Maintaining and optimizing your gardening tools is essential for achieving the best performance in your outdoor projects. Whether you are a professional landscaper or a weekend warrior, knowing the layout and components of your equipment can significantly enhance your efficiency. This section delves into the various elements that make up these machines, providing insights into their functions and importance.

When it comes to ensuring longevity and reliability, a thorough grasp of your tool’s structure can be invaluable. Each part plays a crucial role, and being aware of how they interconnect allows for better maintenance and timely replacements. Understanding these intricacies not only fosters a deeper appreciation for your equipment but also empowers you to tackle repairs and upgrades with confidence.

This exploration serves as a guide for enthusiasts looking to familiarize themselves with the assembly of their trimming apparatus. By dissecting the components and their interactions, users can develop a clearer picture of how to maximize performance and mitigate issues that may arise during operation. Embrace the journey of discovery as you learn to navigate the world of your trimming device.

Understanding Echo CS-330T Components

Exploring the intricacies of outdoor power tools requires a deep dive into their individual elements. Each component plays a crucial role in ensuring optimal performance and longevity. Gaining insight into these elements enhances maintenance and troubleshooting capabilities.

The following are key components found in these devices:

- Engine: The heart of the machine, responsible for power generation.

- Guide Bar: A critical part for directing cutting operations.

- Chain: Essential for cutting through various materials effectively.

- Air Filter: Prevents dirt and debris from entering the engine, ensuring efficient operation.

- Fuel Tank: Stores the mixture needed for engine combustion.

- Chain Brake: A safety feature that halts the chain’s movement in emergencies.

Understanding these components not only aids in the effective use of the equipment but also facilitates timely repairs and replacements when necessary.

Regular maintenance checks should focus on:

- Inspecting the engine for wear and tear.

- Cleaning or replacing the air filter as needed.

- Examining the guide bar and chain for damage.

- Checking fuel levels and ensuring proper mixture ratios.

- Testing the chain brake for reliability.

By familiarizing oneself with these aspects, users can enhance their understanding and ensure their tool remains in top condition for various tasks.

Parts Breakdown for Echo Chainsaw

Understanding the components of a chainsaw is crucial for effective maintenance and repair. Each element plays a significant role in the overall functionality, and knowing how they interact can enhance performance and longevity. This section will explore the various sections of a popular model, providing insight into their functions and importance.

Essential Components

Among the fundamental elements are the power unit, cutting mechanism, and safety features. The engine serves as the powerhouse, generating the necessary energy for operation. The bar and chain are vital for executing cuts, while safety guards protect the user during operation. Understanding these essentials ensures users can troubleshoot effectively when issues arise.

Maintenance Insights

Regular upkeep is essential for optimal performance. Key areas to focus on include the filter system, which prevents debris from entering the engine, and the lubrication system, which ensures smooth movement of the chain. Regular checks and replacements can prevent costly repairs and extend the lifespan of the equipment.

Key Features of CS-330T Model

The CS-330T model stands out in its category due to a combination of advanced technology and user-centric design. This equipment is engineered to deliver optimal performance while ensuring ease of use for operators, making it suitable for a variety of tasks. Below are some of the prominent characteristics that define this remarkable device.

Power and Performance

- Equipped with a robust engine that ensures efficient operation.

- Designed for high torque output, facilitating effective cutting through tough materials.

- Lightweight construction that enhances maneuverability without compromising power.

User-Friendly Design

- Ergonomically designed handle for comfortable grip during extended use.

- Simple starting mechanism to reduce downtime and enhance productivity.

- Integrated safety features that promote secure handling and operation.

Maintenance Tips for Echo Parts

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular maintenance not only extends the life of the machine but also enhances safety and efficiency during operation. By following a few simple guidelines, you can keep your tools in excellent condition and avoid costly repairs.

Regular Inspection

Frequent checks are crucial. Inspect components for wear and tear, looking for signs of damage or fatigue. Pay attention to critical areas such as connections, filters, and belts. Early detection of issues can save time and resources in the long run.

Cleaning and Lubrication

Maintaining cleanliness is vital. Remove debris and buildup regularly, especially from air intakes and exhausts. Additionally, applying the right lubricant to moving parts reduces friction and prevents premature wear. Ensure that you use recommended products for best results.

Common Issues with CS-330T Components

When operating outdoor power equipment, various components can encounter problems that may affect overall performance. Understanding these common issues can help users troubleshoot effectively and maintain their machinery in optimal condition.

- Fuel System Problems:

- Clogs in the fuel lines, leading to insufficient fuel flow.

- Contaminated fuel causing engine stalling or poor performance.

- Ignition Issues:

- Defective spark plugs resulting in difficulty starting.

- Faulty ignition coils causing inconsistent firing.

