Maintaining outdoor machinery can be a daunting task, especially when it comes to understanding its intricate workings. Familiarity with the various elements that constitute your device is crucial for ensuring optimal performance and longevity. A comprehensive overview of these components not only simplifies repair processes but also enhances overall user experience.

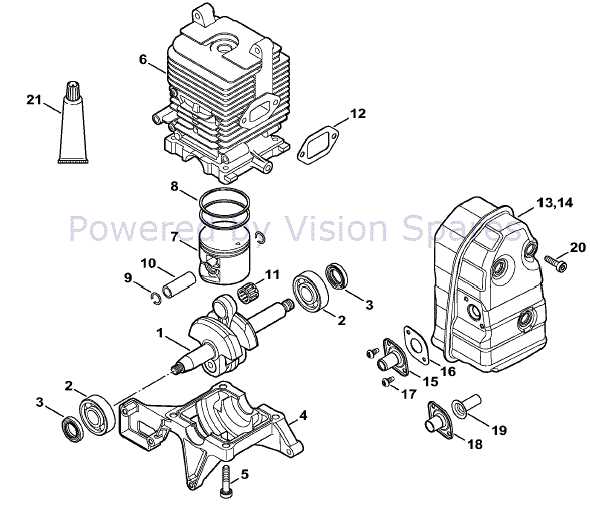

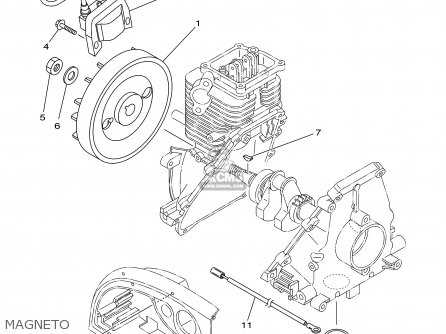

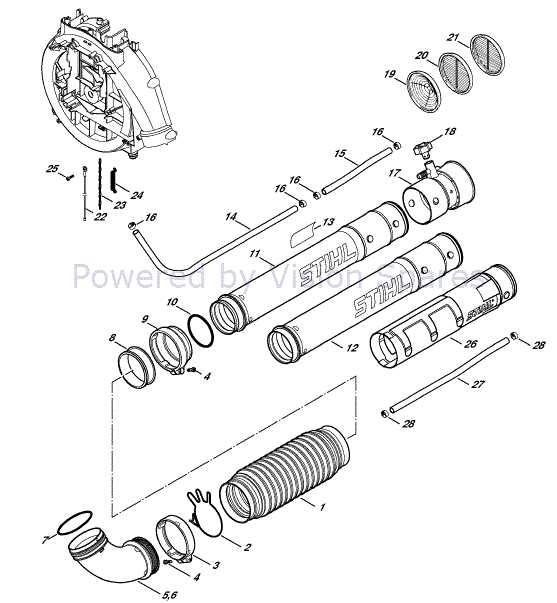

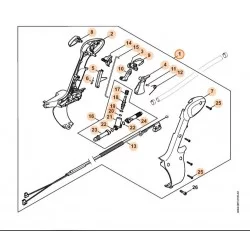

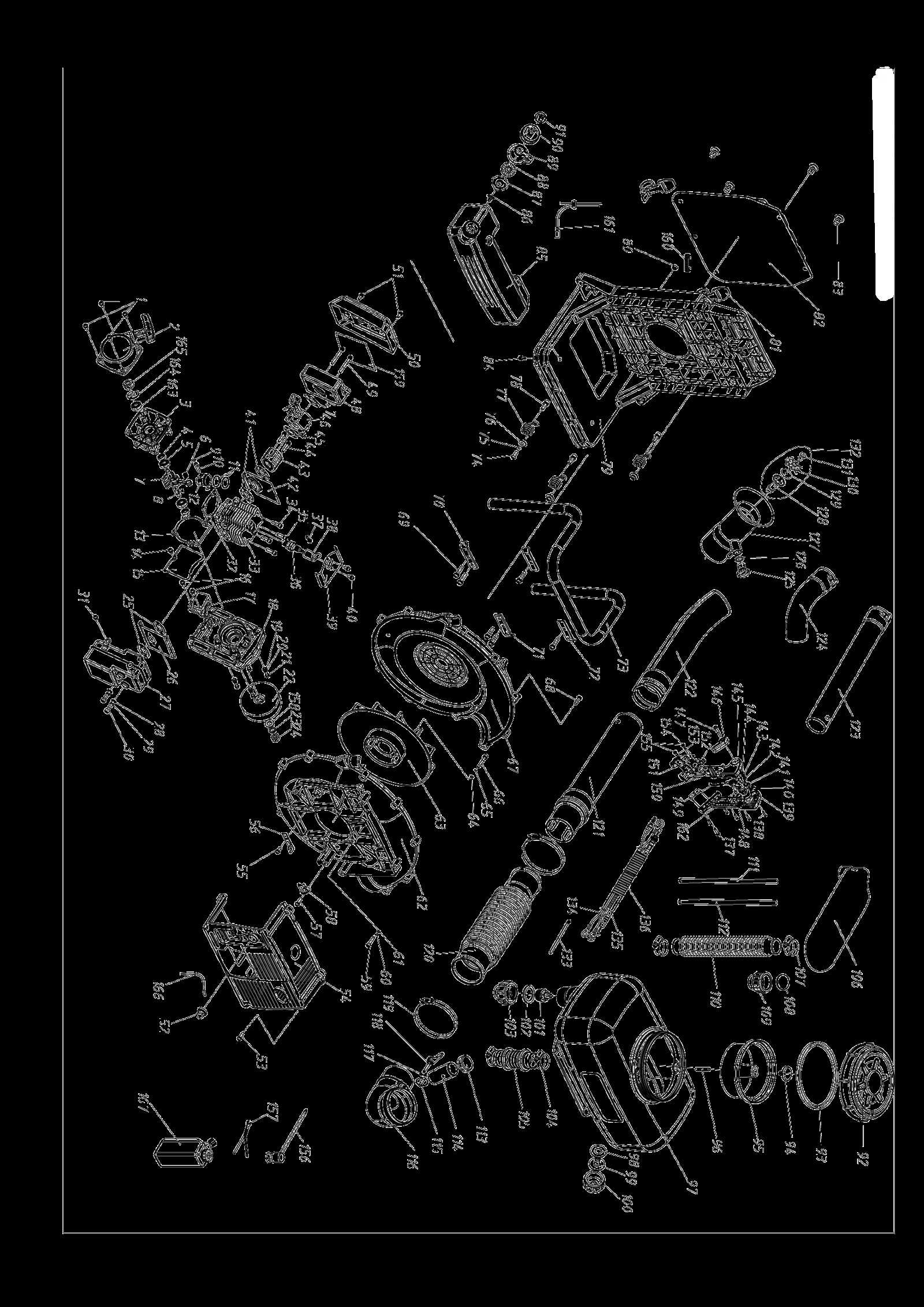

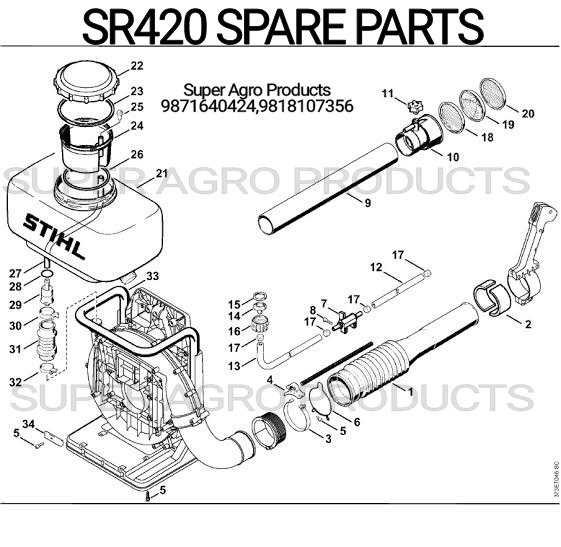

Visual aids play an essential role in this understanding, offering clarity on how each piece fits together and functions within the larger system. By examining detailed representations, users can gain insights into assembly, disassembly, and troubleshooting techniques. This knowledge empowers operators to take proactive measures in maintenance, reducing downtime and increasing efficiency.

Additionally, recognizing the individual components allows for informed decision-making when it comes to replacements or upgrades. As you delve deeper into the specifics of your machinery, you’ll find that a strong grasp of its structure leads to improved operation and satisfaction. This guide aims to equip you with the necessary information to navigate the complexities of your equipment with confidence.

