Ribbon Reverse Mechanism:

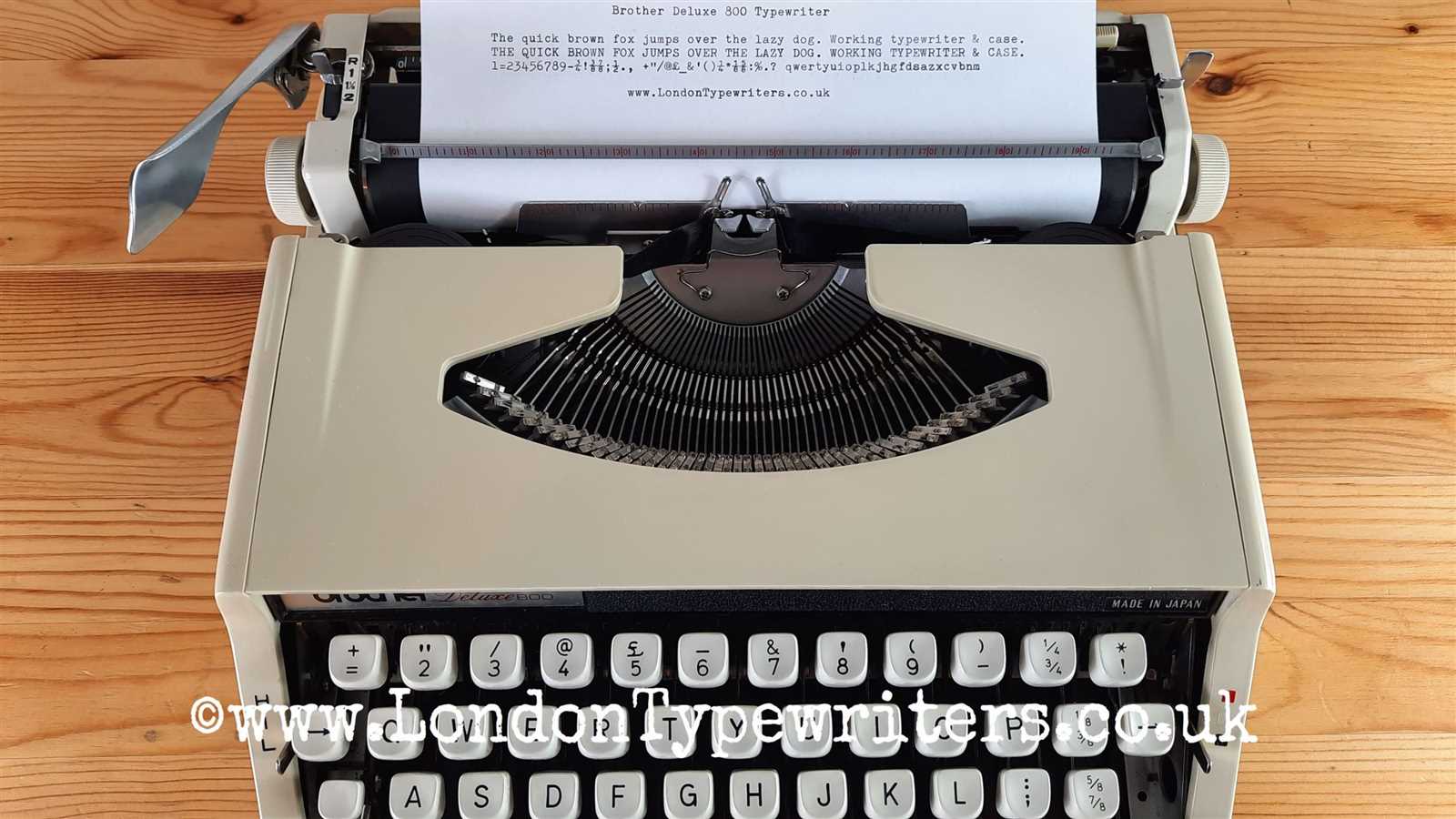

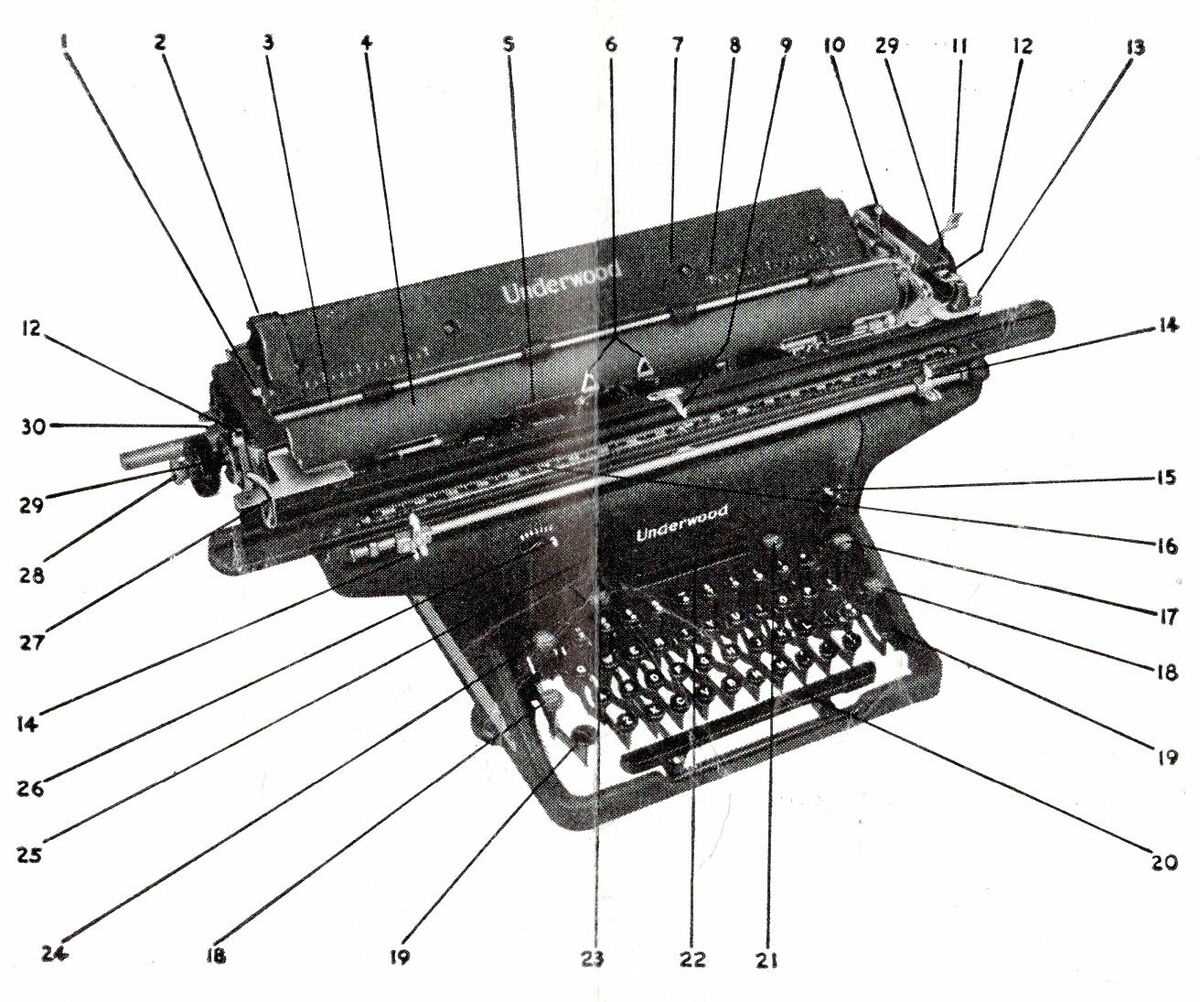

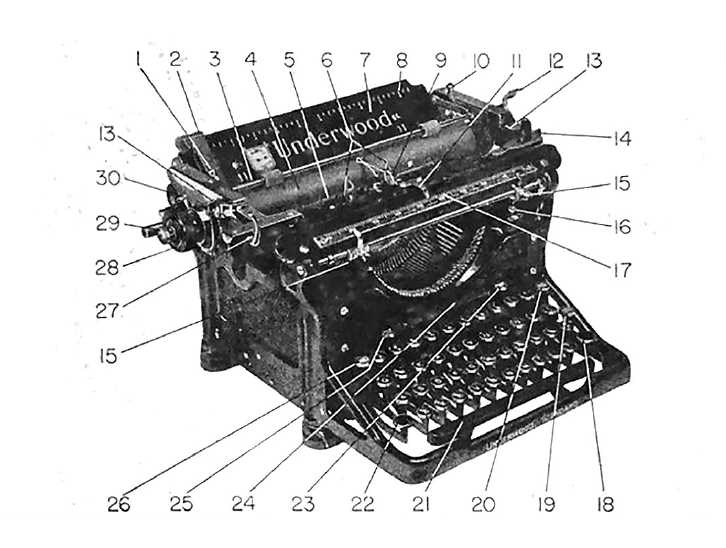

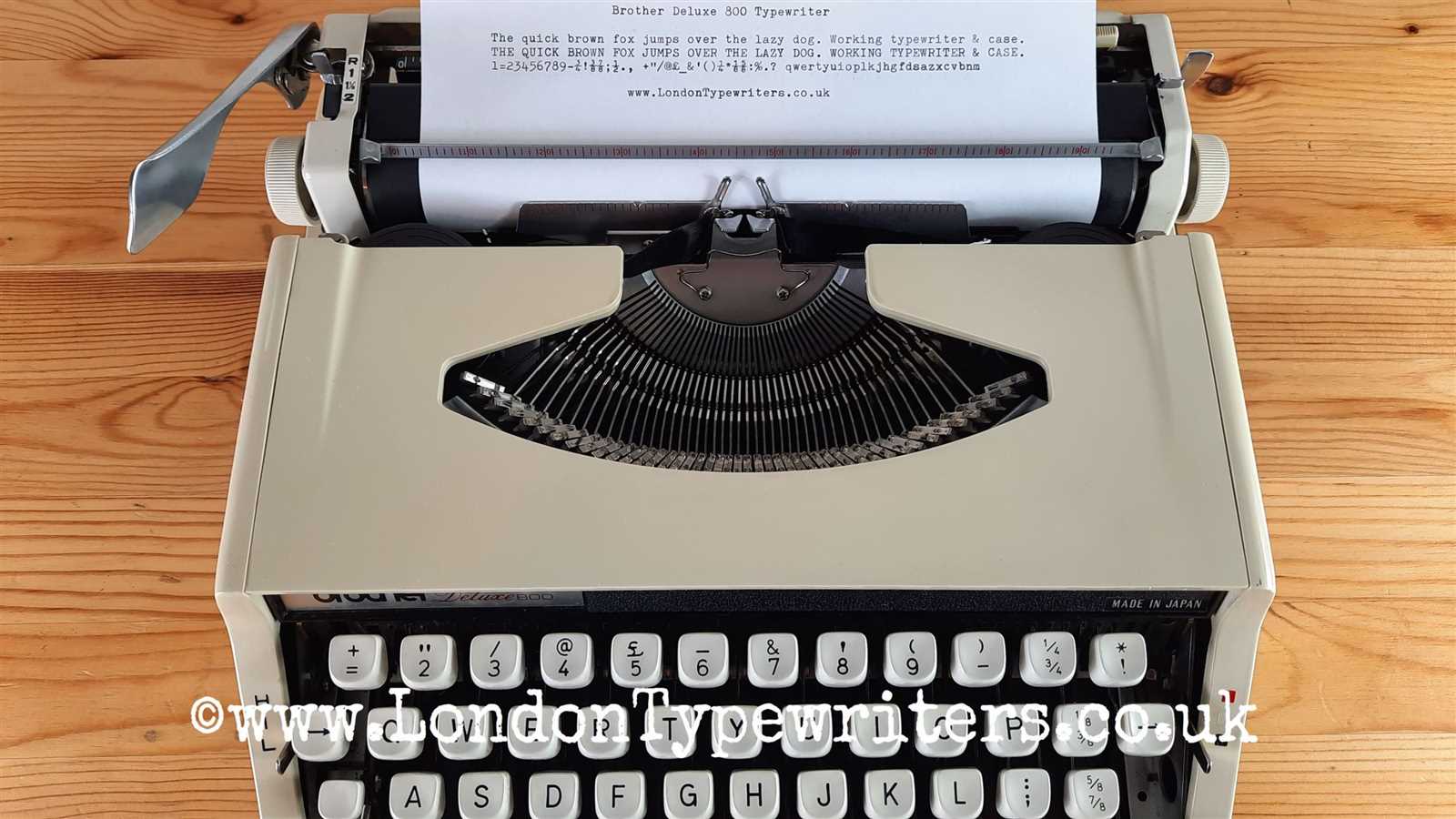

Exploring the Carriage System

The carriage system plays a crucial role in the operation of writing devices, ensuring smooth movement across the paper while producing clear text. It is a dynamic component that shifts horizontally to position the writing head at the start of each new line, providing a seamless flow of writing from left to right. The mechanism is designed to reset efficiently, allowing the user to continue without interruption.

Within this system, various elements work together to facilitate accurate line spacing and alignment. A complex interplay of levers and springs coordinates the movement, securing the writing surface in place as the mechanism advances. This precision ensures consistency in the layout, with uniform letter placement and spacing on each line.

