In any mechanical system, the effective operation relies heavily on the intricate interplay of its individual elements. A comprehensive visual representation of these components provides invaluable insights into their functionality and interconnections. Such illustrations serve as essential tools for maintenance and troubleshooting, enabling users to navigate through complex machinery with ease.

Exploring these visual aids allows one to grasp the overall architecture of a system. By examining how each segment contributes to the performance and efficiency of the whole, users can make informed decisions regarding repairs and upgrades. This not only enhances the longevity of the equipment but also ensures optimal functioning throughout its lifecycle.

Moreover, having access to detailed schematics empowers technicians and operators to diagnose issues swiftly. With a clear understanding of where each component fits into the broader framework, they can pinpoint malfunctions and implement corrective actions more effectively. Ultimately, such resources are indispensable for anyone looking to deepen their knowledge and maintain their equipment in peak condition.

Understanding the layout and components of machinery is crucial for efficient maintenance and repair processes. Visual representations serve as essential tools for identifying individual elements, streamlining troubleshooting efforts, and ensuring proper assembly during reinstallation. These illustrations provide a comprehensive overview, making it easier for technicians to grasp the intricate relationships between various components.

By utilizing visual aids, users can enhance their knowledge of equipment, which ultimately leads to improved performance and longevity. Moreover, clear representations help in ordering the correct components, minimizing downtime and enhancing operational efficiency.

| Key Benefits | Description |

|---|---|

| Enhanced Understanding | Visual representations facilitate a deeper comprehension of how components interact within machinery. |

| Streamlined Troubleshooting | Quick identification of faulty elements allows for faster repair and maintenance activities. |

| Accurate Ordering | Clear illustrations help ensure the right components are ordered, reducing the risk of errors. |

| Improved Efficiency | Better understanding and accurate ordering minimize downtime, enhancing overall productivity. |

Types of Equipment by Atlas Copco

The company offers a diverse range of machinery designed to meet various industrial needs. These tools are engineered for efficiency and reliability, ensuring that businesses can achieve their operational goals with ease. From pneumatic solutions to electrical systems, the equipment caters to multiple sectors, providing tailored solutions for different applications.

Compressed Air Solutions

One of the primary categories includes systems that generate and manage compressed air. These solutions are essential for numerous industries, enabling effective operation of tools and processes. Whether it’s for powering pneumatic tools or supporting manufacturing lines, these units play a vital role in maintaining productivity.

Vacuum Technology

Another significant segment focuses on vacuum systems, which are crucial for applications requiring controlled environments. These units help in material handling, packaging, and various manufacturing processes. The technology is designed to ensure precision and efficiency, contributing to overall operational excellence.

