Maintaining the efficiency of a lawn tractor requires a clear understanding of its inner mechanisms and components. By having a structured guide, it becomes easier to ensure optimal performance and longevity for this essential outdoor machine. In this section, we’ll dive into the key elements that contribute to its functionality and explore how each part plays a critical role in maintaining smooth operation.

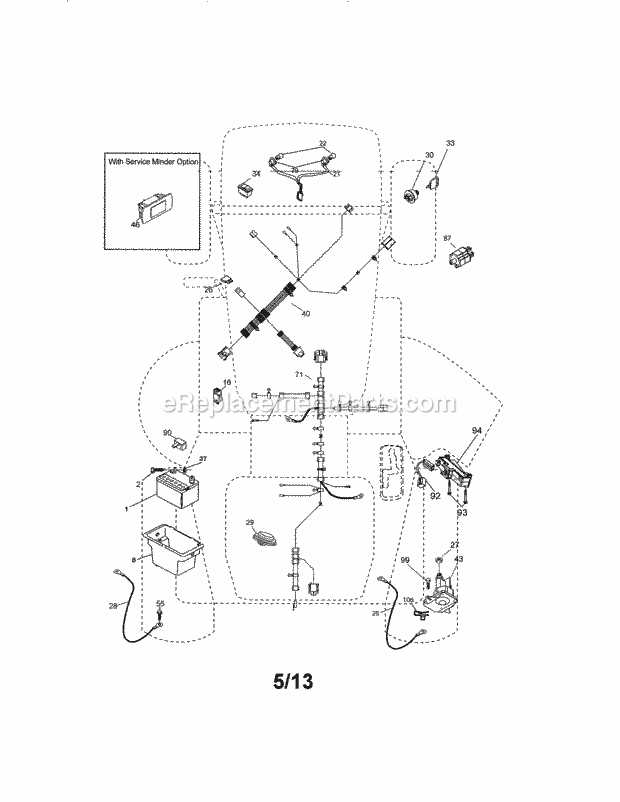

Whether you’re an experienced technician or a dedicated user, having access to a visual breakdown of the essential components is invaluable. This will allow for easier identification and troubleshooting when mechanical issues arise. With this knowledge, keeping your equipment in peak condition becomes a simpler task, even for the most complex systems.

Our detailed breakdown highlights the core elements and their

Understanding the Dyt4000: A Detailed Overview

Comprehending the structure and functionality of complex machinery requires more than just a superficial glance at its components. Each system operates through a precise interaction of mechanical and electrical elements, ensuring the equipment performs seamlessly across various tasks. In this section, we will explore the critical aspects that contribute to the efficient operation and reliability of such equipment, highlighting the interconnected mechanisms that work in harmony to achieve optimal performance.

Exploring the Key Components of Dyt4000

Understanding the main mechanical and functional elements of this machine is crucial for effective operation and maintenance. By breaking down its individual sections, one can appreciate how these elements work in unison to ensure optimal performance. Each component plays a vital role, contributing to the overall efficiency and durability of the equipment.

Engine and Power System

The heart of the machine lies in its engine

How to Locate Essential Components

Understanding how to identify key elements of your equipment is vital for proper maintenance and repairs. Knowing where each crucial piece is located helps streamline the process of replacing or servicing parts efficiently. With a systematic approach, you’ll be able to maintain the functionality of your machine without unnecessary delays.

Consult the Manufacturer’s Guide

One of the best starting points for identifying important elements is the official guide provided by the manufacturer. These documents offer detailed breakdowns of the internal layout, ensuring that you have an accurate reference when searching for specific pieces. This approach saves time and prevents the frustration of misidentification.

Breaking Down the Engine Assembly

The engine system is a complex yet intricately designed machine, comprising various interconnected components that work harmoniously to deliver optimal performance. By understanding the individual elements and their roles within this setup, one can better grasp how each piece contributes to the overall functionality and efficiency of the engine.

Cylinder block forms the foundation, housing the pistons and ensuring smooth combustion processes. It’s supported by a network of other essential units

Understanding the Dyt4000 Transmission System

The transmission mechanism plays a vital role in ensuring smooth power transfer from the engine to the wheels, allowing efficient control and operation of the machine. This system is a critical component that ensures the device operates under various conditions, adjusting the speed and torque as needed for different tasks.

