In the world of construction and excavation, comprehending the intricate workings of machinery is essential for efficient operation and maintenance. The assembly of these powerful machines involves numerous elements, each playing a vital role in their overall functionality.

By exploring the intricate relationships between different components, operators can gain insights into the performance and longevity of their equipment. This knowledge is not only beneficial for troubleshooting but also enhances the ability to execute repairs and upgrades effectively.

Delving into the visual representations of these assemblies provides an ultimate guide for both novice and experienced users. Understanding how each piece interacts allows for informed decision-making and optimal machine usage, ensuring that projects are completed smoothly and efficiently.

Kubota KX91-2 Overview

This section provides a comprehensive insight into a versatile compact excavator designed for a variety of applications. Known for its robust performance and exceptional maneuverability, this machine is a favorite among contractors and landscapers alike. With an efficient engine and advanced hydraulic system, it delivers impressive digging capabilities and speed, making it ideal for both residential and commercial projects.

Key Features

The equipment boasts a compact design that allows it to operate in confined spaces without compromising on power. Its user-friendly controls enable operators to maximize productivity with minimal effort. Moreover, the hydraulic performance is optimized for various attachments, enhancing versatility for tasks such as trenching, grading, and lifting.

Performance and Efficiency

Engineered for reliability, this model excels in fuel efficiency, reducing operating costs while maintaining high output. The combination of a durable chassis and advanced technology ensures longevity, making it a worthwhile investment for any fleet. Overall, this excavator stands out for its balance of strength, precision, and ease of use.

