When working with outdoor power tools, having a clear understanding of their structure is essential for efficient maintenance and repair. Knowing how the different parts interact can help ensure smooth operation and extend the tool’s lifespan. Each machine is composed of various components, each playing a vital role in its functionality.

Breaking down the tool’s anatomy allows you to identify any potential issues or wear and tear. By familiarizing yourself with the individual sections, you can better troubleshoot problems and perform necessary upgrades. Whether you’re a professional or a hobbyist, understanding these crucial elements is key to keeping your equipment in top working condition.

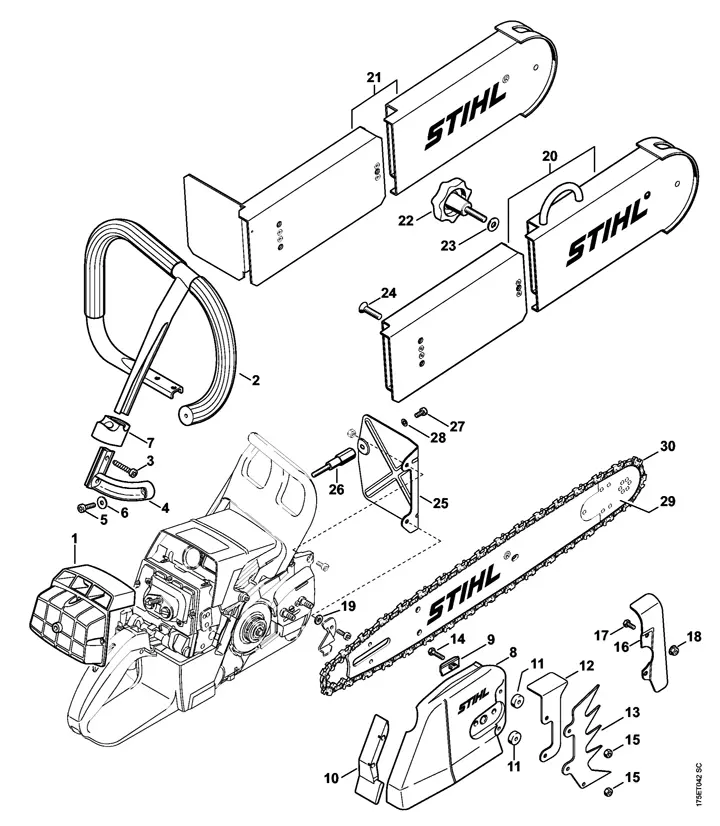

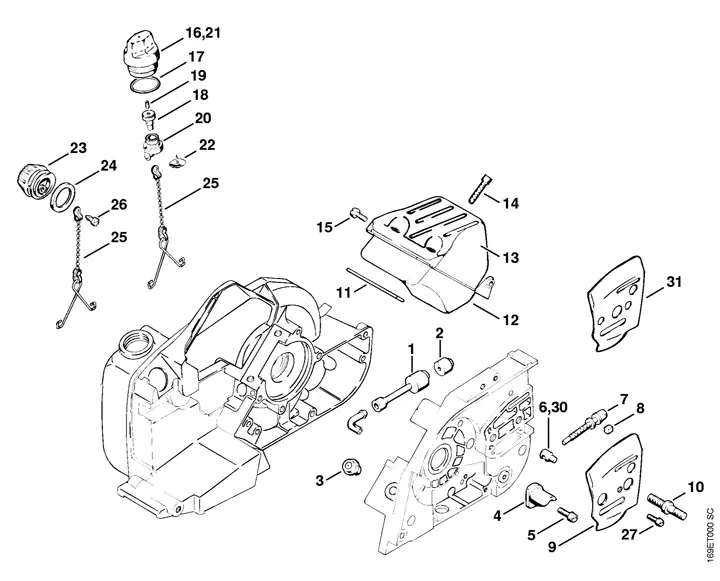