Adjustments within the carriage enable changes in line

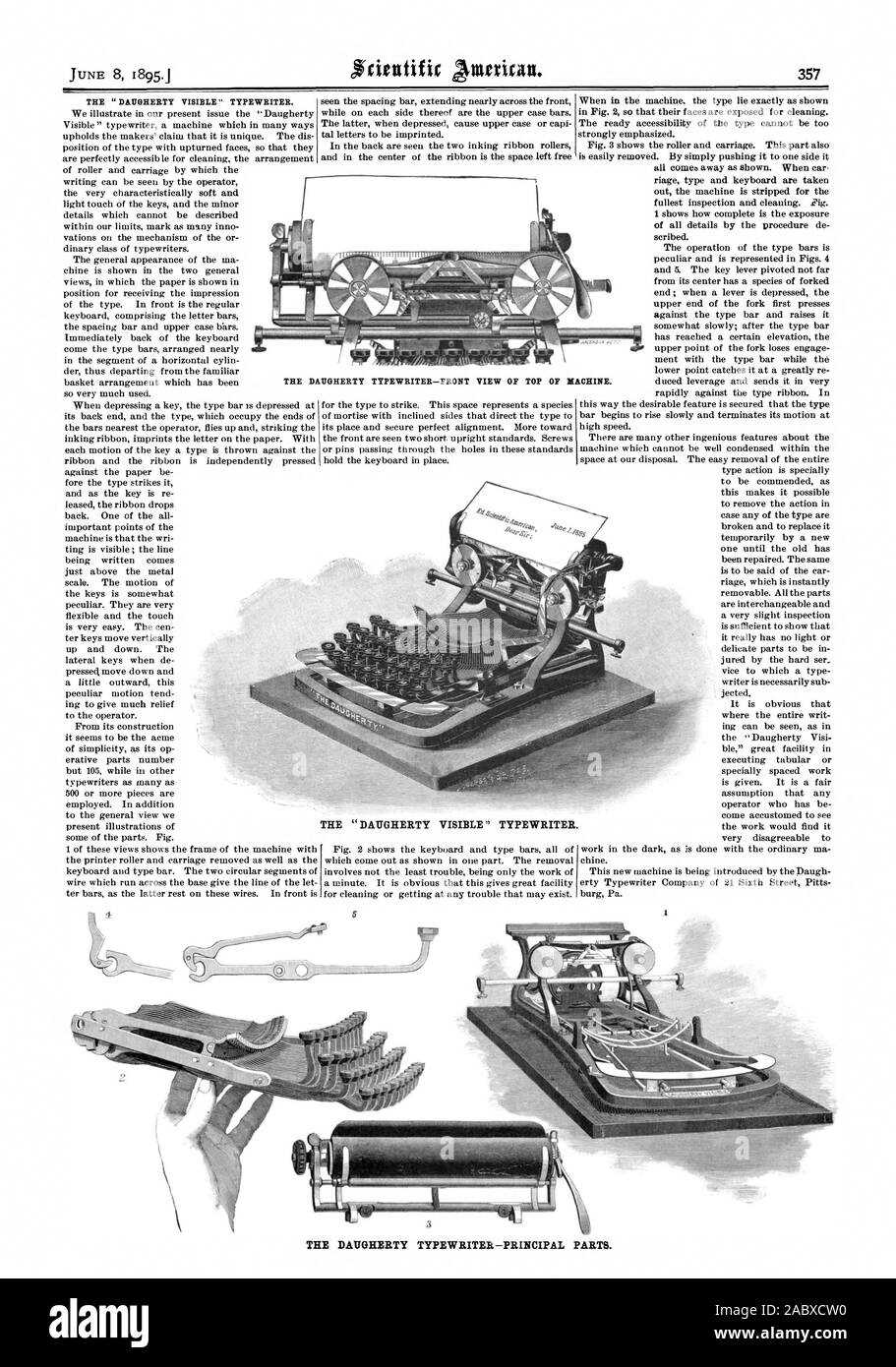

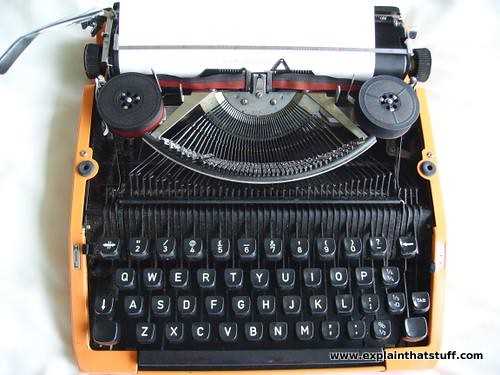

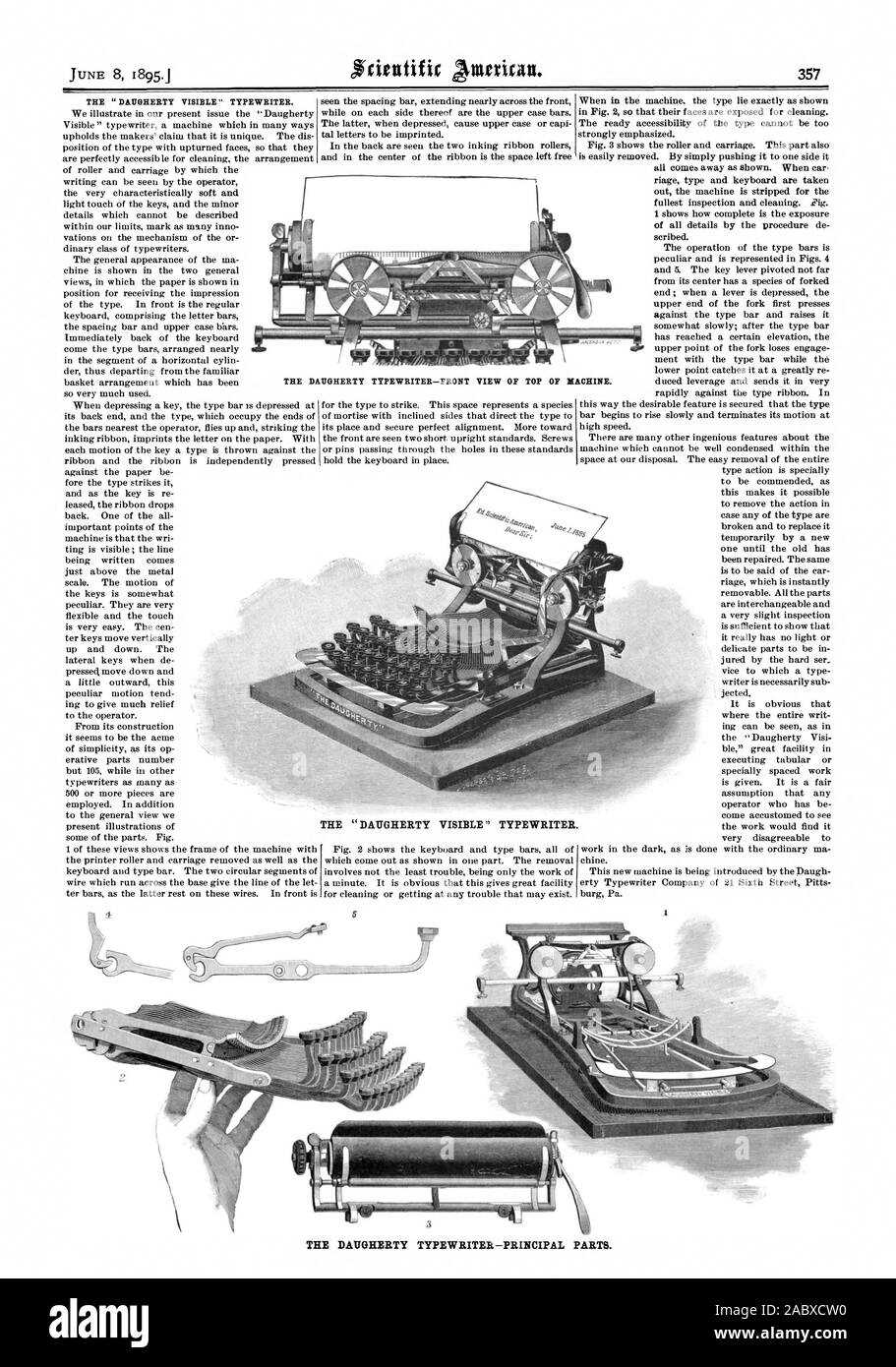

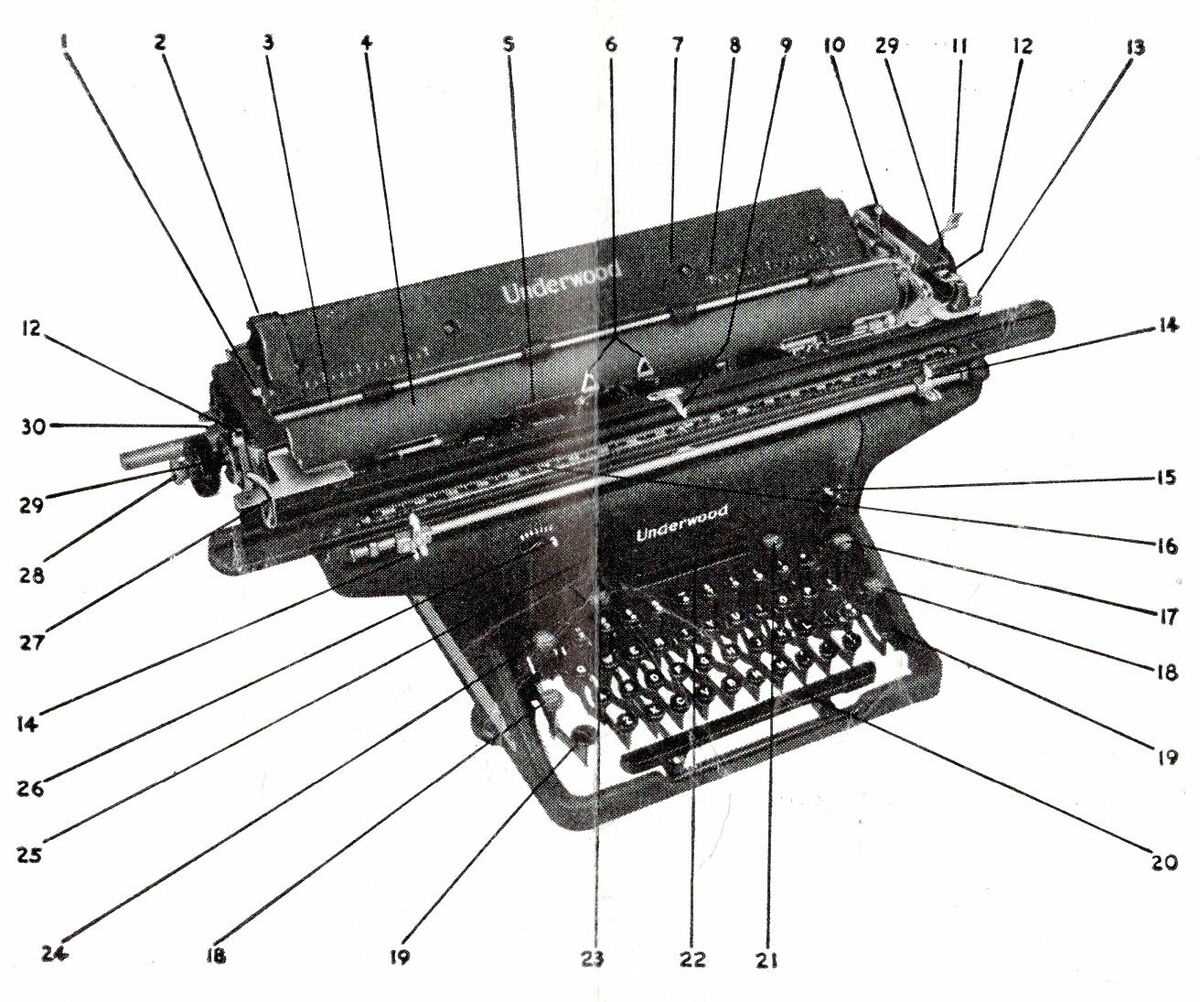

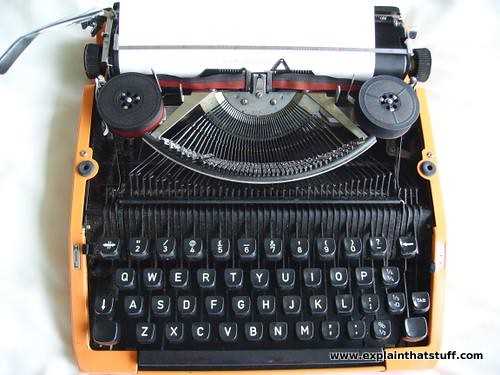

Functions of the Typebars

The mechanisms responsible for transferring each keystroke into visible symbols on paper play a crucial role in the operation of the device. These components work together to create an efficient system for imprinting characters with precision and consistency. Understanding how they function provides insight into the mechanical processes behind each letter’s appearance.

Movement and Alignment

When a key is pressed, a lever mechanism moves, triggering the motion of a corresponding component. These parts align in a specific sequence, ensuring that the chosen character strikes the inked ribbon at the correct angle. The precision in

