In the world of winter maintenance, having a clear grasp of your machinery’s components is essential for optimal performance. Whether you’re clearing pathways or managing snow accumulation, knowing the intricate details of each part can make a significant difference in efficiency.

Identifying each element of your equipment not only enhances its functionality but also aids in timely repairs and upgrades. By familiarizing yourself with the various mechanisms, you’ll be better equipped to handle any challenges that arise during the colder months.

As we delve into the specific assembly of your device, it’s crucial to recognize how each section contributes to the ultimate operation. This knowledge empowers you to maintain your equipment with confidence, ensuring that it remains a reliable ally in the battle against winter weather.

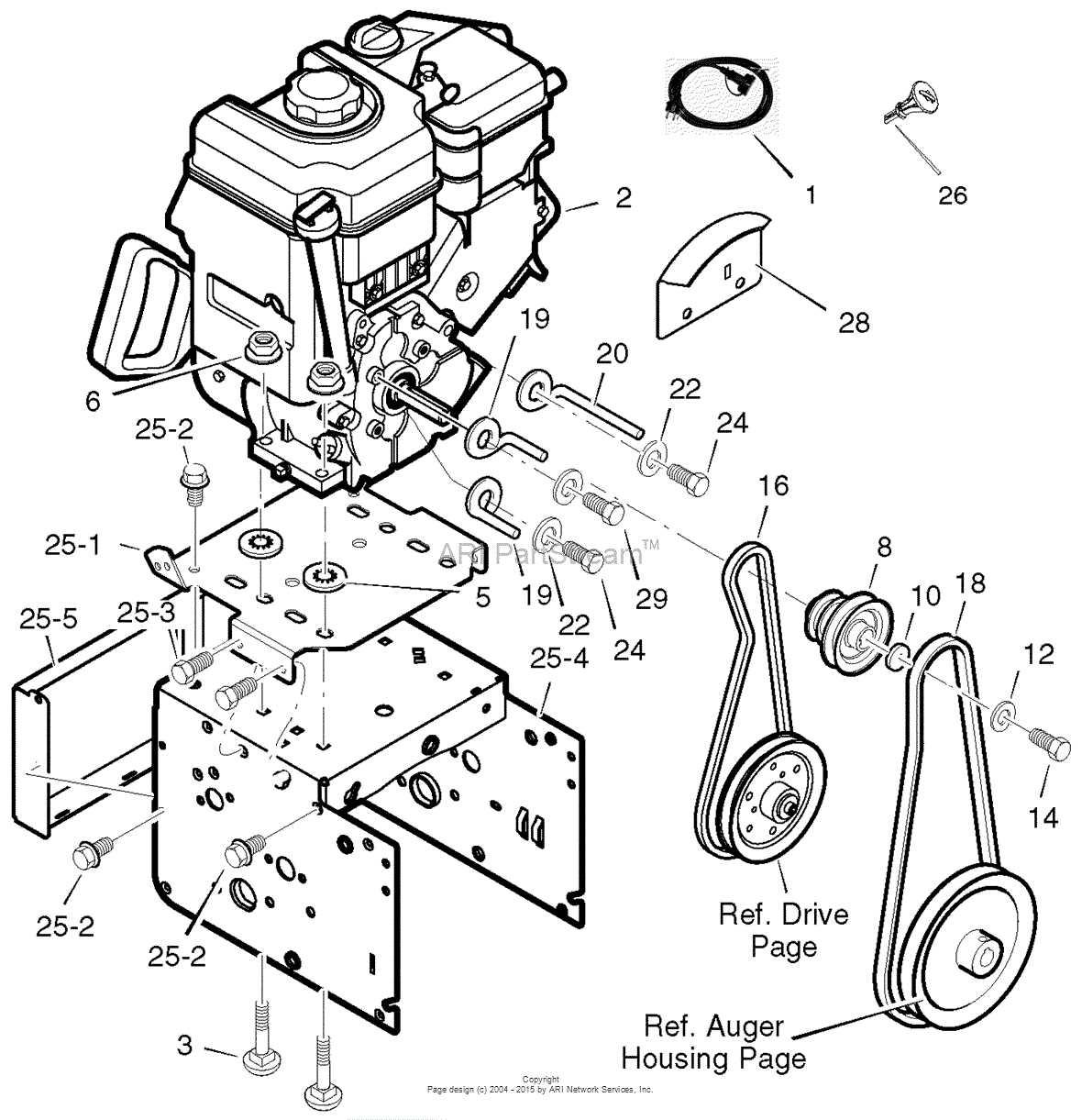

Understanding Craftsman Snowblower Parts

When dealing with winter equipment, comprehending the individual components is essential for effective maintenance and operation. Each element plays a vital role in ensuring optimal performance, making it crucial for users to familiarize themselves with the various parts and their functions. This knowledge not only enhances efficiency but also prolongs the lifespan of the machinery.

Key Components and Their Functions

Several primary elements contribute to the overall functionality of this equipment. The motor serves as the powerhouse, driving the entire system, while the chute directs the snow’s path, allowing for efficient clearing. Additionally, the auger is responsible for breaking up and collecting the snow, which is then expelled through the chute. Understanding these components helps in troubleshooting and ensuring smooth operation during harsh weather conditions.

Maintenance Tips for Longevity

Proper care of these individual elements can significantly extend the life of your winter gear. Regular inspections for wear and tear, lubrication of moving parts, and timely replacement of any damaged components are essential practices. By maintaining these aspects, users can avoid common pitfalls and ensure their equipment remains reliable throughout the season.