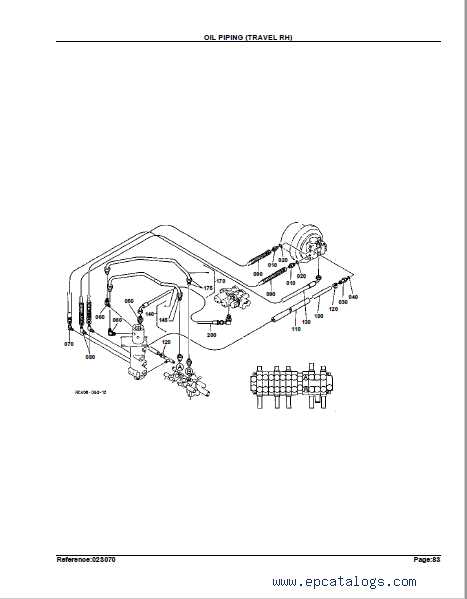

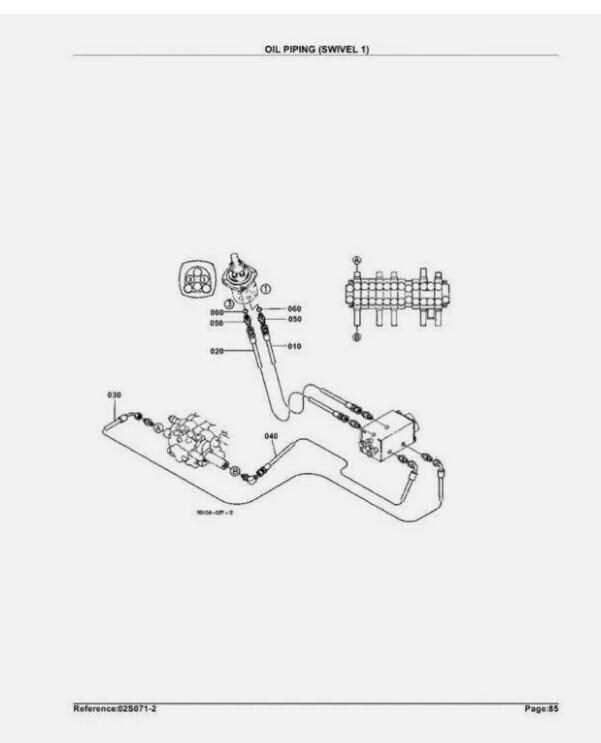

Understanding Parts Diagrams

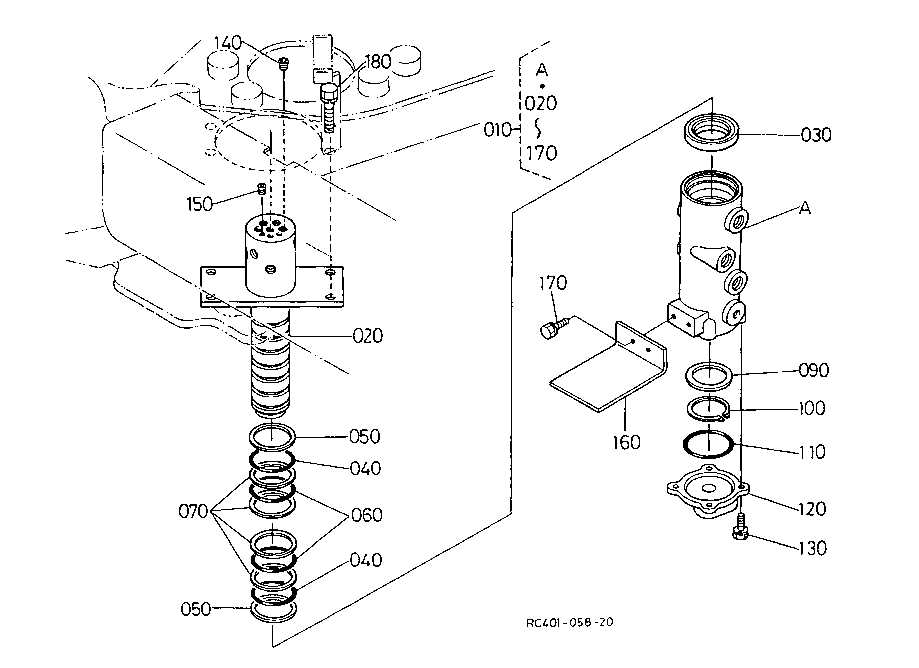

Comprehending the visual representation of components is essential for effective maintenance and repairs. These illustrations serve as a guide, allowing users to identify each element and its specific function within a larger assembly.

Benefits of Visual Representations

- Enhances clarity in locating specific items.

- Facilitates easier troubleshooting and repairs.

- Improves communication among technicians and operators.

Key Components of a Visual Representation

- Labels: Each part is usually annotated for easy identification.

- References: Symbols or numbers linking to detailed descriptions.

- Layout: Arrangement showing the relationships between different elements.

