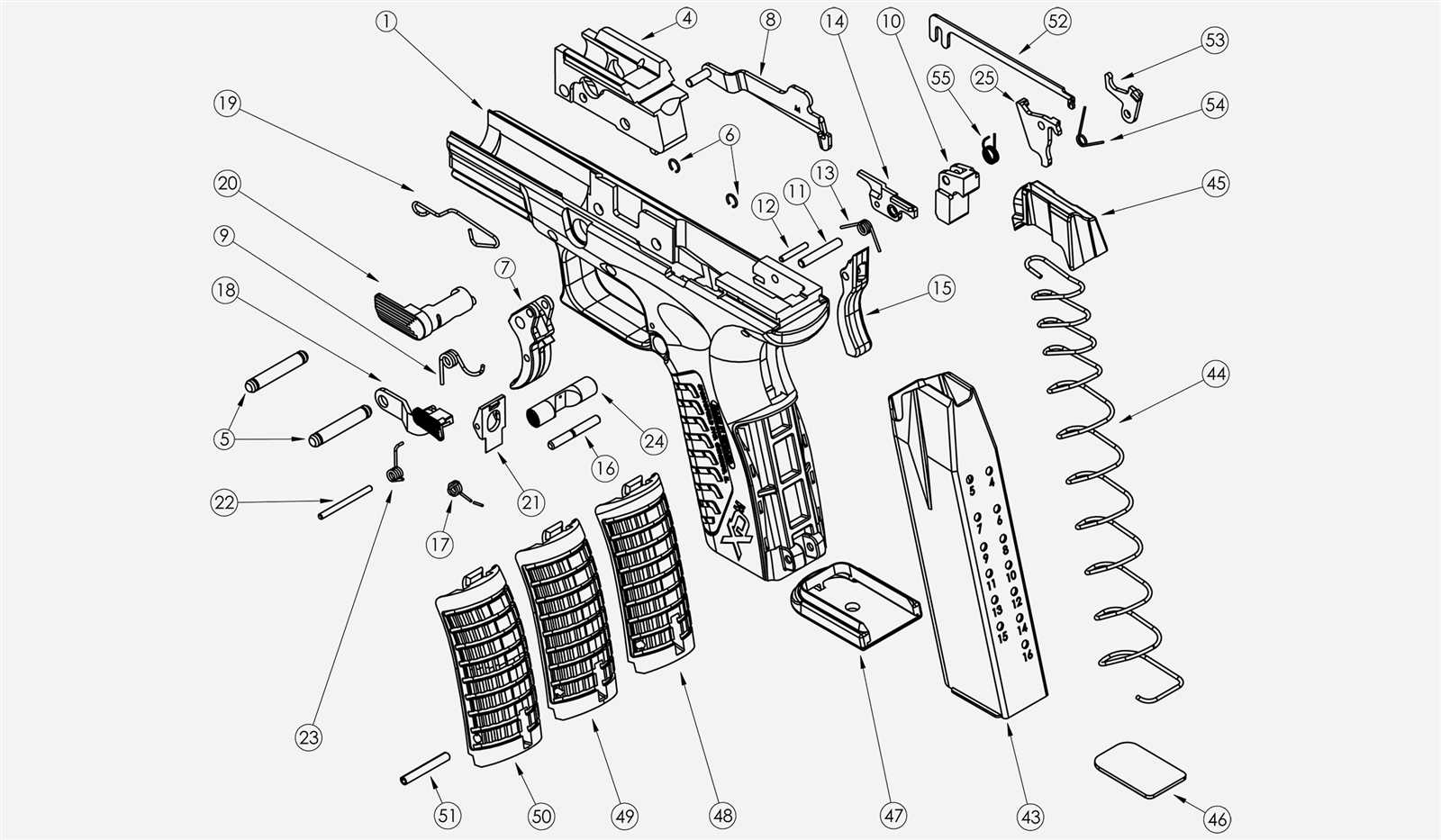

The internal and external mechanisms of modern firearms are intricately designed for precision and reliability. Each element plays a crucial role in ensuring smooth operation and safe handling. Familiarizing yourself with the different components is essential for maintenance and performance optimization.

