When it comes to maintaining outdoor machinery, a comprehensive grasp of its individual elements is crucial. Whether you are a professional landscaper or a dedicated DIY enthusiast, familiarity with the various components ensures optimal performance and longevity of your tools. This section delves into the intricacies of these essential parts, providing a clear overview of their functions and interconnections.

Visual aids play an important role in this understanding, as they illustrate how different elements fit together and interact. By examining a detailed representation of the assembly, users can easily identify each piece’s role within the larger mechanism. This knowledge is invaluable for troubleshooting and repairs, enabling smoother operations and minimizing downtime.

Equipped with this insight, individuals can approach maintenance tasks with confidence. Knowing which components require regular attention or replacement empowers users to keep their machinery running efficiently. In the following sections, we will explore various facets of this subject, shedding light on effective care and the importance of each element in the overall functionality of your equipment.

Overview and Features

This section provides a comprehensive look at a popular model known for its efficiency and reliability in outdoor maintenance tasks. Designed with both functionality and user convenience in mind, it stands out in its category for delivering exceptional performance across various applications.

Key attributes of this machine include a powerful engine that ensures robust operation, allowing users to tackle a range of landscaping duties with ease. Its user-friendly controls simplify operation, making it accessible for both novice and experienced users alike.

Additionally, the build quality is impressive, with durable materials that withstand rigorous use, ensuring longevity. Enhanced features such as adjustable settings provide versatility, allowing for tailored performance according to specific needs.

With a focus on efficiency, this model also incorporates design elements that minimize maintenance requirements, making it an ideal choice for those seeking reliability without excessive upkeep. Overall, it represents an excellent investment for anyone looking to maintain their outdoor spaces effectively.