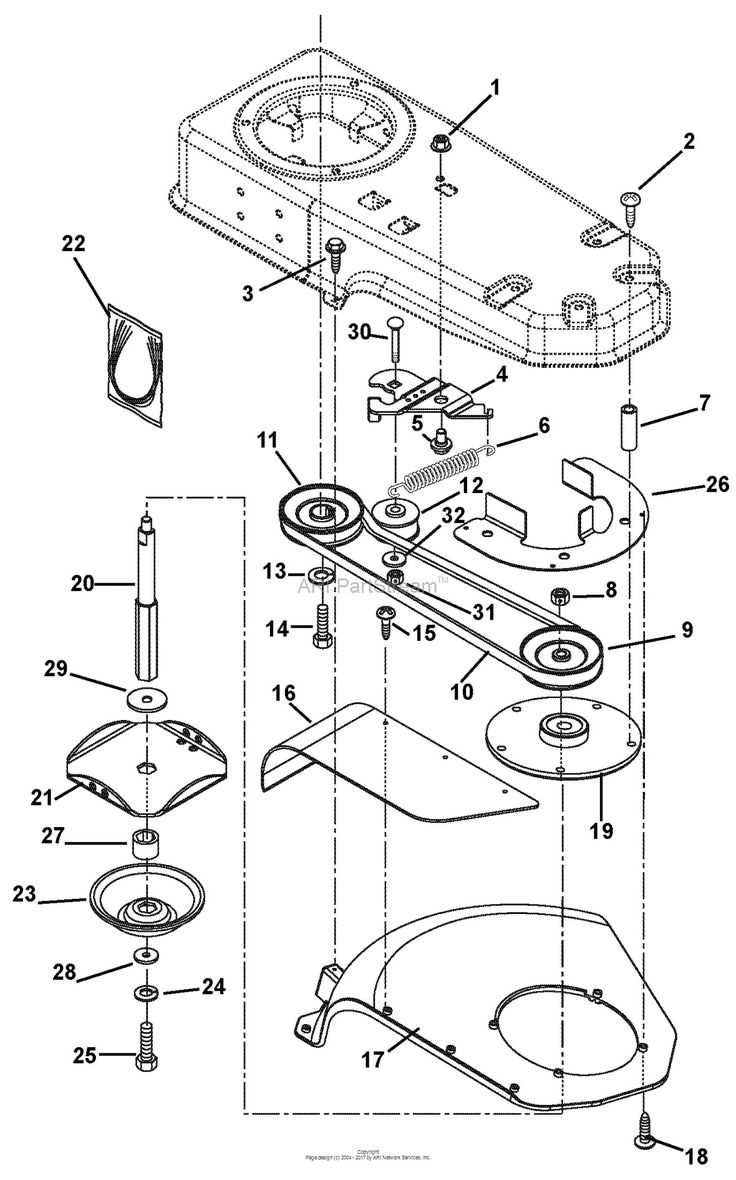

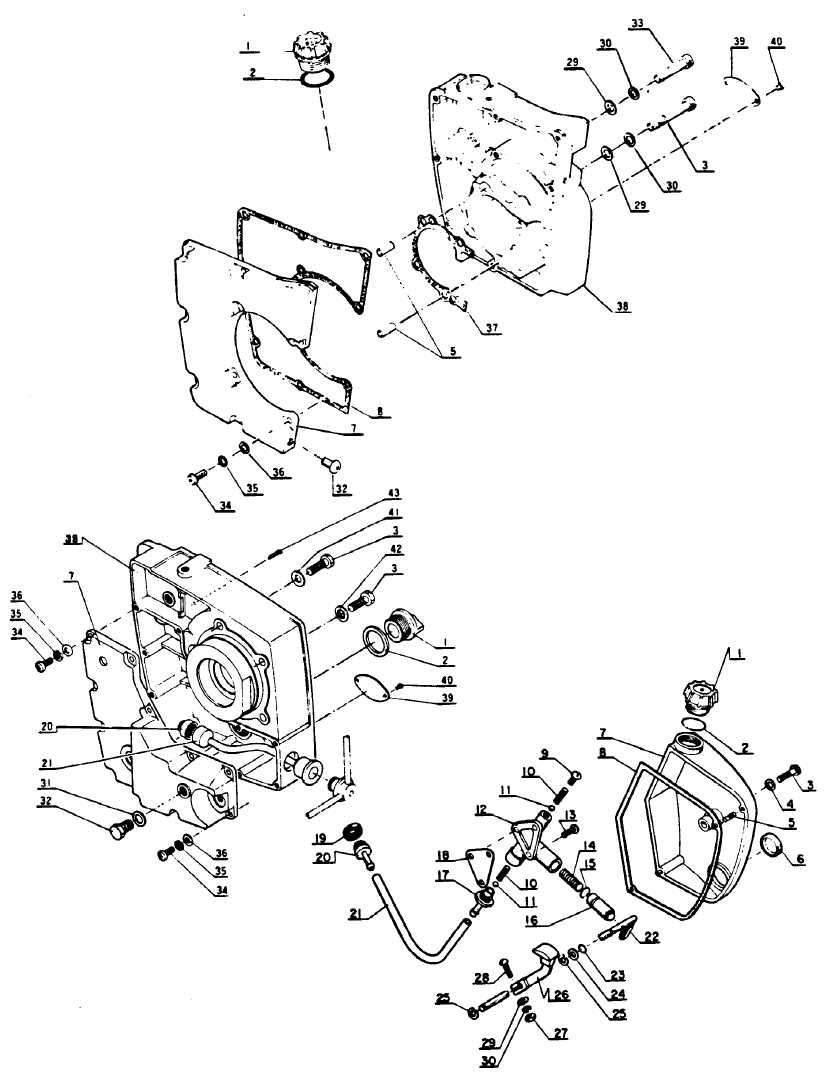

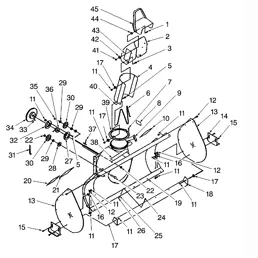

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and function of machinery. They provide users with a clear overview, facilitating easier maintenance and repairs. These illustrations serve as a roadmap for identifying individual elements and their connections.

Benefits of Visual Guides

- Enhance comprehension of complex systems.

- Streamline troubleshooting processes.

- Improve accuracy in assembly and disassembly.

- Assist in ordering the correct replacements.

Effective Communication Tools

- Bridge gaps between technical and non-technical users.

- Standardize terminology and references.

