In the world of aquatic maintenance, comprehending the various elements that contribute to the efficiency of filtration systems is essential. These components play a crucial role in ensuring that water remains clean and clear, enhancing the overall experience for users.

When examining a specific model, it becomes evident that familiarity with its structure facilitates better maintenance and repair practices. By dissecting the arrangement of parts, one can identify potential issues and implement solutions effectively.

This exploration will guide you through the intricacies of a prominent filtration unit, highlighting its essential components and their functions. Gaining insight into the arrangement of these elements empowers users to optimize performance and prolong the lifespan of their equipment.

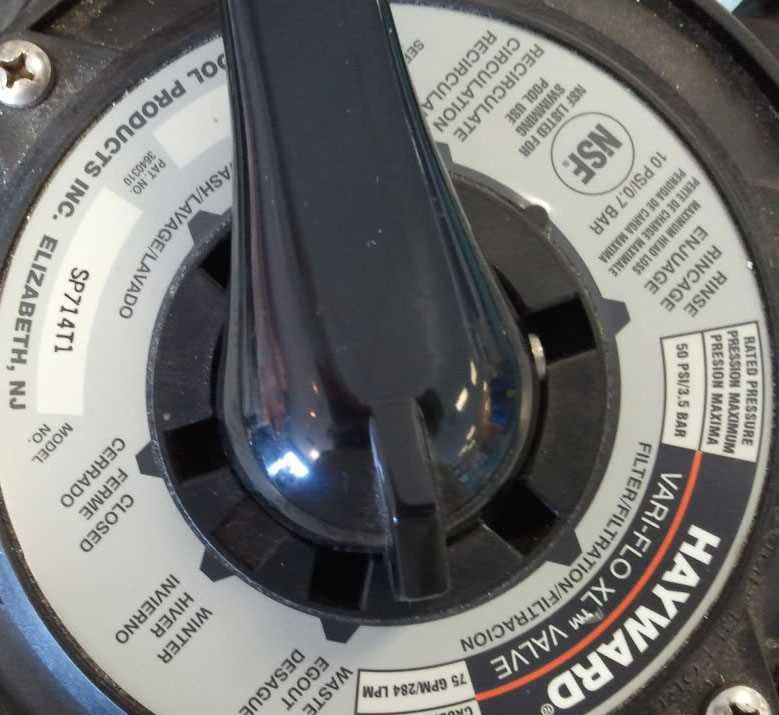

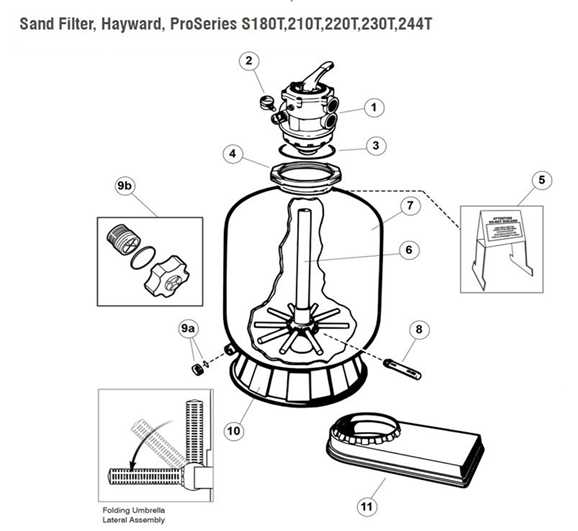

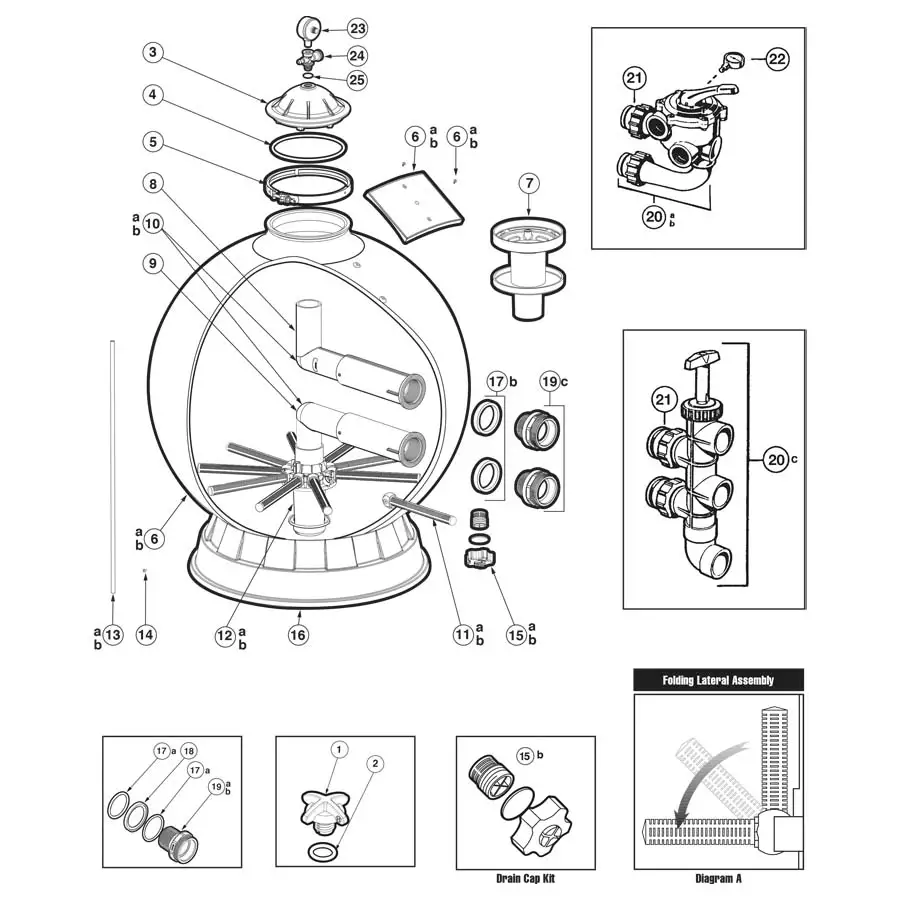

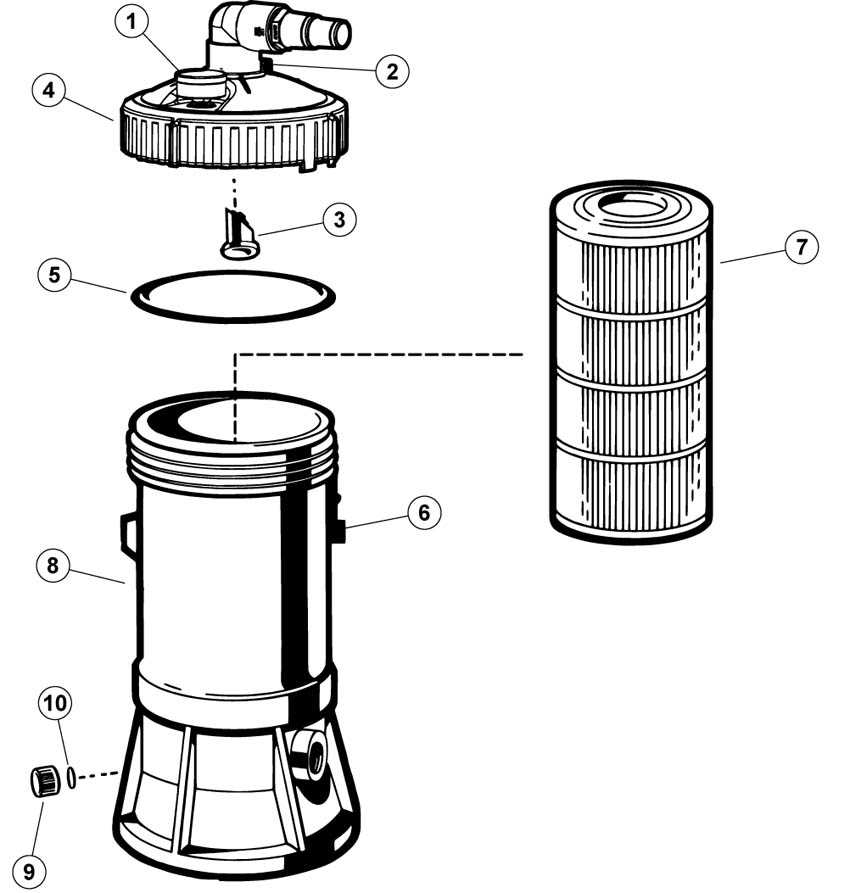

Understanding Hayward S244T Components

Exploring the intricate elements of a filtration system is essential for maintaining its efficiency and performance. Each component plays a crucial role in ensuring optimal operation, making it vital to comprehend their functions and interactions. This knowledge empowers users to troubleshoot issues and enhance overall system longevity.

