In the world of power equipment, comprehending the layout of components is essential for effective maintenance and repair. Knowing the specific arrangement of elements enables users to troubleshoot issues more efficiently and ensures that their tools operate at peak performance. This section delves into the intricacies of these arrangements, providing a clear overview that aids both seasoned professionals and casual users alike.

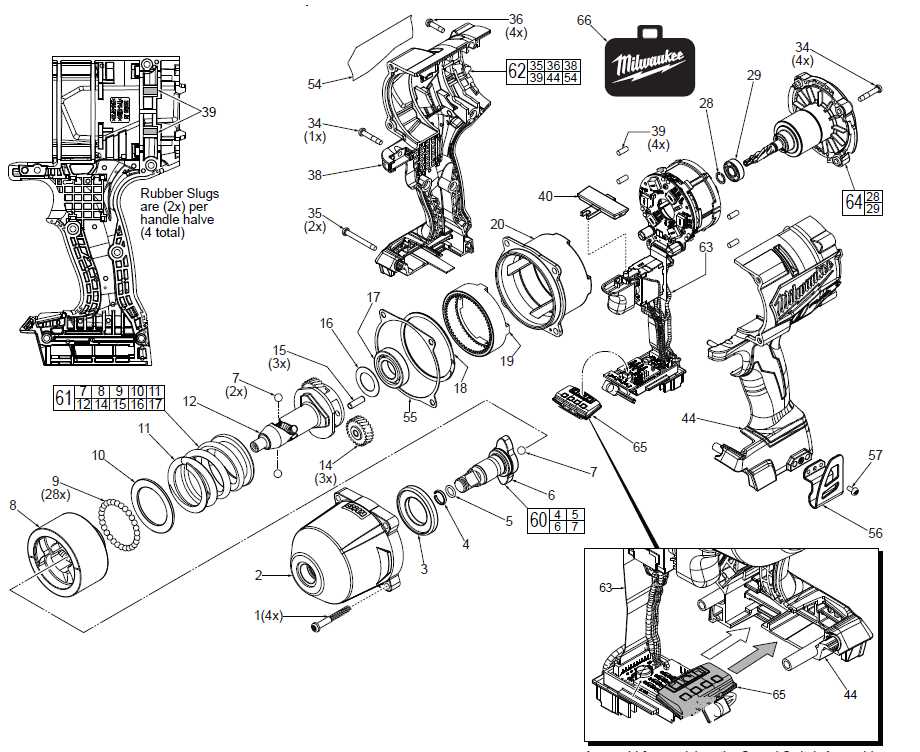

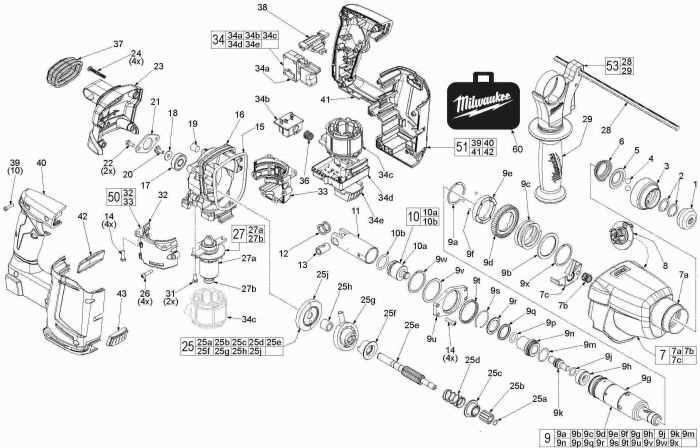