- Reduce the likelihood of errors during repairs.

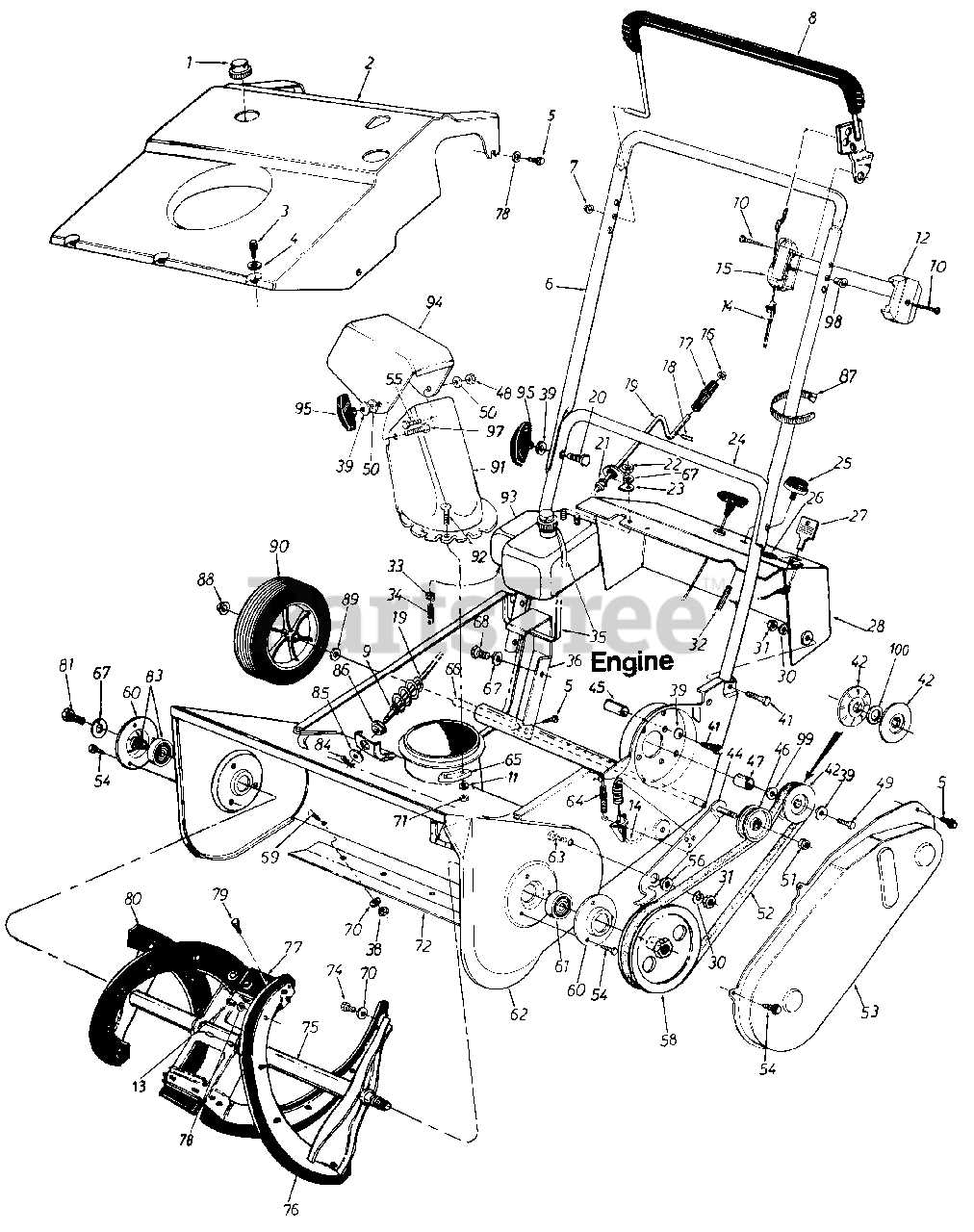

Common Components of Snowblowers

Understanding the essential elements of a winter clearing machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance during snowy conditions. Here, we outline the primary features that contribute to the functionality of these machines.

