In the world of brewing beverages, a thorough comprehension of the various elements that contribute to optimal functionality is essential. Each component plays a crucial role in ensuring efficiency and reliability, impacting the overall performance of the equipment.

Exploring the intricate assembly of these devices can reveal insights into their maintenance and operation. Familiarity with each section not only aids in troubleshooting but also enhances the user experience, allowing for a deeper appreciation of the art of beverage preparation.

Knowledge of the components empowers users to make informed decisions, whether for repairs or upgrades. This understanding can significantly extend the lifespan of the machinery and ensure consistent quality in every brew.

Engaging with the specifics of each element transforms a simple appliance into a sophisticated tool, elevating the brewing process to new heights.

Understanding the fundamental elements of brewing systems is crucial for optimal performance and maintenance. Each model consists of specific components that work together to enhance efficiency and ensure high-quality beverage preparation.

Key Functional Elements

The primary functional elements include the heating unit, water reservoir, and brewing chamber. Each component plays a significant role in the overall operation, affecting both speed and flavor extraction.

Maintenance Considerations

Regular maintenance of these critical components is necessary to prolong the lifespan of the equipment. Proper cleaning and inspection can prevent common issues that may arise during regular use.

| Component | Function |

|---|---|

| Heating Unit | Heats water to the optimal brewing temperature. |

| Water Reservoir | Stores water needed for brewing. |

| Brewing Chamber | Where the brewing process occurs, combining water and coffee. |

Common Issues with Coffee Machines

Understanding typical challenges encountered with coffee brewing devices can enhance maintenance and improve performance. Users often face problems that can hinder the brewing process and affect the quality of the beverage.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inconsistent Brew Temperature | Faulty thermostat, mineral buildup | Check and replace thermostat, descale regularly |

| Leaking Water | Worn seals, loose connections | Inspect seals, tighten connections, replace damaged parts |

| Slow Brewing Time | Clogged filters, insufficient water flow | Clean or replace filters, ensure water supply is adequate |

How to Identify Bunn Parts

Understanding the components of your brewing equipment can significantly enhance your experience and troubleshooting abilities. Knowing how to recognize various elements will enable you to maintain functionality and address issues effectively.

Here are some steps to assist you in identifying essential components:

- Consult the Manual: Start by reviewing the user guide that came with your machine. It typically contains labeled illustrations.

- Use Online Resources: Websites and forums can provide visual references and descriptions to help you identify each component.

- Observe Unique Features: Look for specific characteristics such as size, shape, and material, which can distinguish one part from another.

By following these steps, you’ll be better equipped to manage your equipment and ensure optimal performance.

Maintenance Tips for Bunn Products

Proper upkeep of your brewing equipment is essential for optimal performance and longevity. Regular care not only enhances the taste of your beverages but also prevents potential malfunctions. Following a systematic maintenance routine can ensure that your machine operates efficiently.

Daily Maintenance

To keep your appliance in top shape, perform the following tasks each day:

| Task | Description |

|---|---|

| Clean Brew Basket | Remove and rinse the brew basket to eliminate coffee residue. |

| Check Water Levels | Ensure adequate water supply for optimal brewing performance. |

| Inspect Filters | Replace or clean filters to maintain flavor and quality. |

Weekly and Monthly Care

In addition to daily tasks, consider these additional steps for enhanced upkeep:

| Task | Description |

|---|---|

| Descale Machine | Use a descaling solution to prevent mineral buildup. |

| Check Seals | Inspect and replace worn seals to prevent leaks. |

| Review User Manual | Refer to the manual for specific maintenance guidelines. |

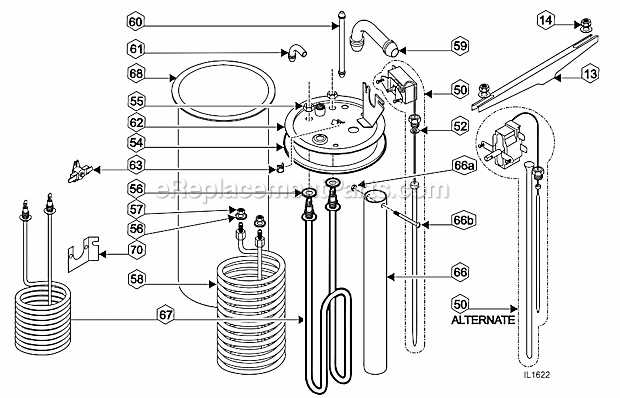

Exploring Bunn’s Replacement Parts

Understanding the components that make up brewing equipment is essential for maintaining optimal performance and longevity. When wear and tear occur, identifying the right substitutes can significantly enhance functionality and ensure a smooth operation. This guide aims to illuminate the various elements involved, aiding users in making informed choices.

Comprehending the intricacies of each element is vital for effective troubleshooting. Many users may not realize the importance of specific components in achieving the ultimate brewing experience. Whether it’s filters, valves, or heating elements, recognizing how these pieces interact can prevent future complications.

When seeking replacements, consider the compatibility and quality of the items. High-grade materials often translate to better efficiency and longer lifespan, ultimately benefiting your brewing rituals. Additionally, consulting reliable resources can provide insights into the best options available.