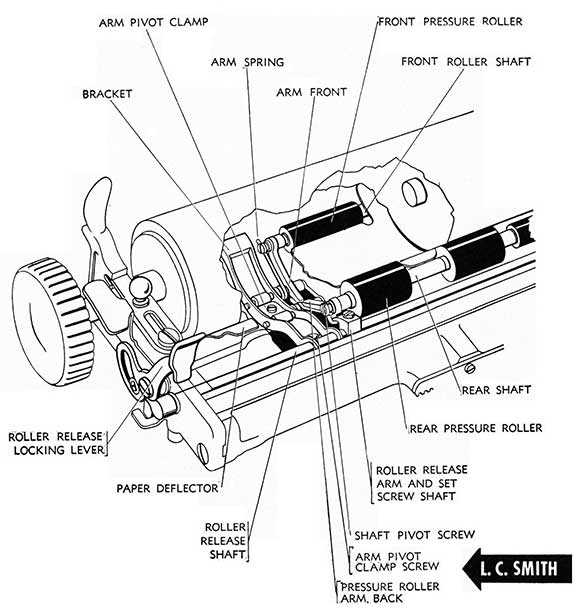

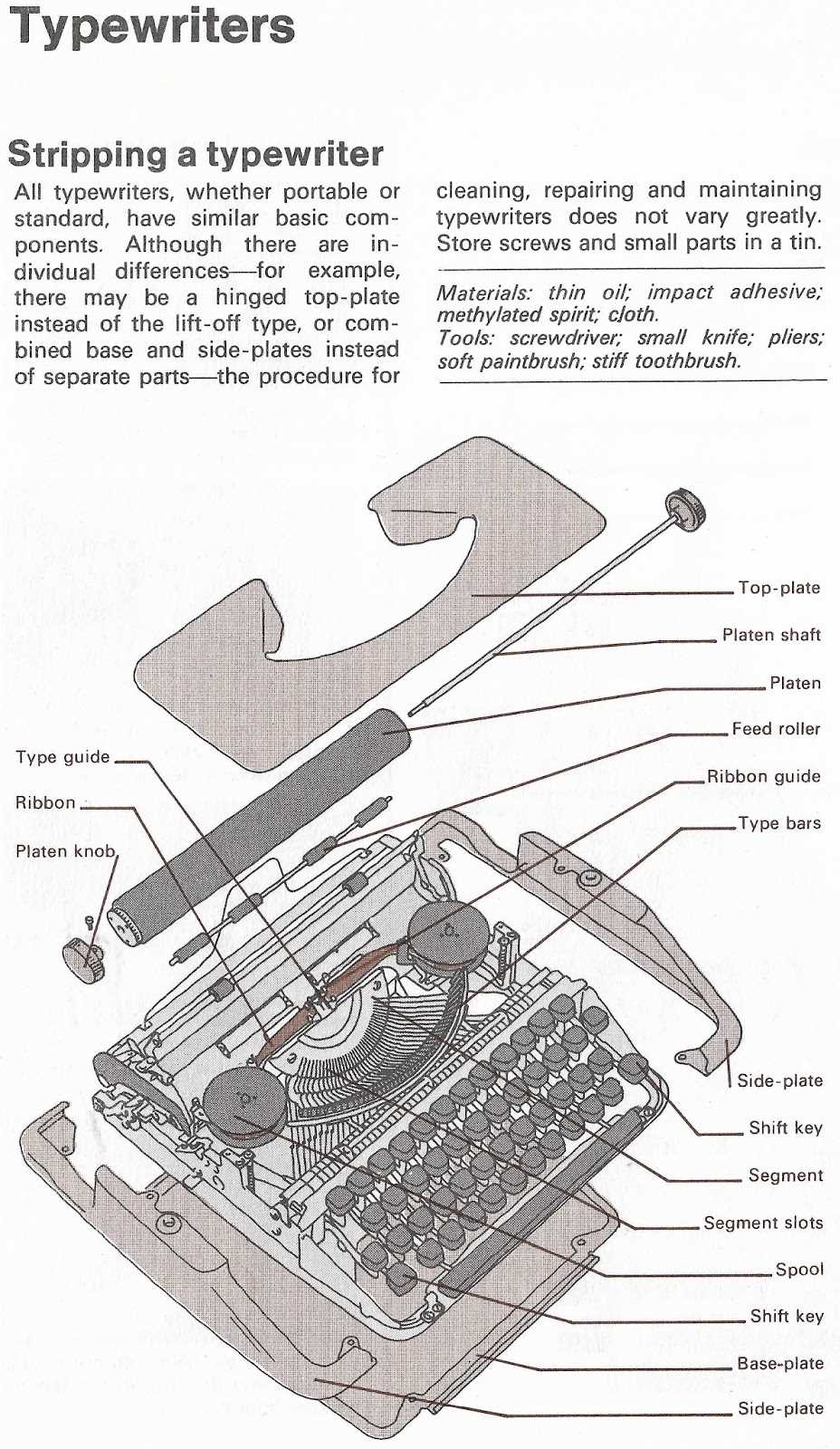

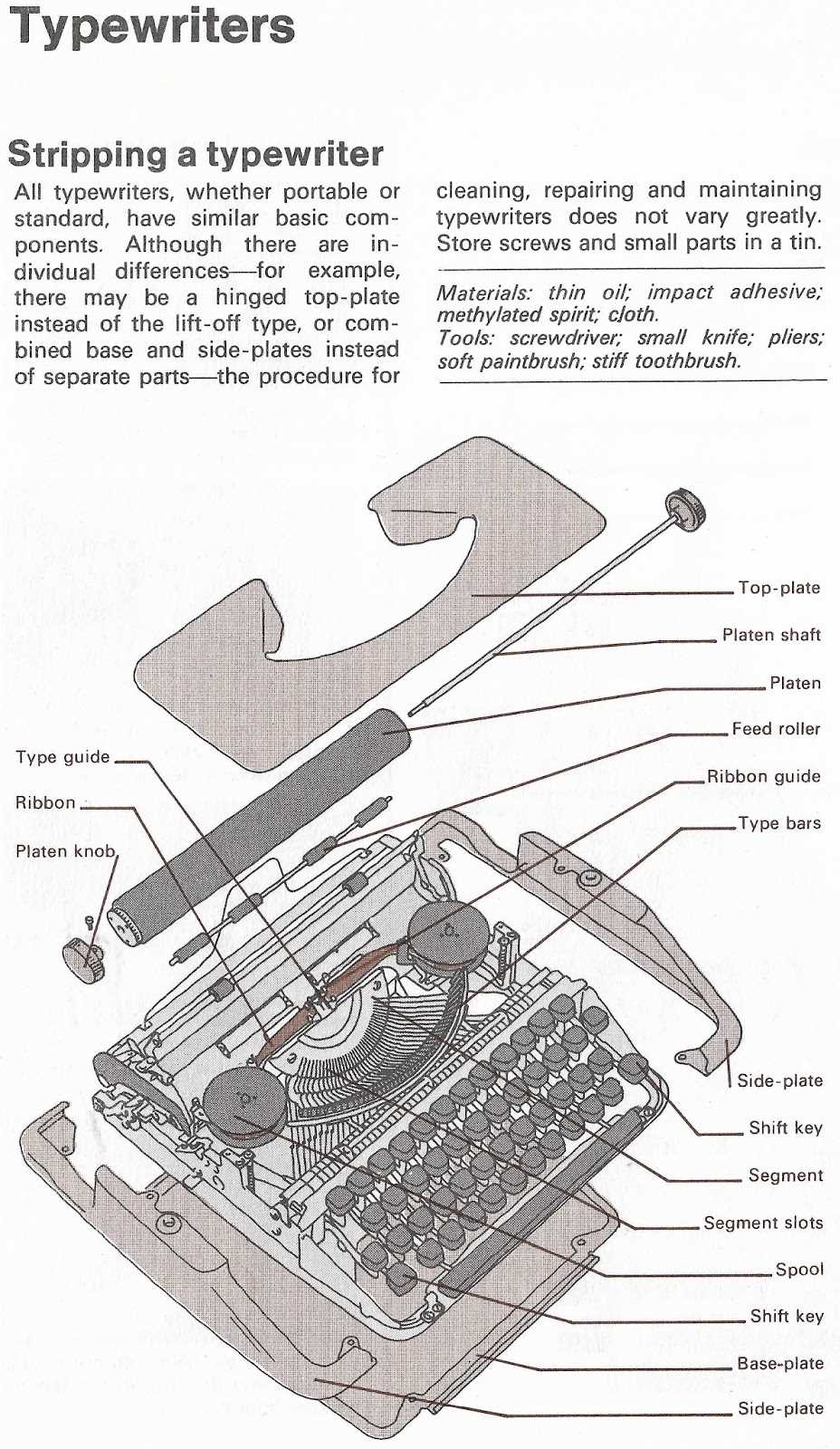

Role of the Platen Roller

The platen roller is a crucial component that significantly influences the printing mechanism of a writing machine. It serves as a cylindrical surface that interacts with the medium on which text is produced, ensuring a smooth transfer of ink from the ribbon to the page.

Functionally, this roller provides the necessary pressure and support, allowing for even and clear impressions. The material and design of the platen are essential, as they affect not only the quality of the imprint but also the durability of the writing device itself. Regular maintenance of this element can prevent issues such as misalignment or uneven printing, thereby enhancing the overall performance.

In summary, the platen roller plays a vital role in the functionality of a writing apparatus, impacting both the aesthetic quality of the output and the efficiency of the writing process. Understanding its significance aids in appreciating the intricate workings of these mechanical systems.