Key Elements

- Engine: The power source that drives the entire system, typically gasoline or electric.

- Auger: A rotating mechanism designed to gather snow and move it toward the discharge chute.

- Discharge Chute: Directs the expelled snow away from the path being cleared, often adjustable to control the direction and distance.

- Skid Shoes: Attachments that regulate the height of the machine from the ground, preventing damage to surfaces.

- Control Panel: The interface that allows the operator to adjust speed, direction, and other settings.

Additional Features

- Drive System: Transmits power to the wheels or tracks, providing mobility across various terrains.

- Headlight: Enhances visibility during early morning or late evening operations.

- Fuel Tank: Holds the necessary fuel to power the engine, varying in capacity depending on the model.

- Chassis: The frame that supports all components, contributing to the overall durability and stability.

How to Identify Part Numbers

Understanding how to pinpoint component identifiers is essential for efficient maintenance and repair. Knowing the exact codes can streamline the process of acquiring the right items and enhance overall performance.

Follow these steps to accurately determine the identifiers:

| Step | Description |

|---|---|

| 1 | Refer to the user manual, which often contains a comprehensive list of identifiers. |

| 2 | Inspect the machine itself for labels or engravings that display the numbers. |

| 3 | Visit official manufacturer websites for searchable databases of identifiers. |

| 4 | Consult online forums and communities where enthusiasts share insights and information. |

By following these guidelines, you can ensure that you are acquiring the ultimate components for your equipment needs.

Maintenance Tips for Snowblower Parts

Proper upkeep of your winter equipment is essential for optimal performance and longevity. Regular attention to individual components ensures that your machine operates efficiently when you need it most. Here are some valuable suggestions for maintaining these crucial elements during the snowy season.

| Component | Maintenance Tips |

|---|---|

| Engine | Check oil levels frequently and replace it according to the manufacturer’s recommendations. Clean or replace the air filter to enhance airflow. |

| Auger | Inspect for any debris or blockages. Lubricate moving parts to prevent rust and ensure smooth operation. |

| Drive Belts | Examine for wear and tear. Adjust tension as necessary and replace any frayed or damaged belts promptly. |

| Fuel System | Use fresh fuel and consider adding a stabilizer to prevent degradation. Clean fuel lines and replace filters to avoid clogs. |

| Chassis | Keep the exterior clean and free from snow buildup. Check bolts and fasteners to ensure everything is secure. |

Regularly attending to these areas not only prolongs the life of your machine but also enhances its reliability during harsh winter conditions. Establish a routine inspection schedule to keep your equipment in top shape.

Where to Find Replacement Parts

Finding the necessary components for your equipment can greatly enhance its performance and longevity. Whether you’re in need of specific elements or general accessories, several reliable sources can assist you in locating what you need.

Online Retailers

- Major e-commerce platforms often carry a wide range of items.

- Specialized websites focus on outdoor machinery, providing detailed listings.

- Manufacturer websites may offer direct sales or links to authorized sellers.

Local Suppliers

- Home improvement stores usually have a section dedicated to outdoor equipment.

- Small, local repair shops may stock common necessities or be able to order them.

- Farm and garden centers can also be excellent resources for durable goods.

Common Issues and Solutions

When operating outdoor equipment, various challenges may arise that hinder performance. Understanding these common problems and their solutions can enhance efficiency and longevity.

- Difficulty Starting:

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for damage or wear.

- Examine the battery connections for corrosion.

- Ineffective Clearing:

- Verify that the chute is not blocked by debris.

- Adjust the height settings to match snow conditions.

- Ensure that the auger is functioning properly.

- Excessive Vibrations:

- Check for loose bolts and tighten them as necessary.

- Inspect the blades for wear and replace if needed.

- Look for uneven tire pressure and adjust accordingly.

By addressing these common issues, users can ensure optimal operation and extend the lifespan of their equipment.

Tools Required for Repairs

When tackling maintenance tasks, having the right equipment is essential for efficient and effective repairs. Whether you are fixing a machine or conducting routine upkeep, specific instruments can make the process smoother and ensure that the job is done correctly.

