In the realm of utility vehicles, having a clear understanding of the individual components and their arrangement is crucial for efficient maintenance and operation. This knowledge allows operators to easily identify necessary repairs and replacements, ultimately enhancing the longevity and performance of the vehicle. An organized layout provides an accessible reference for both seasoned mechanics and casual users alike.

Delving into the intricate configuration of various assemblies offers insights into how each element interacts within the overall system. By familiarizing oneself with these layouts, individuals can streamline their repair processes and ensure that they are utilizing the correct components during maintenance. This section aims to demystify the complexities of utility vehicle arrangements and highlight essential elements that contribute to optimal functionality.

Ultimately, understanding the structure and positioning of critical elements not only aids in troubleshooting but also fosters a deeper appreciation for the engineering that underpins these robust machines. This knowledge empowers users to engage more confidently with their vehicles, leading to improved care and reliability over time.

Understanding the Kubota RTV 900 Model

This section delves into the essential features and functionalities of a well-regarded utility vehicle, known for its versatility and rugged performance. Designed to meet the demands of both work and recreational activities, this model combines robust engineering with user-friendly elements, making it a popular choice among various operators.

Key Features of the Utility Vehicle

Equipped with a powerful engine and an efficient drivetrain, this model excels in various terrains. Its sturdy construction ensures durability, while the spacious cabin provides comfort for passengers. Additionally, the advanced suspension system enhances stability, allowing for smooth navigation even in challenging conditions.

Applications and Versatility

Ideal for agricultural tasks, landscaping, and light towing, this vehicle is suited for a range of applications. Its adaptability makes it valuable not only for farming and maintenance but also for recreational uses, catering to outdoor enthusiasts who seek reliable transportation in diverse environments.

Key Components of RTV 900

This section explores the essential elements that contribute to the functionality and efficiency of the utility vehicle. Understanding these components can enhance the overall performance and maintenance of the machine.

Major Parts

- Engine: The powerhouse that drives the entire vehicle, providing the necessary torque and horsepower.

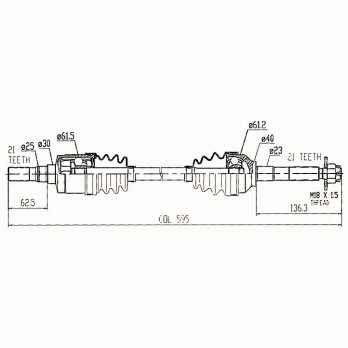

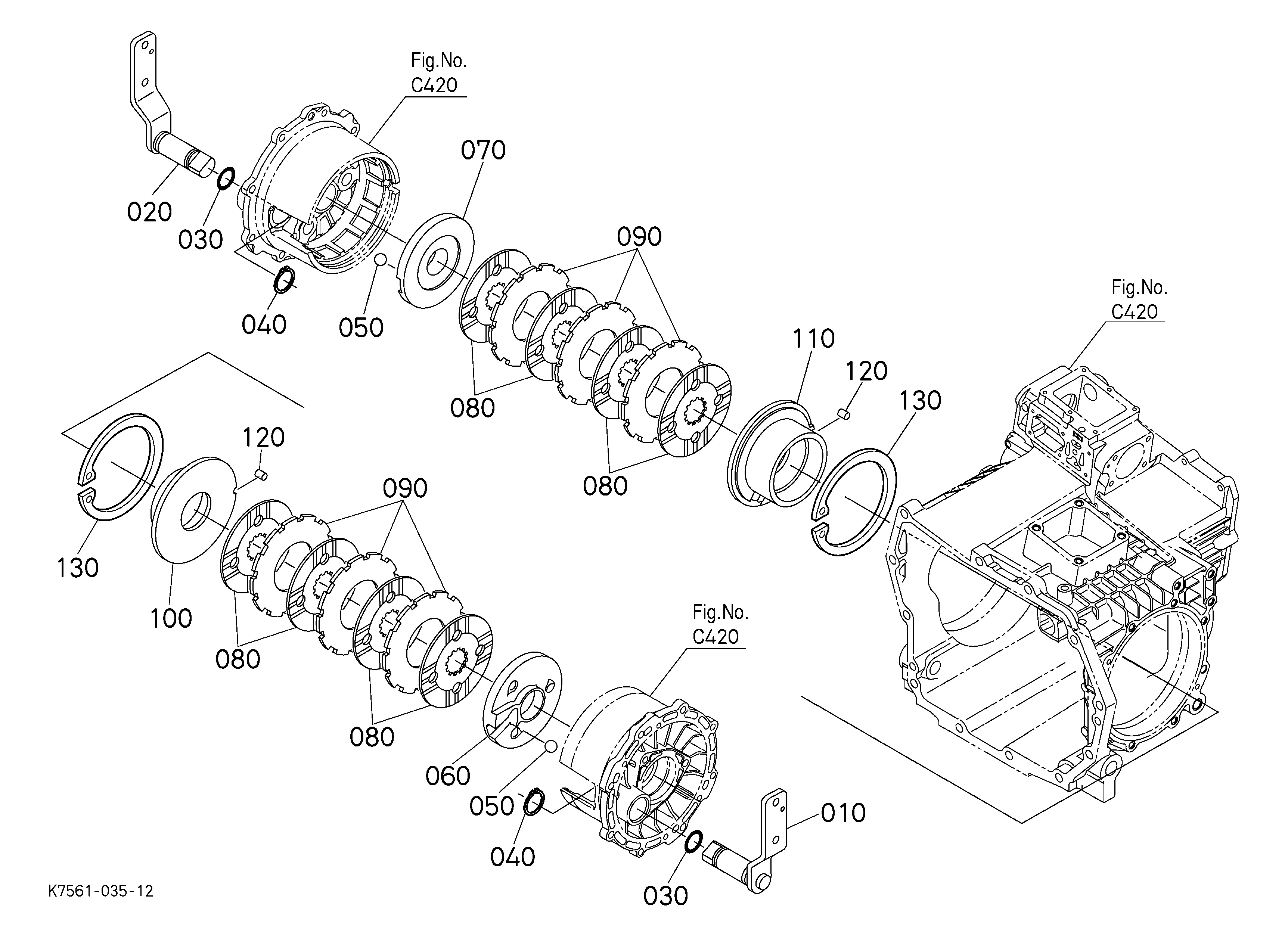

- Transmission: This component facilitates the transfer of power from the engine to the wheels, ensuring smooth acceleration and speed management.