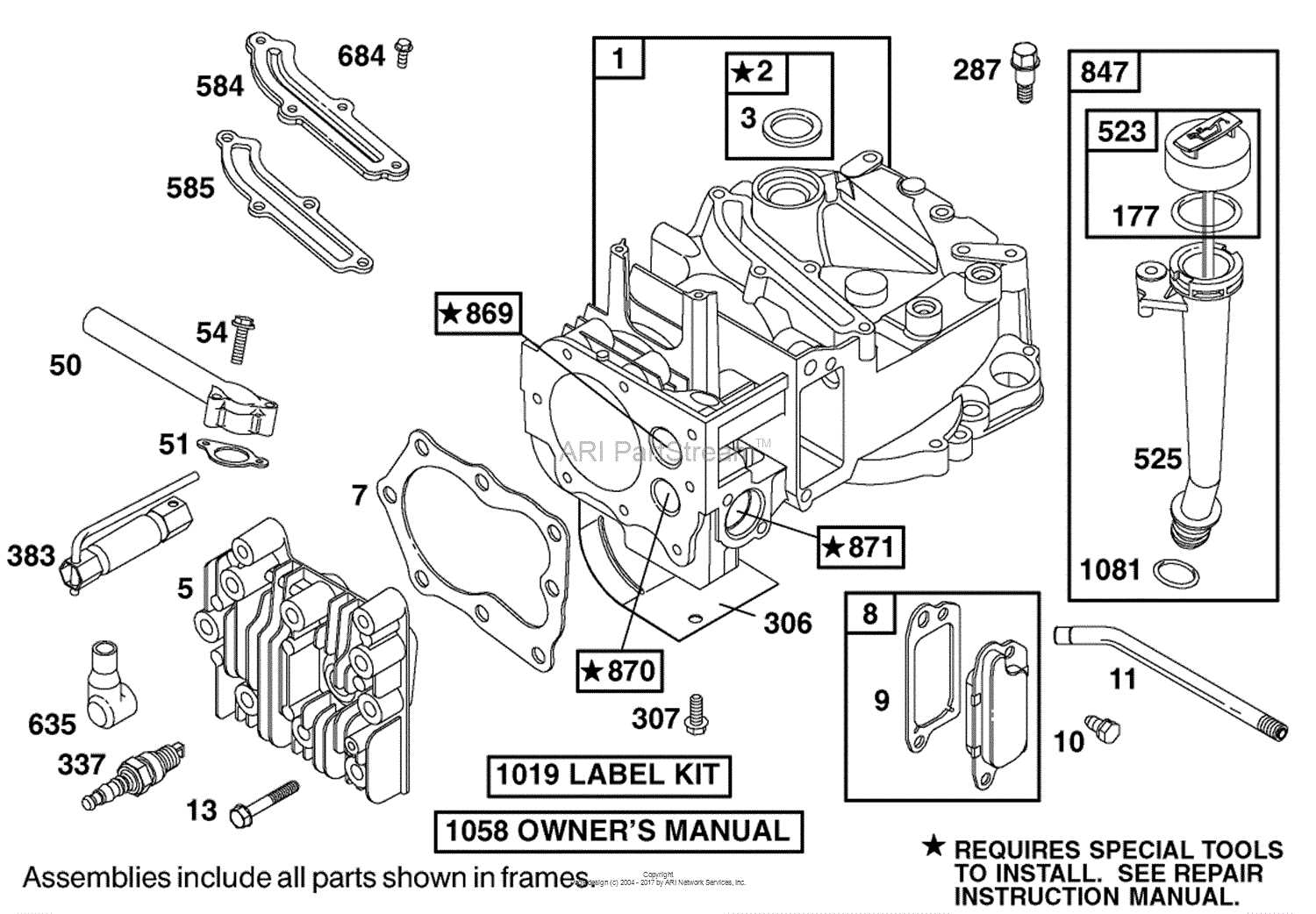

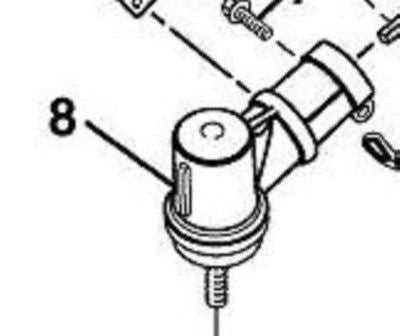

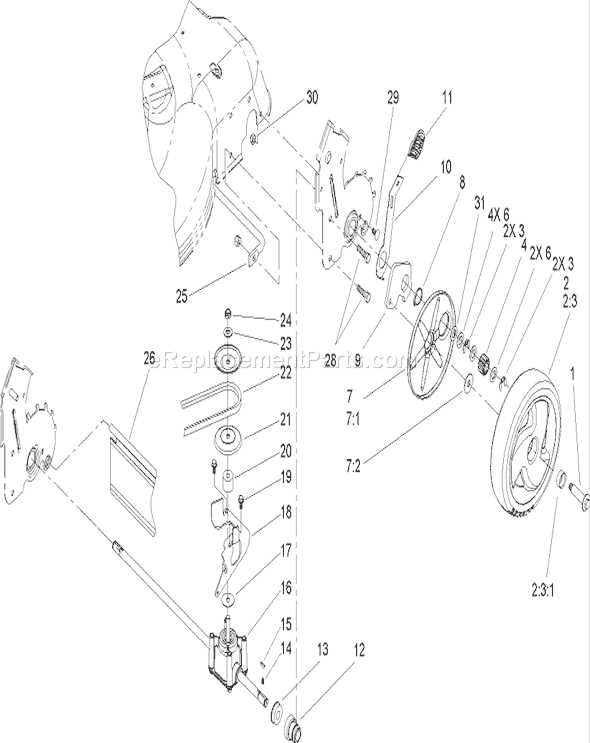

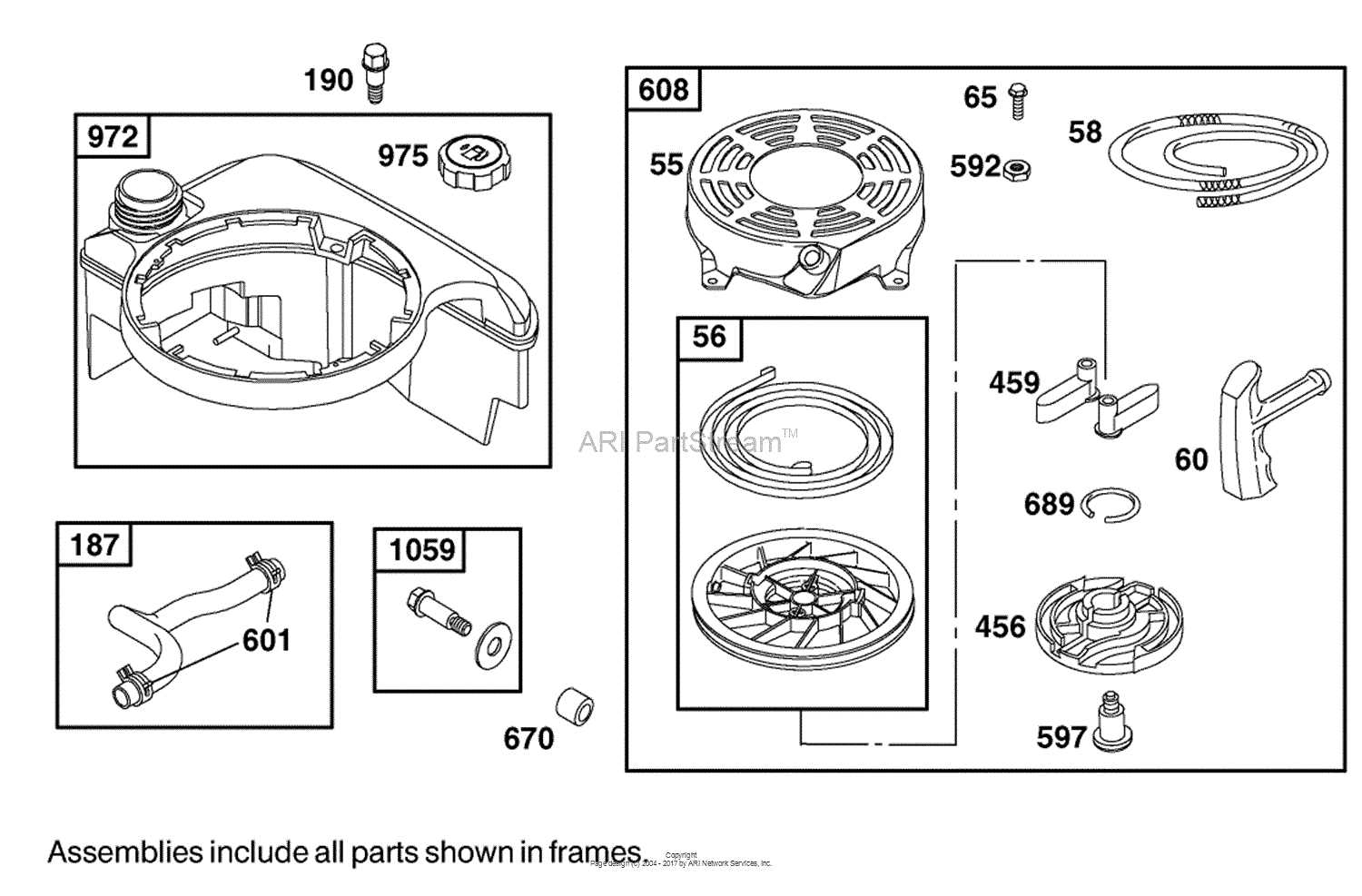

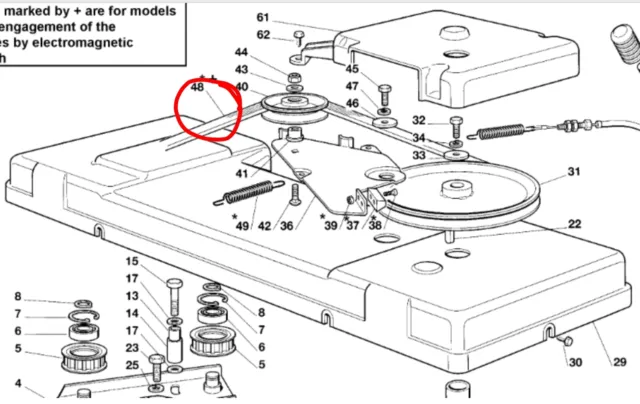

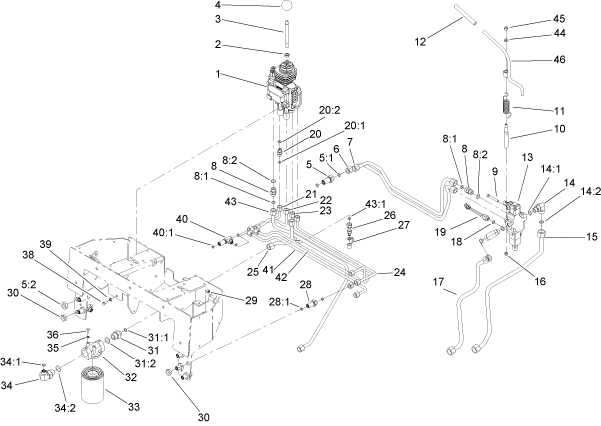

Understanding the Parts Diagram

Grasping the visual representation of components is crucial for efficient maintenance and repairs. This illustration serves as a valuable resource, allowing users to identify individual pieces and their relationships within the overall assembly.

Key benefits include:

- Facilitating quick identification of necessary components

- Enhancing understanding of assembly and disassembly processes

- Streamlining repairs by pinpointing specific parts

To effectively utilize this resource, consider the following steps:

- Familiarize yourself with the layout and symbols used.

- Cross-reference with manuals for detailed information.

- Make notes of frequently needed components for future reference.

By delving into this representation, users can achieve a greater efficiency in their maintenance tasks, ultimately prolonging the life of their equipment.

Common Issues with Toro 20042

When it comes to maintenance equipment, certain challenges frequently arise that can hinder performance and efficiency. Understanding these common problems can significantly enhance the user experience and prolong the lifespan of the machine.