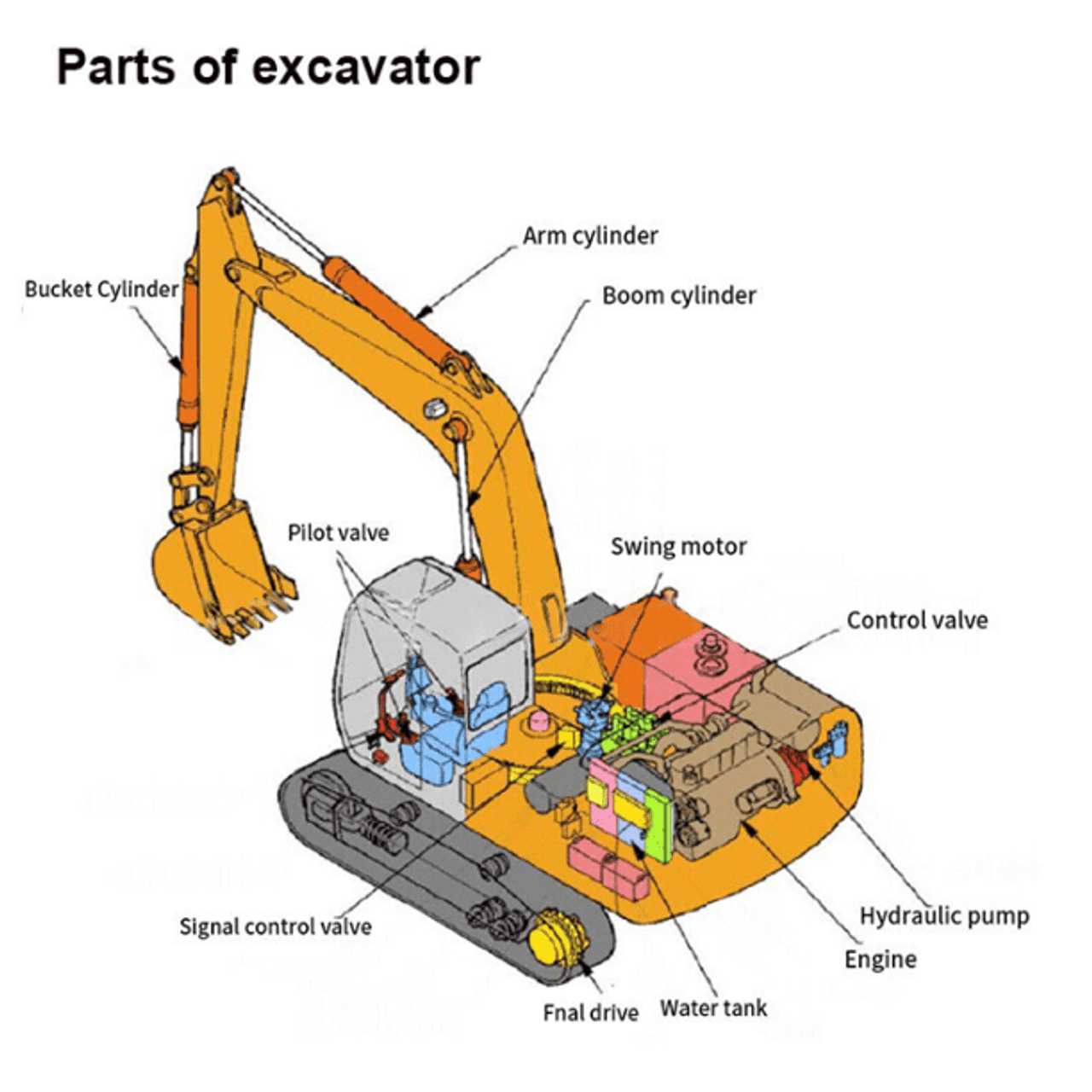

Key Components of Kubota KX91-2

This section explores the essential elements that contribute to the efficiency and functionality of this compact excavator. Understanding these components is vital for maintenance, operation, and overall performance.

Engine and Powertrain

- Engine: A reliable power source that provides the necessary torque and horsepower for various tasks.

- Transmission: Facilitates smooth gear shifting, ensuring optimal power delivery and control.

- Hydraulic System: Powers attachments and enables precise movements, enhancing operational flexibility.

Chassis and Structure

- Frame: The backbone of the machine, designed for durability and stability under heavy loads.

- Tracks: Provide traction and stability on various terrains, essential for mobility.

- Cab: The operator’s space, equipped for comfort and visibility, ensuring safety during operation.

Benefits of Using Official Parts

Choosing authentic components for your machinery offers numerous advantages that enhance performance and longevity. These elements are specifically designed to fit seamlessly, ensuring optimal functionality and reliability.

- Quality Assurance: Genuine items undergo rigorous testing to meet high standards, reducing the risk of failure.

- Compatibility: Original components are engineered to work together, minimizing wear and tear on the equipment.

- Warranty Protection: Utilizing official items often ensures that your warranty remains intact, providing peace of mind.

- Resale Value: Machinery equipped with authentic parts tends to maintain higher resale values, appealing to potential buyers.

- Support and Availability: Official suppliers typically offer robust support and easy access to replacement items when needed.

Ultimately, investing in authentic components not only enhances performance but also contributes to the overall efficiency and durability of your equipment.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair. These visual representations help identify components and their relationships, making it easier to locate specific items when needed.

To effectively interpret these visuals, follow these guidelines:

- Familiarize Yourself with Symbols:

- Learn the common icons used to represent various elements.

- Identify the legend, which explains the symbols and their meanings.

- Follow the Flow:

- Trace the connections between components to understand how they interact.

- Look for directional arrows that indicate movement or flow.

- Note the Numbering System:

- Pay attention to reference numbers that correspond to parts lists.

- Cross-reference these numbers for detailed specifications.

- Understand Assembly Sections:

- Identify grouped components that make up specific assemblies.

- Study how these sections fit together within the overall system.

By mastering these techniques, you can navigate schematics with confidence, leading to more efficient repairs and maintenance.

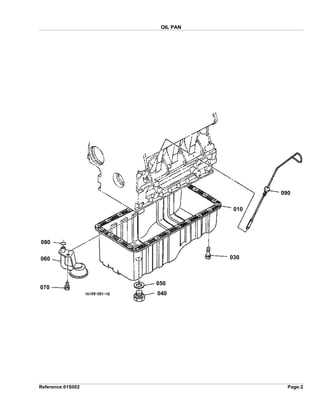

Common Replacement Parts for KX91-2

Maintaining the efficiency of your machinery often requires timely replacements of various components. Understanding which elements are most frequently exchanged can help ensure optimal performance and longevity of the equipment. Below, we highlight some of the essential items that operators typically seek when servicing their machines.

Hydraulic Filters: These components are crucial for maintaining the fluid’s cleanliness and preventing damage to the hydraulic system. Regular replacement can significantly extend the life of hydraulic pumps and valves.

Tracks: The undercarriage plays a vital role in mobility and stability. Worn or damaged tracks can affect traction and overall functionality, making timely replacement essential for safe operation.

Bucket Teeth: Over time, the teeth on excavation buckets can wear down or break, impacting digging performance. Swapping out old teeth for new ones can improve efficiency and reduce strain on the attachment.

Oil Seals: These components help prevent leaks in the hydraulic system. Replacing worn seals is critical to maintaining pressure and preventing fluid loss, which can lead to significant operational issues.

Filters: Engine and fuel filters need regular attention to ensure clean operation and prevent contaminants from affecting performance. Replacing these filters helps maintain engine efficiency and longevity.

By staying aware of these commonly replaced components, operators can better plan maintenance schedules and avoid unexpected downtimes. Keeping a stock of these essential items can lead to more efficient and trouble-free operation.