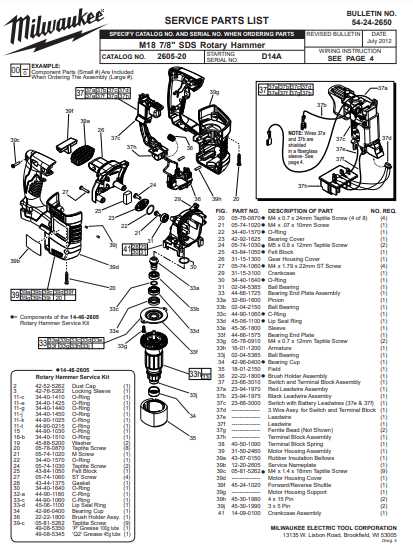

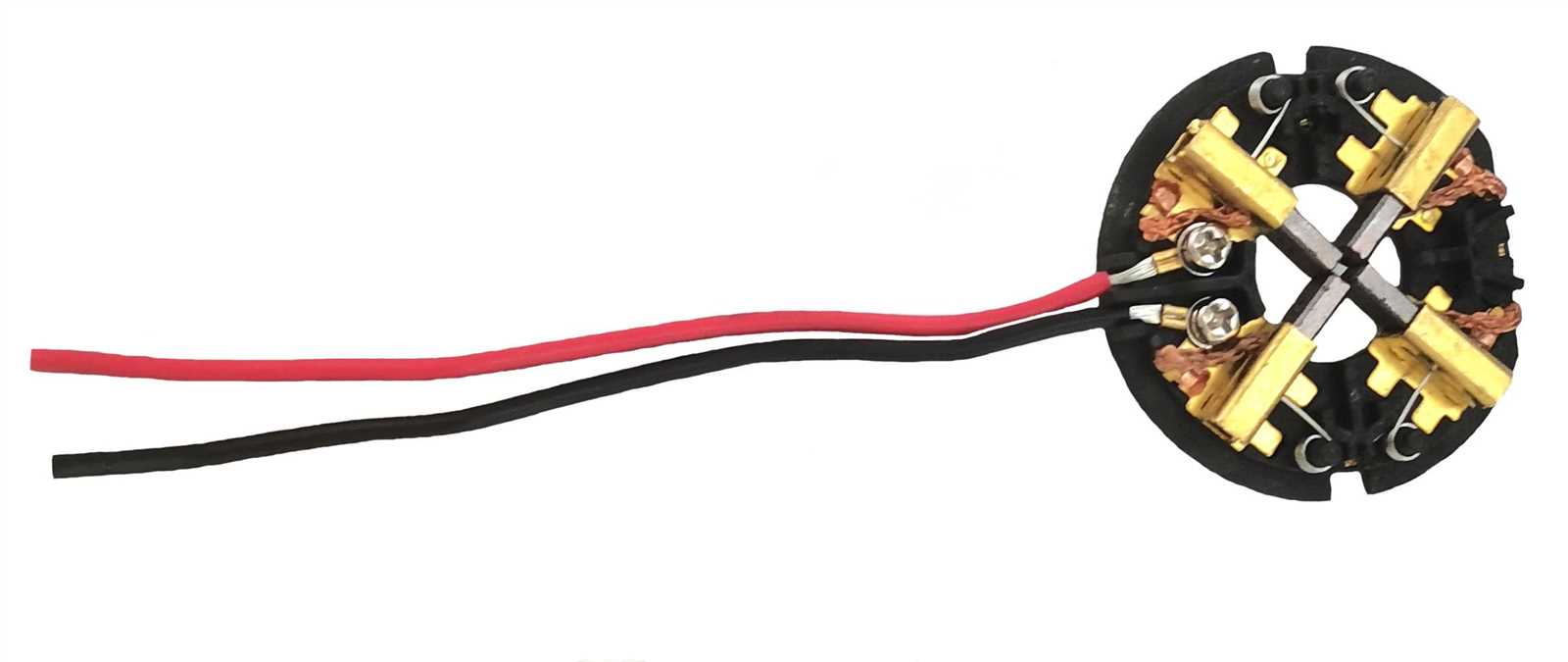

Visual representations of tool configurations are invaluable resources for anyone involved in the upkeep of machinery. They serve as guides that illustrate how individual parts interact, offering insights into assembly and disassembly processes. By familiarizing oneself with these layouts, users can enhance their understanding of the equipment, leading to improved functionality and longevity.