- Suspension System: A critical system designed to absorb shocks and maintain stability during operation on varied terrains.

- Braking System: Essential for safety, this mechanism allows for controlled stopping and enhances maneuverability.

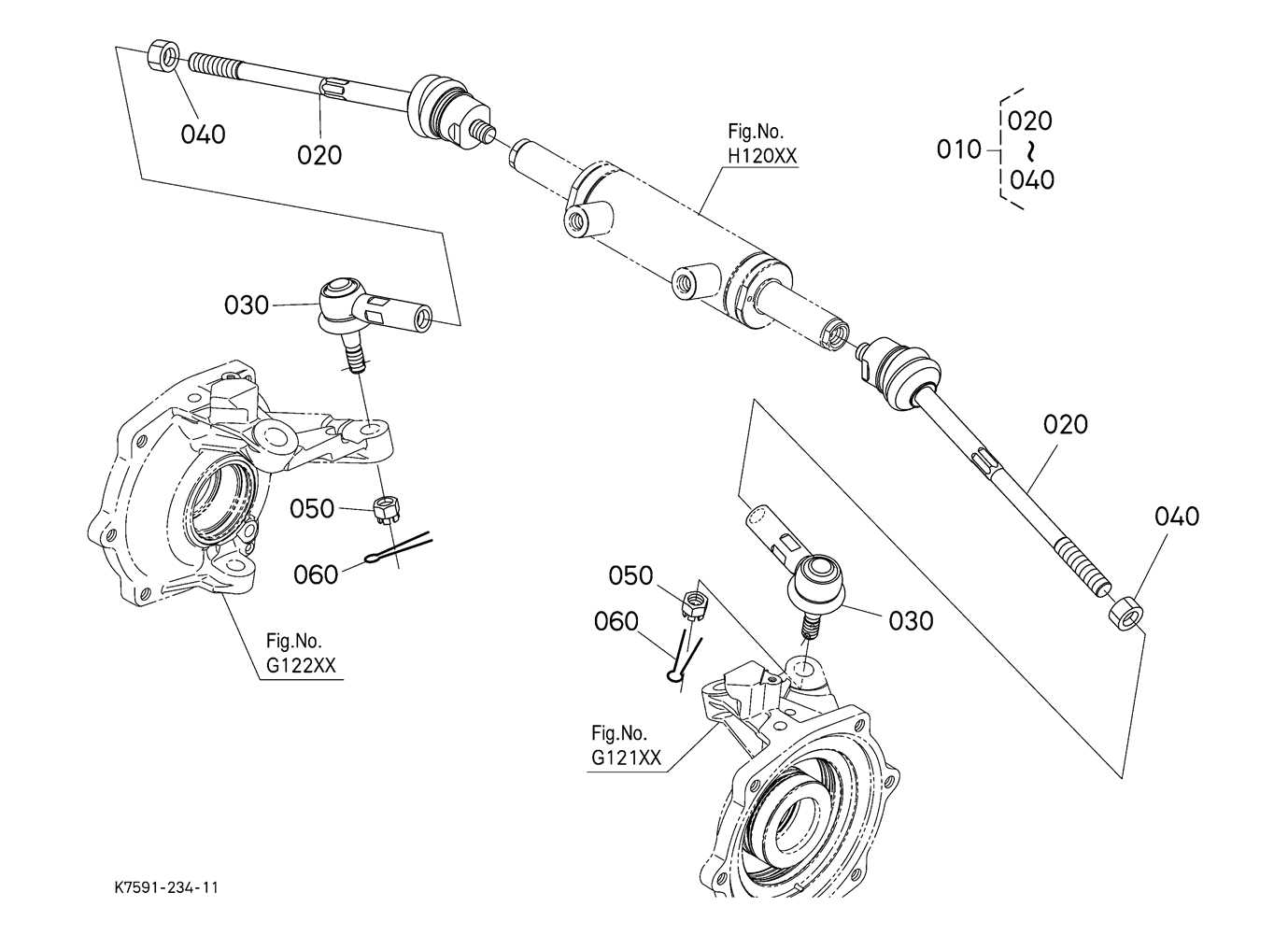

- Steering Assembly: This component provides directional control, enabling precise handling of the vehicle.