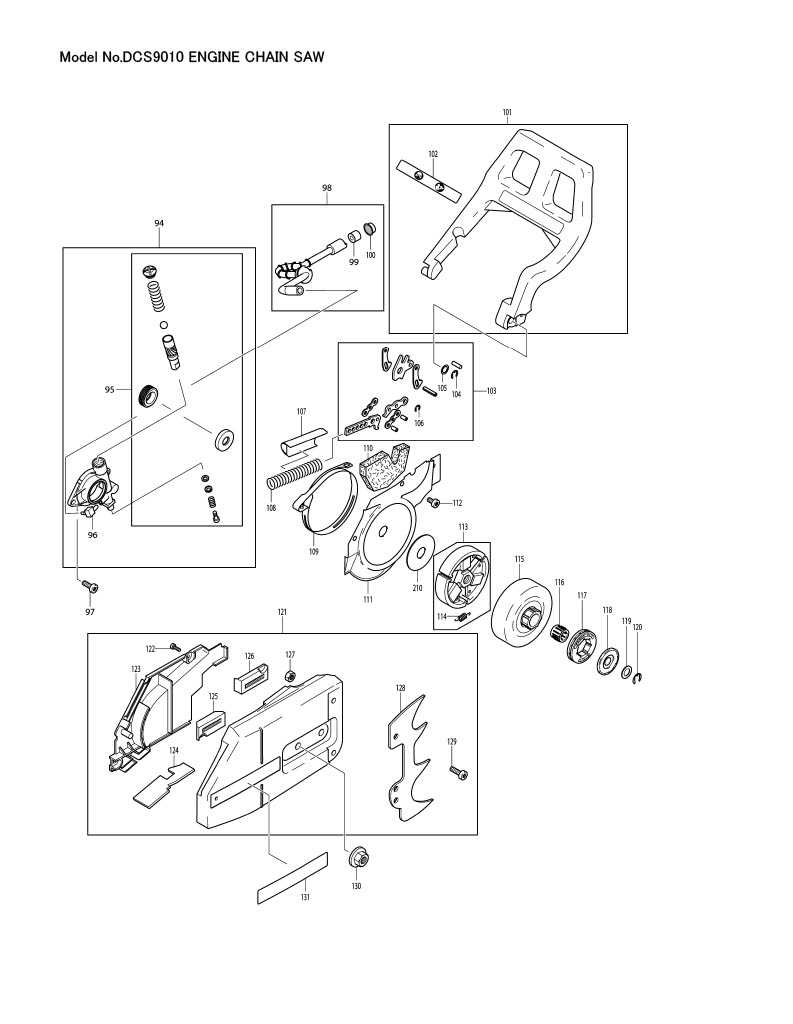

Having a visual representation of the assembly process makes it easier to manage repairs. It also provides insight into the ordering of parts and the connection between them. A detailed guide helps make the task more manageable and gives confidence to those unfamiliar with intricate machinery.

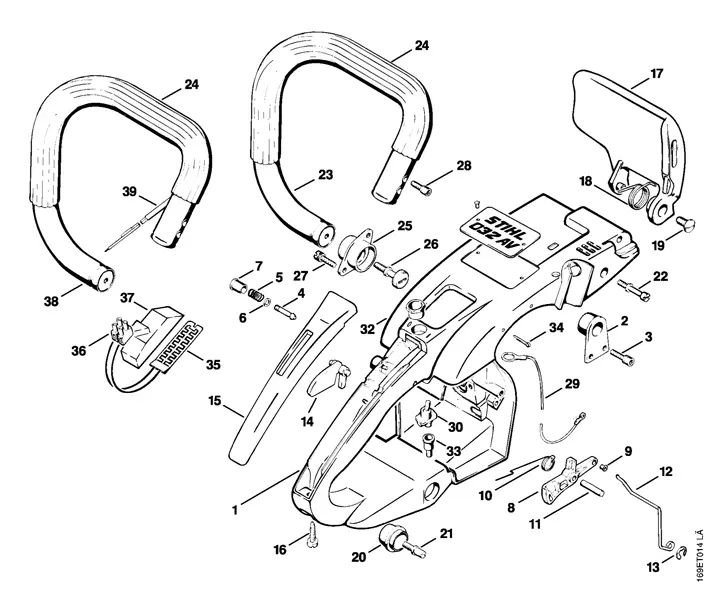

Stihl 032 AV: Essential Parts Overview

Understanding the key components of a high-performance chainsaw is crucial for both maintenance and optimal functioning. Each element plays a role in ensuring smooth operation and longevity, so it is important to be familiar with the essential parts of this tool. Knowing these components will help users troubleshoot, perform repairs, and improve overall usage efficiency.