Furthermore, mastering these layouts not only simplifies repairs but also empowers users to make informed decisions regarding replacements and upgrades. With a solid grasp of the structural relationships within their tools, individuals can approach maintenance tasks with confidence and precision, minimizing downtime and maximizing efficiency.

Understanding Milwaukee 2607-20 Components

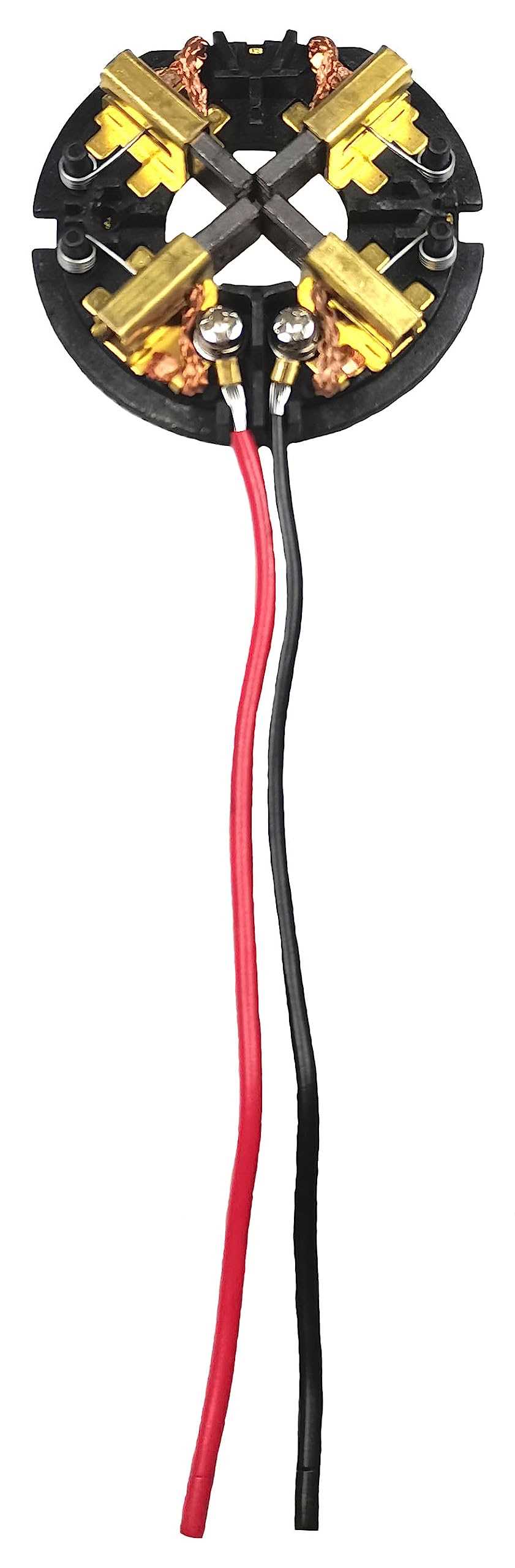

The exploration of any power tool’s structure reveals intricate elements that work in harmony to enhance performance and user experience. Each component plays a vital role, contributing to the overall efficiency and effectiveness of the device. Understanding these individual parts not only aids in maintenance and repair but also empowers users to make informed decisions regarding their usage and care.

Key Elements: A thorough grasp of the critical components allows users to appreciate the engineering behind the tool. For instance, the motor is essential for driving the mechanism, while the battery serves as the power source. Additionally, features such as the trigger, housing, and various attachments can significantly impact functionality and versatility.

Maintenance Considerations: Regular inspections and familiarity with the elements can prevent common issues. Recognizing wear and tear on specific components enables proactive measures to ensure longevity. Users should always refer to manufacturer recommendations for upkeep, enhancing safety and reliability.

In summary, a comprehensive understanding of the distinct elements within the tool can significantly improve user interaction, ensuring optimal performance while extending the lifespan of the equipment.

Importance of Parts Diagrams

Understanding the components of a device is crucial for effective maintenance and repair. Visual representations of these elements provide valuable insight into the assembly and functionality of various tools and machinery. Such illustrations enable users to identify, troubleshoot, and replace necessary components with ease.

