In the realm of outdoor maintenance, having a thorough understanding of equipment and its components is essential for optimal performance and longevity. Each machine comprises various elements, each serving a specific function, contributing to the overall efficiency of the device. Grasping how these components interact can aid users in troubleshooting issues and performing maintenance tasks effectively.

Exploring the layout of these components reveals the intricate design that allows for seamless operation. Identifying individual parts and their respective roles can empower users to make informed decisions when it comes to repairs or replacements. A clear visualization of the setup can facilitate a deeper comprehension of the machine’s workings, enhancing the user experience.

Furthermore, familiarity with the arrangement of parts not only streamlines maintenance efforts but also promotes safety during operation. Understanding how each component fits into the larger system ensures that users can navigate any potential hazards with confidence. This knowledge ultimately leads to a more satisfying and productive experience when utilizing outdoor equipment.

The efficient operation of outdoor equipment heavily relies on its internal elements. Each component plays a crucial role in ensuring the overall functionality and performance of the machinery. Understanding these individual parts can significantly enhance maintenance practices and troubleshooting efforts.

Key Elements of the Equipment

Every model comprises several essential units, each designed to perform specific tasks. Familiarity with these elements enables users to identify issues and implement timely repairs. These units often include components responsible for power generation, airflow management, and control mechanisms.

Maintenance and Care Tips

Regular upkeep of these vital components not only prolongs the lifespan of the machinery but also ensures optimal performance. It’s recommended to periodically inspect each unit, clean any debris, and replace worn-out parts. Such proactive measures can prevent major malfunctions and enhance the overall efficiency of the device.

Main Parts Overview

This section provides an overview of the essential components found in a specific type of outdoor equipment designed for clearing debris. Understanding the functionality and arrangement of these elements is crucial for effective maintenance and operation.

Essential Components

The equipment consists of several key elements that work together to ensure optimal performance. Each part plays a significant role, contributing to the overall efficiency and effectiveness of the machine.

| Component | Description |

|---|---|

| Engine | Provides the power needed for operation. |

| Fan | Creates airflow to direct debris away from surfaces. |

| Fuel Tank | Holds the fuel necessary for engine operation. |

| Throttle Control | Regulates engine speed and airflow intensity. |

| Housing | Encloses and protects internal components. |

| Handle | Allows for maneuverability and ease of use. |

Maintenance Considerations

Regular checks and maintenance of these components are essential for ensuring longevity and reliable performance. Familiarity with the equipment’s structure aids in troubleshooting and identifying any potential issues that may arise during use.

Importance of Each Component

Understanding the significance of every individual element within a device is crucial for its optimal functioning. Each component plays a specific role, contributing to the overall efficiency and performance of the equipment. Recognizing how these parts interact can enhance maintenance practices and ensure longevity.

The engine serves as the powerhouse, driving the entire mechanism. Its performance directly influences the effectiveness of the operation, making it essential to keep it in good condition.

The air intake system is vital for providing the necessary airflow for combustion. A well-functioning intake ensures that the engine receives clean air, which is crucial for optimal performance.

The ignition system is responsible for starting the engine. A reliable ignition ensures that the device operates smoothly and efficiently, reducing the risk of failure during use.

The exhaust system plays a key role in expelling gases produced during combustion. Properly functioning exhaust components minimize emissions and enhance overall efficiency.

The housing protects internal components from damage and environmental factors. A sturdy casing is essential for durability and maintaining the integrity of the machine.

The control system allows the user to manage various functions easily. An intuitive interface enhances usability and ensures that the device can be operated safely and effectively.

In summary, each element is integral to the performance and reliability of the equipment. Understanding their individual roles aids in proper maintenance and enhances overall functionality.

