In the world of power tools, a compact chainsaw stands out for its efficiency and precision. Whether you’re a professional or a hobbyist, knowing the intricate details of this machinery can enhance your experience and ensure optimal performance. This section aims to provide a thorough exploration of the individual elements that contribute to the tool’s functionality.

Every component plays a crucial role, from the motor to the cutting mechanisms. A comprehensive understanding of these pieces can empower users to make informed decisions regarding maintenance and repairs. By delving into the specifics, one can grasp how each part interacts to deliver the ultimate performance during operation.

Equipped with the right knowledge, you’ll be better prepared to tackle any challenges that may arise. Whether it’s identifying a malfunction or simply seeking to optimize your tool’s capabilities, a detailed examination of the various components will prove invaluable. Let’s explore the essentials that make this compact saw a reliable companion in your projects.

Understanding the Stihl 020T Model

This section explores a specific power tool known for its efficiency and reliability in various tasks. Designed for professionals and enthusiasts alike, it combines robust features with a lightweight structure, making it ideal for precision work in forestry and landscaping.

Key Features

- Compact design for easy handling

- Powerful engine for effective performance

- Advanced safety mechanisms

- Low vibration for user comfort

Applications

- Tree trimming

- Pruning branches

- Maintaining landscapes

- Professional forestry work

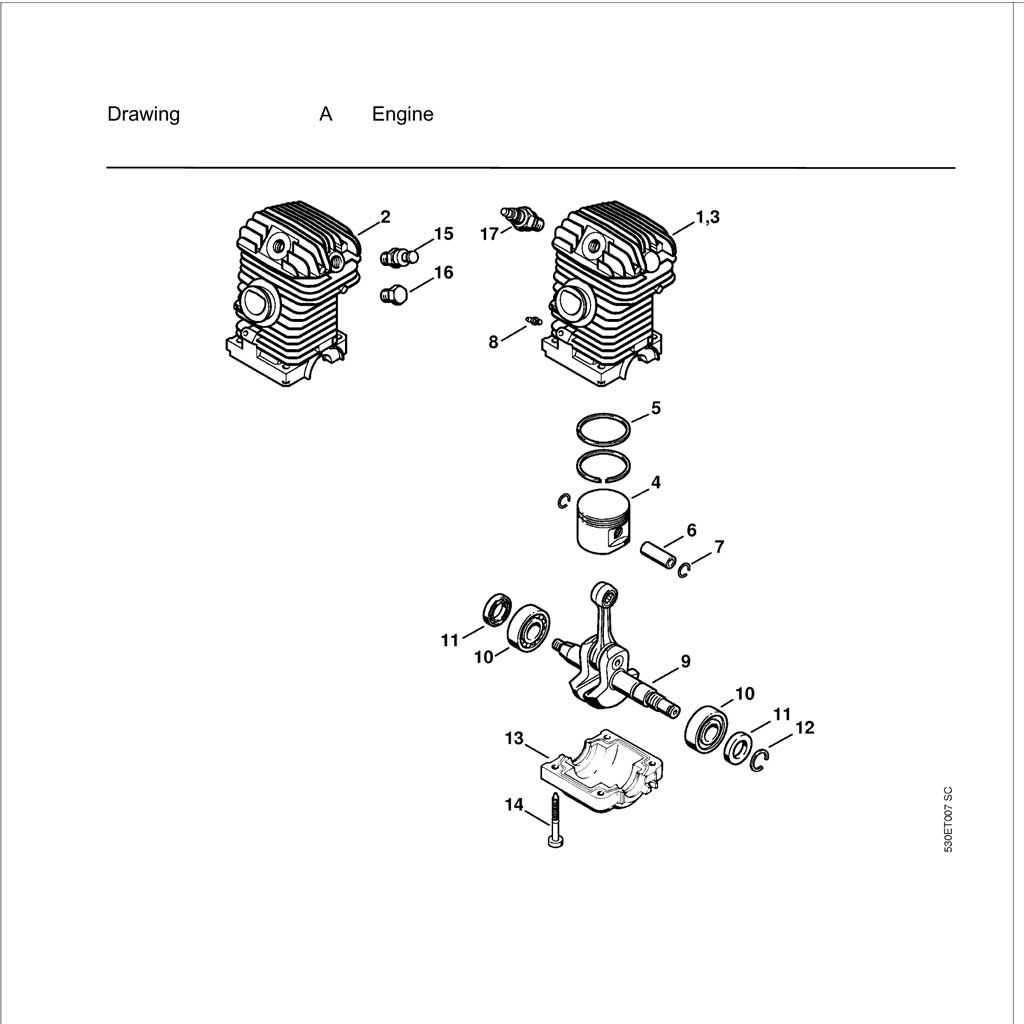

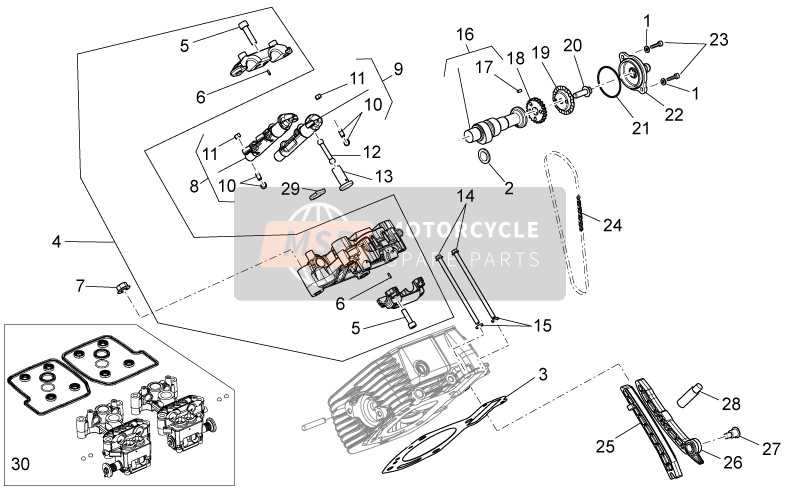

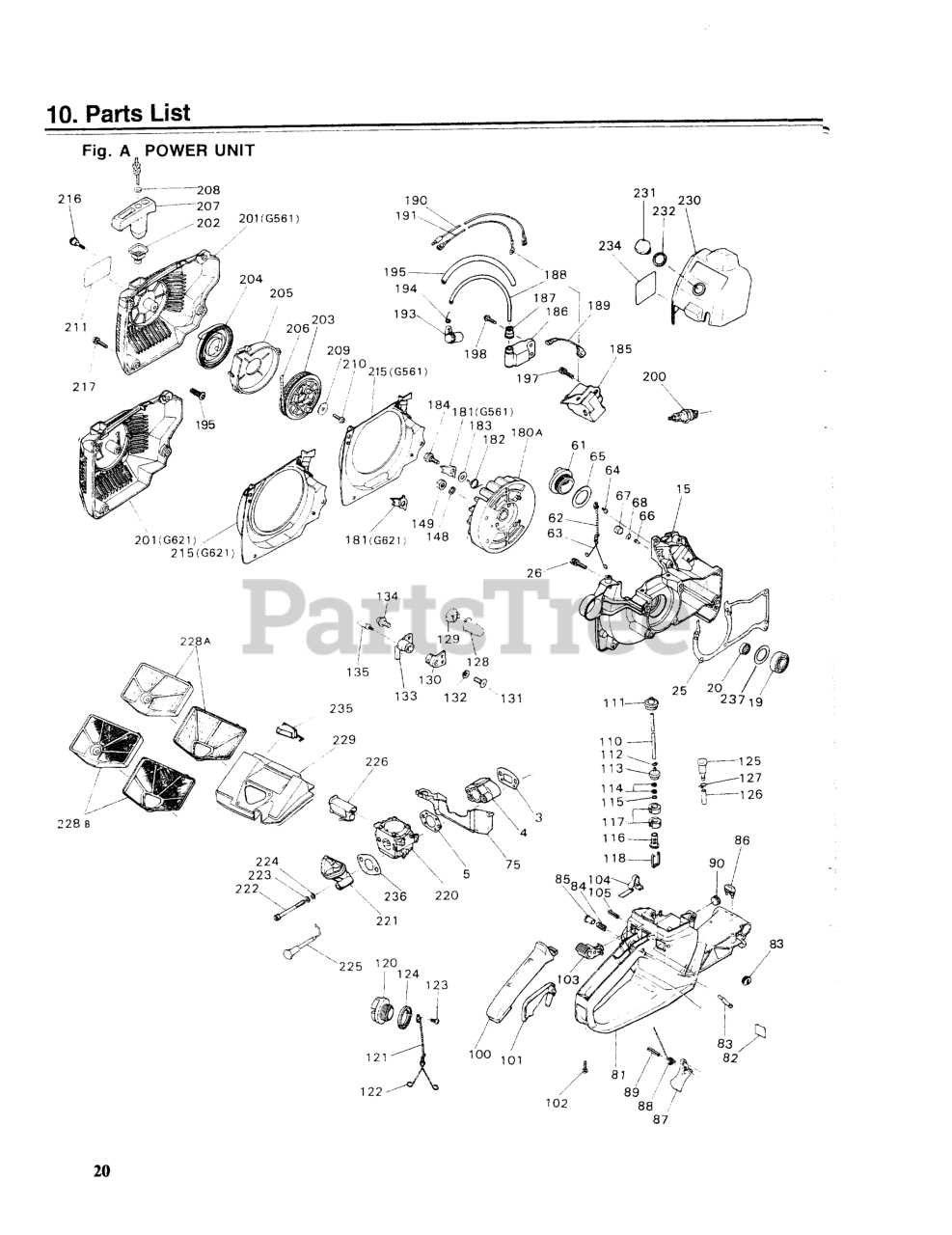

Essential Components of Stihl 020T

The intricate design of this compact cutting tool consists of several crucial elements that work together to ensure optimal performance and reliability. Understanding these components is vital for effective maintenance and troubleshooting.

Power Unit: At the heart of the machine, the power unit generates the necessary energy for operation. This engine is designed for efficiency and durability, providing consistent performance.

Bar and Chain: The cutting mechanism includes a bar and chain, which are fundamental for executing precise cuts. The chain’s sharp teeth interact with the material, allowing for smooth and efficient slicing.

Fuel System: This system manages the mixture of fuel and air, ensuring the engine runs smoothly. Regular checks and maintenance are essential to keep this system functioning optimally.

Ignition System: The ignition components initiate combustion within the engine, making it critical for starting and overall operation. Any issues here can significantly impact performance.

Safety Features: Integrated safety elements are designed to protect the user during operation. These include chain brakes and throttle controls, which enhance safety while cutting.

Each of these components plays a significant role in the functionality of the equipment, and familiarity with them can greatly aid in the effective use and upkeep of the tool.

Importance of Maintenance for Chainsaws

Regular upkeep is essential for ensuring the longevity and efficiency of cutting tools. Neglecting maintenance can lead to diminished performance, increased wear, and ultimately costly repairs. By prioritizing care, users can maximize productivity and enhance safety during operation.

Enhancing Performance

Routine maintenance not only keeps equipment running smoothly but also boosts its overall performance. Tasks such as sharpening blades, cleaning air filters, and checking fuel lines are critical in maintaining optimal functionality. Regular checks prevent minor issues from escalating into major problems.

Ensuring Safety

Safety is paramount when working with power tools. Proper maintenance helps minimize risks associated with malfunctioning equipment. Ensuring that all components are in good condition reduces the likelihood of accidents, providing peace of mind for the operator.

Common Issues with Stihl 020T Parts

Understanding the frequent challenges associated with certain machinery components can enhance maintenance efforts and prolong the equipment’s lifespan. Recognizing these common pitfalls allows users to address issues promptly and efficiently.

Wear and Tear

Over time, various elements can experience significant degradation due to regular use. This can lead to reduced performance and the need for replacements. Regular inspections can help identify these issues before they escalate.

Compatibility Problems

Using non-original components can result in misalignment and improper functioning. It’s crucial to ensure that all replacement items are designed specifically for the equipment to avoid complications.

