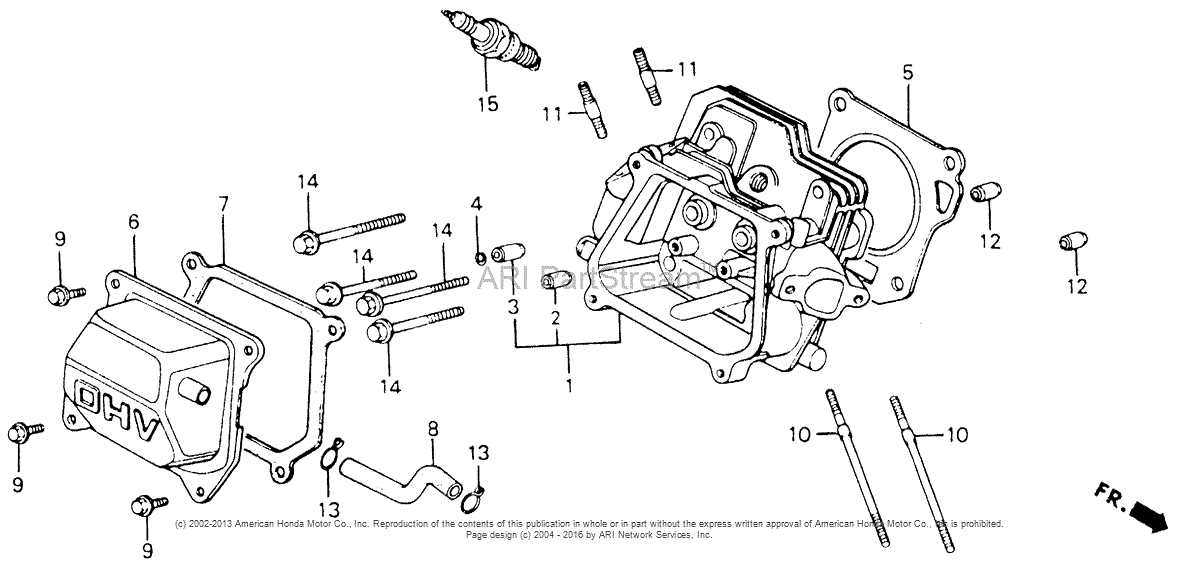

When delving into the intricacies of small machinery, one often encounters the need for a clear representation of the various elements that constitute the engine’s framework. These visual guides are invaluable for enthusiasts and professionals alike, serving as a roadmap to navigate the complexities of assembly and maintenance.

Such illustrations provide detailed insights into the arrangement and function of each piece, enabling users to identify specific components swiftly. This understanding is crucial for effective troubleshooting and ensuring optimal performance of the machinery.

Moreover, having a comprehensive visual reference facilitates the process of sourcing replacements or upgrades, empowering individuals to make informed decisions regarding repairs. By familiarizing oneself with these layouts, users can enhance their skills and confidence in managing their equipment.

Understanding Honda GX110 Engine Components

Exploring the intricacies of small engine elements reveals a complex interplay of parts that ensure optimal performance. Each component plays a critical role in the overall functionality, contributing to efficiency and reliability.

Key Elements of the Engine

The engine consists of various integral parts, each designed for specific functions. Understanding these components aids in maintenance and troubleshooting, leading to a more effective operation.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts fuel combustion into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Camshaft | Controls the opening and closing of valves. |

| Valves | Regulate the intake of air and exhaust of gases. |

Maintaining Performance

Regular inspection and understanding of these engine components are vital for sustaining performance over time. Identifying potential wear and tear can prevent significant issues and enhance longevity.

Key Features of Honda GX110

This compact engine offers a blend of reliability and efficiency, making it a popular choice for various applications. Its design prioritizes performance while ensuring ease of maintenance, providing users with a dependable power source for their equipment.

Efficiency and Performance

The engine is designed to deliver exceptional fuel efficiency, allowing for longer operational periods without frequent refueling. Its robust construction ensures that it can handle demanding tasks while maintaining optimal performance.

Durability and Maintenance

Constructed with high-quality materials, this engine is built to withstand wear and tear, ensuring longevity. Additionally, its straightforward design simplifies maintenance tasks, allowing users to keep it in peak condition with minimal effort.

Importance of Parts Diagrams

Understanding the structure and components of a machine is crucial for efficient maintenance and repair. Visual representations provide clarity, enabling users to identify individual elements and their functions. This knowledge not only aids in troubleshooting but also streamlines the assembly process, ensuring that each piece fits seamlessly within the larger system.

These illustrations serve as essential references for technicians and enthusiasts alike. They simplify the process of ordering replacements, as individuals can easily pinpoint specific components that require attention. Furthermore, having a clear view of the arrangement promotes better understanding of how various parts interact, leading to improved performance and longevity of the equipment.

In addition, visual guides foster a sense of confidence among users, particularly those less familiar with machinery. By offering a straightforward approach to maintenance tasks, these resources empower individuals to take proactive steps in preserving their equipment. Ultimately, effective visual tools play a vital role in enhancing overall efficiency and reducing downtime.

Common Issues with GX110 Engines

Small engines are known for their durability, yet they can encounter several recurring problems that may affect performance and longevity. Understanding these common challenges can help users maintain their machinery more effectively.