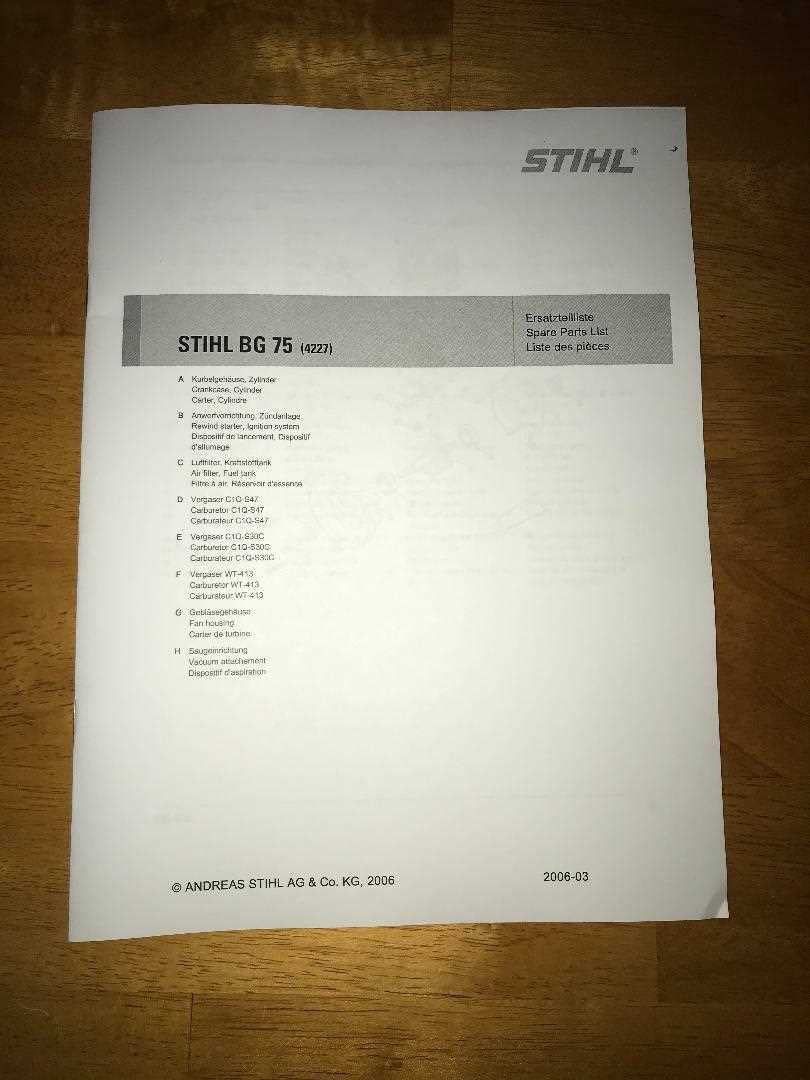

How to Identify Spare Parts

Identifying replacement components for outdoor equipment is essential for maintaining optimal performance and longevity. Properly recognizing the necessary items ensures that repairs are effective and can save time and money. This guide will provide valuable insights into the process of identifying the right components for your equipment.

Start by consulting the manufacturer’s resources, such as user manuals or official websites, which often include detailed information about the various components available. This information typically features part numbers, descriptions, and compatibility details.

| Identification Method | Description |

|---|---|

| Consult Manuals | Look for comprehensive guides that outline all essential components and their specifications. |

| Online Databases | Utilize official websites to access diagrams and lists of compatible items for reference. |

| Professional Advice | Seek assistance from knowledgeable retailers or service centers to help in recognizing specific items. |

| Visual Inspection | Examine the equipment closely to spot any identifying marks or numbers on the components themselves. |

By following these strategies, you can efficiently determine the necessary components needed for repairs and ensure that your outdoor machinery operates smoothly.

Common Issues with Blower Parts

When using outdoor equipment designed for air movement, various challenges may arise that can affect performance and efficiency. Understanding these common difficulties can help users maintain optimal functionality and prolong the lifespan of their devices.

- Fuel System Problems: Inadequate fuel flow or contamination can lead to poor engine performance. Ensure the fuel is clean and the filter is free from obstructions.