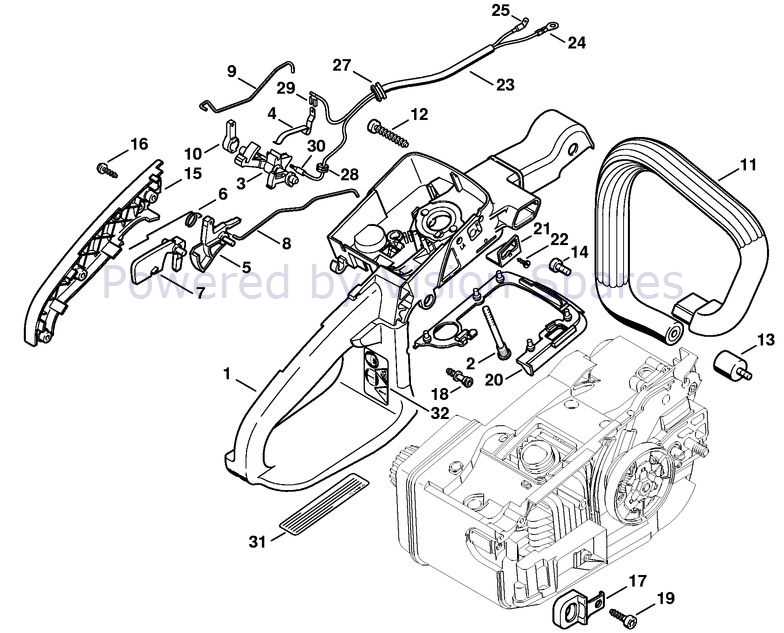

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of the various elements involved, helping users identify and locate specific pieces.

To effectively interpret these visual guides, follow these steps:

- Familiarize Yourself with Symbols: Each illustration often uses specific symbols or lines to denote various parts.

- Identify the Legend: Many illustrations include a legend that explains the symbols and numbering used.

- Break Down Sections: Focus on one segment at a time to avoid feeling overwhelmed.

- Cross-Reference with Manual: Use the accompanying manual to clarify any uncertainties regarding the components.

- Make Notes: Jot down important details or questions as you analyze the representation.

By mastering these techniques, you can confidently navigate visual guides and enhance your understanding of component arrangements and functions.

Replacing the Bar and Chain

Changing the cutting bar and chain is essential for maintaining optimal performance and safety of your equipment. Over time, these components wear down, affecting cutting efficiency and precision.

To ensure a smooth replacement process, follow these steps:

- Gather the necessary tools: wrench, screwdriver, and replacement parts.

- Ensure the engine is off and the equipment is unplugged.

- Loosen the tension on the chain using the adjustment screw.

- Remove the nuts holding the bar in place.

- Carefully slide the old bar and chain off.

- Position the new chain around the bar, ensuring proper orientation.

- Slide the new bar onto the guide and secure it with the nuts.

- Tighten the chain to the recommended tension.

Regularly checking and replacing these parts will enhance your tool’s longevity and performance, allowing you to tackle tasks with confidence.

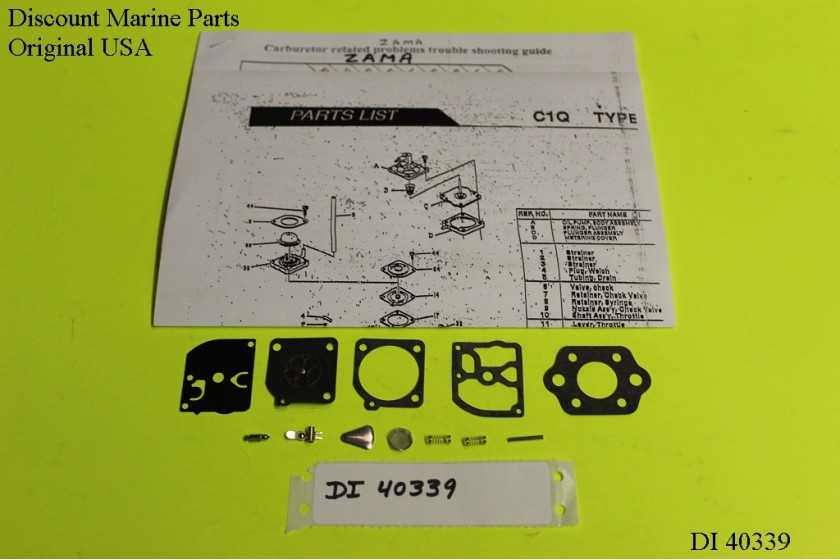

Fuel System Components Explained

The fuel system is vital for optimal engine performance, ensuring a proper mixture of air and fuel for combustion. Understanding its individual elements can enhance maintenance and troubleshooting efforts, ultimately leading to a more efficient machine operation.