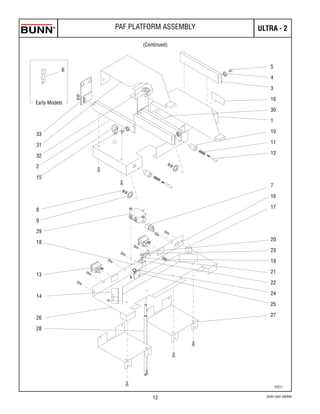

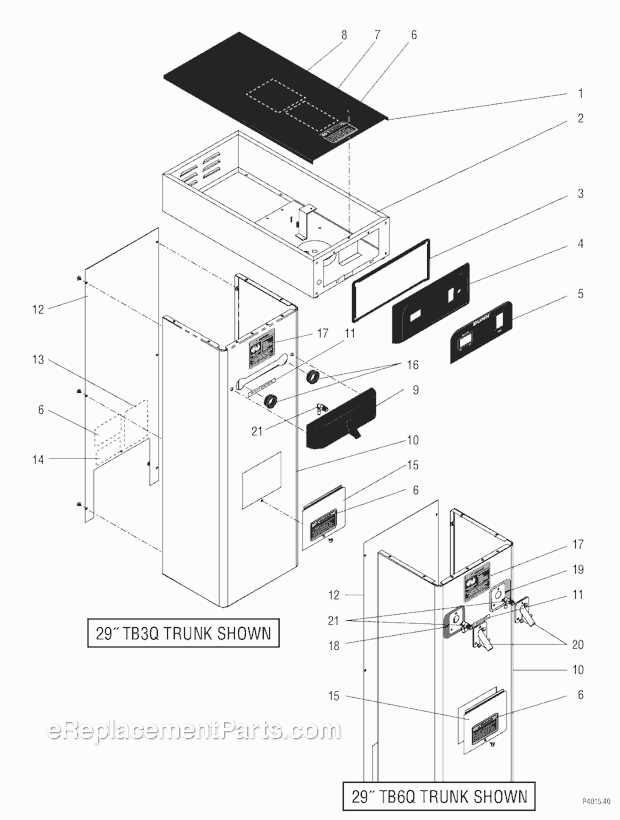

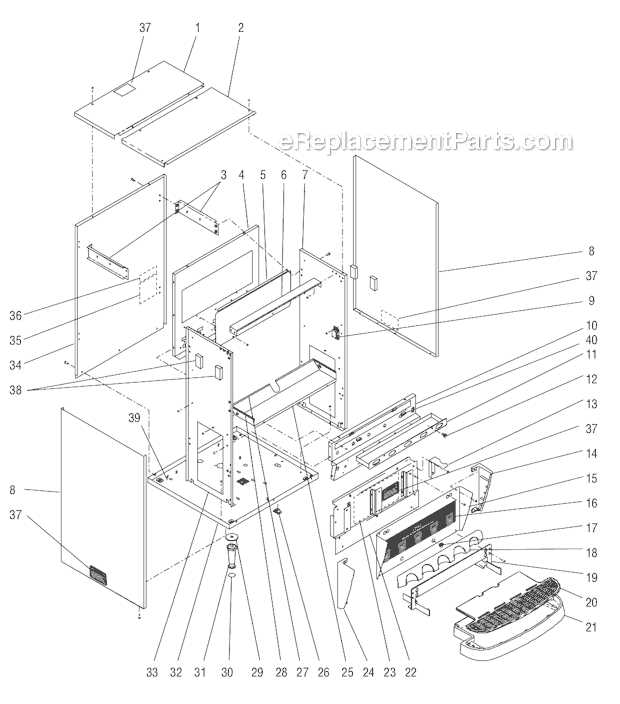

Assembly Guide for Bunn Equipment

This section provides a comprehensive overview of the assembly process for various brewing devices. Understanding the structure and components involved is essential for ensuring optimal functionality and longevity of the equipment. Following this guide will help in the correct installation and maintenance of the machinery.

Required Tools and Equipment

Before beginning the assembly, ensure you have the following tools and materials on hand:

| Tool/Equipment | Description |

|---|---|

| Screwdriver Set | A variety of sizes to fit different screws. |

| Wrench | Adjustable for securing nuts and bolts. |

| Pliers | For gripping and manipulating small parts. |

| Measuring Tape | To ensure precise alignment of components. |

Assembly Steps

Follow these steps to assemble your brewing apparatus:

- Begin by laying out all components on a clean surface to ensure easy access.

- Refer to the assembly instructions specific to your model to identify the sequence.

- Secure the base unit to the platform, ensuring it is level and stable.

- Attach any required connectors or hoses, making sure they are firmly in place to prevent leaks.

- Carefully fit the brewing chamber onto the base, ensuring a tight seal.

- Connect the power source, following safety guidelines to avoid electrical issues.

- Perform a final inspection to ensure all parts are secured and functioning correctly.

By adhering to this assembly guide, you will achieve a properly functioning brewing system that delivers exceptional results.

