In the realm of towing mechanisms, having a clear understanding of the various components involved is essential for ensuring safety and efficiency. The intricate design of these systems requires careful attention to detail, as each element plays a significant role in the overall functionality. By exploring the specifics of these assemblies, users can enhance their knowledge and improve their towing experiences.

From connectors to locking mechanisms, each section of the assembly contributes to the secure attachment between the towing vehicle and the load being transported. A well-organized representation of these components allows for easier identification and understanding of their respective functions. This clarity is particularly valuable for those engaged in maintenance and repair tasks, enabling them to address issues more effectively.

Whether you are a seasoned professional or a newcomer to the world of towing, familiarizing yourself with the various elements will empower you to make informed decisions. This foundational knowledge not only promotes safety but also enhances the overall performance of towing operations.

Overview of Key Components of a Trailing Hitch System

This section provides an insightful look into the essential elements that make up a trailing hitch mechanism used for towing. Understanding these components is crucial for ensuring efficient operation and safety while on the road. Each element plays a significant role in the overall functionality and reliability of the towing setup.

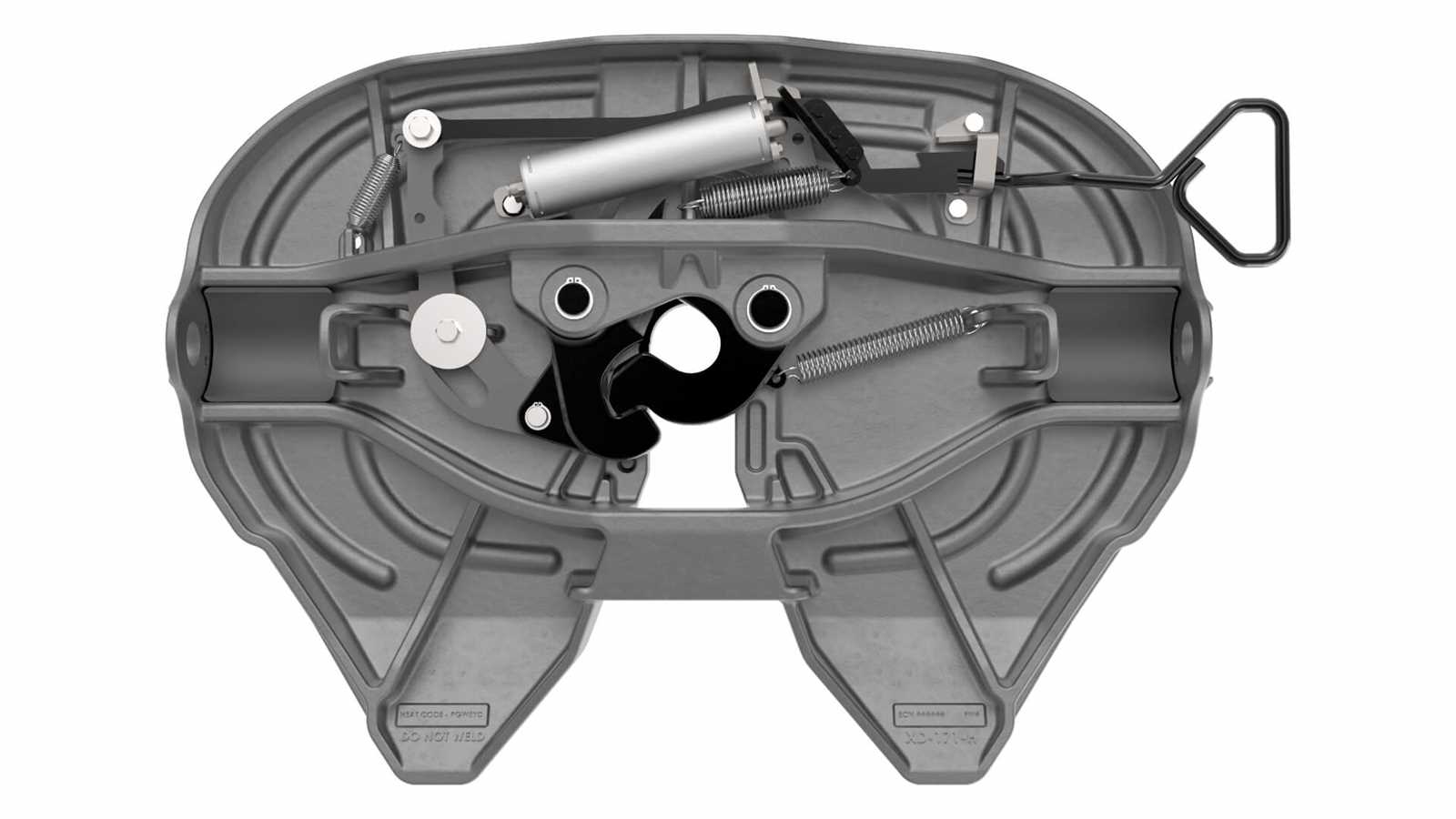

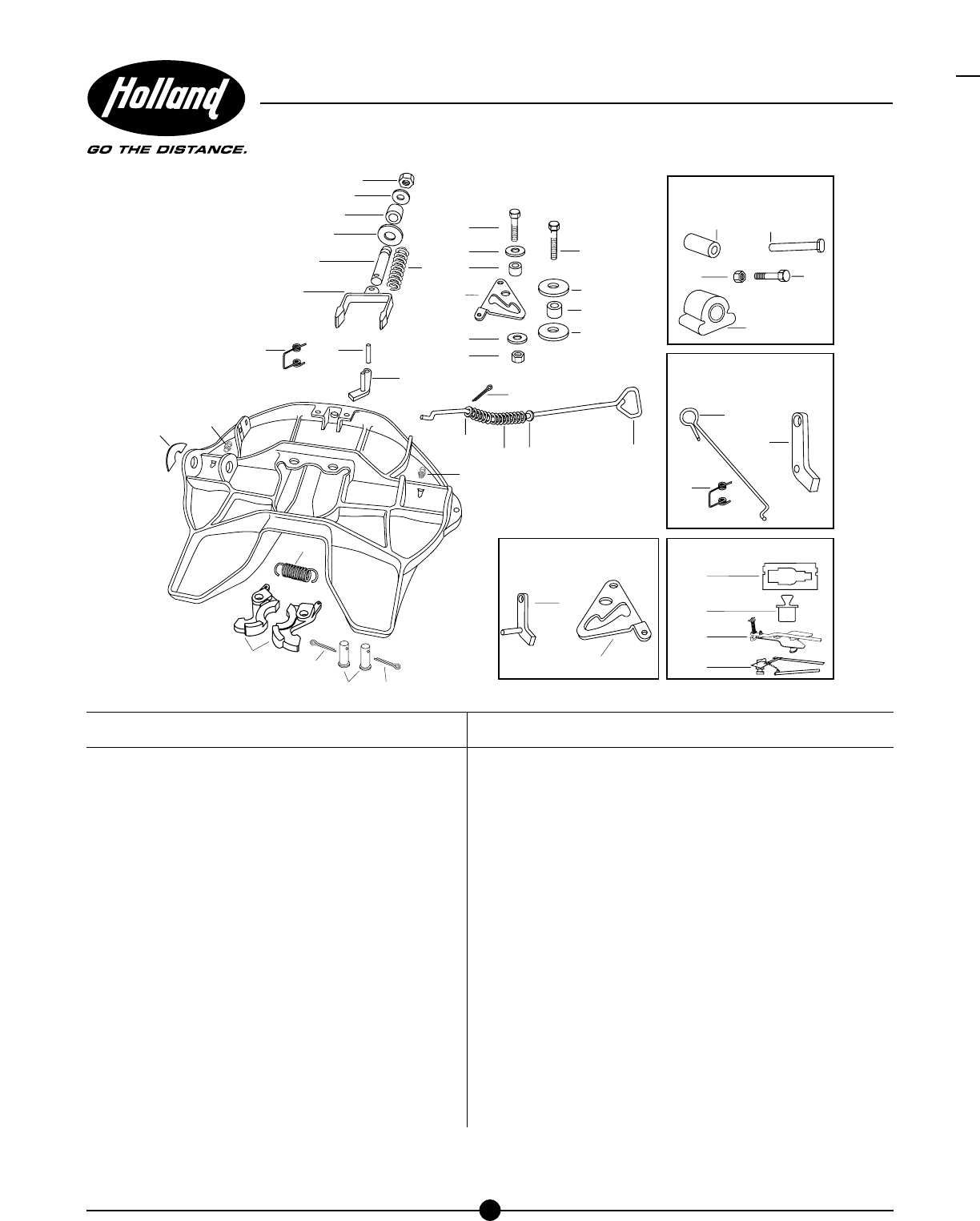

Main Elements of the Towing Assembly

- Coupler: This component securely connects the towing vehicle to the trailer, ensuring stability during transit.