- Chain and Bar Troubles:

- Worn chains that can lead to inefficient cutting.

- Improper tension causing the chain to slip or break.

- Air Filter Blockages:

- Dirty filters reducing air intake and affecting engine power.

- Overheating due to restricted airflow.

By being aware of these issues, users can take proactive steps to ensure their equipment runs smoothly and efficiently.

Where to Find Replacement Parts

Locating components for your equipment can sometimes be a challenging task. Understanding where to source these items is essential for maintaining the functionality and longevity of your tools. Fortunately, there are several reliable options available that cater to your needs.

Authorized Dealers

One of the most dependable sources for obtaining components is through authorized dealers. These retailers are certified to sell genuine items, ensuring compatibility and quality. Visiting their websites or local stores can provide you with a wide range of options, along with expert advice on installation and maintenance.

Online Marketplaces

Another convenient way to find necessary components is through online marketplaces. Websites specializing in equipment supplies often have extensive catalogs, allowing you to compare prices and availability. Always check seller ratings and reviews to ensure you’re purchasing from a reputable source.

Tools Needed for Repairing Echo Chainsaw

Proper maintenance and repair of a power saw require specific tools that ensure effective and efficient work. Having the right equipment on hand not only speeds up the repair process but also enhances the overall quality of the work performed. Understanding which instruments are necessary can make all the difference in achieving optimal performance from the machine.

Basic tools such as screwdrivers and wrenches are essential for disassembling various components. A set of both flathead and Phillips screwdrivers will cover most fasteners. Additionally, adjustable wrenches or socket sets will help tackle nuts and bolts of different sizes, making it easier to access internal parts.

For detailed repairs, specialty tools like a chain pitch gauge or file are important for maintaining the cutting mechanism. A torque wrench can also be crucial for ensuring that components are secured to the manufacturer’s specifications, preventing future issues caused by loose parts.

Lastly, having safety gear such as gloves and goggles is vital to protect against debris and sharp edges during the repair process. With these tools in your toolkit, tackling repairs will be more manageable and safer, leading to a more reliable and efficient machine.

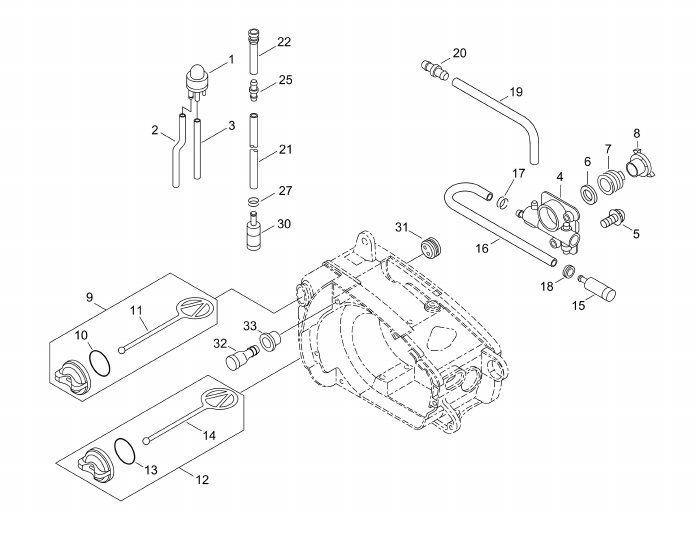

How to Read Parts Diagrams

Understanding illustrations that depict components of machinery can significantly enhance your ability to maintain and repair equipment. These visual aids offer a detailed representation of each element, showcasing how they interact and fit together. Familiarity with these images is essential for effective troubleshooting and ensuring optimal performance.

Familiarize Yourself with the Layout

Start by examining the overall structure of the illustration. Typically, you’ll find a legend or key that identifies each component. This guide is crucial for correlating symbols or numbers with specific parts. Take note of any sections that group related items, as this can provide context for their function within the assembly.

Identify Key Features and Annotations

Look for additional notes, such as arrows indicating movement or lines that connect different parts. These annotations can offer insight into the operational mechanics and potential assembly order. Pay attention to any highlighted sections that may suggest areas requiring special attention during maintenance or repair. Understanding these features will enable you to navigate the illustration with confidence and accuracy.

Benefits of Genuine Echo Parts

Choosing authentic components for outdoor equipment can significantly enhance performance and longevity. High-quality replacements are specifically designed to meet the exact standards of the machinery, ensuring optimal functionality and reliability.

Durability is a primary advantage of using original items. They are manufactured from superior materials, which allows them to withstand wear and tear, thereby reducing the frequency of repairs and replacements.

Another key benefit is compatibility. Genuine components fit seamlessly with your machine, ensuring that all parts work together efficiently. This reduces the risk of malfunction and improves overall efficiency.

