Familiarizing yourself with the various elements of your gardening tool can greatly enhance its performance and longevity. By examining the intricate relationships between each part, users can better appreciate how these mechanisms function together. This knowledge is essential for effective maintenance and troubleshooting, allowing for a smoother and more efficient operation.

Each unit comprises several key components that work in unison to deliver optimal results. Identifying these elements not only aids in repairs but also helps in understanding the assembly and disassembly processes. Recognizing the significance of each section can empower users to take informed actions when it comes to upkeep.

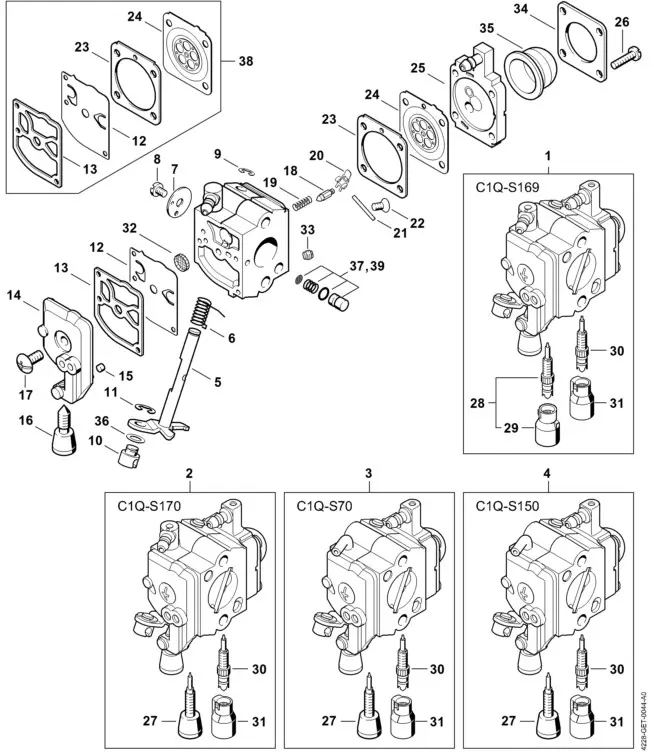

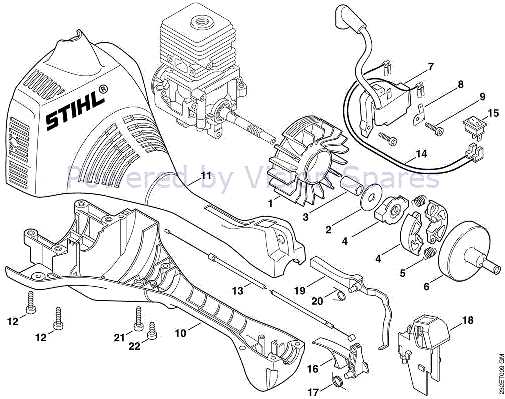

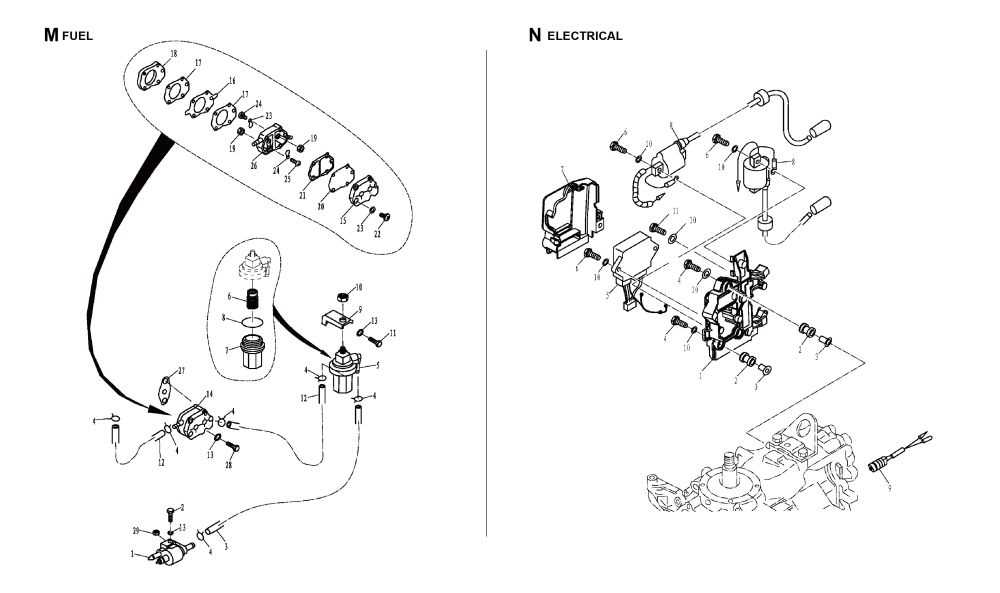

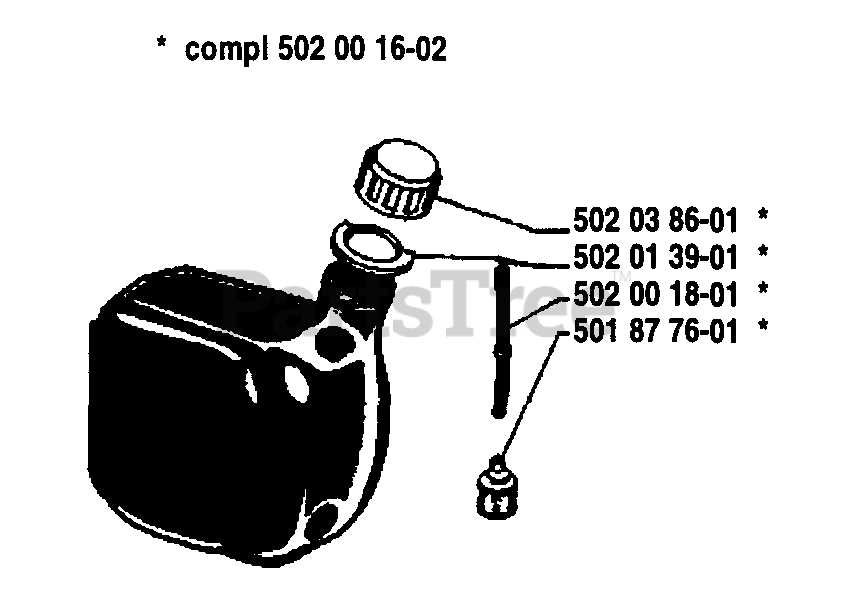

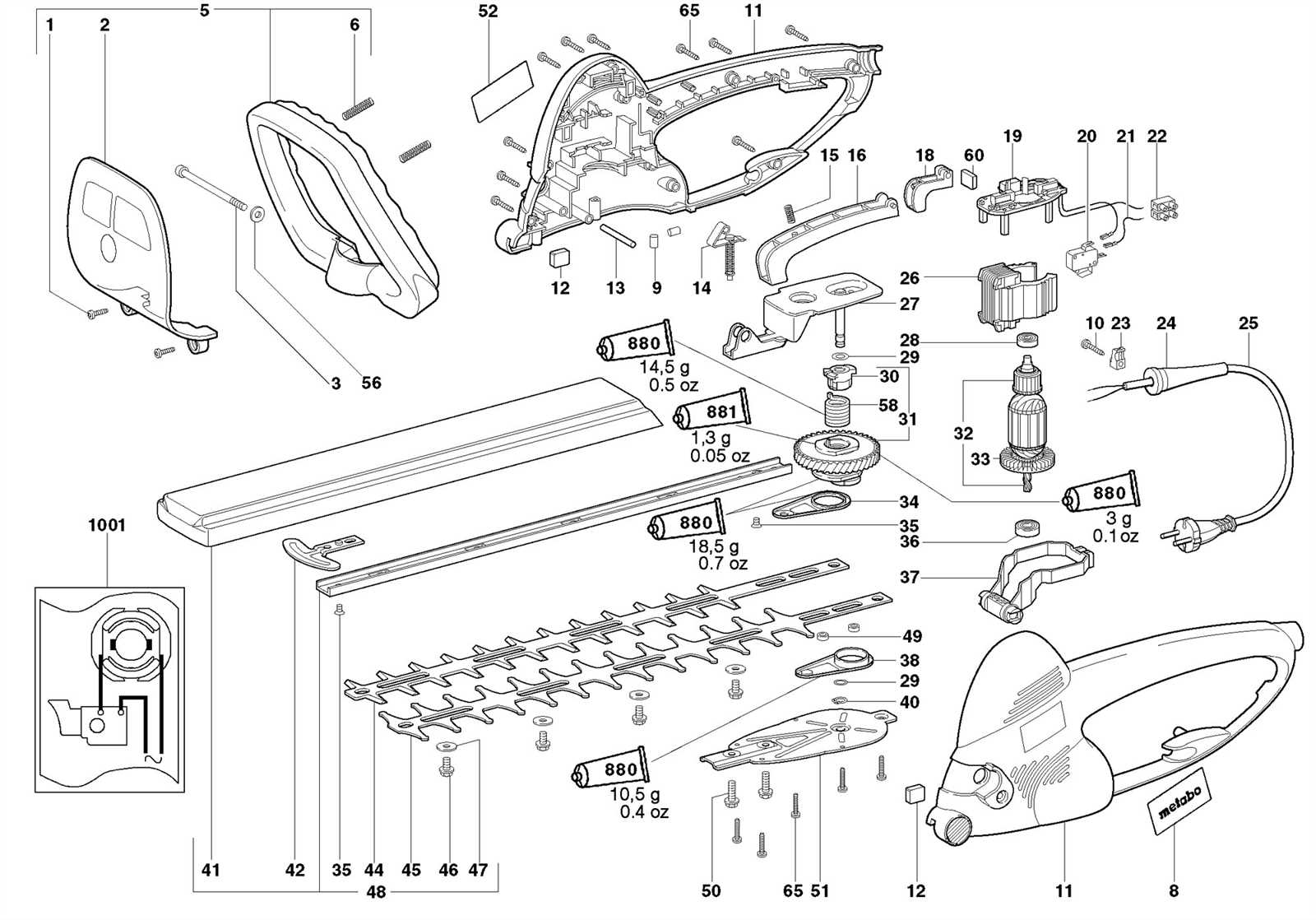