- Air Filter Blockage: A dirty air filter can restrict airflow, causing the engine to work harder and reducing efficiency. Regularly inspect and clean or replace the air filter as needed.

- Worn Components: Over time, various components such as impellers or fans can become worn, resulting in decreased air output. Regular inspections can help identify wear early.

- Ignition Issues: Problems with the ignition system, such as faulty spark plugs, can prevent proper starting or lead to inconsistent operation. Regularly check and replace spark plugs as necessary.

Addressing these issues promptly can enhance the overall performance of your outdoor air-moving equipment, ensuring it remains effective and reliable during use.

Repairing vs. Replacing Components

When maintaining outdoor equipment, one crucial decision is whether to repair or replace certain elements. Each option presents its own set of advantages and considerations, which can significantly impact performance and longevity. Understanding the circumstances under which each approach is most beneficial can lead to more effective and economical solutions.

Benefits of Repairing

Repairing components often offers a cost-effective solution, especially if the damage is minor. This approach can extend the lifespan of the equipment while preserving original parts that are often more reliable than aftermarket replacements. Additionally, repairs tend to be quicker and less labor-intensive, allowing users to get back to their tasks without significant downtime.

When to Consider Replacement

In some cases, replacing a component may be the more prudent choice. If a part is severely worn, damaged beyond feasible repair, or if repair costs approach or exceed the cost of new components, replacement becomes necessary. Furthermore, newer models may offer improved efficiency or features that outdated parts cannot provide. Prioritizing functionality and safety is essential when making this decision.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your outdoor equipment. Adopting a few simple practices can significantly enhance efficiency and reliability. Consistent maintenance not only prevents potential issues but also saves time and money in the long run.

Here are some key practices to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean Air Filter | Every 10 hours | Remove and clean the air filter to ensure proper airflow, preventing engine strain. |

| Check Spark Plug | Every 25 hours | Inspect the spark plug for wear and replace if necessary to maintain ignition efficiency. |

| Inspect Fuel System | Every 50 hours | Examine fuel lines for cracks or leaks, ensuring a clean and efficient fuel flow. |

| Sharpen Blades | Every 20 hours | Keep cutting edges sharp for effective performance and reduced strain on the motor. |

| Clean Exterior | After each use | Remove debris and dirt from the exterior to prevent corrosion and maintain appearance. |

Implementing these maintenance tasks into your routine will not only prolong the lifespan of your equipment but also enhance its performance, making outdoor tasks more efficient and enjoyable.

Where to Find Genuine Parts

When seeking authentic components for your outdoor power equipment, it’s essential to identify reliable sources. Genuine replacements ensure optimal performance and longevity, safeguarding your investment in high-quality machinery.

One of the best places to begin your search is at authorized retailers, where certified representatives can assist you in finding the exact items needed. These vendors often carry a comprehensive range of original components, backed by manufacturer warranties.

Additionally, official websites provide online catalogs featuring an extensive selection of authentic items. Here, you can explore detailed descriptions and specifications to make informed purchasing decisions.

For those who prefer to shop locally, hardware stores specializing in outdoor tools may also stock genuine components. Consulting with knowledgeable staff can lead you to the right solutions tailored to your equipment.

Remember: Choosing authentic items not only guarantees compatibility but also enhances the overall efficiency and reliability of your machinery.

Tools Needed for Repairs

Proper maintenance and repair of outdoor equipment require a variety of tools to ensure efficiency and effectiveness. Having the right instruments on hand can significantly simplify the process, reduce potential issues, and enhance overall performance. Below is a list of essential tools that are commonly needed for various repair tasks.

- Screwdrivers: Both flathead and Phillips screwdrivers are crucial for removing and securing screws.

- Wrenches: Adjustable and socket wrenches are useful for loosening or tightening nuts and bolts.

- Pliers: Needle-nose and regular pliers can help grip small parts and make adjustments.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Replacement Parts: Having spare components on hand can expedite the repair process.

