic Bar Locks

Emergency exit systems come in various forms, each designed to provide quick and efficient egress during critical situations. These systems are essential for safety, especially in commercial and public buildings. They ensure that occupants can swiftly leave the premises without complicated steps or delays, while also securing the door when not in use. Different designs offer varying levels of security, ease of use, and functionality.

There are several types of emergency exit locking mechanisms, each catering to specific needs or building codes. Understanding the differences can help in selecting the most appropriate system for a given environment.

- Lever Handle Locks: These systems incorporate a lever that, when pushed, releases the lock and allows for immediate exit. They are commonly used in areas where quick access is essential and where users may need to exert less force to operate the mechanism.

- Touch Bar Systems: This option features a horizontal bar that, when pressed, activates the locking mechanism. It is often preferred in commercial spaces for its simple design and ease of operation. Touch bar systems offer a balance between safety and accessibility.

- Vertical Rod Mechanisms: Vertical locking systems are generally used on taller doors. These locks engage at both the top and bottom of the door, providing added security. They are ideal for high-traffic areas where extra reinforcement is required.

- Mortise Lock Units: Mortise systems are integrated into the door, providing a more concealed locking mechanism. These are commonly found in high-security areas where discretion and durability are critical. Mortise locks offer advanced security features while maintaining aesthetic appeal.

- Double-Action Systems: Designed for double doors, these systems allow for exit from either side, making them highly versatile for large venues and emergency exits that require simultaneous accessibility from multiple directions.

Choosing the right lock type depends on factors such as building code requirements, traffic flow, security concerns, and the nature of the environment. Proper installation and regular maintenance ensure the functionality of these essential systems during an emergency.

Tools Needed for Panic Bar Repairs

When it comes to restoring or fixing the exit mechanism of doors, having the right tools is essential. Repairing this type of system can require precision and the correct equipment to ensure safety and functionality. Whether you’re replacing a malfunctioning component or conducting regular maintenance, being properly equipped will make the job more efficient and effective.

Basic Tools Required

Before starting the repair, it’s important to gather the necessary tools to avoid delays. Here is a list of common tools that are typically needed:

- Flathead screwdriver

- Phillips head screwdriver

- Measuring tape

- Drill with assorted bits

- Utility knife

- Rubber mallet

- Level

- Pliers

- Socket wrench set

Specialized Tools for Advanced Repairs

For more in-depth repairs or replacements, you may need a few additional tools. These are essential for ensuring a thorough and professional fix:

- Impact driver

- Hacksaw or pipe cutter (for cutting metal parts)

- Wire cutters and strippers

- Tap and die set (for threading parts)

- Torque wrench

Having both basic and specialized tools on hand will allow you to tackle any issues that arise, ensuring a smooth and reliable repair process.

Upgrading Your Panic Bar System

Improving the security and functionality of your emergency exit mechanism is essential for both safety and convenience. An upgrade can enhance the performance, durability, and compliance of the system, ensuring smooth operation under all circumstances. With the right enhancements, you can make your system more reliable, efficient, and adaptable to your building’s specific needs.

Modernizing the locking mechanism is one of the key upgrades. By choosing advanced locking solutions, you ensure better control over access while maintaining quick exit capabilities in emergencies. Modern electronic locks or smart systems can also allow remote management, providing enhanced security and flexibility.

Durability and weather resistance are other factors to consider. If your current system has aged or been exposed to harsh environmental conditions, replacing components with more robust materials can greatly extend its lifespan and performance. Weatherproof finishes and corrosion-resistant materials are particularly useful for installations in outdoor or high-traffic areas.

Upgrading the hardware also involves ensuring the system is compliant with the latest safety regulations. Regularly updating your system to meet evolving legal requirements will ensure you avoid penalties and maintain optimal safety standards for building occupants.

How to Troubleshoot Panic Bar Problems

Ensuring that your emergency exit mechanism functions properly is crucial for the safety of any building. If the mechanism becomes faulty, it can pose significant risks. Identifying and resolving issues promptly is essential to maintain security and compliance with safety regulations. This section will guide you through common problems and solutions to ensure smooth operation.

Follow these steps to troubleshoot and repair any malfunctions:

- Check for Obstructions: Ensure that nothing is blocking the mechanism. Small debris or other objects may prevent the latch from engaging correctly.

- Examine the Locking Mechanism: If the latch doesn’t move freely, the lock or latch might be jammed. Inspect for any visible damage or signs of wear.

- Test the Spring Function: The spring inside the system is responsible for returning the mechanism to its original position. If it’s worn or broken, it might not provide the necessary tension. Replace the spring if needed.

- Inspect the Hardware: Loose screws or components can impair the operation of the system. Tighten or replace any hardware that appears damaged or worn out.

- Evaluate the Release Mechanism: The release mechanism should engage smoothly when pressure is applied. If it’s difficult to operate, check for misalignment or damage to internal components.

- Lubrication: Apply lubricant to moving parts to ensure smooth functioning. Avoid over-lubrication, which can attract dirt and grime, causing more issues over time.

- Test After Repairs: After performing any necessary fixes, thoroughly test the system to ensure it functions properly under different conditions, including pressure and force.

Regular maintenance and inspections can prevent most problems before they become serious issues. Keep an eye on the functionality and integrity of the system to ensure that it remains reliable in times of need.