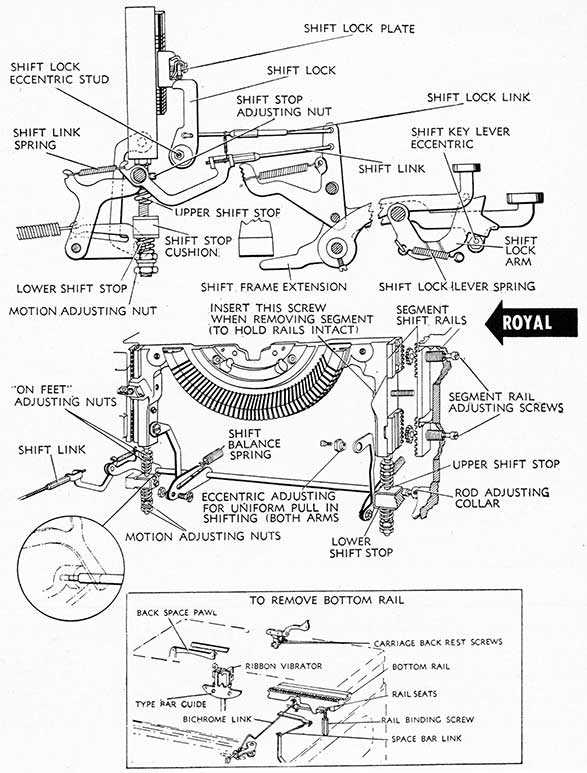

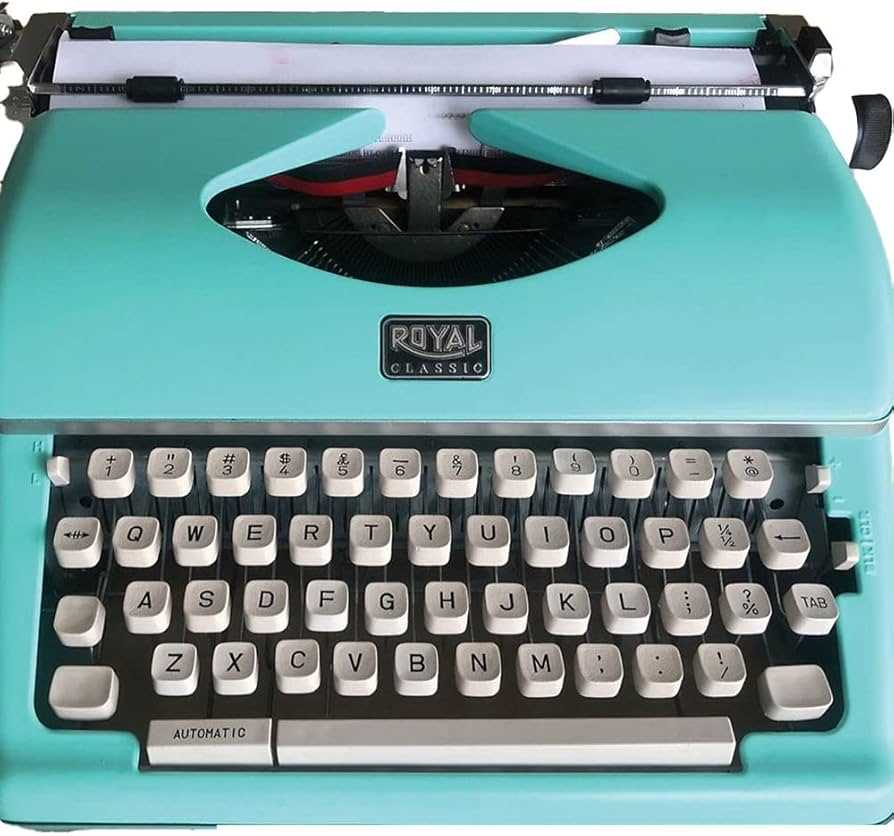

How the Shift Mechanism Works

The shift mechanism is a crucial component that enhances the functionality of writing devices, allowing users to access a range of symbols and characters. This system enables the alteration of the character’s position, thereby facilitating the use of uppercase letters and special characters. Understanding its operation is essential for grasping how these devices achieve versatility in text creation.

Basic Functionality

At its core, the shift mechanism employs a lever system that changes the alignment of the striking elements. When engaged, this mechanism raises or lowers the type elements, enabling different characters to be printed depending on the selected mode. This simple yet effective design ensures seamless transitions between lowercase and uppercase letters, as well as the insertion of punctuation marks.

Importance of Alignment

Proper alignment is vital for the smooth operation of the shift mechanism. Any misalignment can lead to inconsistent results and errors in text output. Regular maintenance and adjustments ensure that the mechanism functions optimally, preserving the quality of written work. Understanding the nuances of this system not only improves usability but also extends the lifespan of the device.

The Escapement System Explained

The escapement mechanism serves a crucial role in the operation of mechanical writing devices, controlling the movement of the carriage while ensuring accurate spacing between characters. This system allows for a precise release of energy, enabling the striking element to hit the ribbon and paper in a coordinated manner, which is essential for producing clear text.

At the heart of this mechanism lies the interplay between various components that work together to create a seamless writing experience. When a key is pressed, the escapement engages, allowing the carriage to shift forward while simultaneously locking in place to prepare for the next character. This interaction prevents double strikes and maintains the integrity of the written material.

Understanding this system not only highlights the ingenuity of mechanical design but also illustrates how each element contributes to the overall functionality. The effective operation of this mechanism is a testament to the craftsmanship involved in creating devices that have stood the test of time, providing insight into the evolution of writing technology.

Maintaining the Paper Feed Rollers

Ensuring the proper functioning of the feeding mechanism is essential for optimal performance. Regular maintenance helps prevent jams and ensures smooth operation during use. Keeping this component in good condition not only enhances efficiency but also prolongs the lifespan of the entire device.

To effectively maintain the feeding mechanism, consider the following steps:

- Regular Cleaning: Dust and debris can accumulate, affecting performance. Use a soft, lint-free cloth to gently wipe the rollers, removing any particles that may hinder their movement.

- Lubrication: Applying a suitable lubricant can help keep the rollers functioning smoothly. Ensure you use a product designed for similar mechanisms to avoid damage.

- Visual Inspection: Frequently check for signs of wear or damage. Look for cracks or deformities that may impact functionality and address them promptly.

- Adjusting Tension: Ensure the feeding mechanism is correctly tensioned. If too loose or tight, it can lead to feeding issues. Follow the manufacturer’s guidelines for adjustments.

By implementing these practices, users can maintain the feeding mechanism effectively, ensuring reliability and performance over time. Regular attention to this aspect can prevent more significant issues down the line.

