When working with construction machinery, a comprehensive understanding of how its mechanical systems are organized is essential. Such knowledge ensures proper maintenance, efficient operation, and smooth troubleshooting. Every machine consists of numerous interconnected elements, each playing a crucial role in its performance. A clear visual representation of these components helps to identify their specific locations and functions, making repairs and upgrades more manageable.

Breakdowns in these machines often require a deeper knowledge of their structure to efficiently address the issue. Without a solid grasp of the equipment’s inner workings, pinpointing the source of a problem can be time-consuming and costly. Therefore, familiarity with the assembly of various systems is indispensable for operators and service personnel alike.

By using detailed visual layouts, it is easier to locate and replace malfunctioning or worn-out components. Such resources become indispensable when tackling complex technical challenges. They simplify the task of understanding how the parts interact, allowing for more precise and quicker repairs or adjustments.

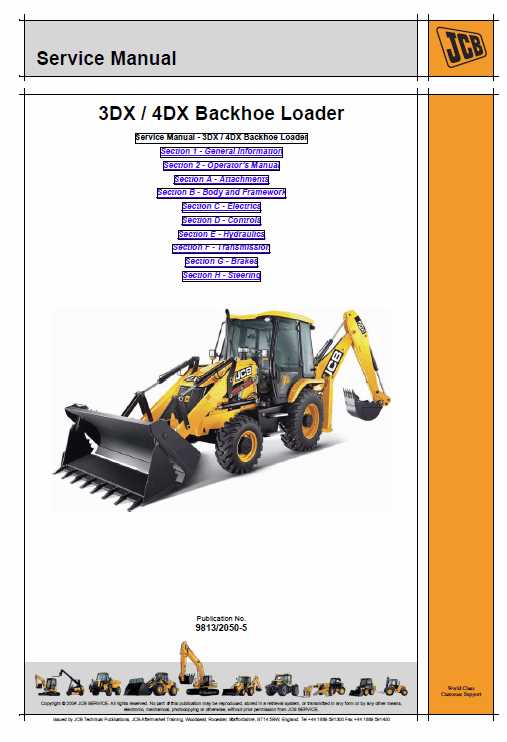

Understanding the JCB Backhoe System

In construction and excavation machinery, the hydraulic system plays a crucial role in ensuring smooth operation and high efficiency. The various components work in unison to deliver power and precision, allowing the machine to perform a wide range of tasks. Understanding how each element functions and interacts can help improve performance and streamline maintenance processes.

The hydraulic system is composed of several interconnected mechanisms. Each section of the equipment is designed to optimize efficiency and control, from the arm to the digging bucket. Every component contributes to the overall effectiveness, ensuring that the machine performs under tough conditions.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates pressure to power the hydraulic system. |

| Hydraulic Cylinder | Translates hydraulic pressure into linear motion, allowing movement of the arm and tools. |

| Valve | Controls the flow of hydraulic fluid to direct the movement of the machine. |

| Reservoir | Stores hydraulic fluid, ensuring proper lubrication and cooling for the system. |

By understanding how these essential elements work together, operators can make informed decisions regarding maintenance, repairs, and troubleshooting, ultimately prolonging the life and productivity of the machinery.

Essential Components of a Backhoe

Understanding the key elements of heavy construction machinery is crucial for maintaining and operating it efficiently. This type of equipment consists of various systems and components that work together to perform tasks such as digging, lifting, and moving materials. Each individual part plays an important role in ensuring the machine’s performance and longevity. Below are the core systems that make up the machinery, offering a deeper look into how they function together to provide optimum utility in construction sites.

Hydraulic System

The hydraulic system is at the heart of this machine’s functionality. It is responsible for providing the power needed for various movements such as lifting and extending the boom, as well as operating attachments like shovels and augers. The key components of this system include:

- Hydraulic pump

- Hydraulic cylinders

- Fluid reservoir

- Control valves

Structural Frame

The structural frame serves as the backbone of the equipment, supporting all other systems. It provides the necessary strength and stability to the vehicle, ensuring that it can handle heavy loads and endure the stresses of tough terrain. Key elements of the frame include:

- Main chassis

- Undercarriage

- Arm and boom support

- Attachment points for implements

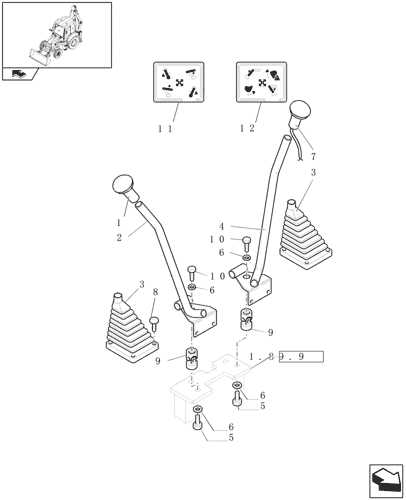

How to Identify JCB Parts

When working with heavy machinery, recognizing individual components is essential for proper maintenance and repair. Every machine consists of various elements that perform specific functions. Knowing how to identify these elements can help you ensure the correct parts are used, avoid unnecessary replacements, and optimize the performance of the equipment.