Key Components

Various elements comprise the fuel system, each playing a significant role in delivering fuel to the engine. From the tank to the carburetor, these parts work in harmony to facilitate combustion.

| Component | Function |

|---|---|

| Fuel Tank | Holds the fuel until needed by the engine. |

| Fuel Lines | Transport fuel from the tank to the carburetor. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Carburetor | Mixes air and fuel in the correct ratio for combustion. |

Maintenance Tips

Regular inspection of these components can prevent performance issues. Clean or replace filters as necessary and ensure fuel lines are free from leaks to maintain the system’s efficiency.

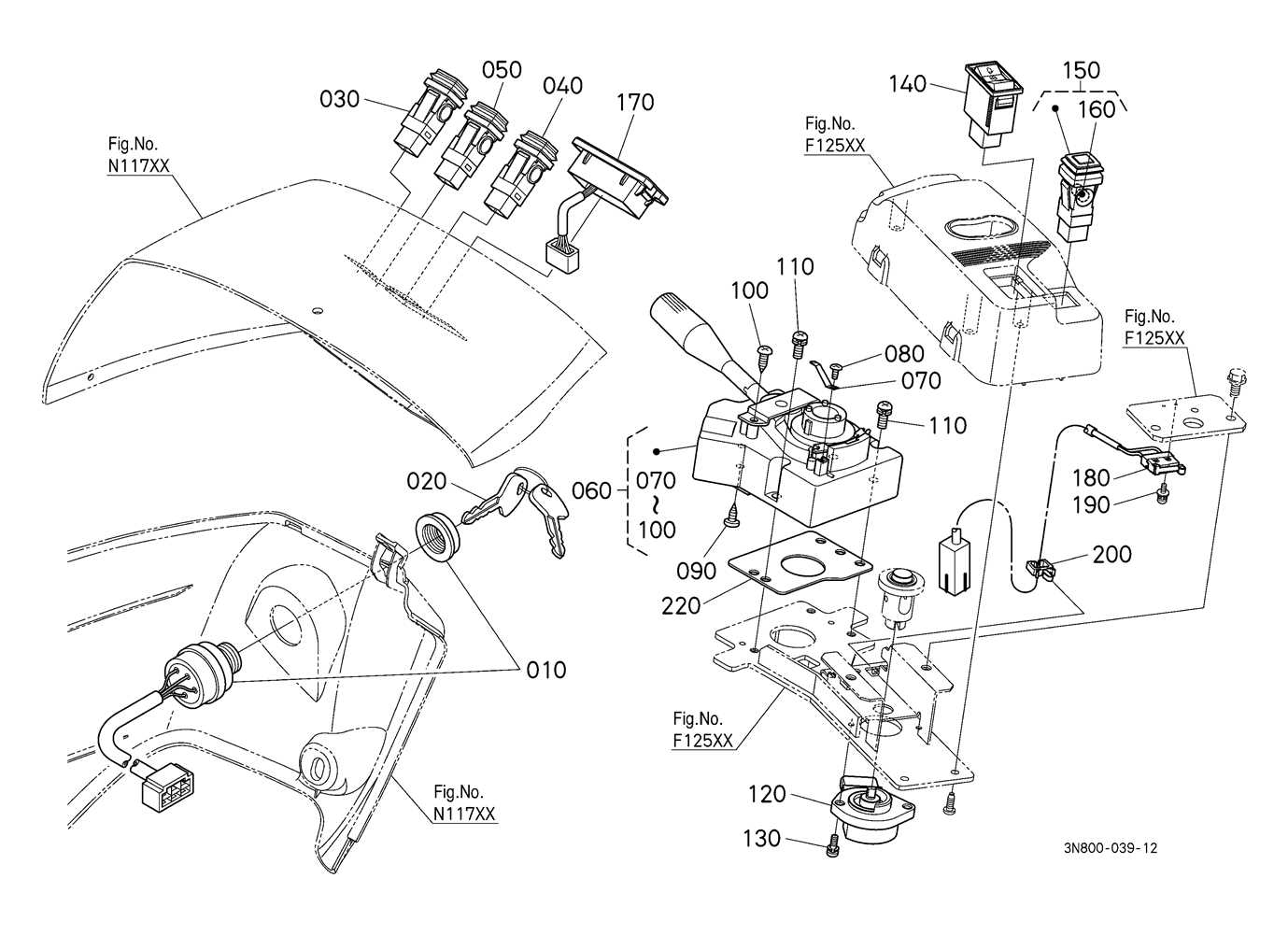

Electrical Parts and Their Functions

The functionality of various electrical components is crucial for optimal performance and safety in power tools. Understanding how these elements interact can enhance efficiency and longevity. Each component plays a specific role in the operation, contributing to the overall effectiveness of the machinery.

Key Components

| Component | Function |

|---|---|

| Ignition Module | Generates the spark necessary for combustion, initiating the engine cycle. |

| Coil | Transforms electrical energy into a high-voltage spark to ignite the fuel-air mixture. |

| Switch | Controls the flow of electricity, enabling or disabling the tool’s operation. |

Importance of Maintenance

Regular inspection and maintenance of electrical components are essential for preventing failures. Timely replacements and adjustments can lead to enhanced performance and safety, ensuring that the tool operates at its ultimate efficiency.

Ordering Genuine Stihl Parts Online

Acquiring authentic components for your equipment has never been easier with the convenience of online shopping. This method allows you to access a wide range of high-quality items that ensure optimal performance and longevity of your tools. It is essential to follow a few key steps to ensure you receive the correct items without hassle.

Steps to Order

Begin by identifying the specific components you need. Consult the user manual or an online resource to find the correct identifiers. Once you have this information, you can proceed to select a reputable online retailer that specializes in authentic equipment accessories.

Benefits of Genuine Components

Using authentic accessories enhances the efficiency and durability of your tools. They are designed to fit perfectly and operate seamlessly, minimizing the risk of malfunctions. Additionally, they often come with warranties that offer peace of mind regarding your investment.

| Step | Description |

|---|---|

| 1 | Identify the required components through manuals or online databases. |