In this section, we will explore the various mechanisms that contribute to the proper function of the upper assembly of a semi-automatic firearm. Understanding these elements will aid in improving maintenance, enhancing performance, and ensuring safety during use.

Through detailed explanations, we will break down the key features, providing clarity on their functions and interactions within the overall system. By gaining a deeper knowledge of these mechanisms, users can perform better upkeep and troubleshoot common issues effectively.

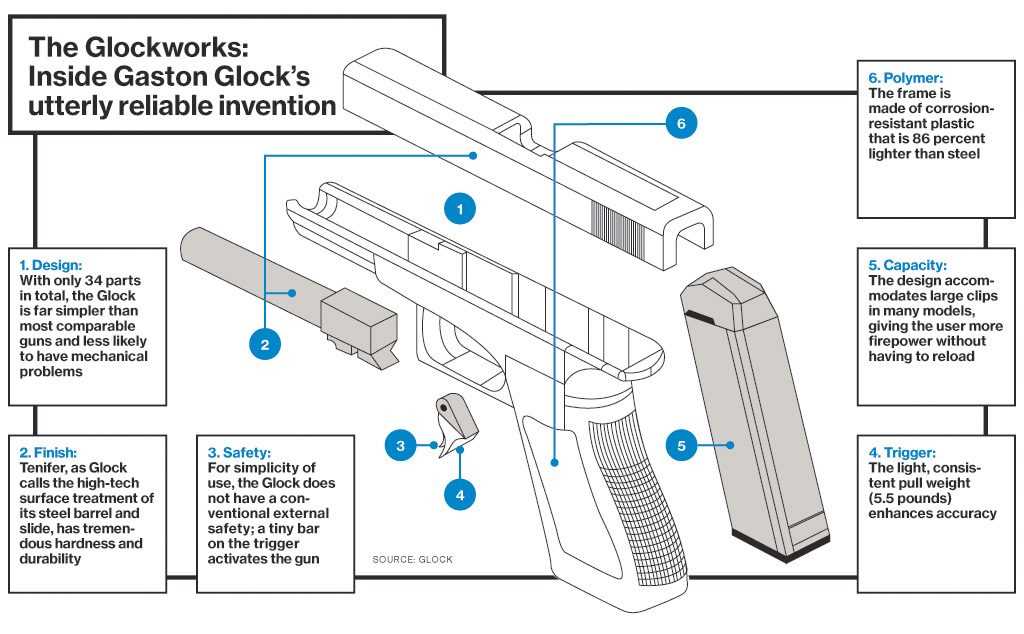

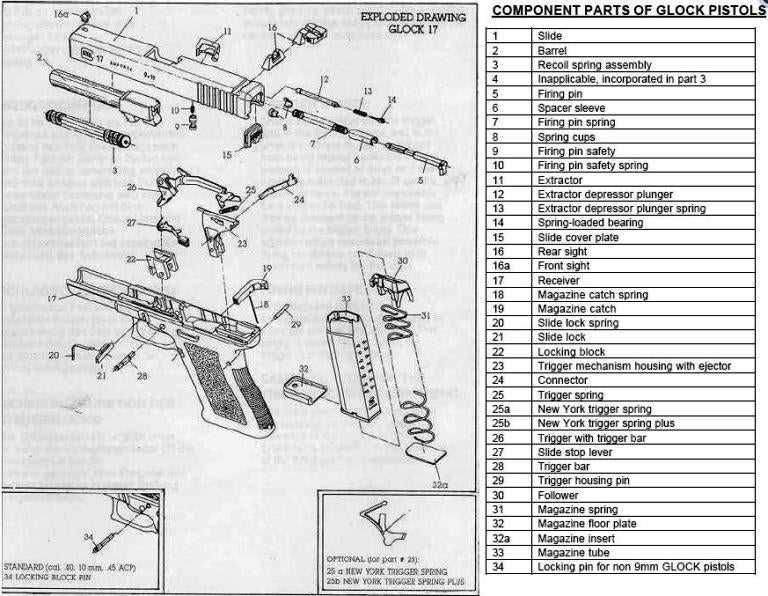

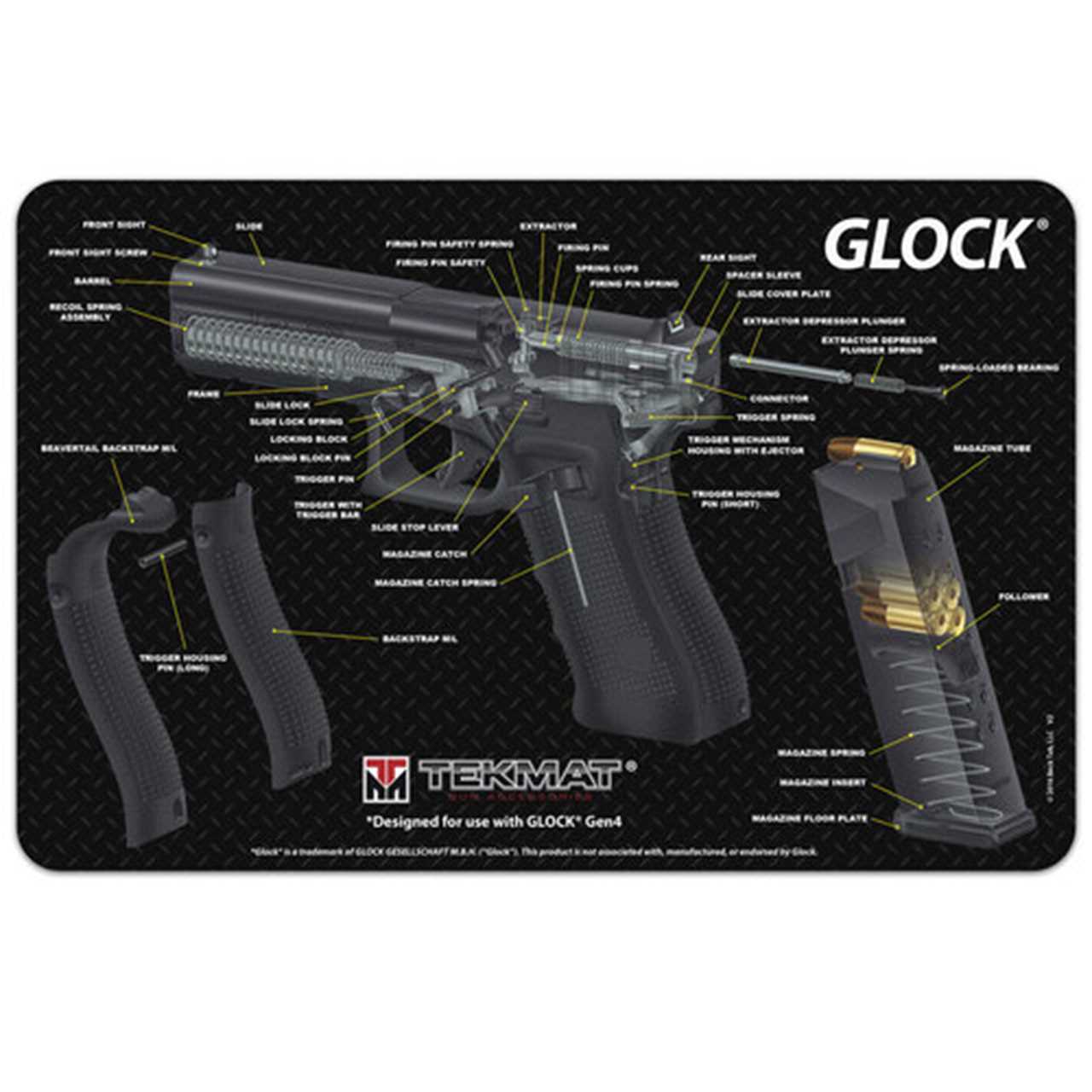

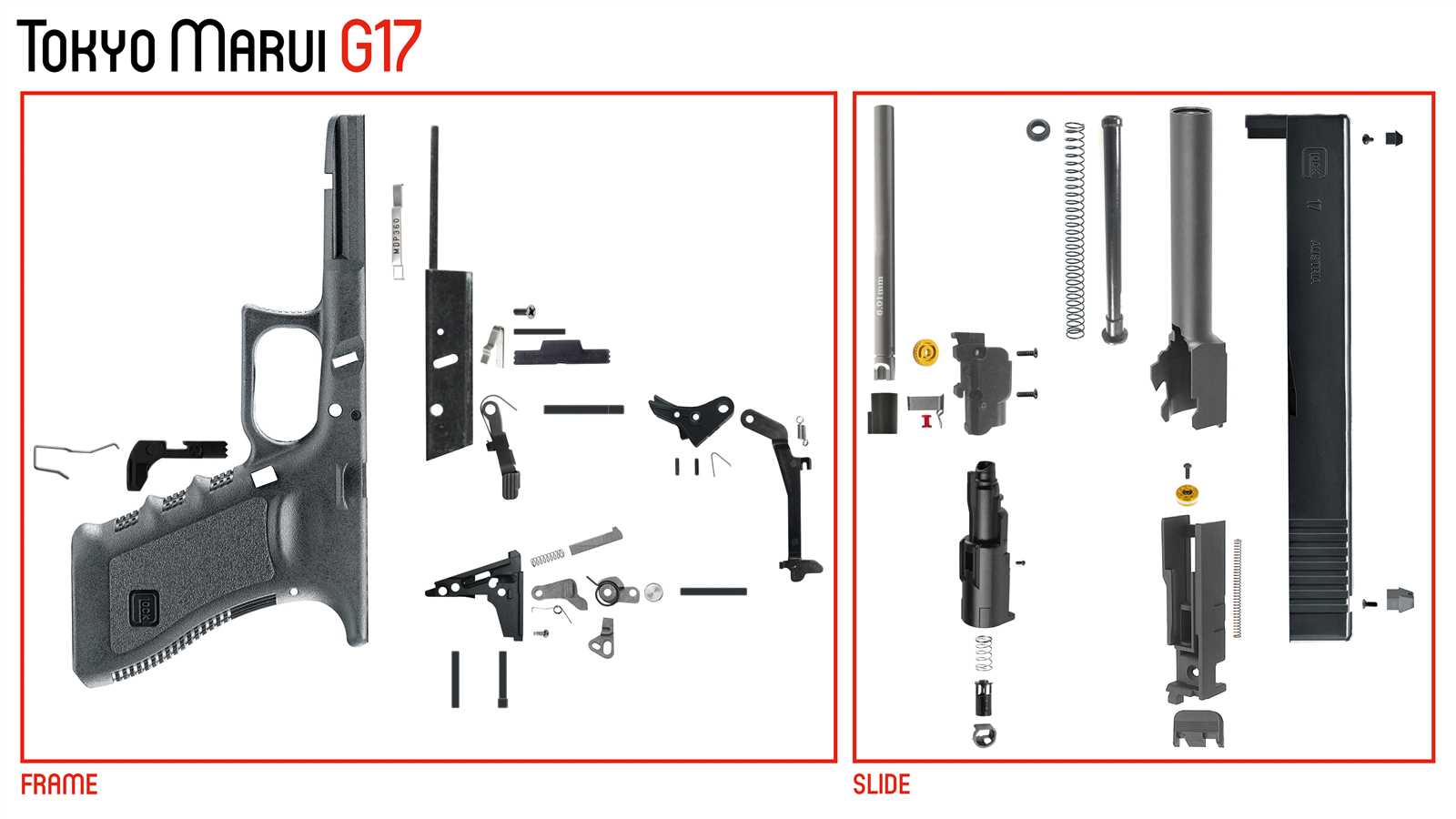

Components Overview of a Glock Slide

In this section, we explore the key elements that form the upper portion of a popular semi-automatic handgun. Each piece plays a crucial role in the firearm’s functionality, contributing to its reliability and performance. Understanding how these elements work together helps ensure proper maintenance and potential upgrades.