Understand the Key Features

Each component in the machinery is designed for a particular purpose, and recognizing these features can aid in identification. Pay attention to the shape, size, and material of each element, as well as any manufacturer’s markings or codes. Some components may also have color-coded labels or tags that indicate their specific function within the system.

- Check for visible identifiers such as part numbers or model codes.

- Look for specific shapes and sizes that match the intended use.

- Inspect the material and finish, as these can vary depending on function.

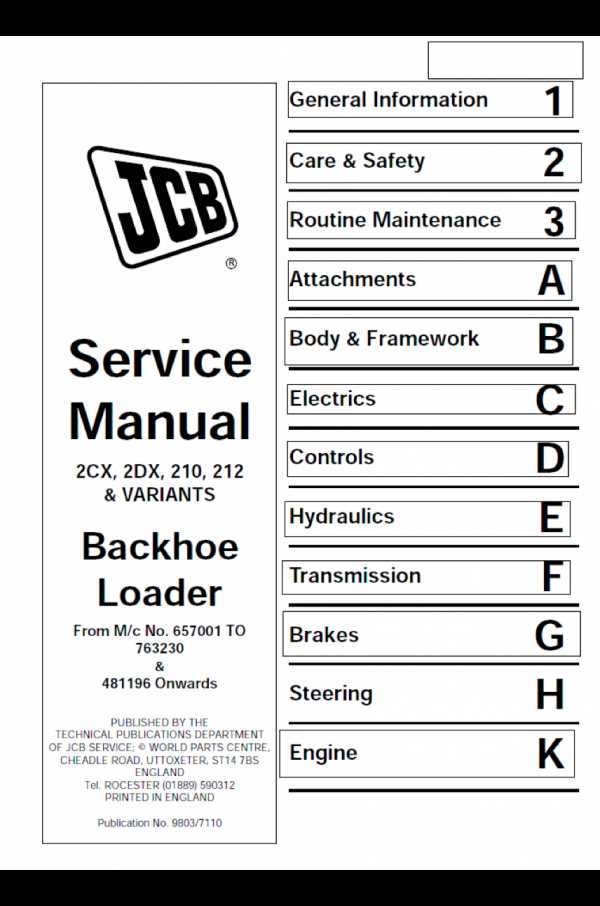

Consult Manufacturer Documentation

Refer to the official manuals and technical documentation for detailed information about the different elements of the machine. These resources often provide part numbers, diagrams, and descriptions that make it easier to identify each component correctly. You can also access digital databases or manufacturer websites to cross-reference any unclear components.

- Locate the section relevant to the machine model or equipment type.

- Use part numbers or descriptions to confirm the correct match.

- Check online resources for additional support and updates.

By following these steps, you can confidently identify and select the correct elements for any project or repair task, ensuring the smooth operation of the machinery.

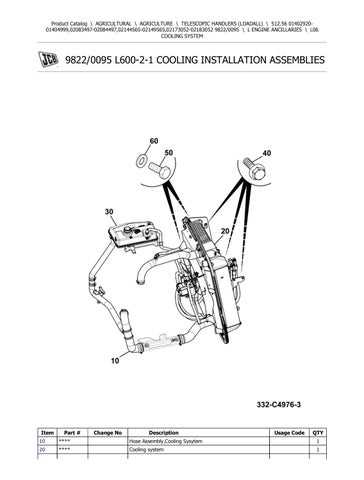

JCB Hydraulic and Mechanical Parts

Hydraulic and mechanical systems play a vital role in the operation of heavy machinery, ensuring the smooth movement and functionality of various components. These systems consist of numerous elements that work together to facilitate tasks like digging, lifting, and stabilizing. Each element is carefully engineered to handle high pressures, offering efficiency and precision for construction projects.

Hydraulic Components

The hydraulic system is responsible for powering many critical functions in construction equipment. It utilizes fluid under pressure to transmit force, enabling tasks such as digging and lifting heavy materials. Essential hydraulic elements include pumps, cylinders, valves, and hoses. Each of these components is crucial for maintaining the system’s pressure and ensuring smooth movement throughout the machinery.

Mechanical Systems

In addition to hydraulics, the mechanical structure of the machine supports its mobility and overall performance. This includes components such as gears, linkages, bearings, and joints. These parts are designed to work in harmony to transfer motion and force, providing the strength and stability necessary for demanding tasks on the worksite.