- Kingpin: The kingpin is the pivotal element that locks into the coupler, allowing for effective weight distribution and maneuverability.

- Jaw Mechanism: This part operates to secure the kingpin within the coupler, providing a reliable connection between the two vehicles.

- Frame Plate: A robust structure that supports the coupling mechanism and enhances the overall strength of the towing setup.

- Safety Chain: Vital for additional security, these chains act as a backup connection, preventing separation of the vehicles in case of a failure.

Importance of Each Component

Each element in the towing assembly is designed to ensure optimal performance and safety. The coupler and kingpin work in tandem to create a stable connection, while the jaw mechanism offers a secure lock. The frame plate provides essential support, and safety chains add an extra layer of security. Understanding the purpose and functionality of these components is essential for effective towing.

Understanding the Function of Each Part

This section aims to explore the various components of a towing mechanism and their roles in ensuring safe and effective transportation. Each element contributes uniquely to the overall functionality, providing stability and reliability during travel.

The connection interface plays a critical role by securing the trailer to the towing vehicle, facilitating smooth maneuverability. Coupling mechanisms ensure a tight fit, preventing any unwanted detachment while in motion. Additionally, the adjustment features allow users to customize the height and alignment for optimal performance, accommodating different vehicle types and loads.

Support structures, including brackets and frames, provide essential strength and balance, distributing weight evenly to enhance stability. Safety features, such as locking pins and release mechanisms, are vital for preventing accidental disengagement, offering peace of mind while on the road.

Finally, maintenance components are crucial for long-term functionality, allowing for easy inspection and repairs. Understanding these various elements is essential for users to appreciate the intricacies of their towing system and ensure proper usage and upkeep.

Common Issues with Fifth Wheel Systems

When it comes to towing setups, various challenges can arise that affect functionality and safety. Understanding these common problems is crucial for maintaining performance and ensuring a smooth towing experience. From mechanical wear to alignment issues, recognizing the signs early can prevent more significant complications down the road.

Wear and Tear on Components

Over time, the various components of a towing setup can experience significant wear. This degradation may lead to instability while driving, making it essential to regularly inspect and maintain these parts. Common signs of wear include unusual noises, excessive movement, and difficulty in coupling or uncoupling.

Improper Alignment

Misalignment can cause a range of problems, including uneven tire wear and decreased handling capability. It is vital to ensure that all elements of the towing assembly are correctly aligned to promote optimal performance. Regular checks and adjustments can help in preventing complications that may arise from poor alignment.

Maintenance Tips for Longevity

To ensure the extended lifespan of your towing equipment, regular upkeep is essential. By following specific guidelines and routines, you can enhance performance and minimize potential issues. Proper attention to these components will lead to more reliable and efficient operations over time.

Here are some crucial maintenance recommendations:

| Task | Frequency | Description |

|---|---|---|

| Inspection | Monthly | Check for any signs of wear, damage, or loose connections. Address any issues promptly to avoid complications. |

| Lubrication | Every 3 months | Apply appropriate lubricant to moving parts to ensure smooth operation and prevent corrosion. |

| Cleaning | After each use | Remove dirt and debris from surfaces to prevent buildup that could hinder functionality. |

| Adjustment | As needed | Ensure that all components are correctly aligned and adjusted according to manufacturer specifications. |

| Storage | Seasonally | When not in use, store the equipment in a dry and protected area to minimize exposure to the elements. |

Implementing these practices will significantly contribute to the durability and effectiveness of your towing setup, ensuring a safer and more enjoyable experience.

Identifying Parts by Model Number

Recognizing components through their specific model identifiers is crucial for effective maintenance and replacement. Each unit is assigned a unique number that corresponds to its design and specifications, allowing users to find the correct replacement items quickly and accurately.