Additional Features

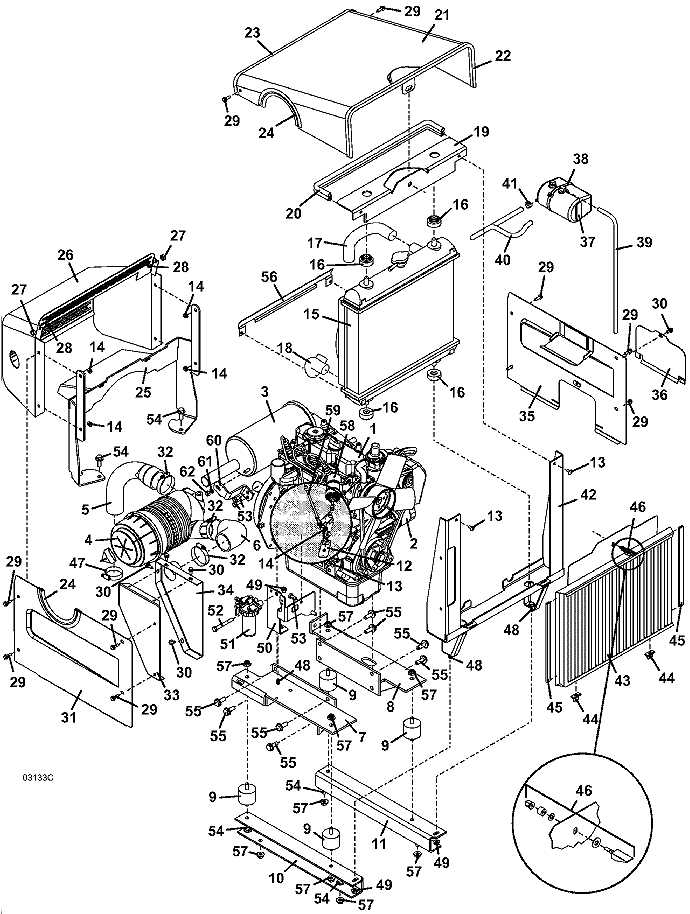

- Fuel System: Responsible for delivering the necessary fuel to the engine for efficient operation.

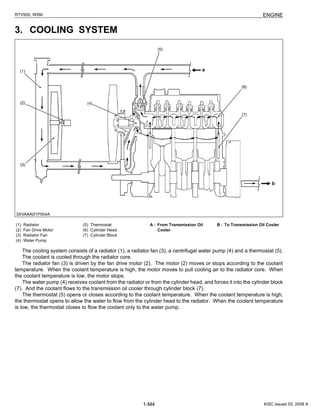

- Cooling System: Maintains optimal engine temperature, preventing overheating during extended use.

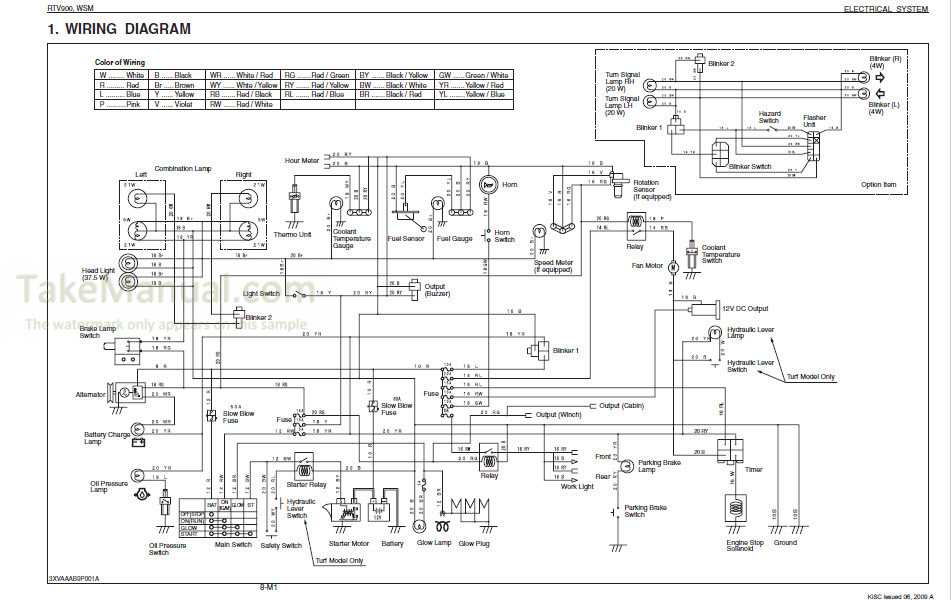

- Electrical System: Powers all electrical components, including lights, ignition, and instrumentation.