Benefits of Genuine Bunn Parts

Utilizing authentic components in your equipment is essential for ensuring optimal performance and longevity. When you choose original elements, you benefit from reliability, compatibility, and superior craftsmanship that imitators often cannot match. This commitment to quality can lead to enhanced functionality and peace of mind.

| Advantage | Description |

|---|---|

| Durability | Original components are designed to withstand rigorous use, reducing the need for frequent replacements. |

| Compatibility | Genuine elements fit perfectly with your machine, ensuring seamless operation without risk of damage. |

| Performance | Using authentic components enhances overall efficiency, leading to better brewing and serving outcomes. |

| Warranty Protection | Many manufacturers offer warranties that cover only the use of original components, providing additional security for your investment. |

| Support | Access to expert guidance and resources is often guaranteed when using genuine elements, ensuring you receive the best care for your equipment. |

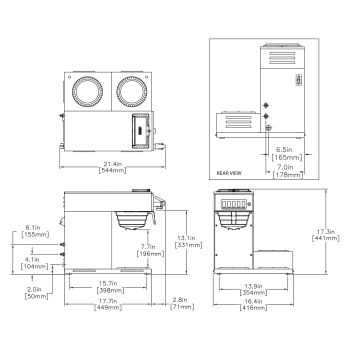

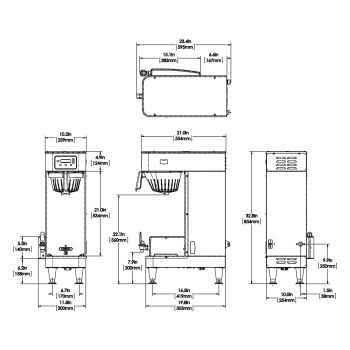

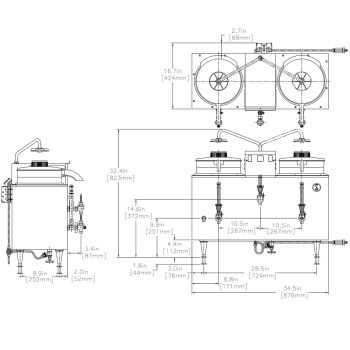

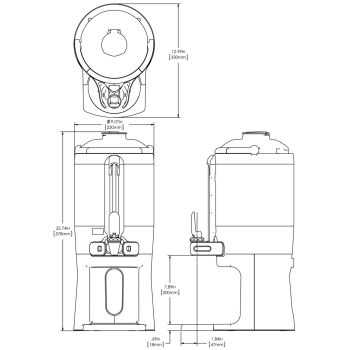

Visual Guide to Bunn Diagrams

This section provides a comprehensive overview of the illustrations that showcase the essential components of coffee brewing equipment. By understanding these visuals, users can easily identify key elements and enhance their maintenance skills, leading to optimal performance.

Understanding the Components

Each visual representation breaks down the intricate features, allowing for a clearer understanding of how everything fits together. Familiarity with these components not only aids in troubleshooting but also empowers users to make informed decisions about repairs.

Utilizing Visual References

Referencing these graphics during maintenance or assembly can significantly streamline the process. By actively engaging with these illustrations, users can delve into the ultimate workings of their machines, ensuring longevity and efficiency.

Frequently Asked Questions About Bunn

This section aims to address common inquiries related to a popular brand known for its beverage equipment. Here, you will find answers that clarify functionality, maintenance, and other essential aspects for users and enthusiasts alike.

Common Inquiries

| Question | Answer |

|---|---|

| What types of machines are available? | There are various models designed for brewing coffee, tea, and other beverages, catering to both home and commercial use. |

| How often should I perform maintenance? | Regular cleaning is recommended, ideally every few weeks, depending on usage frequency to ensure optimal performance. |

| Where can I find replacement items? | Replacement components can typically be sourced from authorized dealers or the official website, ensuring compatibility and quality. |

Helpful Tips

Understanding your equipment can enhance your experience. Always refer to the user manual for troubleshooting and optimal usage practices.

Upgrading Your Bunn Coffee Maker

Enhancing your coffee brewing experience can significantly improve the quality of your daily cup. By making thoughtful upgrades, you can enjoy richer flavors, increased efficiency, and added convenience. This section explores various ways to elevate your coffee machine, ensuring that each brew meets your expectations.

Consider Upgrading Components: One effective way to enhance performance is by replacing certain components with higher-quality alternatives. This can include items such as filters or brew baskets, which may improve extraction and overall flavor.

Incorporate New Technology: Integrating modern technology into your machine can transform the brewing process. Look for features like programmable settings or advanced temperature controls to achieve precise brewing conditions tailored to your preferences.

Regular Maintenance: Keeping your equipment in top condition is crucial. Regular cleaning and maintenance not only prolong the life of the machine but also ensure that each cup remains flavorful. Consider investing in descaling solutions or specialized cleaning tools designed for coffee makers.

Explore Customization Options: Many brewing systems offer customization options, allowing you to adjust brew strength and serving sizes. Experimenting with these settings can lead to discovering the perfect cup that suits your taste.

By implementing these upgrades, you can significantly enhance your coffee brewing experience, making every sip a delight.