Essential Tools

- Socket Set: A variety of sizes to handle different fasteners.

- Wrenches: Both adjustable and fixed to loosen or tighten bolts.

- Screwdrivers: A selection of Phillips and flathead for various screws.

- Pliers: Needle-nose and standard for gripping and bending.

- Torque Wrench: To apply precise torque to bolts.

Additional Equipment

- Multimeter: For electrical diagnostics and troubleshooting.

- Safety Goggles: To protect your eyes during repairs.

- Gloves: To ensure a good grip and protect your hands.

- Work Light: To illuminate dark areas for better visibility.

- Lubricants: To ensure smooth operation of moving parts.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing common issues with outdoor equipment. By following these detailed instructions, users can efficiently troubleshoot and resolve problems, ensuring their machinery operates smoothly. Each step is designed to be straightforward, facilitating a seamless repair experience.

Before beginning any repair, gather all necessary tools and components. Familiarize yourself with the equipment to enhance your understanding of its functionality. Here’s a step-by-step breakdown:

| Step | Description |

|---|---|

| 1 | Identify the issue by observing performance and listening for unusual sounds. |

| 2 | Consult the user manual to understand the assembly and parts layout. |

| 3 | Gather the required tools such as wrenches, screwdrivers, and replacement components. |

| 4 | Disconnect the power source for safety before starting the repair. |

| 5 | Carefully remove the faulty component using the appropriate tools. |

| 6 | Install the new or repaired part, ensuring all connections are secure. |

| 7 | Reconnect the power source and test the equipment to confirm the issue is resolved. |

| 8 | Document the repair process for future reference and maintenance. |

By adhering to these steps, users can effectively manage repairs and extend the lifespan of their equipment. Regular maintenance checks are recommended to prevent future issues and maintain optimal performance.

Safety Precautions While Repairing

Ensuring personal safety during maintenance activities is crucial. By taking the right measures, one can prevent accidents and injuries, fostering a secure working environment. Understanding and adhering to safety guidelines will ultimately enhance the efficiency of the repair process.

Before beginning any work, always disconnect power sources to eliminate the risk of accidental activation. Wearing appropriate protective gear, such as gloves and safety goggles, can significantly reduce the chances of injury from sharp objects or debris.

Maintain a clean workspace to minimize hazards. Ensure that tools are in good condition and properly stored to avoid tripping or slipping. Familiarize yourself with the equipment’s manual to understand specific safety recommendations and operational protocols.

Lastly, never hesitate to seek assistance if unsure about any repair tasks. Collaboration can not only provide additional safety but also enhance the overall quality of the work performed.

Upgrading Your Snowblower Components

Enhancing the performance of your winter machine can significantly improve its efficiency and reliability. Whether it’s boosting power, enhancing maneuverability, or extending the lifespan, upgrading specific elements can make a noticeable difference. This section explores various enhancements that can be made to optimize your equipment for harsh conditions.

Power Upgrades: Increasing engine output or improving fuel efficiency can provide a substantial advantage. Consider installing a high-performance carburetor or tuning the existing one for better fuel flow. This not only elevates power but can also reduce emissions, making your device more environmentally friendly.

Durability Enhancements: Replacing wear-prone components with high-quality alternatives can prevent frequent breakdowns. Upgrading to reinforced augers and impellers ensures they withstand tough conditions, while durable belts and chains can help avoid costly repairs.

Ergonomic Improvements: Comfort during operation is crucial, especially in prolonged use. Upgrading handles with better grips or adjustable heights can enhance user experience. Adding features like heated grips or enhanced control levers makes operating in frigid temperatures much more pleasant.

Storage and Maintenance: Incorporating better maintenance tools can prolong the life of your machinery. Upgrading to a more efficient oil filter or implementing a maintenance tracking system ensures that you keep up with essential servicing. Additionally, improving storage options with protective covers can help shield the equipment from harsh weather when not in use.

By focusing on these upgrades, you can maximize the potential of your winter equipment, ensuring it meets your needs effectively and reliably throughout the snowy season.