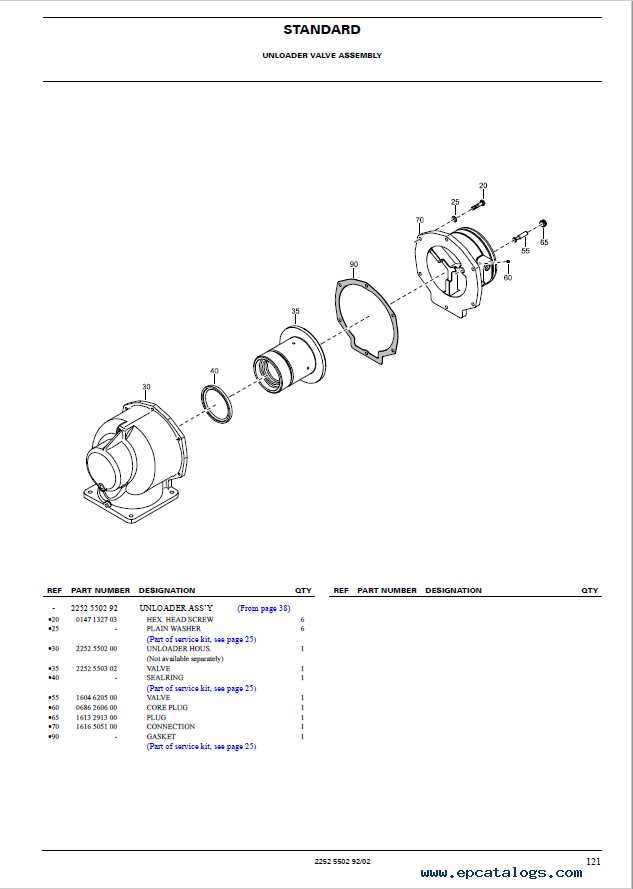

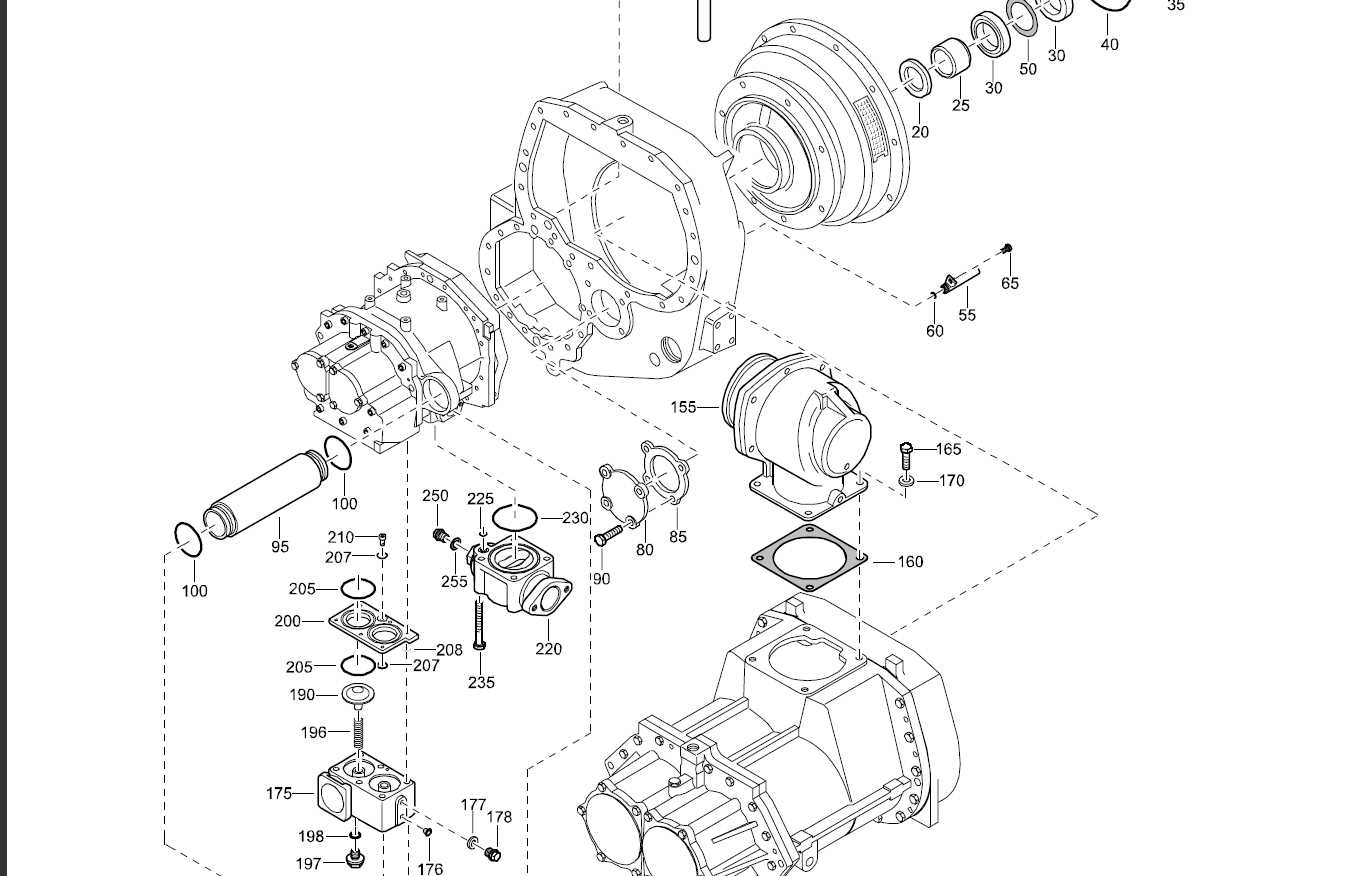

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in maintenance or assembly. These visual representations provide crucial information about individual components and their interrelationships within a system. Grasping how to interpret these visuals can significantly enhance efficiency during repairs or installations.

Begin by familiarizing yourself with the overall layout. Each illustration typically contains a key or legend that explains the symbols used to denote various elements. Identifying these symbols will allow you to quickly discern what each part represents.

Next, pay attention to the numbering system often included alongside the images. Each component is usually assigned a unique identifier, correlating with a list or inventory. This cross-reference will enable you to find the specific items you need for your tasks.

It’s also beneficial to observe how components are arranged. The spatial organization can offer insights into how parts fit together, revealing the assembly sequence or highlighting potential areas of conflict during installation.

Finally, practice is key. Regularly consulting these illustrations will enhance your ability to quickly interpret them, leading to improved performance in your work. Familiarity with technical visuals is an invaluable skill that can streamline processes and reduce the likelihood of errors.

Commonly Used Parts and Their Functions

In the realm of machinery, various components play crucial roles in ensuring optimal performance and efficiency. Understanding these elements helps users maintain equipment effectively, enhancing longevity and reliability. Below is a detailed overview of frequently utilized components and their specific functions.

| Component | Function |

|---|---|

| Compressor | Increases pressure of air or gas to power tools and machinery. |

| Filter | Removes contaminants from air or fluid, protecting internal parts from damage. |

| Regulator | Controls the pressure output, ensuring it remains within specified limits. |

| Receiver Tank | Stores compressed air, providing a steady supply and accommodating fluctuations in demand. |

| Valve | Manages the flow of air or fluid, directing it as needed throughout the system. |

Maintenance Tips for Atlas Copco Equipment

Regular upkeep of your machinery is essential to ensure optimal performance and longevity. Implementing systematic care practices can prevent breakdowns, enhance efficiency, and extend the life of your equipment. By adhering to a structured maintenance routine, operators can minimize operational costs and ensure consistent output.

