When dealing with devices that manage the flow of gases, it’s essential to recognize the key elements that ensure proper functionality. These mechanisms are designed to regulate and control the passage of gases, often used in various industries and applications. By breaking down the system into its core segments, it becomes easier to understand how each part contributes to the overall operation.

Each component within this system has a unique role, whether it’s adjusting the flow, measuring pressure, or maintaining safety standards. Understanding the individual functions can help in both troubleshooting and maintaining the system. A clear understanding of these elements is essential for anyone working with or around such systems.

In this guide, we’ll explore the essential pieces that come together to make up a gas flow control

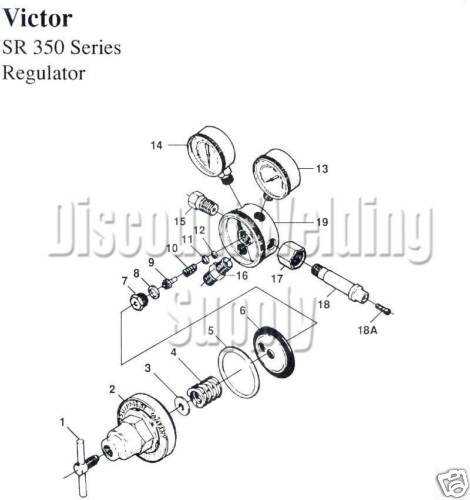

Overview of an Oxygen Regulator’s Components

Understanding the essential elements of this device is key to ensuring efficient operation. It consists of various mechanisms working together to control and deliver a stable flow. Each part plays a specific role, contributing to both safety and accuracy in the system’s functionality.

Main Elements

- Control valve: Adjusts the flow by managing the pressure between the source and the outlet.

- Pressure gauge: Provides a clear reading of the internal pressure, allowing users to monitor levels.

- Connector: Ensures a secure fit between the supply line and the device for seamless operation.

Additional Features

- Flexible material that can withstand constant movement

- Responsive to even the slight

Understanding the Pressure Relief Valve

A pressure relief valve plays a crucial role in maintaining safety and functionality within various systems. It serves as a protective mechanism that prevents excessive pressure buildup, which can lead to potentially hazardous situations. By monitoring and regulating the pressure levels, this component ensures that the overall system operates efficiently and safely.

This device functions by opening at predetermined pressure thresholds, allowing excess gas or fluid to escape. By doing so, it safeguards the integrity of the entire assembly, preventing damage or failure. Understanding its operation is vital for anyone involved in the maintenance or utilization of pressure-dependent systems.

Regular inspection and proper maintenance of the pressure relief valve are essential for optimal performance. Issues such as blockages or wear can compromise its effectiveness, leading to serious risks. Therefore, recognizing the signs of malfunction and knowing when to replace this vital component can significantly enhance safety and reliability.