- Cleaning Supplies: Brushes and cloths for clearing debris from components are essential for maintenance.

Utilizing these tools effectively will help in performing repairs efficiently, maintaining the longevity of the equipment, and ensuring optimal functionality.

Step-by-Step Assembly Instructions

This section provides detailed guidance on the assembly process for your equipment, ensuring a smooth and efficient setup. Proper assembly is crucial for optimal performance and longevity, so following each step carefully will help you achieve the best results.

Begin by gathering all necessary components and tools. Ensure that you have a clean workspace to prevent any parts from getting lost or damaged. Review the components and familiarize yourself with their functions to facilitate a more straightforward assembly process.

Start by connecting the main body to the power unit. Align the mounting brackets and secure them using the provided screws. Ensure that all fasteners are tightened adequately to prevent any movement during operation.

Next, attach the air intake and exhaust sections, making sure they fit snugly. This step is essential for maintaining optimal airflow and efficiency. Use the appropriate clamps to secure these sections firmly.

Afterward, install the handlebar assembly, adjusting its position for comfort and ease of use. Tighten the bolts carefully, ensuring the handle is secure but still adjustable if necessary.

Finally, double-check all connections and fittings. Ensure everything is properly aligned and secured before performing a functionality test. Following these instructions will help you achieve a reliable and efficient assembly.