Here are some key reasons why these visual aids are essential:

- Enhanced Clarity: Visuals simplify complex structures, making it easier for users to comprehend how each part fits and operates within the whole.

- Efficient Repairs: Knowing the specific elements involved allows technicians to quickly diagnose issues and execute repairs, minimizing downtime.

- Accurate Ordering: When a replacement is needed, having a clear representation helps in ordering the correct piece, reducing the risk of errors.

- Improved Safety: Understanding the arrangement of components can help prevent accidents during maintenance by highlighting potential hazards.

- Guided Assembly: For individuals assembling new devices, these representations offer step-by-step guidance, ensuring all elements are correctly installed.

In summary, having a comprehensive visual reference of the various components significantly contributes to effective maintenance, repair, and overall safety of equipment.

Key Features of Milwaukee Tools

Powerful tools designed for professionals and DIY enthusiasts alike are characterized by their innovative technology and reliable performance. These instruments stand out in the market for their ability to deliver exceptional efficiency and durability, making them essential for various applications.

Robust Construction: Crafted from high-quality materials, these devices are built to withstand rigorous use in demanding environments. Their solid design ensures longevity and minimizes the need for frequent replacements.

Advanced Battery Technology: Featuring cutting-edge battery systems, these power tools offer extended runtime and quick charging capabilities. This technology enhances productivity by allowing users to work longer without interruptions.

Ergonomic Design: The user-friendly architecture focuses on comfort and ease of use. Lightweight builds and strategically placed grips reduce fatigue, enabling operators to maintain optimal control during extended tasks.

Versatile Range: A wide variety of tools caters to different needs, from heavy-duty machinery to compact handheld options. This diversity allows users to select the right tool for specific jobs, ensuring maximum efficiency.

Smart Features: Integrated smart technology, such as Bluetooth connectivity and app integration, provides real-time monitoring and enhanced functionality. Users can track performance and receive updates, optimizing their workflow.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This guide will help you navigate through the illustration, enabling you to identify individual elements and their functions.

To effectively interpret the representation, follow these steps:

- Familiarize Yourself with Symbols:

Different symbols may represent various components. Knowing these can simplify the process of identification.

- Identify the Key:

Look for a legend or key that explains the symbols and numbers. This information is crucial for accurate understanding.

- Examine the Layout:

Pay attention to how components are arranged. Their placement often indicates their relationship and order in the assembly.

- Take Note of Labels:

Labels often indicate the part number or function. Use these details to cross-reference with other resources.

- Consult Additional Resources:

Refer to manuals or guides that provide more context about the components depicted in the illustration.

By following these guidelines, you can enhance your ability to understand and work with any technical representation, making repairs and maintenance more efficient.

Common Issues with Milwaukee 2607-20

Power tools, while incredibly useful, can sometimes present challenges that affect their performance. Understanding these common problems is essential for effective troubleshooting and maintenance. This section highlights frequent difficulties encountered with this specific cordless drill model, aiming to provide insights into their causes and solutions.

Battery-Related Problems

One of the most prevalent issues users face is related to the power source. A depleted or malfunctioning battery can lead to insufficient power delivery, resulting in poor tool performance. Signs of battery issues include extended charging times and decreased runtime. To resolve this, ensure the battery is properly charged and consider replacing it if performance does not improve.

Drilling Efficiency Decline

Another common concern involves a decline in drilling efficiency. This may manifest as slower speeds or difficulty penetrating materials. Such problems can often be attributed to worn-out drill bits or improper settings. To enhance performance, regularly inspect and replace drill bits, and verify that the tool is set to the correct mode for the task at hand.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure the extended life of your tools. Following a few straightforward practices can significantly enhance performance and durability, allowing for efficient operation and reducing the need for repairs.

Routine Cleaning

- Regularly wipe down the exterior surfaces to remove dust and debris.

- Check and clean any ventilation openings to prevent overheating.

- Inspect and remove any buildup from moving parts to maintain smooth operation.

Periodic Inspection

- Examine all components for signs of wear or damage.