Key Elements of the Saw

The primary sections of the machine include the motor, cutting mechanism, and vibration reduction system. These are the core elements that ensure the device operates effectively under various conditions. The motor powers the cutting chain, while the cutting mechanism itself is responsible for the actual wood processing. Meanwhile, the vibration system minimizes strain during extended usage, providing a more comfortable user experience.

Maintenance Considerations

Regular upkeep is necessary to extend the lifespan of the tool. Frequent inspection of the motor and cutting system ensures optimal performance. Additionally, keeping the vibration-reducing components in good condition can prevent wear and tear, enhancing overall safety and comfort. A well-maintained machine will consistently deliver strong results, even in challenging tasks.

Key Components of the Stihl 032 AV

The functionality of a high-performance chainsaw depends on the quality and design of its individual elements. Each part plays a crucial role in ensuring smooth operation, reliability, and ease of use. In this section, we will explore the primary components that make up the tool, which are vital for its optimal performance in both professional and recreational use.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power and driving the cutting mechanism. |

| Bar and Chain | The cutting system that slices through wood, made up of a steel bar and sharp, durable teeth. |

| Clutch | Engages the chain with the engine, ensuring efficient transmission of power to the cutting system. |

| Air Filter | Prevents dirt and debris from entering the engine, maintaining clean air for combustion. |

| Fuel Tank | Stores fuel for the engine, designed for easy access and refueling during long jobs. |

| Throttle Mechanism | Controls the engine speed, allowing the operator to adjust power based on cutting requirements. |

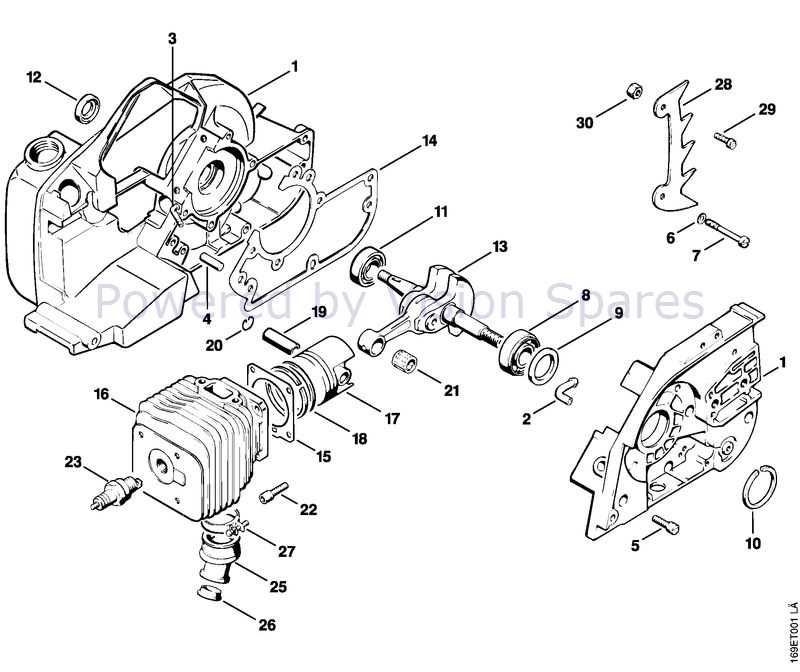

Understanding the Stihl 032 AV Engine Diagram

In order to fully grasp the mechanics of an engine, it is crucial to have a clear view of how its individual components interact. This visual representation helps in identifying the placement and connection of each part, offering a comprehensive understanding of its function. By examining this layout, it becomes easier to troubleshoot and maintain the engine efficiently.

Key Components and Their Functions

The engine layout typically includes various sections that serve distinct purposes. For example, the ignition system, fuel delivery, and exhaust components all work together to ensure optimal performance. Understanding each element’s role within the system is essential for diagnosing issues and performing necessary repairs.

Benefits of a Clear Engine Layout

A well-organized engine layout simplifies maintenance tasks. When the design is visually accessible, it allows technicians to pinpoint problems more quickly and with greater accuracy. Increased efficiency in repair and troubleshooting leads to better overall performance and longevity of the engine.

How to Identify Stihl 032 AV Spare Parts

When maintaining your equipment, recognizing the correct components is essential for proper functionality and longevity. Understanding the structure and function of each element allows for more effective repairs and ensures smooth operation.