Key Elements of the Filtration System

Central to the functioning of any filtration setup are the various segments that work together harmoniously. The main body acts as a reservoir, housing the media responsible for trapping impurities. Additionally, inlet and outlet fittings facilitate the flow of water, while the pressure gauge provides critical feedback regarding system performance. Understanding these elements helps in making informed decisions about maintenance and upgrades.

Maintenance and Upgrades

Regular maintenance is vital to ensure each component operates efficiently. This includes inspecting seals, replacing worn-out parts, and monitoring flow rates. Upgrading specific elements can also improve efficiency, reduce energy consumption, and extend the system’s lifespan. Awareness of each part’s role allows for more effective management and care of the entire setup.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of complex systems. They offer a clear and concise way to identify individual elements and their relationships within a larger assembly. This clarity is essential for effective maintenance, repair, and assembly processes, ensuring that every piece is correctly positioned and functional.

Enhancing Efficiency

When technicians and engineers have access to detailed visual guides, they can work more efficiently. These representations reduce the likelihood of errors, allowing for quicker identification of needed components during repairs. Moreover, a well-structured visual guide facilitates training for new personnel, enabling them to familiarize themselves with the system faster.

Facilitating Communication

Clear visuals also improve communication among team members. Whether discussing modifications or troubleshooting issues, having a common reference point minimizes misunderstandings. This shared understanding is vital in collaborative environments where various stakeholders contribute to the project’s success.

| Benefit | Description |

|---|---|

| Efficiency | Reduces errors and speeds up repair processes. |

| Training | Helps new personnel quickly understand the system. |

| Communication | Enhances clarity in discussions among team members. |

Key Features of the S244T

This section highlights the essential characteristics that make this model stand out in its category. Designed for optimal performance and efficiency, it caters to various user needs, ensuring reliability and ease of use.

- Efficient Filtration: This unit is equipped with advanced filtration technology, ensuring crystal-clear water quality and minimizing maintenance efforts.

- Durable Construction: Crafted from high-quality materials, it guarantees longevity and resilience against harsh environmental conditions.

- Simple Installation: The user-friendly design allows for quick and straightforward setup, making it accessible for both professionals and DIY enthusiasts.

- Energy Efficiency: Engineered to consume less energy, it helps reduce operational costs while maintaining superior performance.

- Versatile Compatibility: This model is compatible with a range of systems, enhancing its functionality across different applications.

Overall, the integration of these features positions this unit as a reliable choice for anyone seeking effective and sustainable solutions.

Common Issues with Hayward Filters

Pool filtration systems can encounter various problems that affect their efficiency and performance. Understanding these common issues can help users maintain their equipment and ensure optimal water clarity.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Clogged Filter | Poor water flow, dirty water | Clean or replace the filter media |

| Leakage | Water pooling around the unit | Inspect seals and fittings; replace damaged parts |

| Unusual Noises | Humming, rattling sounds | Check for loose components; tighten or replace as needed |

| Low Pressure | Reduced suction or flow | Examine for blockages in hoses or valves; clear any debris |

By being aware of these frequent challenges, users can take proactive measures to keep their filtration systems running smoothly and effectively.

Parts Replacement Guide

This section aims to provide essential guidance on the substitution of components within your filtration system. Regular maintenance and timely replacements are crucial for ensuring optimal performance and longevity. Understanding the various elements involved and their functions will help you make informed decisions when it comes to upgrades or replacements.

Below is a table outlining common components that may require attention, along with their respective descriptions and typical replacement intervals:

| Component | Description | Replacement Interval |

|---|---|---|

| Filter Cartridge | Removes debris and contaminants from the water. | Every 1-2 years |

| Pump Motor | Circulates water through the system for effective filtration. | As needed, typically every 3-5 years |

| Seal Gasket | Prevents leaks between components, ensuring proper function. | Every 1-3 years |

| Pressure Gauge | Monitors the system’s pressure levels for safety and efficiency. | Every 2-4 years |

By staying proactive with replacements and monitoring the performance of these critical components, you can enhance the efficiency and reliability of your filtration setup. Always consult your user manual for specific recommendations related to your model.

Identifying Component Functions

Understanding the roles of various elements within a system is crucial for effective maintenance and troubleshooting. Each part plays a specific role that contributes to the overall functionality, and recognizing these roles can streamline the process of repairs or upgrades.

Functionality Breakdown involves analyzing each element’s contribution to the operational flow. For example, certain components may be responsible for regulating flow, while others manage filtration or heating processes. Grasping these distinctions enables users to pinpoint issues more efficiently.