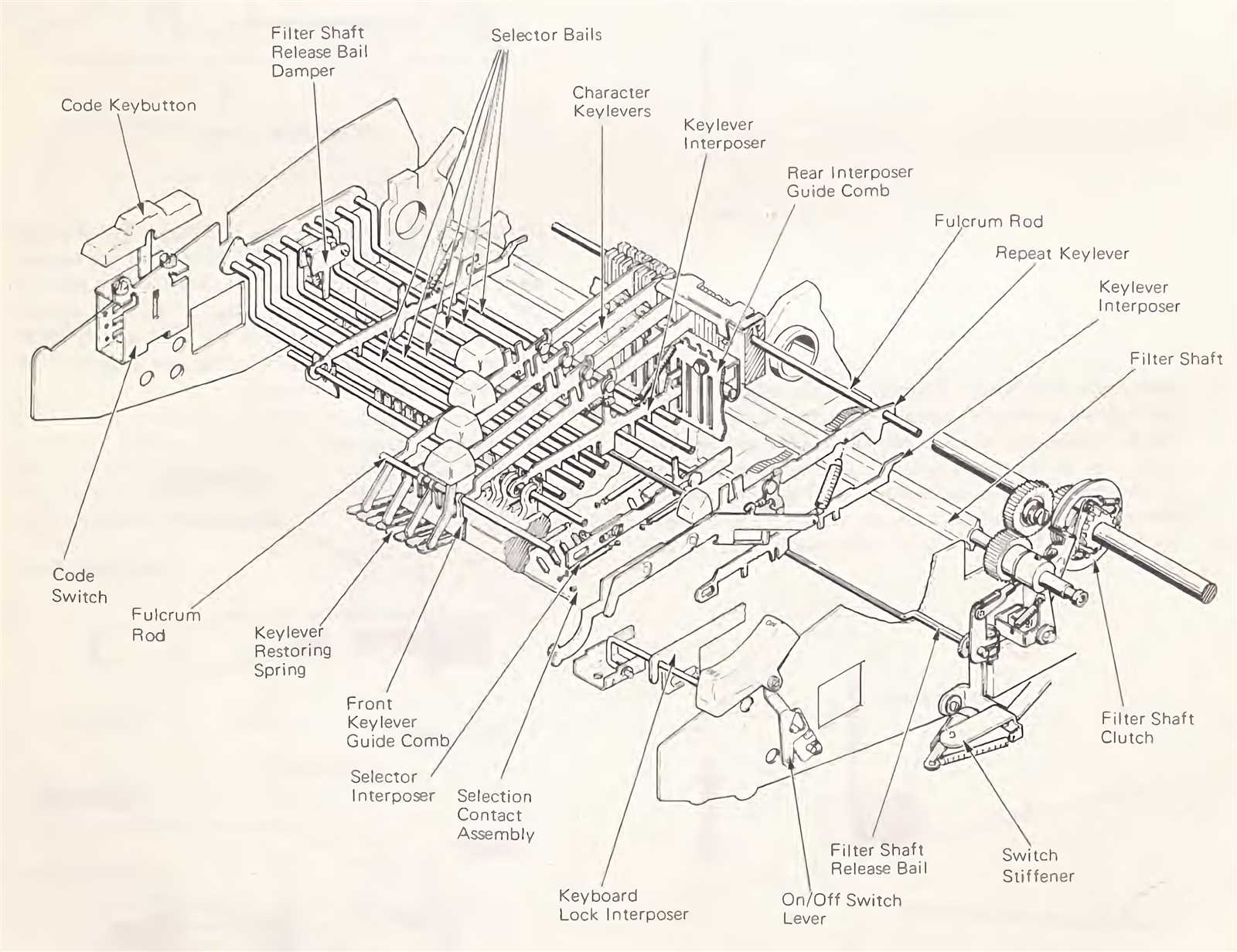

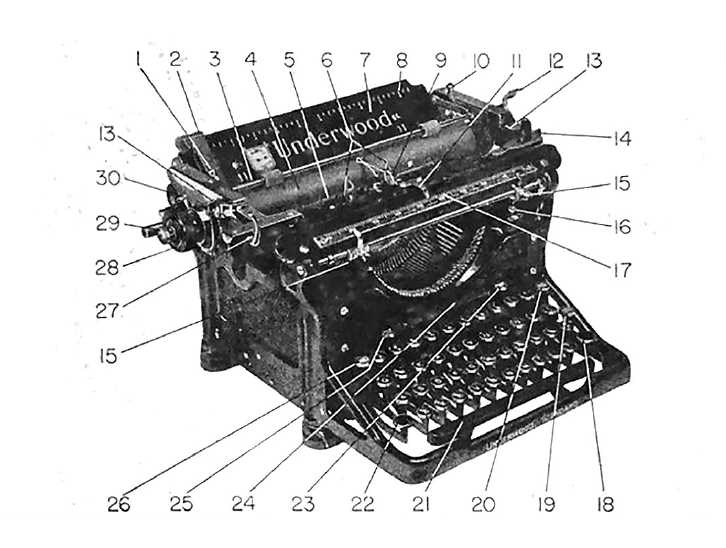

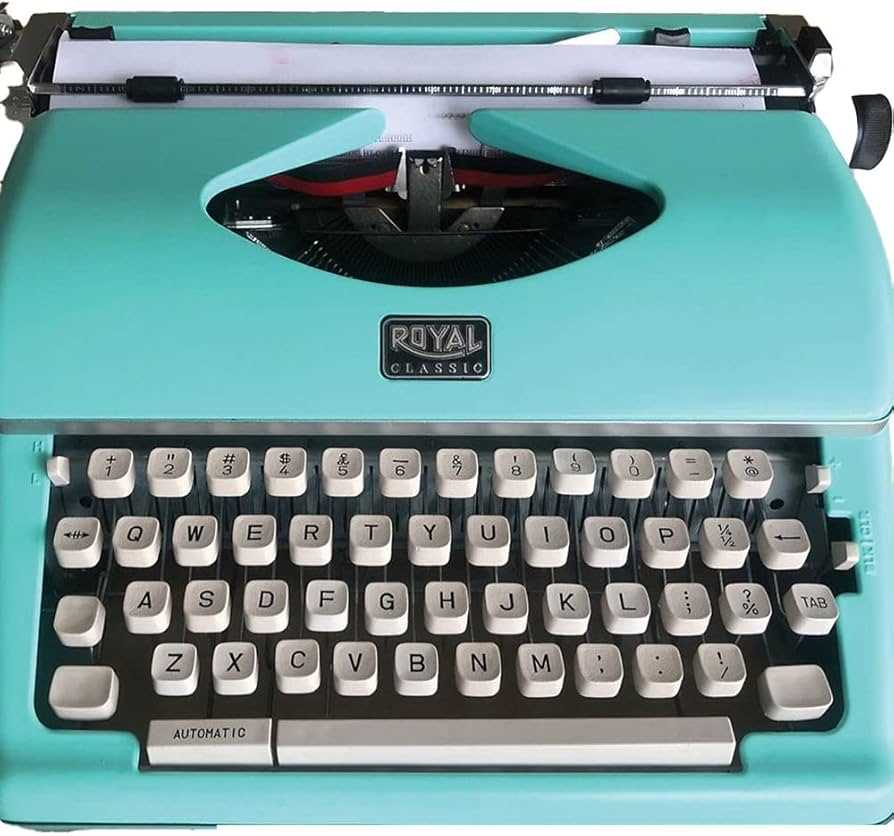

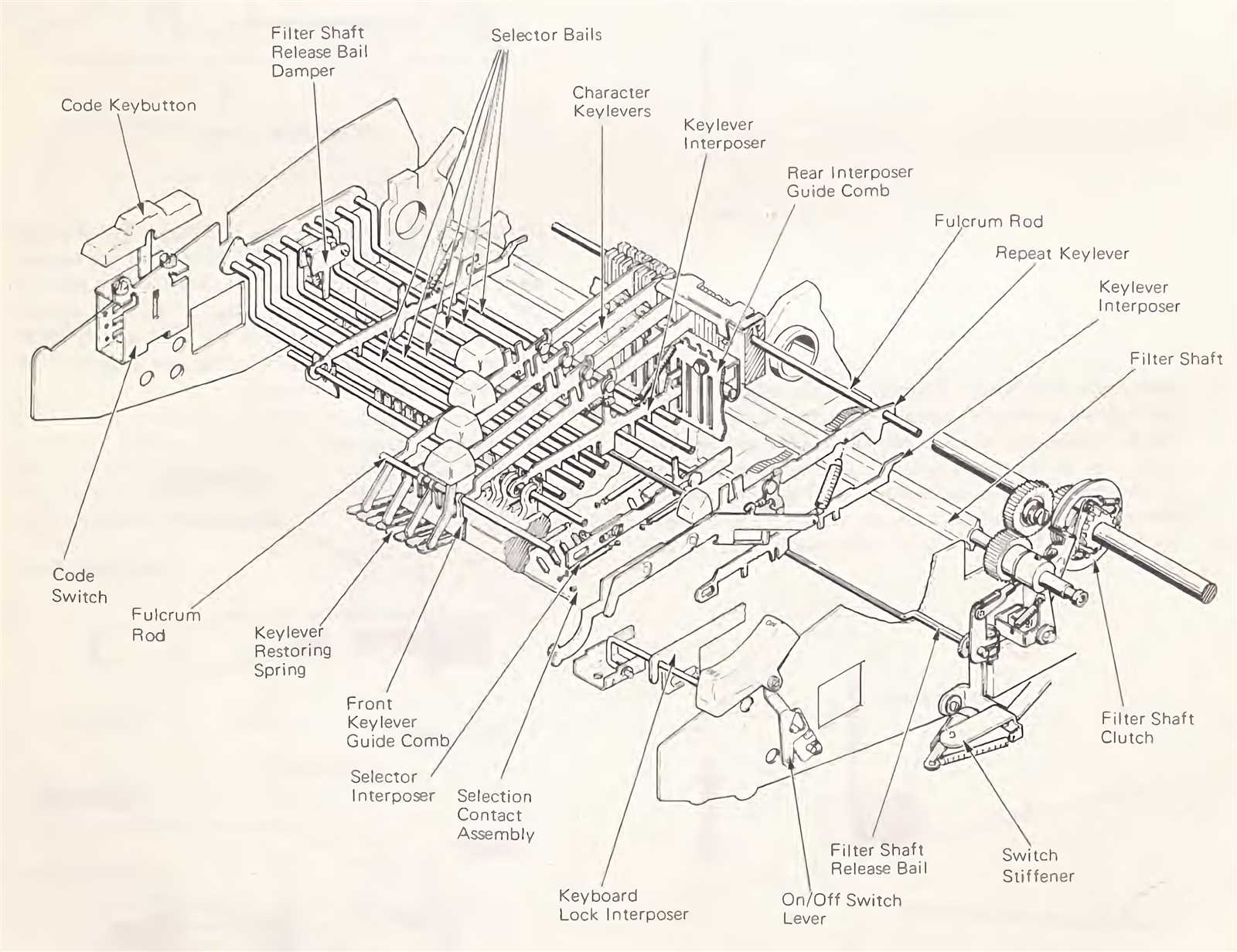

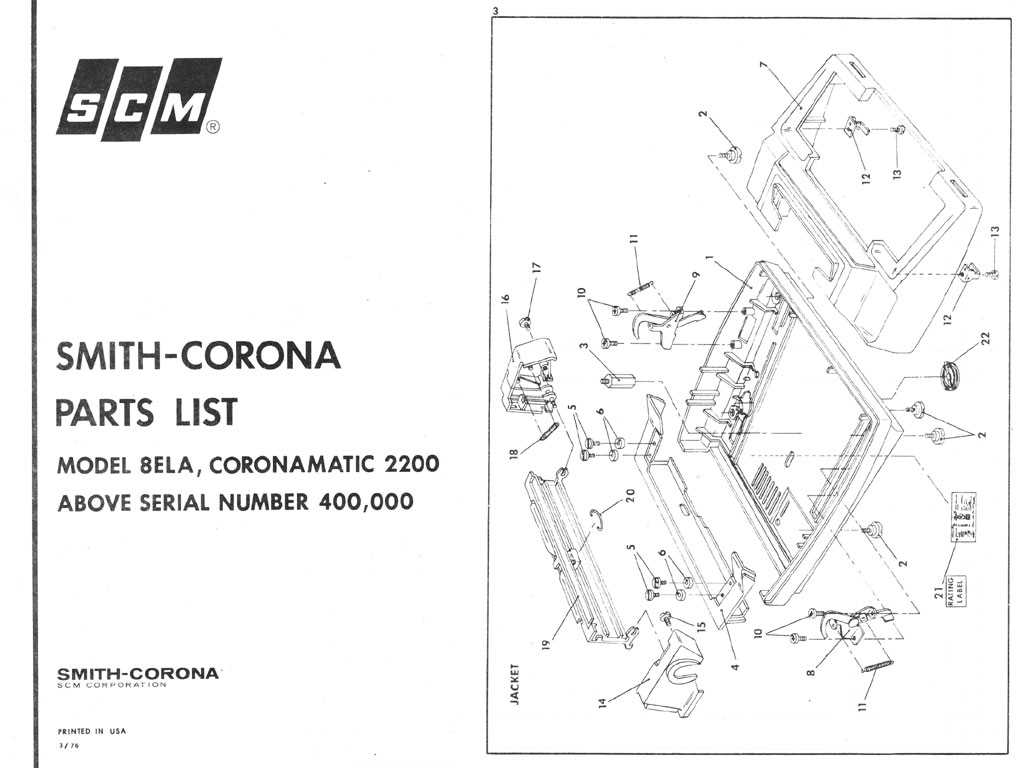

Typewriter Key Structure Guide

This section explores the essential components that make up the mechanism of a keyboard system, focusing on their functions and interactions. Understanding these elements can enhance the user experience and appreciation for this classic writing instrument.

Key Elements of the Keyboard Mechanism

- Key Cap: The visible part that the user presses, often labeled with characters.

- Spring: A crucial element providing resistance and enabling the key to return to its original position after being pressed.

- Stem: The part that connects the key cap to the mechanism, transmitting the motion downwards.

- Lever: A device that translates the downward motion of the key into a striking action on the ribbon.

- Guide Pin: A small component ensuring precise alignment and movement of the key.

Functionality Overview

The interaction between these components creates a seamless typing experience. When a key cap is pressed, the spring compresses, allowing the stem to move downwards. This action triggers the lever, which then strikes the ribbon and paper, imprinting the character. The guide pin maintains stability throughout this process, ensuring each keystroke is accurate and effective.

By understanding the intricate relationships between these elements, users can gain a deeper appreciation for the craftsmanship behind the design, contributing to a more enjoyable writing experience.

Identifying the Margin Controls

Understanding how to manipulate the settings that determine text positioning is crucial for achieving desired outcomes in your writing process. These controls allow users to set boundaries for where the text begins and ends on the page, providing a framework for organization and aesthetics. Mastering these elements not only enhances the overall presentation but also contributes to the clarity of the content.

Typically, you will find two primary adjustments: the left and right boundaries. The left control regulates the starting point of your text on the page, ensuring that your content is aligned properly. On the other hand, the right control manages the endpoint of the text, preventing it from spilling over into the margins. By fine-tuning these settings, one can achieve a polished and professional appearance.

To engage with these features effectively, familiarize yourself with their location and the mechanisms involved in adjusting them. Usually, you will find dials or levers that can be manipulated to set the desired measurements. Some models may include visual indicators, making it easier to see the adjustments being made. Gaining proficiency in utilizing these controls will significantly enhance your writing experience and improve the overall quality of your output.