Key Components of the Transmission

The transmission includes multiple elements working together to provide the necessary power and control. These components interact to manage the flow of energy, ensuring optimal performance during operation. Below is a breakdown of the essential elements:

| Component | Function |

|---|

| Component | Function | Common Applications |

|---|---|---|

| Relay | Controls electrical circuits by opening and closing contacts | Starting and stopping motors, activating lights |

| Fuse | Protects circuits by breaking the connection when excess current flows | Preventing damage from overloads |

| Capacitor | Stores electrical energy and releases it when needed | Starting motors, improving power factor |

| Transformer | Changes voltage levels to suit different applications | Supplying power to various equipment |

| Diode | Allows current to flow in one direction only | Rectifying AC to DC, protecting circuits from reverse polarity |

Importance of Proper Identification

Correctly identifying these electrical components is essential for effective diagnostics and repairs. Regular maintenance checks and familiarity with these parts can prevent unexpected breakdowns, ensuring that the machine operates smoothly and efficiently over time.

Diagram of Dyt4000 Steering Mechanism

The steering system of a riding mower is essential for precise control and maneuverability. Understanding the components involved in this mechanism can enhance maintenance and troubleshooting efforts. This section delves into the intricate arrangement and functionality of the steering assembly, ensuring optimal performance during operation.

The primary elements of the steering arrangement work in unison to provide smooth handling and responsive steering. Below is a detailed representation of the key components that contribute to the steering functionality:

| Component | Description |

|---|---|

| Steering Wheel | Provides the operator with control over the direction of the mower. |

| Steering Column | Connects the steering wheel to the steering mechanism, transmitting input. |

| Sector Gear | Engages with the steering shaft to convert rotational movement into lateral motion. |

| Control Linkages | Connect various components, allowing for fluid movement throughout the system. |

| Spindle Assembly | Houses the pivot points for the wheels, enabling turning. |

| Wheel Hubs | Attach the wheels to the spindle, providing stability and support during operation. |

Understanding these components and their roles helps ensure effective management and troubleshooting of the steering system, ultimately enhancing the mower’s performance and user experience.

Guide to Dyt4000 Mower Deck Components

This section provides a comprehensive overview of the various elements that make up the cutting assembly of a lawn mower. Understanding these components is essential for proper maintenance, repairs, and overall performance optimization.

Key Components of the Cutting Assembly

- Blades: The primary tools responsible for cutting grass, available in different shapes and sizes to achieve desired results.

- Spindles: Crucial for supporting the blades and ensuring they rotate effectively.

- Deck Shell: The protective housing that encases the cutting mechanisms, designed to direct grass clippings and prevent debris accumulation.

- Mounting Brackets: Support structures that secure the deck to the mower chassis.

- Belts: Essential for transmitting power from the engine to the cutting blades, ensuring efficient operation.

Maintenance Tips for Optimal Performance

- Regularly inspect the blades for wear and sharpen them as necessary to maintain cutting efficiency.

- Check the spindles for any signs of damage or wear, replacing them when needed.

- Keep the deck shell clean to prevent grass buildup that can hinder performance.

- Ensure all mounting brackets are securely fastened to avoid vibrations during operation.

- Examine the belts for fraying or damage, and replace them promptly to prevent power loss.

Analyzing the Dyt4000 Fuel System Layout

The configuration of the fuel delivery system plays a crucial role in the overall performance and efficiency of any engine. Understanding the intricacies of this arrangement is essential for diagnosing issues, optimizing operation, and ensuring longevity. This section delves into the essential components and their interconnections, providing insights into how each element contributes to the functionality of the entire mechanism.

The fuel system consists of several vital components, including the tank, pump, filters, and injectors. Each part has a specific function that, when combined, facilitates the effective movement and delivery of fuel to the engine. Below is a detailed table outlining the key elements and their respective roles within the assembly.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel and supplies it to the system. |

| Fuel Pump | Transports fuel from the tank to the engine. |

| Fuel Filter | Removes impurities and contaminants from the fuel. |

| Fuel Injectors | Atomizes the fuel for optimal combustion in the engine. |

| Fuel Lines | Transport fuel between the tank, pump, and engine components. |

Each of these components must work in harmony to ensure that the engine receives the correct amount of fuel at the right pressure and quality. Regular maintenance and inspection of the system are crucial for preventing failures and ensuring smooth operation.

Maintenance Tips for Dyt4000 Parts

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Implementing a routine maintenance schedule can prevent unexpected breakdowns and costly repairs. This guide provides helpful advice for keeping your machinery in excellent condition, enhancing efficiency and reliability over time.

Routine Inspections

Conducting frequent checks on various components can help identify wear and tear before they escalate into serious issues. Look for signs of damage or misalignment, and ensure all parts are securely fastened. Maintaining a clean environment around the equipment will also reduce the risk of contaminants affecting functionality.

Proper Lubrication

Applying the correct lubricant to moving elements is crucial for minimizing friction and preventing overheating. Follow manufacturer recommendations for specific types of grease or oil. Regularly clean areas where residue may build up, ensuring smooth operation and reducing the risk of part failure.