Common Issues with Backhoe Components

Heavy machinery often encounters various mechanical challenges due to the complex systems and numerous moving elements involved. Understanding the typical problems that can arise in these machines helps in better maintenance and timely troubleshooting. By identifying common malfunctions, operators can prevent costly repairs and ensure smooth operation.

- Hydraulic Leaks: One of the most frequent issues is fluid leakage in the hydraulic system. These leaks can occur in hoses, seals, or pumps, leading to reduced efficiency and potential damage to the equipment.

- Engine Overheating: If the cooling system is compromised or the engine is overworked, it can result in overheating. This problem is often linked to clogged radiators, low coolant levels, or malfunctioning thermostats.

- Worn-out Bearings: Bearings in the arms or other moving sections are prone to wear and tear over time. This can cause rough operation, misalignment, and increased strain on the system, leading to premature failure if not addressed.

- Electrical Failures: Faulty wiring, corroded connections, or damaged sensors can disrupt the machine’s electrical systems, leading to operational difficulties or complete breakdowns.

- Transmission Issues: Problems with the transmission can lead to sluggish or jerky movement. This can stem from low fluid levels, damaged gears, or issues with the transmission pump.

- Bucket Wear and Damage: Continuous use of the digging or lifting components can cause excessive wear or even cracks. Regular inspection of the bucket’s teeth and structure is essential to avoid failure during operation.

Regular maintenance and timely repairs are crucial to keeping equipment functioning optimally. Being proactive in addressing these common issues helps minimize downtime and maximize productivity.

Maintaining JCB Parts for Longevity

Regular upkeep of heavy machinery components is essential for ensuring their efficiency and extending their operational lifespan. Proper care and attention not only reduce the likelihood of unexpected breakdowns but also improve overall performance, which can save both time and money. By staying on top of maintenance, operators can avoid costly repairs and replacements, keeping the equipment running smoothly for years.

Routine Inspections

Routine inspections are vital for identifying any potential issues before they escalate into more significant problems. Checking the condition of mechanical elements, hydraulic systems, and other crucial components on a regular basis will help detect wear and tear early. Operators should focus on checking for leaks, corrosion, and any loose fasteners that could compromise safety or functionality. Ensuring that all moving parts are adequately lubricated is also critical to preventing excessive friction and premature wear.

Replacing Worn Components

Over time, certain elements will inevitably experience deterioration due to regular use. It is important to replace these worn-out components promptly to maintain the overall efficiency of the equipment. Not only does this prevent further damage to other parts, but it also ensures the machine continues to operate at peak performance. Regularly replacing filters, seals, and other consumables can go a long way in prolonging the life of the equipment.

Note: Always consult the manufacturer’s guidelines when replacing any components to ensure compatibility and proper installation.

In conclusion, routine maintenance, inspections, and timely replacement of essential elements are key to maximizing the longevity of machinery and minimizing downtime. By following these practices, equipment owners can ensure that their machinery remains in optimal working condition for years to come.

Aftermarket Parts vs. Original JCB Parts

When it comes to maintaining heavy machinery, the choice between using replacement components from the manufacturer and opting for third-party alternatives can significantly impact performance, cost, and long-term reliability. Each option has its own set of advantages and potential drawbacks, depending on factors such as quality, price, and availability. Understanding the differences between original equipment and aftermarket offerings can help make an informed decision for equipment owners.

Benefits of Manufacturer-Supplied Components

Original components are designed and tested to meet the exact specifications of the machine. They offer several key advantages:

- Precision Engineering: Ensures compatibility and optimal performance with the rest of the equipment.

- Durability: Typically made from high-quality materials, leading to longer lifespan and fewer breakdowns.

- Warranty Protection: Often comes with a manufacturer’s warranty, giving peace of mind regarding the integrity and performance of the product.

- Long-Term Reliability: Designed to function seamlessly within the specific model, reducing the likelihood of complications or additional repairs.

Advantages of Aftermarket Components

On the other hand, third-party alternatives can offer competitive pricing and flexibility, with some distinct benefits:

- Cost Savings: Generally more affordable than manufacturer-supplied alternatives, making them an attractive option for budget-conscious operators.

- Variety: Aftermarket suppliers may offer a wider range of options, which could include enhanced or specialized features not available from the original manufacturer.

- Availability: In some cases, aftermarket components may be easier to find, reducing downtime in urgent situations.

- Customization: Some third-party options allow for customization to meet specific operational needs or preferences.

Safety Tips for Working with JCB Equipment

Operating heavy machinery requires careful attention to detail and strict adherence to safety guidelines. To prevent accidents and ensure efficient operation, workers must follow specific precautions when handling construction machinery. Whether you are performing routine maintenance or operating the equipment for various tasks, maintaining a safe work environment is crucial for both personal and team safety.