By utilizing the model number, individuals can streamline the search process, ensuring they acquire the correct components without unnecessary delays. This practice not only enhances the efficiency of repairs but also contributes to the longevity of the system in question.

| Model Number | Description | Common Applications |

|---|---|---|

| MN12345 | Universal connection plate | Standard towing setups |

| MN67890 | Height adjustment mechanism | Various load configurations |

| MN11223 | Safety lock assembly | Enhanced security features |

Comparison of Different Models

This section delves into the variety of designs available within the category of towing apparatuses. By examining distinct characteristics, users can better appreciate the nuances and advantages of each type, facilitating informed decision-making for their specific needs.

Model Features

Each variant showcases unique features tailored for different applications. For instance, some designs are engineered for enhanced stability and load-bearing capacity, while others prioritize ease of attachment and detachment. Understanding these differences can significantly impact performance during usage.

Durability and Maintenance

When considering longevity, the robustness of the construction materials is a crucial factor. Some models offer superior resistance to wear and tear, which can lead to lower maintenance requirements over time. Evaluating these attributes ensures that users select a model that meets their durability expectations while also fitting within their maintenance capabilities.

Tools Required for Replacement Tasks

When undertaking the task of replacing components in your towing setup, having the right tools at your disposal is essential for ensuring a smooth and efficient process. The appropriate equipment not only aids in completing the job effectively but also enhances safety and reduces the risk of damage to the assembly.

Basic Hand Tools: A selection of hand tools is fundamental. Commonly required items include wrenches, pliers, and screwdrivers. These will assist in loosening and tightening fasteners, making disassembly and reassembly much simpler.

Torque Wrench: This tool is vital for ensuring that bolts are tightened to the manufacturer’s specified torque. Proper torque is critical in maintaining the integrity of the connections and preventing premature failure.

Jack and Stands: A reliable jack is necessary for lifting the vehicle safely, while jack stands are crucial for providing support once the vehicle is elevated. This equipment allows you to work comfortably under the vehicle without compromising safety.

Safety Gear: Don’t overlook the importance of safety equipment. Wearing gloves, goggles, and other protective gear is essential to safeguard yourself from potential hazards during the replacement process.

By gathering these essential tools and safety equipment, you can ensure that the replacement tasks are conducted efficiently and safely, leading to optimal performance of your towing system.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to assist you in effectively addressing common issues encountered with towing mechanisms. Following these instructions will ensure a systematic approach to restoring functionality and enhancing safety.

Preparation and Safety Measures

Before beginning any repair work, ensure you have the necessary tools and materials on hand. Disconnect the unit from the towing vehicle to prevent accidental movement. Wear appropriate safety gear, including gloves and goggles, to protect yourself from potential hazards.

Disassembly and Inspection

Carefully remove the components that require attention, taking note of their arrangement for reassembly. Inspect each part for signs of wear or damage, paying particular attention to critical areas that may impact performance. Document any findings, as this will aid in determining necessary replacements or repairs.

Safety Precautions During Maintenance

When undertaking the upkeep of towing equipment, it is essential to prioritize safety to prevent accidents and ensure smooth operations. Proper planning and adherence to safety protocols can significantly reduce the risk of injury and equipment damage. Understanding and implementing safety measures will help create a secure working environment.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial during maintenance tasks. This includes gloves, safety glasses, and steel-toed boots to safeguard against potential hazards. Ensure that all personnel involved in the maintenance process are equipped with the necessary protective equipment to mitigate risks effectively.

Tools and Equipment Handling

Proper handling of tools and equipment is vital for safe maintenance. Inspect all tools before use to ensure they are in good condition and free from defects. Use the correct tools for each task to prevent accidents and injuries. Always follow the manufacturer’s instructions when using equipment to maintain safety and functionality.

Finding Replacement Parts Online

In today’s digital age, locating necessary components for your equipment has never been easier. Numerous online platforms provide a wide selection of items tailored to meet various needs. With just a few clicks, you can access a wealth of resources that streamline the search for the right components.

Begin your search by exploring dedicated websites that specialize in mechanical accessories. These sites often feature detailed catalogs, allowing users to filter options based on specific requirements. Utilizing search functionalities can significantly narrow down choices, ensuring you find what you need quickly.

Additionally, consider visiting online marketplaces where multiple sellers offer their inventory. This can present opportunities for competitive pricing and product availability. Always check user reviews and ratings to gauge the reliability of sellers before making a purchase.

For further assistance, consult forums and communities related to your equipment. Engaging with experienced users can provide insights into where to find quality components and what to look for when selecting items. These discussions often lead to valuable recommendations, enhancing your chances of making informed choices.