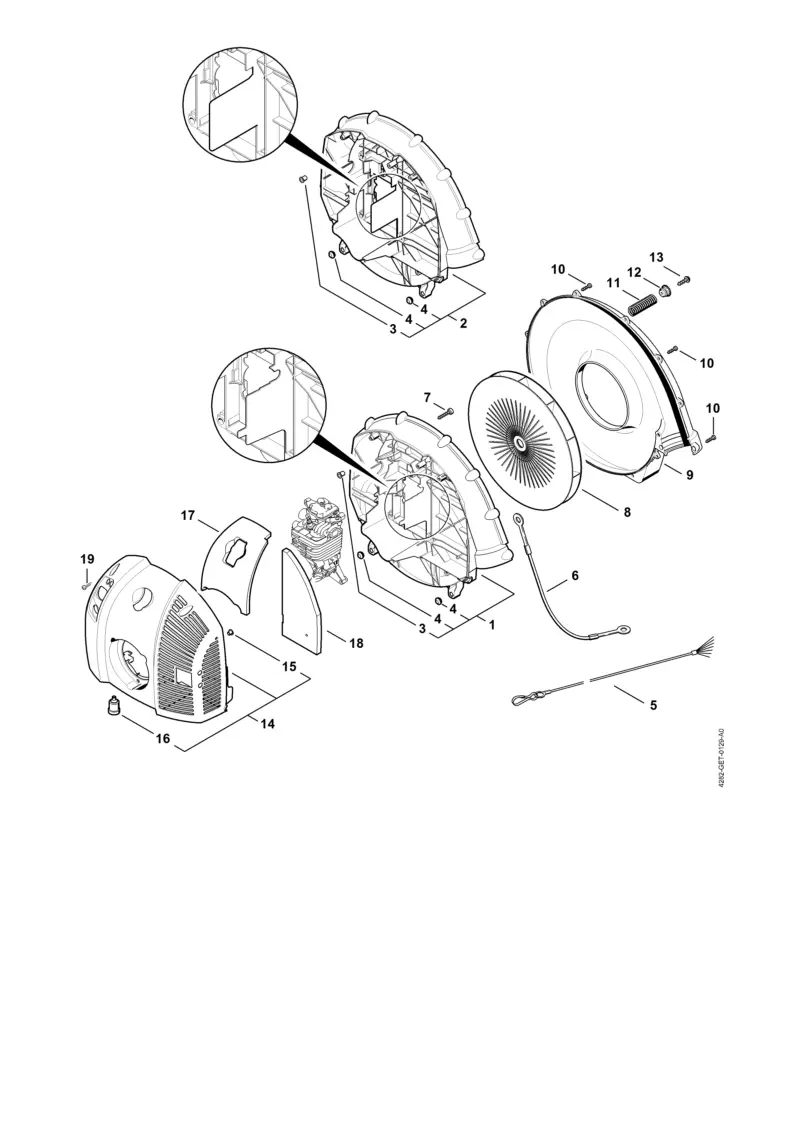

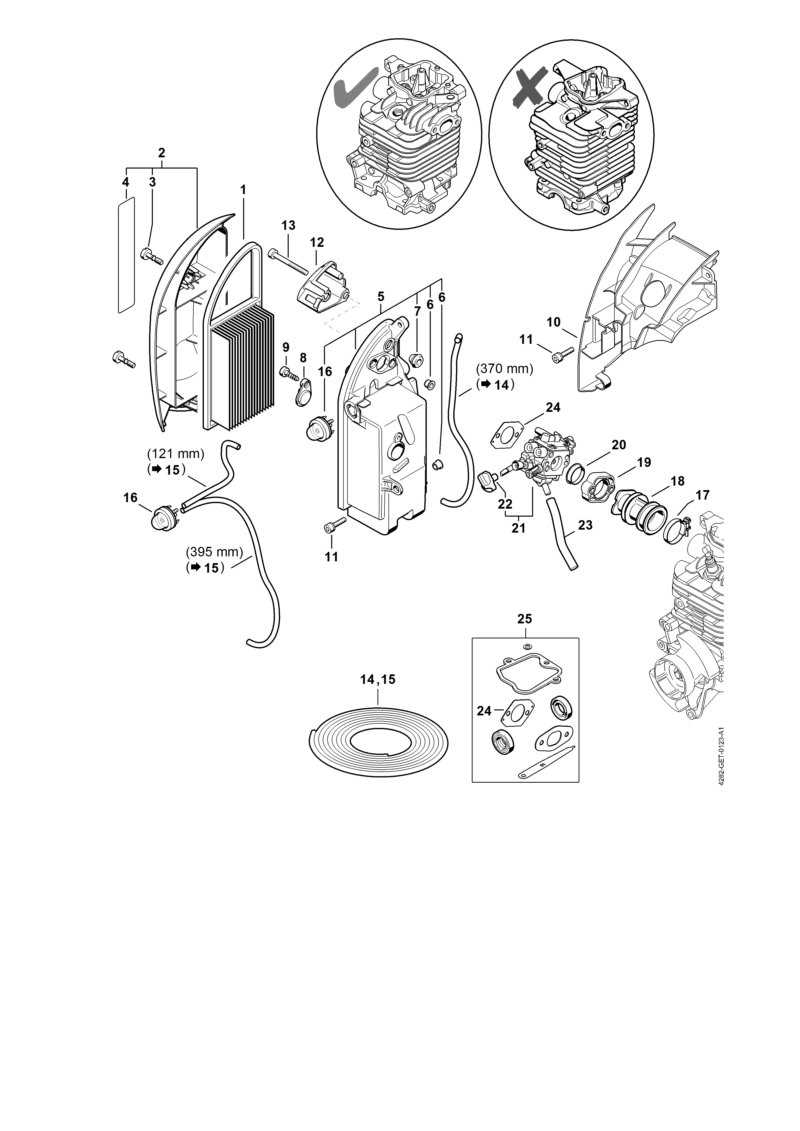

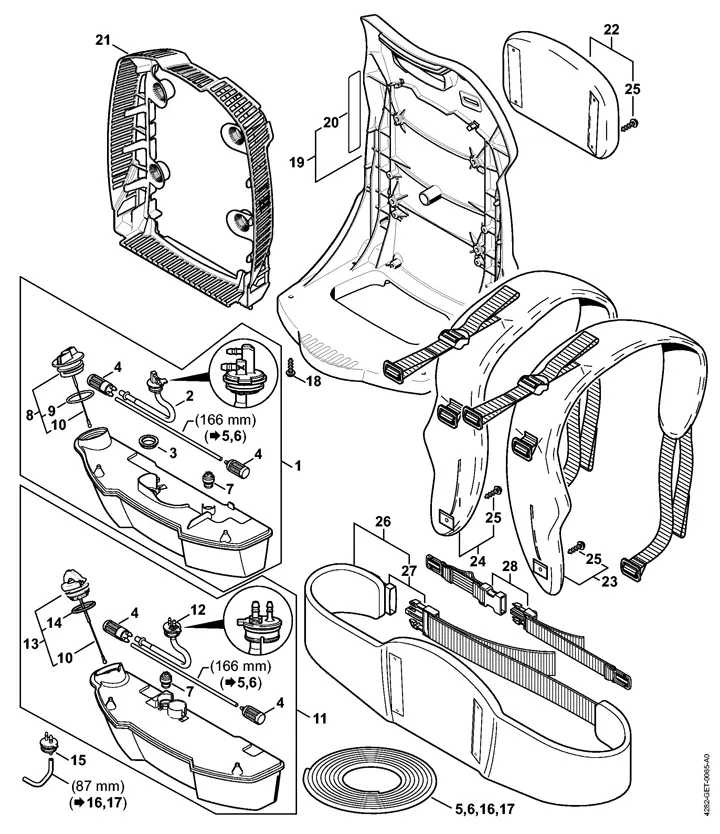

Visual Aids for Reference

Utilizing visual aids can significantly enhance understanding and facilitate the identification of components within complex equipment. Diagrams, illustrations, and exploded views serve as valuable resources for users, allowing them to grasp the relationships and functions of various elements. Such references not only simplify the assembly and disassembly processes but also assist in troubleshooting by highlighting specific areas of concern.

Importance of Illustrations

Illustrations provide clarity, making it easier for individuals to visualize intricate systems. By examining detailed drawings, users can better comprehend how each component fits together and operates in conjunction with others. This understanding is essential for effective maintenance and repair, ensuring that users can confidently navigate through their tasks.

Utilizing Exploded Views

Exploded views offer a unique perspective, displaying components separated for clearer visibility. This method not only aids in understanding the layout but also simplifies the reassembly process. By referencing these visuals, individuals can ensure that every part is correctly positioned, reducing the likelihood of errors and enhancing overall efficiency.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and operation of outdoor equipment. Understanding these aspects can significantly enhance user experience and equipment longevity. Here, we compile the most frequently asked questions along with comprehensive answers to assist users in resolving their concerns effectively.

General Maintenance Queries