Key Functional Elements

The upper assembly includes several essential components, such as the mechanism that guides the rearward and forward motion and the firing pin system. These parts ensure smooth operation, allowing for efficient cycling and precise firing.

Structural and Safety Features

In addition to the firing mechanism, there are structural elements that secure stability and reinforce safety during use. These include components responsible for guiding movements and retaining critical elements in place, ensuring both accuracy and user safety.

Functionality of Recoil Spring Assembly

The recoil spring assembly is a crucial mechanism responsible for ensuring the proper functioning of a firearm during the firing cycle. This component helps manage the backward motion caused by the discharge, allowing for smooth and reliable operation.

Below are the key functions of the recoil spring assembly:

- Absorbs the energy produced from the discharge, reducing the impact on the frame.

- Facilitates the controlled return of the barrel and other moving components to their initial positions.

- Ensures consistent cycling, enabling rapid follow-up shots.

- Prevents excessive wear and tear by regulating the force exerted on other internal mechanisms.

By effectively controlling these actions, the recoil spring assembly plays an integral role in maintaining the firearm’s reliability and longevity.

Detailed Look at Extractor Mechanism

The extractor mechanism plays a crucial role in the reliable function of any firearm. It ensures the proper removal of spent casings after each shot, maintaining the cycle of operations smoothly. This component works in conjunction with other internal elements to securely grip and eject the cartridge from the chamber during the firing sequence.

Understanding how the extractor operates involves examining its precise interaction with the casing and the recoil forces that occur upon discharge. The tension applied by the spring ensures that the extractor holds onto the rim of the casing, allowing for clean and consistent ejection. Any malfunction in this area can lead to failures in the cycle, such as jams or improper ejection.

Proper maintenance of the extractor mechanism is vital for the continued reliability of a firearm, as residue buildup or mechanical wear can negatively impact its performance. Regular inspection and cleaning will prevent potential issues and ensure that the mechanism functions as intended.

How the Firing Pin Safety Operates

The firing pin safety is a crucial mechanism that ensures the weapon can only discharge when the trigger is intentionally pulled. This safety feature prevents accidental firing by blocking the striker’s movement unless the proper sequence of actions occurs during operation.

Primary Function of the Safety Mechanism

In normal conditions, the firing pin is held in place by a small block. This block is positioned in such a way that it physically obstructs the pin from moving forward, ensuring the weapon remains inactive unless the trigger is engaged.

Engagement During Firing

When the trigger is pressed, the safety block is pushed upward, clearing the path for the pin. Only then is the firing pin released, allowing it to strike the

Role of the Firing Pin in Action

The firing pin plays a crucial role in the mechanics of a firearm. It is responsible for striking the primer of the ammunition, initiating the combustion of the propellant, and subsequently firing the bullet. This component is essential for the chain of events that lead to the shot being discharged, making it a fundamental part of the firearm’s operation.

Initiating the Firing Sequence

When the trigger is pulled, several internal components work together to move the firing pin into position. The pin is then propelled forward with enough force to strike the primer, igniting the gunpowder. This precise motion must occur smoothly and without interruption for the shot to be fired successfully.

- The trigger mechanism activates the pin’s movement.

- Proper alignment ensures the primer is struck accurately.

- The firing pin must move with speed and force for ignition.

Safety

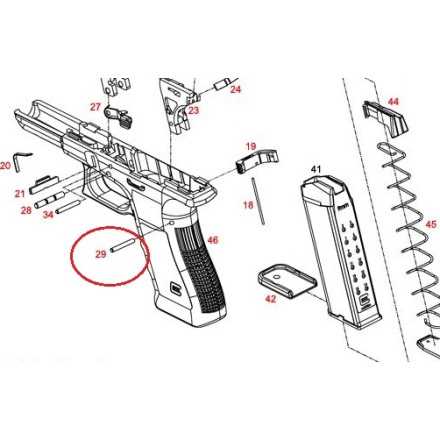

Significance of the Slide Lock Lever

The mechanism that secures the top assembly plays a crucial role in the overall functionality of a firearm. It ensures that the moving components operate smoothly while also providing a safe means to prevent accidental discharge. This feature enhances the user’s control during operation and maintenance, making it a fundamental aspect of reliable weapon handling.