Common Functions include filtration, circulation, and temperature control. Filtration systems work to remove impurities, ensuring clean output. Circulation elements are vital for maintaining fluid movement, preventing stagnation. Temperature control mechanisms ensure that the system operates within optimal thermal ranges, enhancing efficiency and prolonging lifespan.

By conducting a thorough evaluation of these roles, operators can develop a deeper understanding of their systems, leading to improved performance and reliability. This knowledge empowers users to make informed decisions during maintenance and to implement necessary adjustments for enhanced functionality.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. Regular attention not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some practical recommendations to extend the lifespan of your system.

Regular Cleaning: Keeping components free from debris and contaminants is crucial. Schedule frequent cleanings to prevent build-up that could impair functionality.

Inspection: Routine checks allow you to identify wear and tear early. Look for any signs of damage or corrosion that might require immediate attention.

Lubrication: Ensure that moving parts are adequately lubricated. This reduces friction and helps maintain optimal operation, ultimately prolonging the life of the machinery.

Temperature Control: Avoid exposure to extreme temperatures. Maintaining an appropriate environment can significantly affect performance and longevity.

Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule and practices from the manufacturer will help ensure your equipment runs smoothly for years to come.

Where to Find Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Whether you’re dealing with a maintenance issue or upgrading features, sourcing quality replacements is essential. Here are some reliable avenues to explore.

Authorized Retailers

- Check with certified vendors who specialize in your equipment type.

- These sellers often provide genuine items and expert advice.

- Visit their websites or physical locations for a wider selection.

Online Marketplaces

- Popular platforms offer a variety of options, including new and refurbished items.

- Look for reputable sellers with positive reviews to ensure quality.

- Compare prices and shipping options for the best deal.

By exploring these resources, you can efficiently locate the necessary components to keep your system running smoothly.

Comparison with Other Models

This section explores the differences and similarities between the featured equipment and its counterparts in the market. Understanding these distinctions is crucial for users seeking the best fit for their needs.

When comparing various models, several factors come into play:

- Performance: Different models may exhibit varying levels of efficiency and output. Users should consider the required performance based on their specific applications.

- Durability: The lifespan and construction materials can significantly impact the longevity of the devices. It is essential to evaluate these aspects to avoid frequent replacements.

- Maintenance: Some designs require more regular upkeep than others. Identifying which models offer user-friendly maintenance can save time and effort.

- Cost: The price range for similar devices can differ widely. It is advisable to assess the cost-effectiveness based on features and longevity.

In summary, potential buyers should carefully analyze these criteria when selecting the most suitable option from the variety available in the market.

User Reviews and Feedback

This section provides insights from individuals who have utilized the product, offering a diverse range of experiences and opinions. Their evaluations highlight various aspects, from performance to ease of use, helping potential buyers make informed decisions.

Overall Impressions

- Most users appreciate the efficiency and reliability of the device.

- Many note its user-friendly design, making installation straightforward.

- Several customers mention significant improvements in their system’s performance.

Common Concerns

- Some users experienced minor issues with initial setup.

- A few reported challenges with customer support responsiveness.

- Several noted that certain components may require occasional maintenance.

Safety Precautions for Repairs

When undertaking maintenance or repair tasks, it is crucial to prioritize safety to prevent accidents and ensure effective work. Proper precautions not only protect the individual performing the repairs but also help maintain the integrity of the equipment involved. By adhering to specific guidelines, you can minimize risks and create a safer working environment.

General Guidelines

Before commencing any repair work, always assess the situation thoroughly. Ensure that the power supply is disconnected, and the equipment is completely shut down. Utilize the appropriate personal protective equipment (PPE) such as gloves, goggles, and masks to shield yourself from potential hazards. Additionally, keep your workspace organized to avoid clutter that may lead to accidents.

Emergency Procedures

Having a clear plan for emergencies is vital in any repair situation. Identify the location of first aid kits, fire extinguishers, and emergency exits before starting. Make sure to communicate with anyone else in the vicinity about potential hazards. In case of an accident, knowing how to respond quickly can mitigate further harm.

| Safety Equipment | Purpose |

|---|---|

| Gloves | To protect hands from sharp objects and chemicals |

| Goggles | To shield eyes from debris and harmful substances |

| Mask | To prevent inhalation of harmful dust and fumes |

| First Aid Kit | To provide immediate care for injuries |

| Fire Extinguisher | To extinguish small fires that may occur |