Recognizing Key Components

Start by familiarizing yourself with the major sections of the machine. The engine, fuel system, and cutting mechanism each have their unique parts. Identifying these categories helps narrow down which specific elements need attention. Look for model-specific markings or numbers that indicate compatibility with your model.

Using Reference Guides

One of the most effective ways to identify components is by consulting detailed reference guides. These often provide visual aids and part numbers, allowing you to easily cross-reference with the item you’re examining. Be sure to use trusted sources to avoid confusion and ensure accuracy.

Maintenance and Repair Tips for Your Chainsaw

Proper upkeep and timely repairs are crucial for the longevity and efficiency of your chainsaw. Regular maintenance ensures smooth operation, reduces downtime, and prevents costly damage. Understanding basic maintenance tasks and troubleshooting techniques can keep your tool in top condition, ensuring it performs reliably during every use.

Regular Cleaning and Lubrication

One of the most essential tasks for maintaining your chainsaw is cleaning. After each use, ensure the saw chain, air filter, and sprocket are free of debris and built-up grime. Regular cleaning will prevent clogging and overheating, which can shorten the lifespan of the equipment. Also, keep the chain lubricated with proper oil to ensure smooth movement and reduce wear on components.

Inspecting Key Components for Wear

Regularly inspect the chainsaw’s critical components such as the chain tension, bar, and the overall alignment of the motor. If the chain is too tight or too loose, it can affect performance and cause unnecessary strain on the machine. Also, check for any signs of wear or damage on the guide bar and sprocket, as these can impact cutting efficiency and lead to more serious issues if left unattended.

Common Problems with Stihl 032 AV Parts

Many users of these forestry tools encounter recurring issues with their components over time. Understanding these challenges can help in identifying solutions and ensuring smoother operation. Below are some of the most common concerns that users face with this equipment.

Engine Performance Issues

- Frequent Stalling: This problem often results from clogged air filters, fuel line issues, or a malfunctioning carburetor. Regular maintenance is essential to prevent this.

- Power Loss: A decrease in engine performance may occur due to worn-out spark plugs, old fuel, or fuel mixture inconsistencies.

Component Wear and Tear

- Chain and Bar Wear: Over time, the cutting chain and guide bar may become dull or damaged, reducing cutting efficiency.

- Broken Vibration Dampeners: The vibration dampeners often wear out, leading to uncomfortable operation and increased strain on the user.

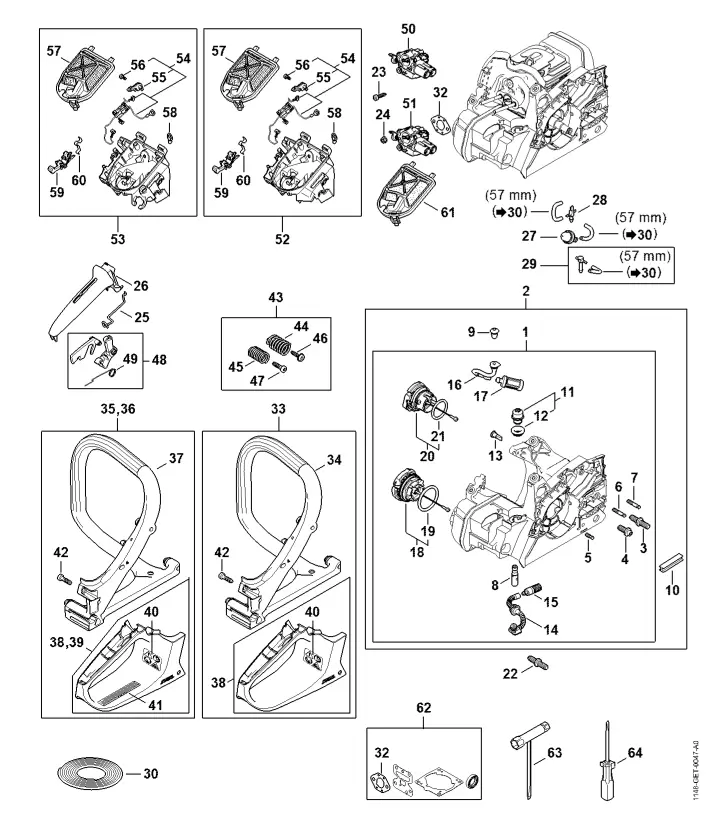

How to Replace Stihl 032 AV Parts

Replacing components in your chainsaw can restore its performance and extend its lifespan. Properly handling the replacement process ensures that your machine runs efficiently and with minimal disruptions. Whether you’re upgrading worn-out parts or performing routine maintenance, following the correct steps is key to a successful repair.