Understanding the importance of this mechanism allows users to appreciate its contribution to safety and efficiency. It not only aids in proper reloading but also ensures that the firearm remains secure during transport. By effectively managing the interaction between various elements, it significantly influences the reliability and performance of the firearm.

Regular inspection and maintenance of this component are vital for optimal performance. A malfunction can lead to serious operational issues, potentially compromising user safety. Therefore, awareness and knowledge regarding its function and upkeep are essential for all firearm enthusiasts.

Understanding the Function of Slide Rails

Rails play a crucial role in the operation of a firearm, guiding the movement of the upper assembly as it cycles during firing. Their design ensures smooth and reliable motion, allowing for effective engagement and disengagement of various components. Proper functioning of these elements is essential for optimal performance and accuracy.

The interaction between the rails and the upper assembly allows for controlled motion, which is vital for the cycling process. Any misalignment or wear can lead to malfunctions, impacting the overall reliability of the firearm. Therefore, regular maintenance and inspection of these components are necessary to ensure their longevity and proper functioning.

| Function | Description |

|---|---|

| Guidance | Ensures the smooth movement of the upper assembly during operation. |

| Alignment | Maintains proper positioning of the components for reliable performance. |

| Support | Provides structural integrity to the upper assembly during cycling. |

| Durability | Resists wear and tear to ensure long-term functionality. |

Purpose of the Glock Slide Cover Plate

The cover plate serves a crucial role in maintaining the functionality and aesthetics of a firearm’s upper assembly. It acts as a protective barrier, safeguarding internal mechanisms from dust, debris, and moisture, which can compromise performance and reliability.

Additionally, this component contributes to the overall integrity of the structure, ensuring that the assembly remains securely sealed. Its design also facilitates ease of access for maintenance and servicing, allowing users to perform necessary tasks without difficulty.

Moreover, the cover plate can influence the visual appeal of the firearm, offering customization options for enthusiasts. Different styles and finishes can enhance the overall look, catering to personal preferences and enhancing the individuality of the weapon.

Impact of Barrel Lug on Slide Performance

The barrel lug plays a crucial role in the overall functionality of a firearm. Its design and interaction with the upper assembly can significantly affect the weapon’s reliability and accuracy. Understanding this component’s influence is essential for optimizing performance.

When the barrel lug engages with the upper assembly, it facilitates the locking process during firing. This connection ensures that the projectile is stabilized as it travels down the barrel, directly impacting the precision of each shot. Any wear or misalignment can lead to reduced accuracy and inconsistent performance.

Additionally, the quality of materials used in the barrel lug’s construction can influence durability and resistance to wear. A well-engineered lug can withstand the stresses of repeated firing, ensuring consistent engagement and enhancing the longevity of the firearm.

Ultimately, attention to the design and maintenance of the barrel lug is vital for achieving optimal performance in a firearm. Modifications or enhancements to this component can lead to improvements in shooting efficiency and overall effectiveness in various scenarios.

Slide Serrations and Their

The texturing and grooves found on the upper portion of a firearm play a significant role in enhancing grip and control during operation. These features allow for improved handling, ensuring users can effectively manipulate the mechanism under various conditions. Their design not only serves a functional purpose but also adds to the overall aesthetic appeal of the weapon.

| Type | Function | Benefits |

|---|---|---|

| Forward Serrations | Facilitate easier manipulation when moving the action forward. | Improved grip for press checks or malfunction clearing. |

| Rear Serrations | Assist in retracting the action to chamber a round. | Enhanced control during loading and unloading. |

| Vertical Grooves | Provide a textured surface for thumb placement. | Allow for more secure handling and reduced slipping. |

| Angled Cuts | Improve grip angle for faster access. | Promote quicker operation and response times. |