Pre-Operation Precautions

Before starting any equipment, inspect it thoroughly. Ensure that all components are secure, and check fluid levels, tires, and other key features. Pay close attention to any potential hazards such as loose or worn-out parts, as they could cause malfunction during operation. Always read the manufacturer’s manual for safety instructions and familiarize yourself with the operating system. Additionally, make sure that safety devices, such as lights, signals, and alarms, are functioning properly.

Personal Protective Equipment

Always wear appropriate personal protective gear (PPE), including safety boots, hard hats, gloves, and high-visibility clothing. In certain environments, additional protection like earplugs or safety glasses may be necessary. By ensuring that proper PPE is worn at all times, you can reduce the risk of injury from unexpected incidents or environmental factors.

Never operate machinery under the influence of fatigue or alcohol. It is essential to remain alert and focused to avoid potential accidents. Follow all workplace safety protocols and report any equipment malfunctions or safety concerns immediately to prevent serious injuries.

Safety should be a top priority in any job site environment. Taking the necessary precautions can significantly reduce risks and ensure that every operation runs smoothly and without incident.

Troubleshooting JCB Backhoe Malfunctions

When operating heavy machinery, encountering malfunctions is an inevitable part of the process. Identifying and resolving issues early is essential for maintaining operational efficiency and preventing more severe damage. This guide provides insights into diagnosing common mechanical failures and outlines basic steps to troubleshoot them effectively. With the right approach, many problems can be fixed on-site without needing extensive repairs.

Common Issues and Causes

- Hydraulic System Failures: Inadequate lifting power, slow response times, or erratic movements may indicate hydraulic fluid contamination or low pressure.

- Engine Overheating: If the engine is overheating, this could be due to a blocked radiator, low coolant levels, or a malfunctioning thermostat.

- Transmission Problems: Slipping gears or unresponsive shifting may result from low fluid levels or damage to internal components.

- Electrical Failures: Issues with starting the engine or malfunctioning lights could be traced to faulty wiring, a dead battery, or malfunctioning relays.

Steps to Resolve the Issues

- Inspect the Fluid Levels: Begin by checking the oil, hydraulic fluid, and coolant levels. Ensure they are within the recommended range.

- Check for Leaks: Look for signs of leaks around the hydraulic system, engine compartment, and transmission to identify any potential points of failure.

- Clean the Components: Ensure filters, radiators, and cooling systems are clean and functioning correctly. Dust and debris can impair performance.

- Test the Electrical System: Inspect the battery, wiring, and fuses to ensure proper connectivity and avoid electrical short circuits.

By systematically identifying and addressing these key areas, most operational issues can be managed effectively, keeping your equipment running smoothly and minimizing downtime.

Upgrading JCB Backhoe Parts for Efficiency

Enhancing the performance and productivity of heavy machinery is crucial for any construction project. By upgrading certain components, operators can improve operational efficiency, reduce downtime, and extend the lifespan of the equipment. Whether it’s optimizing mechanical systems or incorporating advanced technologies, every improvement contributes to a smoother, more reliable work process.

To achieve the best results, it is essential to focus on key areas of enhancement that have a direct impact on performance. Here are a few suggestions to consider when upgrading machinery:

- Improve hydraulic systems for faster and more precise control.

- Upgrade the engine for increased fuel efficiency and higher power output.

- Consider advanced transmission options to enhance gear shifting and overall movement.

- Install enhanced safety features to ensure better operator protection and reduce risks on the site.

- Use durable materials for high-wear parts to increase longevity and reduce maintenance costs.

By carefully selecting and implementing these upgrades, machinery owners can ensure their equipment operates at peak efficiency, helping to tackle tougher jobs with greater speed and reliability.

Where to Find Reliable Parts Diagrams

Finding accurate and trustworthy visual guides for machinery components is crucial for maintaining efficiency in repairs and upgrades. These visual aids help identify specific elements within the system, ensuring correct replacement and assembly. Whether you’re a professional technician or an enthusiast, knowing where to locate these resources can save time and prevent costly errors.

One of the most dependable sources is the official manufacturer’s website. Often, companies provide detailed schematics and technical manuals for all models, allowing users to access precise information directly from the source. Another option is specialized forums and communities where experts share knowledge and resources, including diagrams for various machines. These platforms are often supported by professionals who provide feedback and insights based on hands-on experience.

If online resources are not sufficient, repair shops and local dealerships may offer physical or digital copies of relevant guides. These establishments typically maintain archives of technical documents and may be able to provide support or even offer recommendations for high-quality aftermarket alternatives.