In the world of agricultural machinery, comprehending the intricate arrangement of essential elements is crucial for optimal performance and maintenance. A thorough exploration of how these components interact not only enhances efficiency but also extends the lifespan of the equipment.

Detailed visual representations serve as valuable tools for operators and technicians alike. These illustrations simplify the identification of various sections and facilitate effective troubleshooting and repair. By becoming familiar with these schematics, users can ensure that their machinery operates smoothly and efficiently.

Moreover, grasping the layout of individual components allows for informed decision-making regarding replacements and upgrades. This knowledge empowers users to undertake maintenance with confidence, fostering a deeper connection with their machinery and improving overall productivity.

This section highlights the essential characteristics of a specific agricultural machine that enhance its functionality and usability. Understanding these attributes is crucial for potential users to appreciate the efficiency and reliability offered by this model.

Performance and Efficiency

- Robust engine providing excellent power for various tasks.

- Optimized fuel consumption, ensuring economical operation.

- Advanced transmission system that allows for smooth gear shifting.

User-Friendly Design

- Comfortable operator station designed for extended use.

- Easy access to controls, enhancing user experience.

- Compact dimensions that facilitate maneuverability in tight spaces.

Essential Components Explained

This section delves into the fundamental elements of machinery, providing insights into their functionality and significance. Understanding these components is crucial for effective maintenance and operation.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for converting fuel into mechanical power. |

| Transmission | Facilitates power transfer from the engine to the wheels, ensuring smooth movement. |

| Hydraulic System | Utilizes fluid pressure to operate various attachments and lift heavy loads. |

| Chassis | The framework that supports all other components, providing structural integrity. |

| Electrical System | Powers lights, ignition, and other electronic systems, essential for operation. |

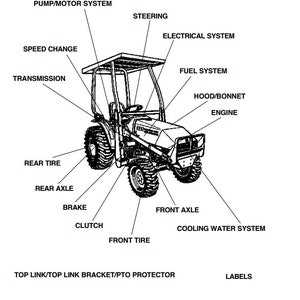

Understanding the Parts Diagram

The visual representation of components serves as a vital resource for identifying various elements within machinery. This illustration not only aids in comprehending the relationship between parts but also facilitates efficient maintenance and repair tasks. By analyzing this schematic, operators can gain insights into the overall structure and functionality of the equipment.

Benefits of Component Illustrations

Utilizing a visual guide enhances the ability to pinpoint specific elements, ensuring that users can easily navigate through complex systems. This clarity assists in troubleshooting issues, enabling timely and accurate repairs. Additionally, such representations provide a valuable reference for assembly processes, minimizing the risk of errors during installation or maintenance.

Interpreting the Visual Guide

To effectively interpret the schematic, one must familiarize themselves with the symbols and annotations used within the illustration. Each element is typically labeled, indicating its role and how it connects to other components. Understanding these details empowers users to make informed decisions when addressing repairs or upgrades, ultimately leading to improved performance and longevity of the equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of your equipment. By adhering to simple maintenance practices, you can enhance performance and reduce the risk of breakdowns. Implementing a structured routine will not only keep your machinery in optimal condition but also improve its efficiency over time.

Regular Inspections

Conducting periodic checks allows you to identify potential issues before they escalate. Inspect fluid levels, belts, and hoses to ensure everything is functioning properly. Keeping an eye on these components helps maintain smooth operation and avoids costly repairs.

Proper Cleaning

Maintaining cleanliness is crucial for preventing dirt and debris from affecting performance. Regularly clean filters and external surfaces to promote efficient operation. A clean machine is less likely to encounter problems, ensuring it runs efficiently for years to come.

Common Issues and Solutions

In the realm of machinery maintenance, users often encounter various challenges that can hinder performance and efficiency. Recognizing these common problems and understanding their solutions is crucial for optimal operation and longevity.

Engine Overheating: A frequent concern is overheating, which can result from inadequate coolant levels or a malfunctioning thermostat. Regular checks of the cooling system and timely replacement of worn components can prevent this issue.

Hydraulic Fluid Leaks: Leaks in hydraulic systems can lead to decreased functionality. It is essential to inspect hoses and fittings regularly, replacing any damaged parts promptly to maintain proper pressure and performance.

Starting Difficulties: Trouble starting the engine can stem from a weak battery or faulty ignition components. Ensuring the battery is fully charged and inspecting the ignition system for any wear can alleviate this issue.

Unresponsive Controls: If the controls become unresponsive, it may indicate a problem with the linkages or hydraulic fluid levels. Regular maintenance and adjustments can ensure smooth operation.