Fuel-Related Problems

One frequent issue arises from fuel quality and management. Stale or contaminated fuel can lead to starting difficulties and reduced efficiency. Regular checks and appropriate storage practices are essential for optimal operation.

Mechanical Failures

Wear and tear on components such as gaskets and seals can result in leaks and loss of power. Regular inspection and timely replacement of these parts are crucial for maintaining engine health.

| Issue | Symptoms | Solutions |

|---|---|---|

| Fuel Contamination | Difficulty starting, poor performance | Use fresh fuel, clean fuel system |

| Oil Leaks | Visible leaks, low oil levels | Replace seals, check for wear |

| Overheating | Strange noises, smoke | Check coolant levels, clean air filter |

Identifying Replacement Parts

Recognizing the components necessary for repairs is crucial for effective maintenance. A comprehensive understanding of each element ensures smooth operation and longevity of the machinery. By familiarizing oneself with the various segments, users can confidently approach replacements and upgrades.

| Component Name | Description | Common Issues |

|---|---|---|

| Fuel Tank | Stores fuel for operation. | Leaks, cracks. |

| Air Filter | Prevents debris from entering the engine. | Clogging, reduced airflow. |

| Spark Plug | Ignites the fuel-air mixture. | Misfiring, wear. |

| Cylinder Head | Seals the top of the cylinder. | Overheating, leaks. |

Tools Required for Repairs

When embarking on maintenance or restoration tasks, having the right equipment is crucial for achieving optimal results. The appropriate instruments not only enhance efficiency but also ensure safety throughout the process.

Basic Tools: Start with a set of wrenches, screwdrivers, and pliers. These essentials are vital for loosening and tightening various components.

Specialized Instruments: Depending on the specific repairs, you might need items like a torque wrench or a multimeter. These tools help in achieving precision and understanding electrical issues.

Protective Gear: Always prioritize safety by wearing gloves and goggles. This precaution protects against injuries and ensures a secure working environment.

Gathering the right tools before beginning repairs allows for a smoother and more effective experience, ultimately leading to a successful outcome.

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for ensuring optimal performance and longevity. Reliable sources not only guarantee quality but also help maintain the integrity of your equipment. Below are some key avenues to explore when searching for original elements.

Authorized Dealers

One of the most dependable options is to visit authorized dealers. They provide certified items that meet the manufacturer’s specifications, ensuring compatibility and durability.

Online Retailers

Numerous online platforms specialize in equipment supplies. Always check for seller ratings and reviews to confirm the authenticity of the items offered.

| Source Type | Advantages |

|---|---|

| Authorized Dealers | Certified quality and direct manufacturer support |

| Online Retailers | Wide selection and competitive pricing |

| Local Repair Shops | Expert advice and immediate availability |

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires regular care and attention. By following a few essential practices, you can extend the lifespan of your machinery and maintain its efficiency. This section outlines key maintenance strategies that will keep your tools in optimal condition.

Regular Inspections

Performing frequent checks on your machinery helps identify wear and tear before they lead to major issues. Look for signs of damage, loose components, or unusual sounds. Addressing these problems promptly can prevent costly repairs and downtime.

Proper Lubrication

Maintaining the correct lubrication levels is crucial for reducing friction and wear. Use the recommended oils and greases for your specific model. Be sure to follow the manufacturer’s guidelines regarding intervals for lubrication to ensure smooth operation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for wear | Monthly | Check all moving parts. |

| Change oil | Every 50 hours | Use high-quality oil. |

| Clean air filter | Every 25 hours | Replace if heavily soiled. |

| Check spark plug | Every season | Replace if worn or dirty. |

Upgrading Honda GX110 Performance

Enhancing the performance of small engines can lead to improved efficiency and power output. Various modifications can be implemented to achieve optimal results, catering to both enthusiasts and everyday users. These upgrades range from simple adjustments to more complex replacements that ultimately boost overall functionality.

| Upgrade | Description | Benefits |

|---|---|---|

| Air Filter | Replace the stock filter with a high-flow variant. | Increases airflow, improving combustion efficiency. |

| Exhaust System | Install a performance exhaust to reduce back pressure. | Enhances engine sound and increases power output. |

| Carburetor Tune | Adjust fuel mixture for optimal performance. | Maximizes power and efficiency under load. |

| Ignition Upgrade | Install a high-performance ignition coil. | Improves spark consistency for better combustion. |

Customer Reviews on GX110 Parts

This section highlights feedback from users regarding components related to a specific engine model. These insights can guide potential buyers in making informed decisions about the quality and reliability of various offerings in the market.

Many customers have shared their experiences, emphasizing the following aspects:

- Quality: Users often mention the durability and performance of the components, noting how they hold up under various conditions.

- Ease of Installation: Several reviews praise the straightforward installation process, making it accessible even for those with minimal mechanical experience.

- Cost-Effectiveness: Many find the prices to be reasonable compared to competitors, highlighting value for money.

Here are some specific user comments:

- “The replacement I purchased worked perfectly, and installation was a breeze!”

- “After using these components, I noticed a significant improvement in performance.”

- “Great value! They last longer than similar products I’ve tried in the past.”

Overall, feedback suggests a positive reception among users, reinforcing confidence in the components related to this engine model. Such reviews serve as a valuable resource for anyone looking to enhance their machinery’s functionality.