Visual representations play a crucial role in grasping the layout and function of individual components. By studying illustrations, users can easily pinpoint where each piece fits within the larger structure. This clarity fosters confidence in handling maintenance tasks and ensures that any replacements or adjustments are made accurately.

This section aims to provide a comprehensive understanding of the essential elements that constitute a particular outdoor power tool. Each component plays a critical role in ensuring optimal functionality and performance, which is vital for users seeking to maintain or repair their equipment effectively.

Key Elements

- Engine Assembly

- Fuel System

- Ignition System

- Cutting Blades

- Handle and Grip

- Gearbox

- Protection Cover

- Control Switches

- Support Frame

- Exhaust System

- Air Filter

Importance of Each Component

Understanding the role of each part is crucial for troubleshooting and performing maintenance tasks. Regular inspection of these components ensures longevity and efficient operation, making it essential for users to familiarize themselves with their functionality.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements enable users to identify and locate specific parts quickly, facilitating smoother operations and reducing downtime. These illustrations serve as essential tools for both novices and experienced technicians, ensuring that any issues can be addressed efficiently.

Enhancing Maintenance Efficiency

Clear visuals provide insights into how various elements fit together, making it easier to spot wear and tear or malfunctions. This knowledge streamlines the maintenance process, allowing for timely interventions and extending the lifespan of equipment.

Facilitating Accurate Repairs

When repairs are needed, having access to a comprehensive visual guide ensures that replacements are made correctly. Misunderstandings about component placements can lead to errors, resulting in further complications. By utilizing these guides, users can approach repairs with confidence, knowing they have accurate information at hand.