Here are some valuable suggestions for maintaining your machinery:

| Tip | Description |

|---|---|

| Routine Inspections | Conduct regular checks to identify wear and tear early. Look for any unusual noises or vibrations that may indicate underlying issues. |

| Lubrication | Ensure all moving parts are properly lubricated. Use recommended lubricants to prevent friction and overheating. |

| Filter Replacement | Regularly replace air and oil filters to maintain clean airflow and optimal performance. Clogged filters can lead to inefficiencies. |

| Coolant Levels | Monitor and maintain appropriate coolant levels to prevent overheating. Regularly check for leaks in the cooling system. |

| Calibration | Periodically calibrate your machinery to ensure it operates within specified parameters. This will improve accuracy and reduce waste. |

Identifying Replacement Parts

Understanding how to recognize the necessary components for equipment maintenance is essential for ensuring optimal functionality. When machinery requires servicing, knowing which elements to replace can enhance performance and prolong lifespan. Proper identification not only minimizes downtime but also prevents unnecessary expenditures on incorrect items.

Key Considerations for Recognition

When determining which components need replacement, it’s vital to assess the equipment’s model and specifications. Each unit may have unique characteristics that dictate specific requirements. Visual inspection is often the first step; look for signs of wear, damage, or malfunction. This can include rust, cracks, or unusual noises during operation.

Utilizing Resources Effectively

Consulting available resources can significantly aid in identifying the right components. Manuals and online guides provide detailed information on compatible items. Additionally, reaching out to experts or technicians can offer insights that streamline the selection process. Remember, accurate identification is key to maintaining efficiency and reliability.

Where to Find Parts Diagrams

Accessing detailed illustrations and schematics for machinery components is essential for effective maintenance and repair. Various resources are available to assist users in locating these visual references, providing essential guidance for efficient servicing and part replacement.

Official manufacturer websites often serve as the primary source for comprehensive visuals, typically available in the support or resource sections. Users can explore online platforms dedicated to industrial equipment, where many documents are categorized by model and function.

Additionally, industry forums and community groups can be valuable for sharing insights and user-generated content. Members frequently exchange useful links, manuals, and recommendations that enhance understanding of specific equipment configurations.

Lastly, authorized service centers provide access to proprietary materials, ensuring that users receive accurate and up-to-date information necessary for effective troubleshooting and repairs.

Advantages of Using Official Diagrams

Utilizing authorized schematics offers numerous benefits for users seeking to enhance their understanding and maintenance of complex machinery. These visuals provide clear and precise representations of components, facilitating efficient troubleshooting and assembly processes. By relying on authentic illustrations, users can ensure accuracy and compatibility, ultimately leading to improved operational effectiveness.

Enhanced Clarity and Understanding

Official visuals present information in a structured manner, allowing individuals to easily identify various elements and their relationships within the system. This clarity aids technicians and operators in grasping intricate details that may be overlooked with less reliable sources.

Increased Reliability and Compatibility

When working with authentic representations, users can trust that the information is accurate and tailored for their specific equipment. This reliability reduces the risk of errors during repairs or installations, ensuring that all components work harmoniously together. Moreover, employing certified schematics often leads to better overall performance and longevity of the machinery.

Common Issues and Solutions

In any complex machinery, various challenges may arise during operation, leading to performance inefficiencies or breakdowns. Identifying and addressing these problems promptly is crucial for maintaining optimal functionality and extending the lifespan of the equipment. Below are some frequent concerns encountered by users and their effective resolutions.

One prevalent issue involves unusual noises during operation, which can indicate loose components or wear. To resolve this, users should perform a thorough inspection of all connections and replace any worn parts to restore quiet functionality.

Another common concern is insufficient power output. This may stem from clogged filters or inadequate lubrication. Regular maintenance, including cleaning filters and ensuring proper lubrication, can significantly enhance performance and prevent such issues from occurring.

Overheating is also frequently reported, often caused by blocked vents or low coolant levels. Ensuring that air pathways are clear and maintaining appropriate fluid levels will help prevent overheating and maintain operational efficiency.

Finally, erratic pressure readings can signal potential leaks or faulty gauges. Regularly checking for leaks and calibrating pressure gauges are vital steps to ensure accurate performance monitoring and safety.

Impact on Equipment Performance

The efficiency and reliability of machinery are heavily influenced by the quality and compatibility of its components. Understanding how various elements interact within the system can help in maximizing operational effectiveness and minimizing downtime. When every part functions optimally, the overall performance of the equipment is enhanced, leading to improved productivity and reduced maintenance costs.

Key Factors Influencing Performance

- Compatibility of Components

- Quality of Materials

- Precision in Manufacturing

- Regular Maintenance and Upgrades

Benefits of High-Quality Components

- Enhanced Durability: Quality materials withstand wear and tear better.

- Improved Efficiency: Properly functioning components optimize energy use.

- Reduced Operational Costs: Fewer breakdowns lead to lower repair expenses.

- Increased Safety: Well-maintained equipment minimizes hazards during operation.