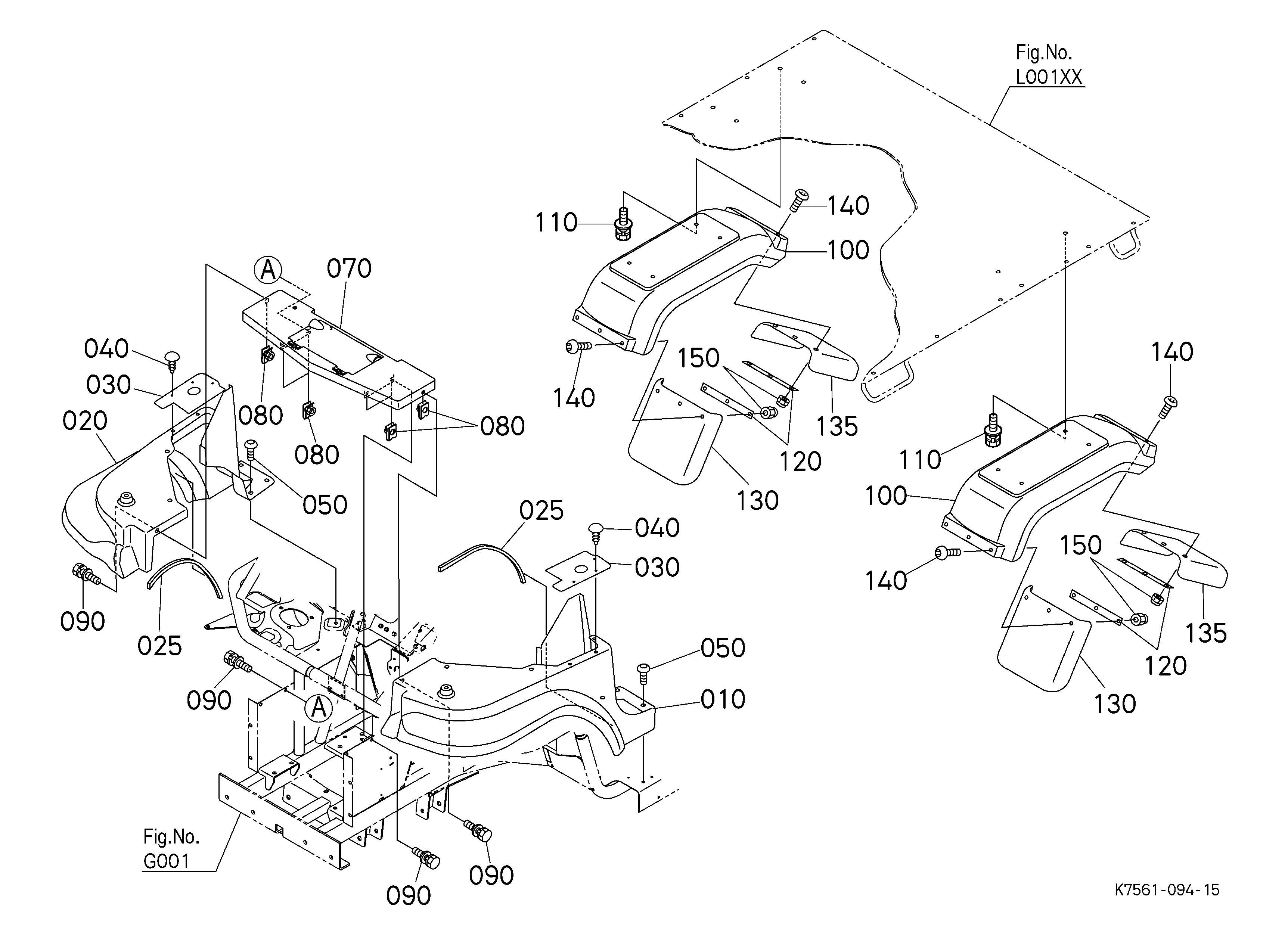

- Frame and Chassis: The structural foundation that supports all other components, providing durability and strength.