Maintenance Tips for Kubota KX91-2

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Implementing a consistent maintenance routine can prevent costly repairs and enhance productivity. Here are some key practices to keep in mind.

Firstly, always check fluid levels, including oil and coolant, to maintain efficiency and prevent overheating. Regularly replacing filters helps ensure clean operation and reduces wear. Additionally, inspecting belts and hoses for signs of wear or damage can prevent breakdowns during critical tasks.

Cleaning the exterior and undercarriage regularly is vital to avoid rust and debris accumulation, which can affect performance. Lubrication of moving parts should also be performed as per the manufacturer’s guidelines to reduce friction and wear.

Lastly, scheduling professional inspections at regular intervals can identify potential issues before they escalate, ensuring your equipment remains in top condition for any project.

Finding Parts Suppliers Online

In today’s digital age, locating reliable suppliers for machinery components can be a straightforward process. With numerous online platforms and resources available, users can easily explore various options to meet their needs. It’s essential to evaluate these sources carefully to ensure quality and reliability.

Start by utilizing search engines to identify reputable websites that specialize in machinery parts. Look for suppliers with comprehensive inventories and positive customer reviews. Forums and industry-specific groups can also provide valuable recommendations from experienced users who have navigated similar searches.

Additionally, many manufacturers offer online catalogs that allow users to browse components by model or type, making it easier to find exactly what is required. Contacting suppliers directly can also yield insights into availability, pricing, and shipping options.

Frequently Asked Questions

This section aims to address common inquiries related to machinery components and their maintenance. Here, you’ll find answers to some of the most pressing concerns users have, helping to enhance your understanding and experience with your equipment.

What should I do if I can’t find a specific component? If you’re unable to locate a particular part, consider consulting your user manual or reaching out to a certified dealer for assistance.

How often should I perform maintenance on my machinery? Regular maintenance is crucial; typically, it is recommended to check key components every 100 operating hours.

Can I use aftermarket components? While aftermarket options are available, ensure they meet the necessary specifications for optimal performance and safety.

What signs indicate a component needs replacement? Look for unusual noises, decreased performance, or visible wear, as these can signal that a part may need to be replaced.

Cost Considerations for Replacement Parts

When it comes to maintaining heavy machinery, evaluating the expenses associated with substitute components is crucial for both operational efficiency and budget management. Understanding the financial implications can help operators make informed decisions about sourcing and replacing essential elements, ensuring minimal downtime while keeping costs manageable.

Quality vs. Price

One of the primary factors affecting expenditure is the balance between quality and cost. While opting for cheaper alternatives may seem appealing, it often results in compromised durability and performance. Investing in high-quality substitutes typically leads to enhanced longevity and reliability, ultimately saving money on frequent replacements and repairs.

Availability and Sourcing

The availability of components can also influence costs. Sourcing items from reputable suppliers may incur a higher initial price, but the assurance of quality and proper fit can mitigate risks associated with malfunction or early failure. Additionally, considering local vendors versus online marketplaces may affect shipping fees and delivery times, impacting overall budgeting.

In conclusion, thorough analysis of the expenses related to replacement items is essential. By prioritizing quality and considering sourcing options, operators can make strategic decisions that align with both performance needs and financial constraints.

DIY Repairs and Parts Installation

Engaging in hands-on maintenance can significantly enhance your machine’s longevity and performance. By understanding the structure and components, you can tackle common issues yourself, saving both time and money while gaining valuable skills.

Understanding Your Equipment

Before diving into any repairs, familiarize yourself with the essential elements of your machinery. Consult the user manual for specific details about each component, ensuring a smooth and informed approach. This foundational knowledge is crucial for effective troubleshooting and successful installations.

Step-by-Step Approach

Begin your repair journey by gathering necessary tools and replacement components. Carefully dismantle the affected areas, taking notes or photos to aid in reassembly. Once replacements are secured, follow the reverse process to restore functionality, checking for proper alignment and tightness as you work.

Resources for Further Learning

Expanding your knowledge about machinery components and their functionalities can greatly enhance your skills and understanding in the field. Whether you are a novice or an experienced operator, utilizing various resources can help you gain valuable insights and practical knowledge.

- Online Forums: Engage with communities dedicated to heavy equipment. Platforms like Reddit and specialized forums offer discussions, advice, and troubleshooting tips.

- Manufacturer Websites: Explore official sites for comprehensive guides, manuals, and technical specifications related to machinery.

- YouTube Channels: Many experts share tutorials and reviews that can help you visualize components and their operations.

- Books and Manuals: Invest in industry-specific literature that covers equipment maintenance and repair techniques.

- Local Workshops: Consider attending workshops or training sessions that provide hands-on experience with machinery.

By tapping into these resources, you can enhance your expertise, troubleshoot more effectively, and stay updated on the latest advancements in the industry.