Preparation Before Starting

Before you begin, it’s important to gather all necessary tools and the replacement parts. Here’s a list of items you may need:

- Replacement components (check compatibility)

- Wrenches and screwdrivers

- Gloves for safety

- Cleaning materials

- Manual or guide for the specific model

Step-by-Step Process

- Start by disconnecting the power source to prevent any accidents.

- Carefully remove the cover or casing to access the internal mechanisms.

- Locate the component to be replaced and take note of its position.

- Using appropriate tools, detach the damaged part. If it’s stuck, gently wiggle it free.

- Install the new piece by aligning it correctly and securing it in place.

- Double-check the installation and reassemble the casing.

- Test the equipment to ensure everything functions smoothly.

Where to Buy Stihl 032 AV Parts

Finding reliable components for your tool is essential for maintaining its performance and longevity. Whether you’re looking for specific replacement pieces or general maintenance items, there are various places to purchase these essentials. By choosing trusted sources, you ensure that your equipment continues to run smoothly for years to come.

Authorized Dealers

One of the best options for acquiring original components is through authorized dealers. These retailers offer genuine replacements, ensuring compatibility and quality. By visiting a local dealer or their online store, you can access a wide selection of components tailored to your machine’s specific needs.

Online Marketplaces

For those who prefer the convenience of shopping from home, online marketplaces provide a variety of choices. Websites like eBay, Amazon, and specialized retailers offer new and used items. Be sure to check customer reviews and seller ratings to make informed decisions and avoid counterfeit or low-quality goods.

Stihl 032 AV Part Compatibility Guide

Ensuring the right components work together is essential for the smooth operation of any machine. This guide provides a comprehensive overview of how different elements of a specific model interact and what to consider when looking for replacements or upgrades. By understanding compatibility, users can enhance performance, prevent damage, and extend the lifespan of their equipment.

Key Considerations: When selecting parts for your machine, always verify their compatibility with the existing framework. Some parts may seem similar, but even slight differences in size, shape, or function can impact overall performance. Pay close attention to the specific requirements of the motor, safety mechanisms, and attachment points.

Manufacturer Recommendations: It’s advisable to consult the manufacturer’s guidelines or trusted experts to ensure compatibility. Using parts that are designed for the model’s unique specifications can prevent unnecessary maintenance issues and reduce wear on critical components.

Stihl 032 AV Diagram: Parts for Beginners

Understanding the inner components of a chainsaw is essential for anyone looking to maintain or repair their tool. For those who are new to this type of equipment, knowing the specific functions and arrangement of each element can make a significant difference in performance and longevity. This guide aims to break down the key elements and their roles in the overall operation, offering a clear overview for beginners.

The primary elements of a chainsaw include the engine, cutting mechanism, and safety features. Each part plays a crucial role in ensuring smooth operation, efficient cutting, and user safety. Gaining familiarity with how these parts interact and their location within the device will help in understanding both its maintenance and troubleshooting needs.

For beginners, starting with a visual map of the machine’s layout can be incredibly helpful. This approach helps identify where each component is situated and how they connect. Whether you’re performing routine checks or deeper repairs, recognizing these parts will help you manage the tool with confidence and ensure its continued efficiency.

Upgrade Your Stihl 032 AV with New Parts

Enhancing the performance and longevity of your trusted outdoor tool can make a significant difference in its efficiency and overall experience. By upgrading essential components, you can ensure smoother operation and better results, especially for heavy-duty tasks. Fresh, high-quality elements contribute to improved power, reduced wear, and enhanced durability, keeping your equipment in top shape for longer periods of time.

Benefits of Using New Components

- Improved performance and smoother operation

- Increased reliability for challenging jobs

- Enhanced durability, reducing the need for frequent repairs

- Better fuel efficiency and less environmental impact

Key Upgrades to Consider

- Replace the ignition system for faster starts and efficient fuel use

- Upgrade the air filter for better air intake and combustion

- Install a new chain and bar for improved cutting precision and reduced effort

- Check the exhaust system to reduce emissions and enhance performance