Main Features of HS45 Model

This model stands out for its exceptional design and functionality, making it a preferred choice for many users. Its robust construction ensures durability, while the thoughtful engineering allows for efficient operation. The following features contribute to its high performance and user satisfaction.

Ergonomic Design

The tool is designed with user comfort in mind. Its lightweight structure and well-placed handles reduce strain during prolonged use, making it suitable for both professionals and hobbyists.

Powerful Engine

Equipped with a high-performance engine, this device delivers reliable power for various tasks. Its efficient fuel consumption ensures extended operation without frequent refueling.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine providing robust performance |

| Cutting Length | Ideal length for various trimming tasks |

| Weight | Lightweight design for easy maneuverability |

| Safety Features | Includes safety guards and easy-start mechanisms |

Common Issues with HS45 Parts

Maintenance of outdoor equipment is crucial for optimal performance. Various components can experience wear and tear, leading to inefficiencies. Understanding these common problems can help users effectively troubleshoot and resolve issues.

Typical Problems Encountered

- Fuel System Issues: Clogged filters or old fuel can lead to starting difficulties.

- Blade Dullness: Blades may become less effective over time, requiring sharpening or replacement.

- Electrical Failures: Faulty ignition coils or spark plugs can hinder operation.

- Vibration Problems: Excessive shaking may indicate loose screws or misaligned components.

Troubleshooting Tips

- Inspect the fuel for freshness and replace as needed.

- Regularly check and sharpen the blades for improved cutting efficiency.

- Test electrical connections and replace faulty components promptly.

- Tighten any loose screws and ensure all parts are properly aligned.

Understanding the Parts Breakdown

Grasping the structure and components of a machine is crucial for efficient maintenance and repairs. By analyzing how different elements interact, users can quickly identify the root of potential issues and ensure smooth operation. This overview highlights key mechanisms and how they contribute to overall functionality.

| Component | Function |

|---|---|

| Engine Unit | Powers the entire system and ensures mechanical movement. |

| Blade Set | Handles cutting tasks and is responsible for precision in trimming. |

| Fuel System |

Maintenance Tips for Stihl HS45Proper upkeep of your hedge trimming tool is essential for ensuring long-lasting performance and efficiency. Regular care helps prevent wear and tear, reduces the risk of malfunctions, and extends the life of the machine. Keep blades sharp: Dull cutting components can strain the motor and make trimming more difficult. Sharpening the edges regularly maintains smooth operation. Clean after use: Removing debris and build-up from the equipment after each session prevents corrosion and clogging, keeping the unit in optimal condition. Check fuel levels: Always use fresh fuel and the recommended oil mixture. Regularly inspect the fuel system to avoid block How to Identify Replacement PartsWhen it comes to maintaining your equipment, recognizing the correct components for replacement is essential to ensure optimal performance and longevity. Understanding which elements need to be replaced requires attention to detail and familiarity with the various mechanisms of your tool. First, assess the condition of the worn-out piece by comparing it with similar ones in your toolkit or guidebook. Carefully examine wear patterns, dimensions, and connectors to match them accurately. If visual inspection isn’t enough, referencing model specifications can provide the exact information you need to find the suitable replacement. Once identified, sourcing these components from a reliable supplier ensures quality and compatibility, guaranteeing that your equipment continues to function effectively without unnecessary downtime. Ordering Stihl HS45 Spare PartsWhen maintaining or repairing garden equipment, finding the correct replacement components is crucial. Ensuring the right choice of elements guarantees optimal performance and longevity of your tools. Steps to Identify the Right ComponentsBefore placing an order, it’s essential to follow a few simple steps to ensure compatibility and efficiency. Here’s how to get started:

Where to Purchase Quality ReplacementsThere Assembly Instructions for HS45Assembling this model requires attention to detail and following specific guidelines to ensure proper operation. The components must be correctly aligned and secured to guarantee the machine’s efficiency and durability. Below is a step-by-step guide to help with the process.

|