Moreover, employing authentic items can lead to better performance. These components are engineered to enhance the capabilities of your equipment, resulting in improved operation and productivity.

Lastly, investing in original parts often comes with warranty protection. This means that you can have peace of mind knowing that your purchase is backed by the manufacturer, which can save you money in the long run.

Comparing Aftermarket and OEM Components

When maintaining or upgrading machinery, the choice between original manufacturer products and alternatives can significantly impact performance and longevity. Understanding the distinctions between these two categories is essential for informed decision-making, ensuring that users receive the best value and reliability.

Quality and Performance

One of the primary factors to consider is the quality and performance of the components:

- OEM Products: Typically designed to meet strict specifications, these items often guarantee compatibility and optimal performance.

- Aftermarket Alternatives: While many alternatives are of high quality, the variance in standards can lead to inconsistencies in performance and fit.

Cost and Availability

Pricing structures and accessibility also play a crucial role in the decision-making process:

- OEM Products: Generally priced higher due to brand reputation and assurance of quality.

- Aftermarket Alternatives: Often more affordable and available through a wider range of suppliers, these options can appeal to budget-conscious users.

Ultimately, the choice between these two types hinges on individual needs and priorities, balancing factors such as budget, performance expectations, and long-term maintenance considerations.

Step-by-Step Repair Process

When it comes to maintaining outdoor power tools, a methodical approach to repairs can significantly enhance performance and longevity. This section outlines a comprehensive procedure to troubleshoot and fix common issues effectively.

- Preparation:

- Gather necessary tools and replacement components.

- Ensure you have a clean and well-lit workspace.

- Review the user manual for specific guidance related to your equipment.

- Disassembly:

- Carefully remove any covers or guards.

- Take note of the order and orientation of parts as you detach them.

- Use a container to keep screws and small components organized.

- Inspection:

- Examine all components for wear, damage, or blockage.

- Check for signs of rust or corrosion.

- Assess seals and gaskets for integrity.

- Replacement:

- Swap out any defective parts with new ones.

- Ensure that replacements are compatible with your specific model.

- Follow manufacturer specifications for installation procedures.

- Reassembly:

- Carefully put all components back in reverse order of disassembly.

- Double-check that all screws and fittings are secure.

- Reattach any covers or guards ensuring they fit snugly.

- Testing:

- Start the machine and observe its operation.

- Listen for unusual sounds or vibrations that could indicate further issues.

- Perform a test run to ensure everything functions correctly.

Following this systematic approach not only facilitates effective repairs but also helps in developing a deeper understanding of the equipment, ultimately leading to improved maintenance practices.

Safety Precautions During Repairs

When undertaking maintenance or restoration tasks, ensuring personal safety and minimizing risks should be the top priority. Proper precautions can prevent accidents and injuries, creating a secure environment for both the individual and the equipment involved.

Wear Appropriate Personal Protective Equipment (PPE): Before starting any repair work, equip yourself with the necessary safety gear. This includes gloves to protect your hands, safety goggles to shield your eyes from debris, and sturdy footwear to prevent injuries from falling objects.

Work in a Well-Lit Area: Ensure that your workspace is adequately illuminated. Good lighting reduces the likelihood of errors and allows for better visibility of small components, making the repair process smoother and safer.

Disconnect Power Sources: Always ensure that the device is disconnected from any power supply before beginning repairs. This reduces the risk of electric shock and accidental activation, safeguarding both the technician and the equipment.

Keep the Work Area Organized: A tidy workspace helps prevent accidents. Keep tools and components neatly arranged, and remove any unnecessary items from the area to minimize distractions and tripping hazards.

Follow Manufacturer Guidelines: Adhering to the manufacturer’s instructions during the repair process is crucial. These guidelines provide important safety information and proper procedures that help avoid potential hazards.

Be Aware of Surroundings: Stay alert to your environment while working. Be mindful of other individuals nearby and ensure that no one unintentionally interferes with the repair process, which could lead to accidents.

By implementing these safety measures, you can create a secure atmosphere that allows for effective and safe repair work. Prioritizing safety not only protects you but also ensures the longevity and proper functioning of the equipment being serviced.

FAQs About Echo CS-330T Parts

This section addresses common inquiries regarding components and accessories related to a specific outdoor power tool model. Understanding these details can enhance user experience and ensure proper maintenance of the equipment.

Common Questions

- What are the essential components of this model?

- How can I identify which part needs replacement?

- Where can I find high-quality replacements?

- Are there specific maintenance tips for these components?

- What is the warranty policy for these items?

Maintenance and Care

- Regularly inspect all parts for wear and tear.

- Clean components after each use to prevent buildup.

- Follow the manufacturer’s guidelines for lubrication.

- Store the equipment in a dry place to avoid rust.