- Test the tool’s functionality to identify any issues before they escalate.

- Ensure all screws and fasteners are tight and secure.

Implementing these maintenance strategies will not only extend the lifespan of your equipment but also optimize its efficiency, making every task easier and more enjoyable.

Identifying Parts by Model Number

Understanding the significance of model identifiers is crucial for anyone seeking to replace components or perform maintenance on their tools. Each model number serves as a unique key, unlocking access to specific components that ensure the optimal functioning of the equipment. By familiarizing oneself with these identifiers, users can streamline their repair processes and avoid unnecessary complications.

Benefits of Using Model Identifiers

Utilizing the model identifier enables users to efficiently locate the necessary components. This not only saves time but also minimizes the risk of acquiring incorrect items. Having accurate information leads to better performance and longevity of the tools, ensuring that users can rely on their equipment for various tasks.

Steps to Identify Components

To pinpoint the required elements, begin by locating the model number, often found on the tool itself. Once obtained, refer to the manufacturer’s reference materials, which typically include comprehensive listings of compatible components. Cross-referencing this information with online resources can further aid in confirming the exact specifications needed for replacement or repair.

Where to Find Replacement Parts

Finding suitable components for your power tools is essential to maintaining their functionality and ensuring longevity. Various sources offer access to high-quality replacements, enabling users to restore their equipment to optimal performance. Whether you’re looking for original items or reliable alternatives, knowing where to search can make all the difference.

Official Retailers and Service Centers

One of the most reliable options for sourcing new components is through authorized dealers and service centers. These establishments typically stock genuine replacements that match the original specifications. Additionally, purchasing from these sources can provide peace of mind, as they often offer warranties and support services. It is advisable to check the manufacturer’s website for a list of certified retailers in your area.

Online Marketplaces

Another effective way to locate essential replacements is by exploring online marketplaces. Websites like Amazon and eBay feature numerous listings from various sellers, providing a wide range of options. When shopping online, pay attention to customer reviews and ratings to ensure the quality of the items being purchased. This approach not only allows for price comparisons but also enables you to find rare or hard-to-find components.

Benefits of Using Original Parts

Utilizing authentic components in your tools and equipment ensures optimal performance and longevity. These high-quality elements are designed specifically for each model, providing seamless integration and reliability that enhances the overall functionality.

Choosing genuine replacements significantly reduces the risk of malfunction and wear. Below are some key advantages of opting for original replacements:

| Advantage | Description |

|---|---|

| Quality Assurance | Original components undergo rigorous testing, ensuring they meet stringent quality standards, which translates to better performance and durability. |

| Perfect Fit | Authentic replacements are engineered to fit seamlessly with your device, minimizing the chances of compatibility issues that can arise with generic options. |

| Improved Safety | Using original elements reduces the likelihood of accidents caused by faulty or substandard parts, ensuring safer operation. |

| Warranty Protection | Many manufacturers provide warranties for devices that use genuine components, offering peace of mind and potential savings on future repairs. |

| Enhanced Resale Value | Maintaining a tool with original parts can help preserve its value, making it more attractive to potential buyers when it comes time to sell or trade. |

DIY Repairs with Parts Diagrams

Understanding the assembly of tools and machinery can significantly enhance your ability to perform repairs at home. By utilizing visual aids that break down the components of devices, you can identify issues and find suitable replacements more efficiently. This approach not only saves time but also reduces costs associated with professional repairs.

Benefits of Using Visual Guides

- Enhanced Clarity: Visual representations make it easier to understand complex systems.

- Improved Accuracy: Identifying specific elements leads to more precise repairs.

- Cost Efficiency: By performing repairs yourself, you can avoid expensive service fees.

- Time Savings: Quickly locate the parts you need without guesswork.

Steps for Effective Repairs

- Identify the malfunctioning tool or equipment.

- Consult a visual reference to understand its structure.

- Locate the necessary components that require replacement.

- Gather the appropriate tools for disassembly.

- Carefully follow the steps to replace the faulty parts.

- Reassemble the device and test it to ensure proper functionality.