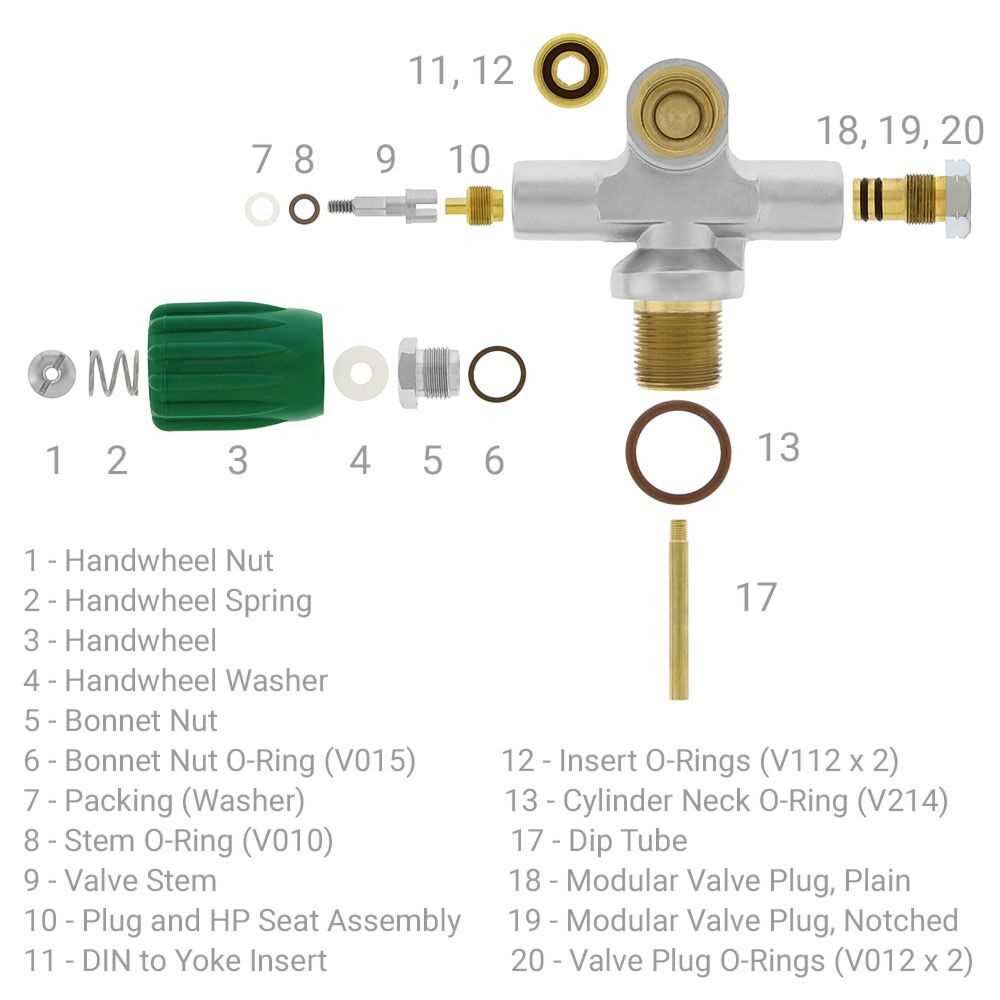

Connections and Fittings in Oxygen Regulators

Understanding the various linkages and components in gas management systems is essential for efficient operation. These elements play a crucial role in ensuring a secure flow of gases, maintaining pressure levels, and preventing leaks. A comprehensive grasp of how these connections function can enhance the overall safety and performance of gas applications.

The fittings utilized in gas management systems come in various forms, each designed to serve specific functions. These components include adapters, couplings, and valves, which work in unison to create a seamless interface between different equipment and the gas source. Recognizing the importance of each fitting aids in proper assembly and maintenance.

Component Type Description Adapters Used to connect two different types of fittings or equipment, facilitating compatibility. Couplings Serve to join two hoses or pipes together, allowing for an uninterrupted gas flow. Valves Control the gas flow, enabling users to start, stop, or regulate the amount of gas delivered. Seals Prevent leakage at connection points, ensuring the system remains airtight. Maintaining and regularly inspecting these linkages is vital for operational efficiency. By ensuring that each component is in good condition and properly connected, users can prevent accidents and ensure a steady and safe flow of gas in various applications.

Oxygen Inlet and Outlet Ports Explained

The functionality of a system designed for the management of gas flow relies heavily on its entry and exit points. These openings play a critical role in ensuring the efficient transfer of the substance, facilitating controlled release and intake as needed. Understanding the significance of these connectors can enhance the operation and safety of the apparatus.

Entry Point: This is where the gas enters the system. It serves as the initial gateway, often equipped with mechanisms to regulate the pressure and volume. The design and integrity of this opening are vital, as they must withstand fluctuations and prevent any leaks, ensuring that the flow remains steady and secure.

Exit Point: Conversely, the outlet is responsible for the release of the gas into the intended environment. This outlet must be designed to accommodate varying demands, allowing for adjustments in flow rate based on the specific requirements of the user or application. Proper sealing and connection are essential here as well, ensuring that the gas exits efficiently without any risk of backflow or contamination.

Overall, the interplay between these two connectors is essential for the optimal functioning of the entire system, promoting reliability and safety in gas management processes.

Common Materials Used in Regulator Parts

Understanding the materials utilized in the construction of pressure-controlling devices is crucial for ensuring optimal functionality and durability. Various elements are chosen based on their unique properties, which contribute to the overall performance and reliability of these mechanisms.

Here are some frequently employed materials in the manufacturing of these devices:

- Brass: This alloy is favored for its strength, corrosion resistance, and ease of machining. It is often used in fittings and connectors.

- Aluminum: Lightweight yet robust, aluminum is often used in housing components, providing a balance between weight and durability.

- Stainless Steel: Known for its exceptional resistance to oxidation and corrosion, this material is ideal for components exposed to harsh environments.

- Plastic: Certain types of durable plastics are utilized for seals and insulators, offering flexibility and resistance to chemical degradation.

- Rubber: Commonly used for gaskets and seals, rubber provides excellent sealing properties to prevent leaks.

Each of these materials plays a vital role in enhancing the performance and safety of pressure-controlling systems, making their selection critical during the design process.

Maintenance Tips for Regulator Components

Ensuring the longevity and efficiency of your control mechanisms requires regular attention to their individual components. Proper upkeep not only enhances performance but also minimizes the risk of malfunctions. Here are some essential suggestions for maintaining these crucial elements.

Regular Inspections: Conduct frequent evaluations to identify wear or damage. Look for signs of corrosion, leaks, or cracks, as these issues can significantly impact functionality.

Cleaning Procedures: Keep surfaces clean by removing dust and debris. Use appropriate solvents and tools to avoid damaging sensitive areas. A clean environment helps maintain optimal performance.

Lubrication: Apply suitable lubricants to moving components to reduce friction and wear. Ensure you choose products that are compatible with the materials used in the mechanism.

Storage Practices: When not in use, store the equipment in a dry and cool place to prevent deterioration. Cover components to protect them from dust and moisture, ensuring they remain in good condition.

Professional Servicing: Schedule regular check-ups with qualified technicians. Their expertise can help spot issues that may go unnoticed and ensure everything operates smoothly.

Key Elements in Oxygen Regulator Construction

When it comes to the design of these vital control devices, understanding the key components is crucial. Each segment is designed to ensure precise management of the flow and pressure of essential gases, supporting their reliable operation in various environments. This section outlines the primary structures that contribute to the safe and efficient performance of these systems.

Main Components

The framework consists of several critical elements that work together to maintain balance and control. These include adjustable control valves, pressure indicators, and filter systems that ensure smooth operation. Below is an overview of the most important components in the construction process:

| Component | Function |

|---|---|

| Control Valve | Regulates the flow of gases to ensure steady output. |