Engine Troubles: One prevalent issue involves the engine failing to start or running inconsistently. This can stem from fuel quality, spark plug condition, or even the battery’s state.

Cutting Problems: Users often encounter uneven cutting or clogged blades. Regular cleaning and ensuring that the blades are sharp can mitigate these concerns.

Electrical Failures: Another area of concern is electrical malfunctions, which may arise from faulty wiring or issues with the ignition system. Regular inspections can help identify these problems early.

Fluid Leaks: Leaks can occur in various components, leading to decreased efficiency. Routine checks on seals and hoses are essential to prevent this issue.

By being aware of these common complications, users can take proactive measures to address them, ensuring optimal performance and longevity of their equipment.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing the right components is crucial for optimal performance. Whether you’re looking to enhance efficiency or simply replace a worn item, knowing where to locate these essentials can save both time and money.

Online Retailers

Numerous websites specialize in providing high-quality components for various models. Shopping online offers convenience and often a broader selection.

| Website | Features |

|---|---|

| www.equipmentparts.com | Extensive inventory, user-friendly navigation |

| www.partswarehouse.com | Competitive pricing, fast shipping options |

| www.mowersupplies.com | Specialized parts, expert customer support |

Local Dealers

Visiting nearby dealerships can provide immediate access to components and knowledgeable assistance. Establishing a relationship with local suppliers can also ensure you receive tailored recommendations.

Maintenance Tips for Toro 20042

Keeping your lawn equipment in optimal condition is essential for ensuring its longevity and performance. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. Here are some practical tips to help you maintain your machine effectively.

1. Regular Cleaning: After each use, take a moment to clean the exterior and undercarriage. Removing grass clippings and debris will prevent rust and damage over time.

2. Inspect and Change Fluids: Check the oil and fuel levels regularly. Changing the oil as recommended in the owner’s manual ensures the engine runs smoothly. Use fresh fuel to avoid issues with starting and performance.

3. Sharpen Blades: Dull blades can lead to uneven cuts and stress the engine. Sharpen them at the start of each season and check for damage before use.

4. Check Belts and Cables: Inspect belts for wear and ensure cables are intact. Replace any frayed or damaged components to maintain safe operation.

