The intricate world of machinery often requires a deep dive into the essential elements that make up its functionality. Navigating through the various components and their interconnections can reveal the underlying principles that drive efficiency and performance. A comprehensive analysis of these elements is crucial for anyone looking to enhance their understanding of mechanical systems.

In this exploration, we will break down the structural arrangements of various units, shedding light on how each piece contributes to the overall operation. By visualizing these configurations, users can gain insights into maintenance, troubleshooting, and potential upgrades. This knowledge empowers both professionals and enthusiasts to engage more effectively with their equipment.

Moreover, understanding the layout fosters better communication among technicians and engineers, facilitating a collaborative approach to problem-solving. As we delve into this topic, we aim to equip readers with the tools necessary to interpret these layouts, ensuring a more profound comprehension of the machinery at hand.

Lx277 Parts Overview

This section aims to provide a comprehensive understanding of the various components that make up the machine. Each element plays a crucial role in ensuring optimal performance and functionality. By familiarizing yourself with these pieces, you can better appreciate how they work together to achieve desired outcomes.

Key elements to consider include:

- Engine components that drive the overall operation.

- Electrical systems responsible for powering various functionalities.

- Structural elements that provide stability and support.

- Hydraulic parts that facilitate movement and control.

Understanding the interplay between these components can enhance maintenance practices and troubleshooting efforts. Below are some common categories of these essential elements:

- Mechanical Parts: These include gears, belts, and pulleys that transfer motion.

- Electrical Components: Wires, switches, and sensors that ensure proper electrical flow.

- Hydraulic Components: Pumps, valves, and hoses that manage fluid dynamics.

- Fasteners: Nuts, bolts, and screws that secure the assembly.

By grasping the significance of each category, users can enhance their interaction with the equipment and ensure its longevity and efficiency.

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repairs. This visual representation serves as a roadmap, guiding users through the intricate relationships between various elements of a machine. A clear understanding of this schematic can significantly enhance troubleshooting and enhance operational efficiency.

The significance of this graphical representation lies in its ability to simplify complex structures. Each segment is meticulously labeled, allowing for easy identification and reference. This clarity aids both novice and experienced individuals in quickly locating and addressing specific areas of concern.

| Component | Description | Function |

|---|---|---|

| Element A | Main driving mechanism | Transfers energy to the system |

| Element B | Supporting structure | Stabilizes the entire assembly |

| Element C | Control unit | Regulates operation parameters |

| Element D | Safety feature | Prevents malfunctions and hazards |

By leveraging this information, users can efficiently diagnose issues and implement solutions. Understanding the configuration fosters a deeper connection with the equipment, ultimately leading to better care and longevity of the system.

Key Components of Lx277

The intricate assembly of machinery relies on various essential elements that work harmoniously to ensure optimal performance. Understanding these fundamental components is crucial for effective maintenance and troubleshooting.

Engine Unit: This vital part serves as the powerhouse, converting fuel into mechanical energy. Its efficiency directly impacts the overall functionality of the system.

Transmission System: Acting as the mediator between the engine and the wheels, this mechanism facilitates the transfer of power, allowing for smooth acceleration and deceleration.

Electrical System: Comprising various circuits and wiring, this network provides the necessary power for operational controls, lighting, and other electronic components, ensuring everything runs smoothly.

Chassis: The foundational structure that supports all other elements, it ensures stability and durability, allowing the machine to withstand various conditions.

Hydraulic Components: These parts are essential for enabling fluid movement within the system, facilitating functions such as lifting and steering, which are critical for maneuverability.

Cooling System: This assembly is crucial for regulating temperature, preventing overheating and ensuring that the engine operates within safe limits, thus extending its lifespan.

By comprehending the roles of these components, operators can enhance their knowledge and skills, leading to more effective usage and maintenance of the machinery.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in various fields, facilitating understanding and communication. These illustrations serve as essential tools that bridge the gap between complex concepts and practical applications, ensuring that users can effectively interpret and utilize the information presented.

Enhancing Understanding

Well-crafted visuals enhance comprehension in several ways:

- Provide clarity by breaking down intricate details into digestible parts.

- Enable quicker recognition of components and their functions.

- Assist in identifying relationships and interactions between different elements.

Facilitating Communication

Accurate visuals are vital for effective communication among various stakeholders:

- They ensure everyone is on the same page, reducing misunderstandings.

- Serve as a reference point during discussions or training sessions.

- Help in standardizing terminology and concepts across different teams.

In conclusion, the importance of precise illustrations cannot be overstated. They not only improve understanding but also foster clear communication, making them indispensable in technical and collaborative environments.

Common Issues with Lx277 Parts

In the realm of machinery maintenance, certain components can often present challenges that require attention. Understanding these common problems is essential for ensuring optimal performance and longevity of equipment. Below are some frequently encountered issues that users should be aware of when dealing with these specific elements.

Frequent Problems

Users may experience a variety of complications related to wear and tear, compatibility, and installation errors. These challenges can lead to inefficient operation and may necessitate timely intervention to avoid more significant damage.