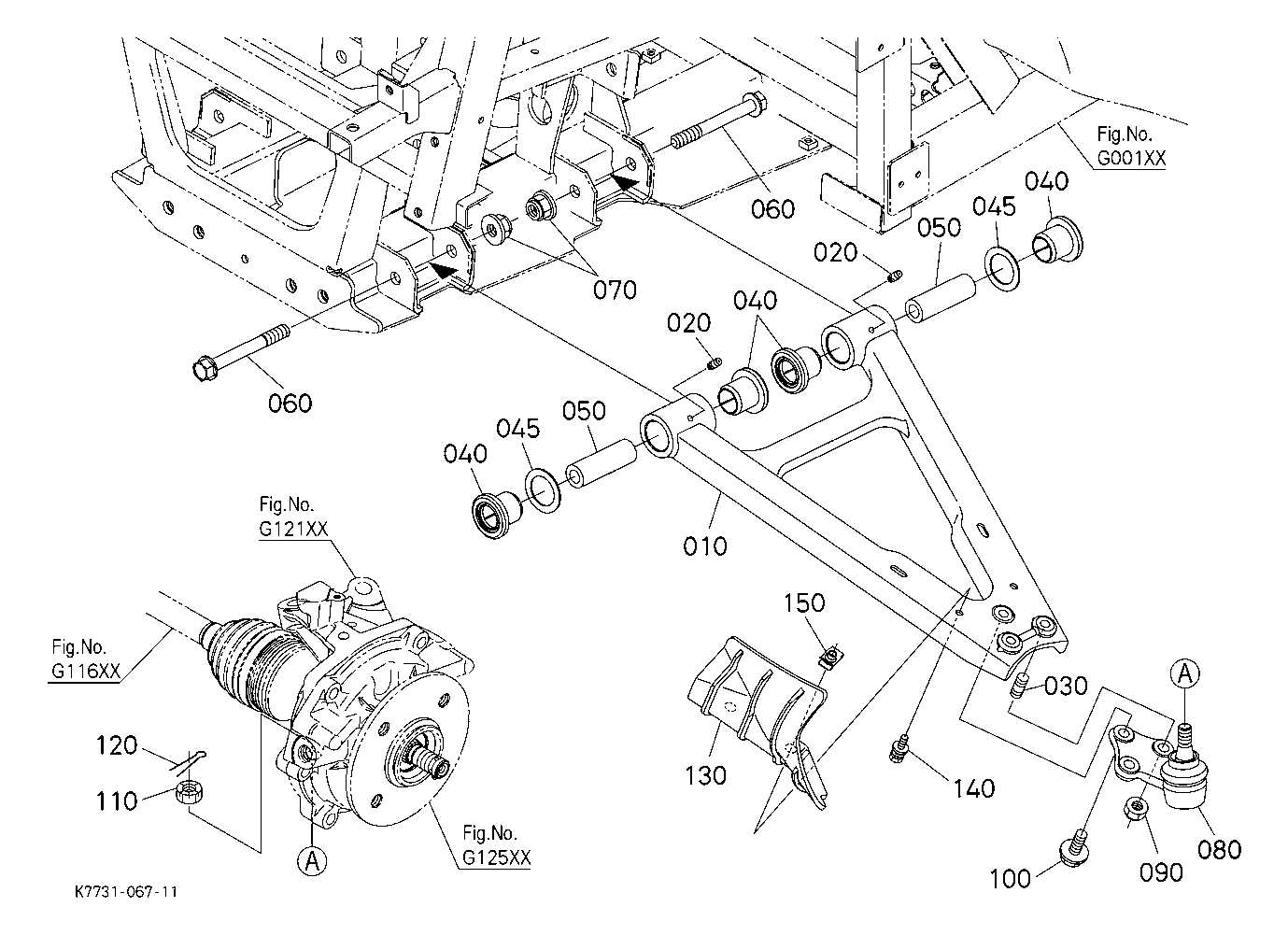

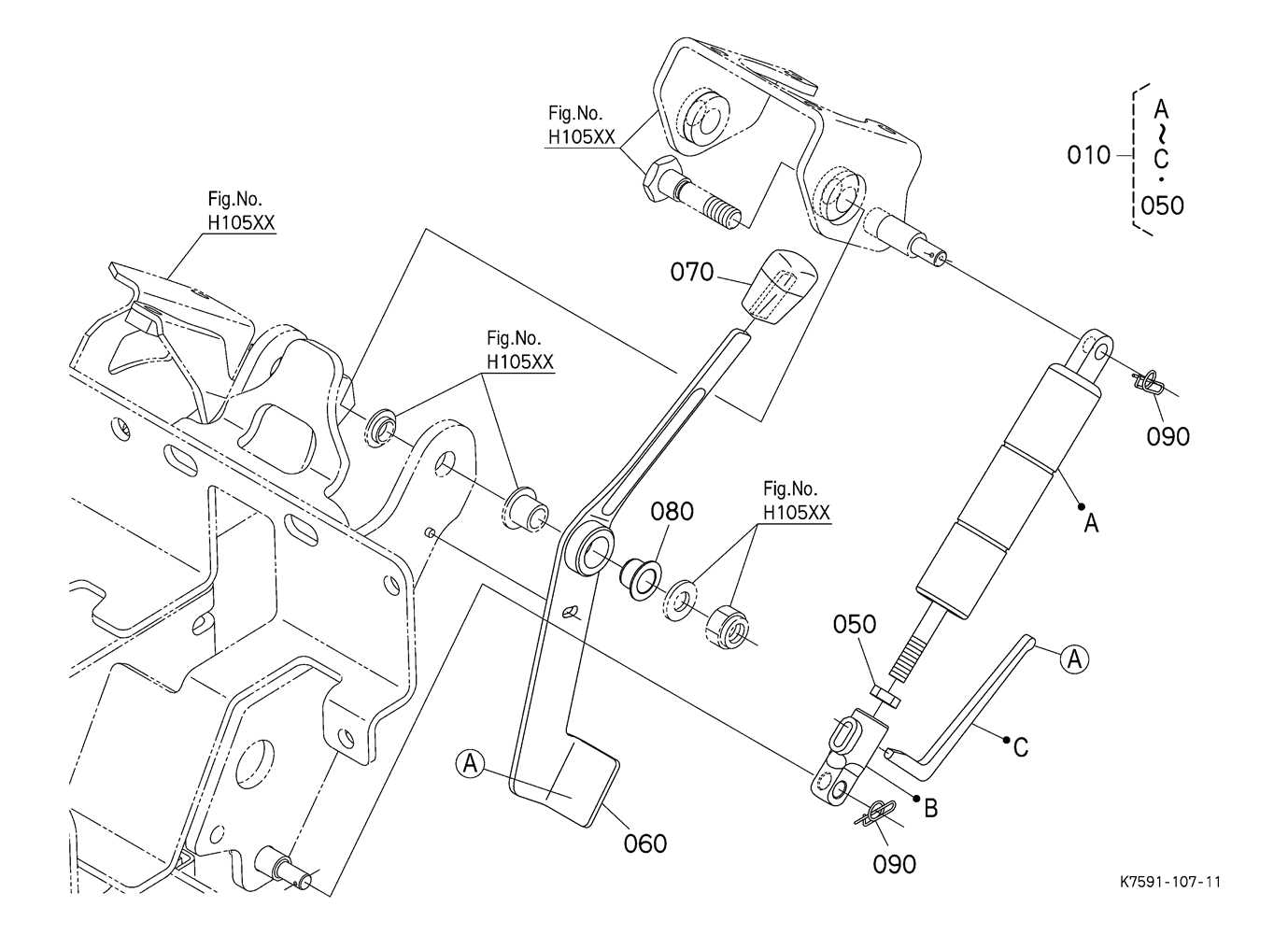

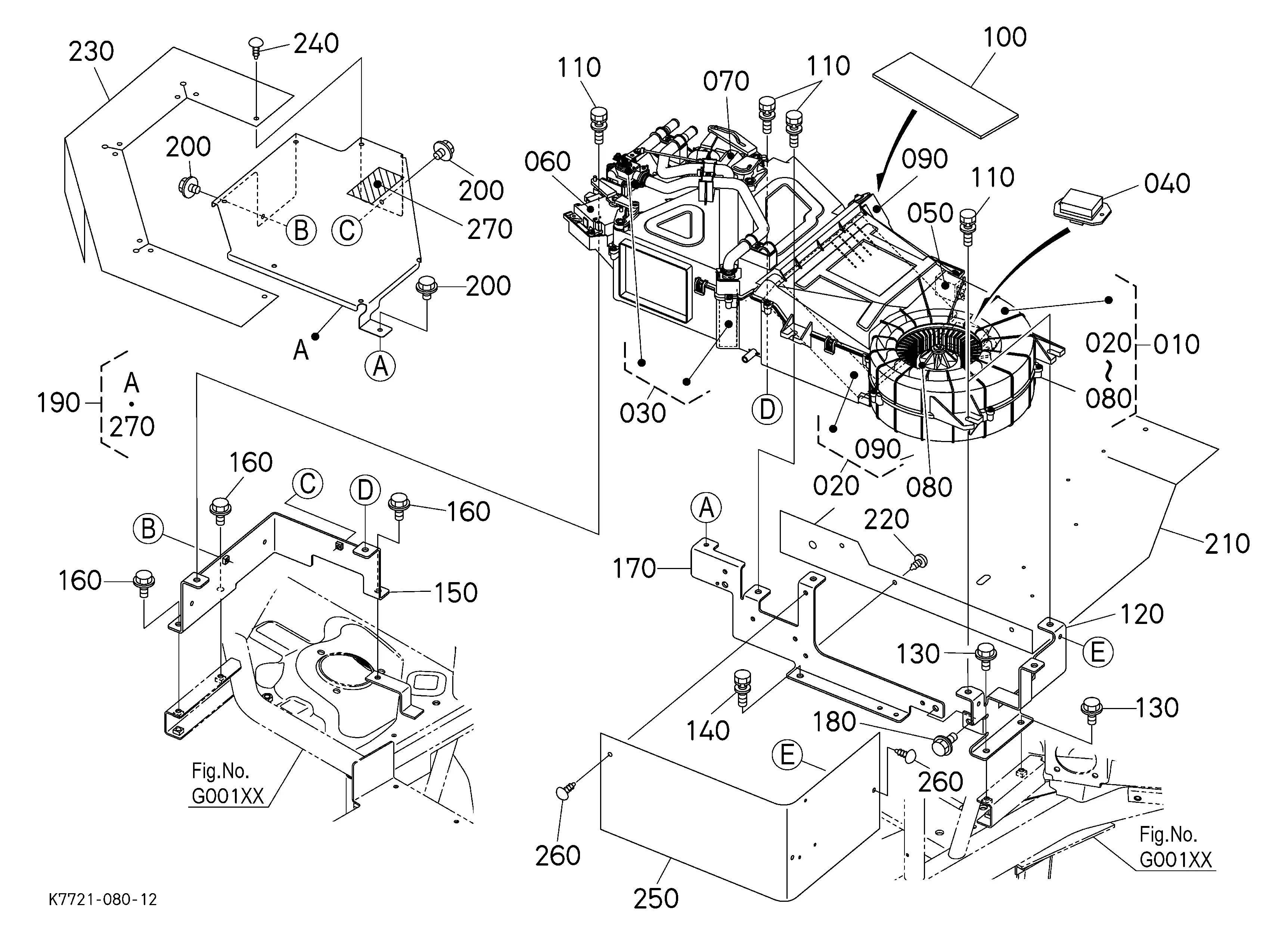

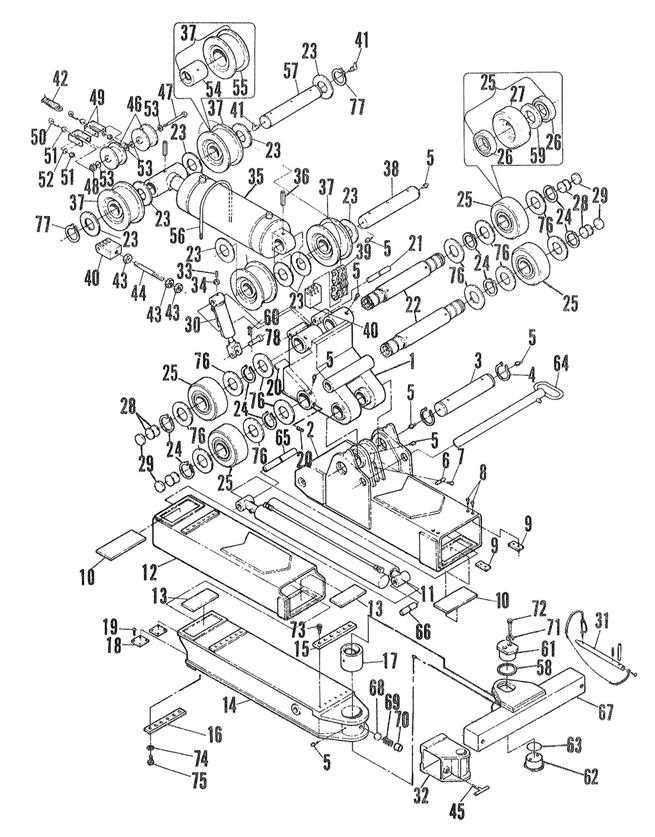

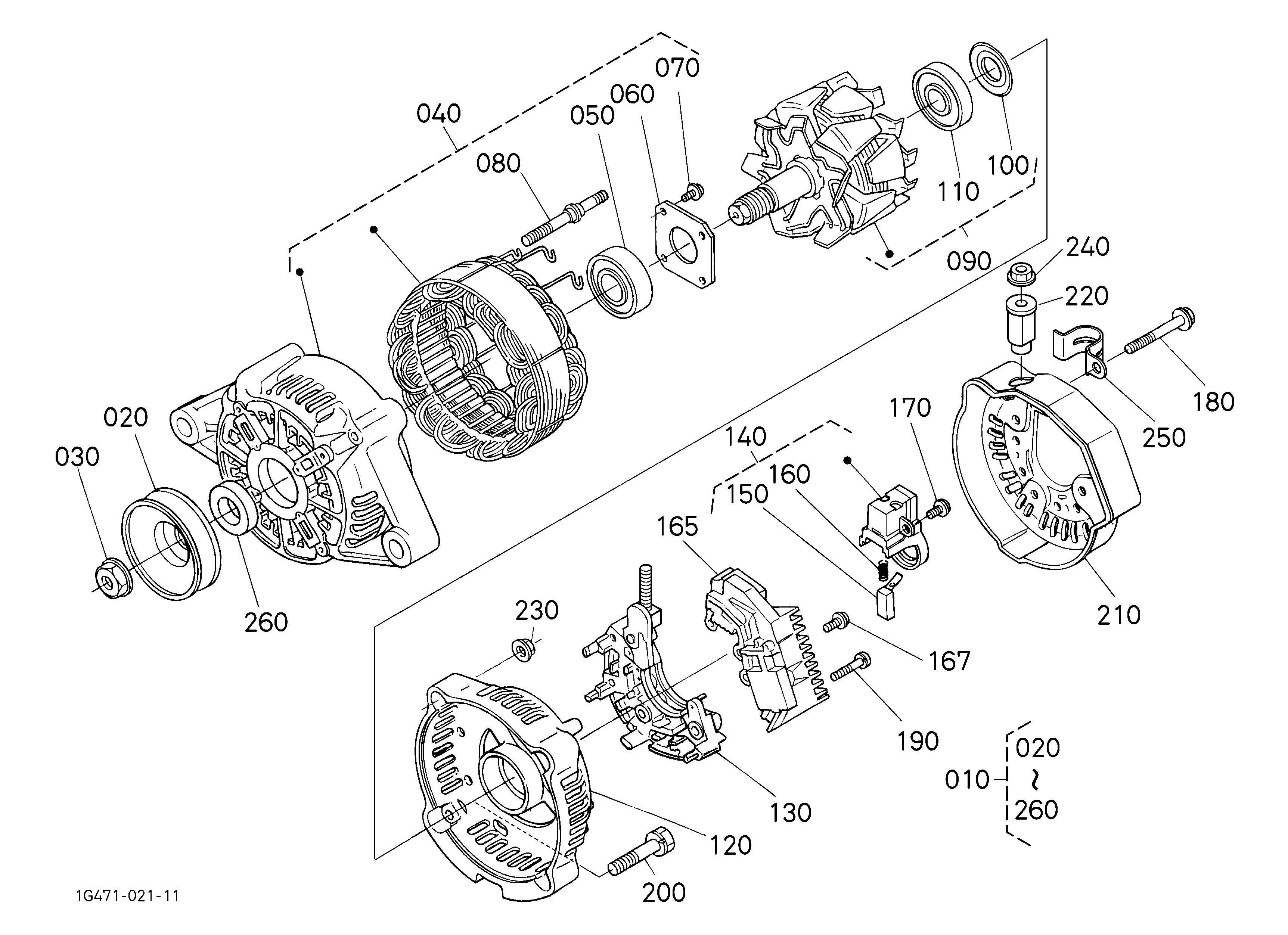

Importance of Parts Diagrams

Understanding the intricate layout of components within a machine is essential for effective maintenance and repair. Visual representations of these assemblies provide crucial insights, enabling users to identify individual elements and their specific functions. This knowledge is vital for ensuring that each part operates harmoniously, contributing to the overall performance and longevity of the equipment.

Accurate identification of components is one of the primary benefits of these visual aids. When working on repairs or upgrades, having a clear reference allows technicians to locate the exact piece they need without confusion. This accuracy not only streamlines the repair process but also minimizes the risk of errors that could lead to further complications.

Moreover, diagrams serve as a valuable educational resource, particularly for those new to machinery maintenance. They simplify complex assemblies into understandable visuals, making it easier for individuals to grasp how different parts interact. This foundational knowledge can empower users to perform routine checks and minor repairs independently, fostering a sense of confidence and competence.

In addition, these illustrations facilitate efficient ordering of replacements. When a specific component needs to be replaced, having a visual guide allows users to reference the part number accurately, ensuring they receive the correct item. This efficiency not only saves time but also reduces costs associated with misordered supplies.

Ultimately, the significance of these visual representations extends beyond mere identification; they enhance overall operational efficiency, support learning, and contribute to informed decision-making during maintenance tasks.

Navigating the Parts Manual