By addressing these typical challenges with proactive measures, users can enhance the functionality and reliability of their machinery.

Aftermarket Parts Considerations

When exploring options for replacement components, it’s crucial to assess the quality and compatibility of available alternatives. Opting for non-original parts can often provide a cost-effective solution while still maintaining functionality. However, understanding the implications of such choices is essential for optimal performance and longevity of machinery.

Quality Assurance

Not all aftermarket components are created equal. Here are factors to consider when evaluating quality:

- Material Durability: Check if the materials used meet industry standards.

- Manufacturer Reputation: Research the reliability of the manufacturer.

- Warranty Offerings: Look for parts that come with a solid warranty.

Compatibility Issues

Ensuring that the replacement items are compatible is vital to avoid operational problems. Consider the following:

- Verify specifications against the original components.

- Consult with suppliers about fitment and performance.

- Review user feedback on compatibility experiences.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also enhance the overall efficiency of the process.

Before beginning any work, it is essential to wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. These items help shield against potential hazards, including sharp edges and falling objects.

Always disconnect the power source before attempting repairs to avoid electrical shocks or equipment malfunctions. Make sure to follow the manufacturer’s guidelines regarding disconnection procedures.

In addition, keeping the workspace organized is vital. A clutter-free area reduces the risk of tripping or misplacing tools, allowing for a smoother workflow. Ensure that all tools and materials are within reach and stored safely when not in use.

Lastly, be aware of your surroundings and communicate effectively with others nearby. Informing colleagues of your actions can prevent misunderstandings and create a safer working environment.

Tools Required for Maintenance

Proper upkeep of machinery necessitates a variety of essential instruments to ensure optimal performance and longevity. Utilizing the right tools not only simplifies the maintenance process but also enhances the overall efficiency of the equipment.

Basic Hand Tools

Having a selection of basic hand tools is crucial for routine checks and adjustments. Items such as wrenches, pliers, and screwdrivers enable quick fixes and facilitate access to various components. Regularly inspecting these tools ensures they remain in good condition for reliable usage.

Specialized Equipment

In addition to standard hand tools, certain specialized equipment may be required for more intricate tasks. This could include torque wrenches and diagnostic devices, which help in accurately measuring and troubleshooting specific issues. Investing in quality tools can significantly contribute to effective maintenance practices.

Assembly and Disassembly Process

This section outlines the procedures involved in putting together and taking apart machinery components effectively. Understanding these steps is essential for maintaining optimal functionality and ensuring longevity of the equipment.

Preparation Steps

- Gather necessary tools and safety equipment.

- Review the manual for specific instructions related to the model.

- Ensure a clean and organized workspace to avoid losing parts.

Disassembly Procedure

- Disconnect the power source to ensure safety.

- Remove any protective covers or panels.

- Carefully unscrew bolts and fasteners in the proper sequence.

- Label components as they are removed for easier reassembly.

Following these guidelines will help facilitate a smooth assembly and disassembly process, reducing the risk of errors and damage.

Manufacturer Recommendations for Parts

When it comes to maintaining machinery, adhering to the manufacturer’s guidance for components is essential for optimal performance and longevity. By following these recommendations, operators can ensure their equipment runs smoothly and efficiently.

It is advisable to utilize components that are specifically designed for your model. This ensures compatibility and minimizes the risk of malfunction. Original equipment manufacturers (OEM) provide quality parts that meet stringent standards, thus enhancing the reliability of your machinery.

| Component | Recommendation |

|---|---|

| Engine Oil | Use recommended viscosity grade for optimal engine performance. |

| Air Filter | Replace regularly to maintain proper airflow and efficiency. |

| Fuel Filter | Change as per service intervals to prevent contamination. |

| Belt | Inspect frequently and replace if signs of wear are visible. |

In conclusion, adhering to the prescribed guidelines ensures the machinery operates at its best, reducing downtime and maintenance costs in the long run.

Where to Find Replacement Parts

Locating suitable components for your machinery can be essential for maintaining its performance and longevity. Several reliable sources can provide the necessary items, ensuring that your equipment remains in optimal working condition.

Authorized Dealers

One of the best options is to approach authorized retailers. These suppliers often stock genuine components that match the specifications required for your equipment, ensuring quality and compatibility.

Online Marketplaces

Another effective avenue is exploring online platforms. Many e-commerce sites offer a wide range of components, often at competitive prices. However, always verify the credibility of the seller to ensure you are purchasing quality products.