Proper care is essential for ensuring optimal performance. Below are some of the key questions regarding upkeep.

| Question | Answer |

|---|---|

| How often should I clean the air filter? | It is recommended to clean the air filter every 10 hours of operation for optimal performance. |

| What type of fuel should I use? | Use a high-quality fuel with a minimum octane rating of 89, mixed with the appropriate oil. |

Operational Tips

Understanding how to effectively use your equipment can enhance its efficiency. Here are some common operational inquiries.

| Question | Answer |

|---|---|

| What is the ideal technique for using the equipment? | Maintain a consistent speed and keep the nozzle at a slight angle for best results. |

| Can I operate it in wet conditions? | It is advisable to avoid use in wet conditions to prevent damage and ensure safety. |

Contacting Customer Support

When seeking assistance for your equipment, reaching out to customer support is essential for resolving issues or obtaining information. Reliable help can streamline the troubleshooting process and ensure optimal performance.

Various channels are available to connect with support representatives. It’s important to choose the one that best fits your needs. Here are the most common options:

| Contact Method | Description |

|---|---|

| Phone Support | Immediate assistance through direct conversation with a representative. |

| Email Support | Send detailed inquiries and receive responses at your convenience. |

| Online Chat | Real-time communication through chat platforms for quick solutions. |

| Help Center | Access to FAQs and guides for self-service solutions. |

Utilizing these resources can help you get the answers you need promptly, ensuring your equipment operates efficiently and effectively.