Understanding the components of any machinery is crucial for effective maintenance and repair. A well-structured reference guide serves as an essential tool, providing users with comprehensive information on each element of the equipment. This section will explore how to efficiently utilize such a guide to ensure a smooth operation and prolong the lifespan of the machinery.

Key Features of the Manual

- Illustrative Diagrams: Visual representations aid in identifying various components quickly.

- Component Listings: Detailed lists categorize items by function, making it easier to locate specific parts.

- Part Numbers: Unique identifiers simplify ordering replacements and ensure compatibility.

Utilizing the Manual Effectively

- Familiarize yourself with the layout and sections of the guide.

- Refer to the index for quick access to specific components.

- Cross-reference part numbers with the manufacturer for accurate replacements.

- Make notes on frequently referenced items for future use.

Common Issues and Solutions

In the realm of utility vehicles, various challenges can arise over time, impacting performance and reliability. Understanding these frequent problems and their corresponding remedies is essential for maintaining optimal operation. Below are some typical issues encountered and effective solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Engine Not Starting | This can occur due to battery failure, fuel issues, or ignition problems. | Check battery connections, ensure fuel is available, and inspect ignition components. |

| Overheating | Excessive heat can result from coolant leaks or a malfunctioning thermostat. | Examine the cooling system for leaks and replace the thermostat if necessary. |

| Poor Steering Response | Difficulty in steering may indicate low fluid levels or a faulty steering mechanism. | Verify fluid levels and inspect the steering system for wear or damage. |

| Brake Issues | Brake failure or reduced effectiveness can be caused by worn pads or low fluid. | Replace brake pads as needed and top off brake fluid to the appropriate level. |

| Electrical Failures | Malfunctions in lights or other electrical components can stem from wiring issues. | Inspect wiring for damage and replace any faulty connectors or components. |

Identifying OEM and Aftermarket Parts