| 2 | Choose a reputable online retailer that specializes in authentic items. |

| 3 | Add items to your cart and proceed to checkout. |

| 4 | Confirm your order and wait for delivery, ensuring tracking is available. |

Tools Needed for Repair Work

When undertaking maintenance tasks, having the right equipment is essential for efficiency and precision. This section outlines the necessary tools that will aid in the repair process, ensuring that each job is completed effectively.

Essential Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Torque wrench

Additional Equipment

- Safety goggles

- Gloves

- Workbench

- Lubricants and cleaning agents

- Measuring tools (calipers and rulers)

Equipping yourself with these tools will not only enhance your repair skills but also provide a smoother workflow and better outcomes.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring and maintaining your equipment, ensuring optimal performance. By following these detailed instructions, you can tackle common issues with confidence and enhance the longevity of your machine.

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and safety gear before starting the repair process. |

| 2 | Carefully disassemble the unit, taking note of each component’s placement. |

| 3 | Inspect parts for wear and damage, making a list of items that need replacement. |

| 4 | Clean all accessible areas to remove debris and old lubricant. |

| 5 | Install new components as needed, ensuring proper alignment and fitting. |

| 6 | Reassemble the unit methodically, following your notes from the disassembly. |

| 7 | Perform a functionality test to confirm everything operates smoothly. |

Benefits of Using Original Parts

Choosing authentic components for machinery ensures optimal performance and longevity. These genuine items are specifically engineered to meet the exact specifications of the equipment, promoting reliability and efficiency. When maintenance is required, selecting original elements significantly enhances the overall user experience and reduces the likelihood of complications.

| Benefit | Description |

|---|---|

| Quality Assurance | Original components are manufactured to high standards, ensuring durability and effectiveness. |

| Perfect Fit | Designed for specific models, authentic parts ensure seamless compatibility with the equipment. |

| Improved Performance | Using genuine items helps maintain the machine’s efficiency and operational capabilities. |

| Warranty Protection | Employing original components often preserves the warranty, safeguarding against potential future costs. |

| Increased Resale Value | Equipment maintained with authentic parts tends to retain higher market value over time. |