Identification and Solutions

| Issue | Description | Possible Solution |

|---|---|---|

| Wear | Components may become worn over time, leading to decreased performance. | Regular inspection and timely replacement can mitigate this issue. |

| Compatibility | Some elements may not fit well with others, causing operational inefficiencies. | Ensure correct specifications before installation to avoid mismatches. |

| Installation Errors | Improper installation can lead to malfunction or damage. | Follow manufacturer guidelines closely during setup. |

Where to Find Replacement Parts

Locating the necessary components for your equipment can be a straightforward process if you know where to look. Numerous resources are available to help you source high-quality replacements, ensuring optimal performance and longevity for your machinery.

Online Retailers

One of the most convenient ways to find what you need is through online marketplaces. Here are some popular options:

- Amazon – A vast selection with customer reviews.

- eBay – Often features new and used items at competitive prices.

- Specialty websites – Look for retailers that focus specifically on your equipment type.

Local Stores

Don’t overlook brick-and-mortar establishments. Local hardware or specialty shops can be invaluable for quick access to essential components:

- Home improvement stores – Typically carry a variety of general parts.

- Authorized dealers – Offer genuine components and expertise.

- Salvage yards – A cost-effective option for used parts.

By exploring these avenues, you can efficiently find the items you require to keep your machinery running smoothly.

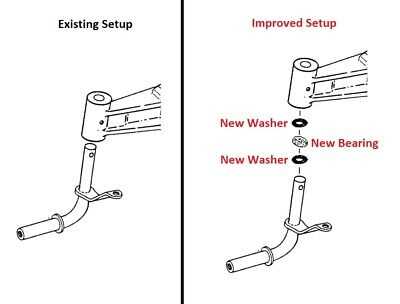

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your equipment efficiently. Following a systematic process ensures that each component is properly installed, leading to optimal performance and longevity. Each step is carefully outlined to facilitate a smooth assembly experience.

Preparation and Organization

Before beginning the assembly, gather all necessary components and tools. Organize parts in a way that allows for easy access, and refer to the accompanying documentation to familiarize yourself with the individual pieces. This preparation stage is crucial for avoiding confusion during assembly.

Assembly Process

Start by securing the base, ensuring it is stable and level. Proceed by attaching the main structure, followed by installing any auxiliary elements. Carefully check that each connection is firm and aligned. As you progress, double-check the arrangement of parts to confirm that everything matches the provided specifications. Finish by testing the assembled unit for any adjustments that may be necessary.

Tools Needed for Maintenance

Effective upkeep of machinery requires a selection of essential implements that ensure optimal performance and longevity. Understanding which tools to have on hand can make routine checks and repairs more efficient, ultimately saving time and resources.

Basic Hand Tools: A set of reliable hand tools is fundamental for any maintenance task. This typically includes wrenches, screwdrivers, and pliers, which are vital for tightening, loosening, and securing various components.

Power Tools: For more demanding jobs, power tools like drills and impact wrenches can significantly speed up the process. These tools are particularly useful for tasks requiring greater force or precision.

Measuring Instruments: Accurate measurements are crucial when diagnosing issues or making adjustments. Calipers and torque wrenches are invaluable for ensuring specifications are met, enhancing the overall reliability of the equipment.

Cleaning Supplies: Regular cleaning is essential for maintaining functionality. Brushes, solvents, and cloths should be included in your toolkit to remove debris and contaminants that could hinder performance.

Safety Equipment: Lastly, personal protective gear, such as gloves and goggles, is imperative to ensure the safety of the individual performing maintenance tasks. Prioritizing safety helps prevent accidents and promotes a secure working environment.

Visual Identification of Parts

Understanding the various components of a system is essential for effective maintenance and troubleshooting. This section focuses on the visual recognition of elements, aiding in quick identification and assessment. By familiarizing oneself with the distinct characteristics and features, one can ensure more efficient handling and operation.

Key aspects to consider for effective identification include:

- Color Coding: Many components are designed with specific color schemes to indicate function or compatibility.

- Shape and Size: Unique shapes and dimensions can provide clues about the role and placement of each element.

- Markings and Labels: Some items feature engravings or stickers that convey important information about their specifications.

To enhance recognition skills, consider the following techniques:

- Refer to manuals or guides that include visual aids.

- Practice identifying components in various settings to build familiarity.

- Engage with online forums or communities for shared insights and tips.

By honing these identification skills, one can improve overall proficiency and confidence in managing equipment effectively.

Tips for Troubleshooting Lx277

Effective problem-solving is essential when dealing with machinery issues. Identifying and addressing common challenges can save time and resources. This guide offers practical strategies to help you navigate potential complications.

Common Issues to Look For

- Check for unusual noises that may indicate wear or damage.

- Inspect connections and wiring for signs of corrosion or disconnection.

- Monitor performance; a decrease in efficiency often signals underlying problems.

- Examine fluid levels and leaks that could impact operation.

Steps for Diagnosis

- Begin with a thorough visual inspection to identify obvious issues.

- Refer to the user manual for specific troubleshooting procedures.

- Conduct tests on electrical components to ensure proper functionality.

- Document findings and compare with previous performance metrics.

By following these tips and staying vigilant, you can enhance the reliability and longevity of your equipment, ensuring it operates smoothly.