When maintaining or repairing your utility vehicle, distinguishing between original equipment manufacturer (OEM) components and aftermarket alternatives is crucial. Each type of component has its advantages and potential drawbacks, impacting performance, durability, and warranty considerations. Understanding these differences can help you make informed choices, ensuring your vehicle operates efficiently.

Understanding OEM Components

Original parts are manufactured by the same company that produced the vehicle, ensuring compatibility and quality. These components often come with warranties and are designed to meet the specific standards of the original model, providing peace of mind regarding reliability and performance.

Exploring Aftermarket Alternatives

Aftermarket components, on the other hand, are produced by third-party manufacturers. While they can often be more affordable, the quality may vary. Some aftermarket options may exceed OEM specifications, offering enhanced features or improved performance, while others may not provide the same level of durability.

| Feature | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality Assurance | High, meets manufacturer standards | Varies, dependent on the manufacturer |

| Price | Generally higher | Often more affordable |

| Warranty | Included, often longer | Varies by manufacturer |

| Availability | Usually limited to authorized dealers | Widely available through various retailers |

Tools for Effective Maintenance

Proper upkeep of machinery requires a set of essential instruments that ensure optimal functionality and longevity. Utilizing the right tools not only enhances the efficiency of maintenance tasks but also reduces the risk of damage to the equipment. This section discusses various implements that are indispensable for thorough maintenance practices.

Essential Hand Tools

Hand tools form the backbone of maintenance activities. Wrenches, screwdrivers, and pliers are vital for performing adjustments and repairs. Quality hand tools allow for precise work, making it easier to access tight spaces and secure fittings effectively. Ensuring that these tools are readily available can significantly streamline the maintenance process.