5. Battery Maintenance: If your equipment uses a battery, ensure it is charged and connections are clean. A well-maintained battery extends the life of your machine.

6. Store Properly: When not in use, store your equipment in a dry, covered area. This helps protect it from the elements and prolongs its lifespan.

By following these maintenance practices, you can ensure your machine remains efficient and reliable for years to come.

Comparing Toro Models and Parts

When examining various models from a renowned manufacturer, it’s essential to explore the differences in their components and features. Each design serves unique needs, showcasing innovations tailored for specific applications. This analysis aims to highlight key aspects that differentiate these offerings, making it easier for consumers to make informed decisions.

Design Variations

Different models often exhibit distinctive engineering solutions, catering to a range of user preferences. For instance, some versions might prioritize efficiency, while others focus on durability or ease of use. Understanding these variations can significantly enhance the user experience, ensuring the selected machine aligns with intended tasks.

Component Interchangeability

Another critical aspect is the interchangeability of elements across various designs. While some features may be specific to a particular model, others might be compatible across several versions. Assessing compatibility can provide significant cost savings and simplify maintenance, allowing users to optimize their investments over time.

Assembly Instructions for Toro 20042

Proper assembly is crucial for the optimal performance of your equipment. Following a structured approach ensures that each component is fitted correctly, enhancing durability and efficiency. This guide provides step-by-step instructions to help you achieve a seamless assembly process.

Step-by-Step Process

Begin by organizing all components and tools required for assembly. Refer to the manufacturer’s guidelines for specific instructions related to each piece. Start with the main unit, ensuring all connections are secure before moving on to auxiliary parts. Attention to detail at this stage is vital.

Final Checks

Once assembled, conduct a thorough inspection of all joints and connections. Make sure there are no loose parts. This final check will guarantee that your machine operates at its ultimate efficiency, minimizing the risk of future issues.

Benefits of Using Original Parts

Choosing authentic components for machinery ensures optimal performance and longevity. These high-quality items are specifically designed to fit seamlessly, reducing the risk of malfunctions and enhancing efficiency.

Original pieces often come with warranties, providing peace of mind and protection against defects. This assurance can lead to lower long-term costs, as the durability of these items typically results in fewer replacements and repairs.

Moreover, using genuine components helps maintain the integrity of the equipment, preserving its resale value. Owners can expect superior compatibility, which minimizes wear and tear on other parts, ultimately supporting a smoother operation.

In addition, the use of original elements contributes to safety, as they adhere to strict quality standards. This commitment to excellence not only protects the user but also enhances the overall functionality of the machine.

DIY Repairs and Troubleshooting

Maintaining equipment can often seem daunting, but with the right guidance, many common issues can be resolved at home. Understanding how your machine functions and identifying problems early on can save you both time and money. This section focuses on practical solutions and tips to help you tackle minor repairs and improve the longevity of your tools.

Identifying Common Issues

Before jumping into repairs, it’s crucial to diagnose the problem accurately. Common signs such as unusual noises, decreased performance, or visible wear can indicate specific issues. Make a checklist of symptoms and consult your manual for troubleshooting guidance. This proactive approach will help you pinpoint the root cause effectively.

Simple Repair Techniques

Once you have identified the problem, several straightforward methods can often lead to a resolution. Regularly cleaning components, checking for loose connections, and replacing worn-out parts are essential practices. Additionally, familiarizing yourself with basic tools and techniques can empower you to perform many repairs without the need for professional assistance.

Frequently Asked Questions About Toro

This section addresses common inquiries regarding equipment maintenance, troubleshooting, and accessories. Understanding these aspects can enhance user experience and extend the life of your machinery.

| Question | Answer |

|---|---|

| What should I do if my machine won’t start? | Check the fuel level, battery connections, and any safety features that may prevent starting. |

| How often should I perform maintenance? | Regular maintenance should be conducted according to the user manual, typically every season or after a specific number of hours of operation. |

| Where can I find replacement components? | Replacement parts can be sourced from authorized dealers or online retailers specializing in outdoor equipment. |

| What accessories are recommended for better performance? | Consider attachments or enhancements that suit your tasks, such as mulching kits or specific blades for your needs. |