Diagnostic Equipment

Incorporating diagnostic instruments into your maintenance toolkit is crucial for identifying issues before they escalate. Devices such as multimeters and diagnostic scanners enable users to assess the operational status of various components. These tools provide valuable insights, helping to pinpoint problems accurately and facilitate timely interventions.

Replacing Worn-Out Components

Over time, various elements of machinery may degrade due to regular use, leading to decreased efficiency and performance. Identifying and replacing these deteriorated parts is crucial for maintaining the overall functionality of your equipment. Proper attention to this process not only enhances performance but also extends the lifespan of the entire system.

When it comes to swapping out components, it’s essential to first diagnose which parts have suffered the most wear and tear. Common culprits include bearings, bushings, and seals. Inspecting these areas regularly can help you catch issues before they escalate. Using quality replacement components is equally important; opting for genuine or high-quality aftermarket options ensures reliability and compatibility with your machinery.

During the replacement process, make sure to follow manufacturer guidelines for installation. This practice ensures that each component is fitted correctly, reducing the risk of future failures. Additionally, keep a record of the parts replaced and their respective service dates; this information is invaluable for planning future maintenance and repairs.

Ultimately, prioritizing the replacement of worn-out elements is a proactive approach to machinery care. By taking these steps, you can enhance operational efficiency and prevent unexpected downtime caused by malfunctioning components.

Upgrading Performance Parts

Enhancing the functionality and efficiency of your utility vehicle can significantly improve its overall performance. By selecting high-quality components, operators can experience increased power, better handling, and improved durability. This section will delve into various options available for optimizing the capabilities of your vehicle.

Engine Modifications: One of the most effective ways to boost performance is through engine enhancements. Upgrading to a high-flow air filter can increase airflow, resulting in improved combustion and power output. Additionally, performance exhaust systems can help reduce back pressure, allowing the engine to breathe better and operate more efficiently.

Suspension Upgrades: A stable and responsive suspension system is crucial for maintaining control, especially in rugged terrains. Consider installing heavy-duty shock absorbers and springs designed for enhanced load capacity and comfort. This will not only improve handling but also provide a smoother ride during off-road adventures.

Tire and Wheel Enhancements: Selecting the right tires can dramatically affect traction and stability. Upgrading to all-terrain or mud-terrain tires ensures better grip on various surfaces, making it easier to navigate challenging environments. Additionally, lightweight alloy wheels can reduce unsprung weight, improving acceleration and braking performance.

Brake System Improvements: Enhancing the braking system is essential for safety and performance. Upgrading to larger, high-performance brake rotors and pads can increase stopping power and reduce fade during heavy use. Consider installing a dual-circuit braking system for added reliability and efficiency.

By focusing on these key areas, you can effectively elevate the performance of your vehicle, ensuring it meets the demands of any task while providing an enjoyable driving experience.

Maintenance Tips for Longevity

Ensuring the durability of machinery requires consistent care and attention to detail. By implementing effective maintenance practices, operators can significantly extend the lifespan of their equipment. Here are essential strategies to keep in mind.

Regular Inspections

- Conduct thorough checks on all components, looking for signs of wear or damage.

- Pay attention to fluid levels and ensure they are within recommended ranges.

- Inspect tires and tracks for proper inflation and wear patterns.

Routine Servicing

- Follow a scheduled servicing plan that includes oil changes, filter replacements, and other key maintenance tasks.

- Use manufacturer-recommended lubricants and fluids to enhance performance.

- Keep the exterior clean to prevent rust and corrosion.

By adhering to these guidelines, users can maintain their equipment in peak condition, reducing the likelihood of unexpected breakdowns and costly repairs.

Resources for Parts Purchase

Finding reliable sources for obtaining components is crucial for maintaining the functionality of your equipment. Various options are available to ensure that you can procure the necessary elements efficiently and effectively.

Online Retailers

Numerous online platforms offer a wide selection of components. These websites often provide detailed descriptions, customer reviews, and competitive pricing.

- Amazon: A vast marketplace with various sellers.

- eBay: An auction site that may offer used or new items at different prices.

- Specialty Websites: Platforms dedicated to equipment parts, providing specific options tailored to your needs.

Local Dealerships and Stores

Visiting local dealers can provide immediate access to essential components. Engaging with knowledgeable staff can also offer valuable insights into compatibility and installation.

- Authorized Dealers: Official representatives that ensure the quality and authenticity of the components.

- Hardware Stores: General supply stores that may carry a selection of compatible items.

Connecting with Kubota Communities

Engaging with fellow enthusiasts can greatly enhance your experience and knowledge about machinery. These communities provide a wealth of information, support, and camaraderie for individuals interested in similar equipment. Whether you are seeking advice, sharing experiences, or looking for parts, being part of a dedicated group can be incredibly beneficial.

Benefits of Joining Enthusiast Groups

- Access to valuable insights and tips from experienced users.

- Opportunities to participate in events and gatherings.

- Ability to exchange information regarding maintenance and upgrades.

- Networking with like-minded individuals.

Where to Find Community Support

- Online Forums: Websites dedicated to equipment discussions often have sections for specific models and brands.

- Social Media Groups: Platforms like Facebook and Reddit host numerous groups focused on various machinery.

- Local Clubs: Many areas have clubs or organizations that meet regularly to discuss interests and share knowledge.

- Trade Shows and Expos: Attending industry events can help you connect with fellow enthusiasts and professionals.

FAQs about RTV 900 Parts

This section addresses common inquiries regarding components related to the utility vehicle, offering clarity and guidance for those seeking information on maintenance, replacement, and compatibility of various elements.

Common Questions

- What are the most frequently replaced components?

- How can I identify the specific parts I need?

- Are there aftermarket options available for essential components?

- What tools are required for basic repairs and replacements?

Understanding Compatibility

It is crucial to ensure that any replacements are compatible with the vehicle model. Consider the following:

- Check the manufacturer’s specifications for compatibility.

- Consult with local dealerships or authorized distributors for guidance.

- Look for user reviews or forums discussing part compatibility and performance.