Understanding Stihl SR450 Components

This section aims to explore the essential elements of a popular outdoor power tool, providing insights into its structure and functionality. A thorough comprehension of these components can enhance maintenance practices and overall performance.

- Engine: The heart of the machine, responsible for power generation.

- Fuel System: Includes the tank, lines, and filters that ensure efficient fuel delivery.

- Air Filter: Critical for maintaining clean airflow, impacting performance.

- Ignition System: Comprises spark plugs and coils, essential for engine start-up.

- Drive Mechanism: Translates engine power to operational efficiency.

Each of these parts plays a pivotal role in the ultimate functionality of the tool, enabling users to tackle various outdoor tasks effectively.

- Regular maintenance of the engine enhances longevity.

- Checking the fuel system prevents operational failures.

- Cleaning the air filter improves overall performance.

Understanding these key components allows for better handling and troubleshooting, ensuring the tool operates at its best.

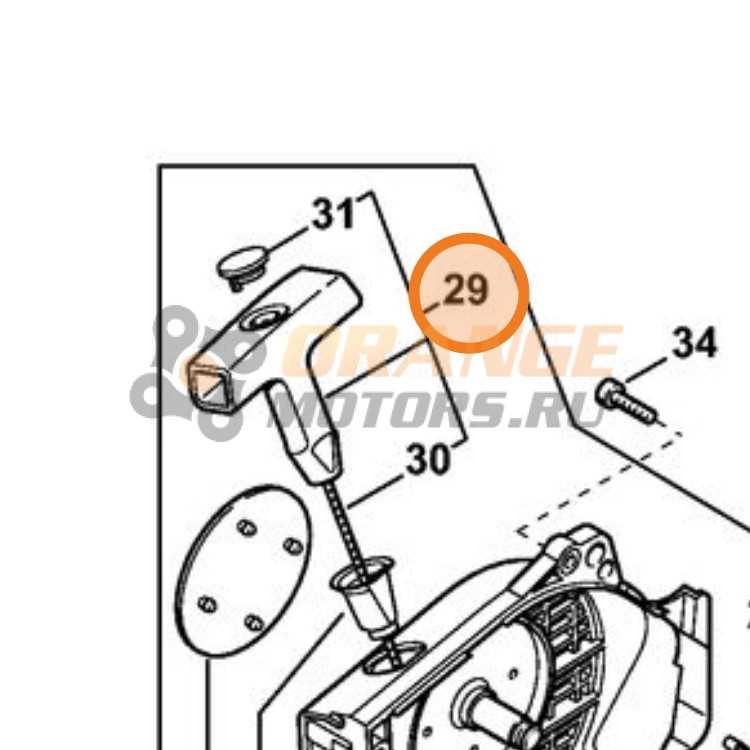

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of complex machinery. They provide an intuitive way to identify each element, facilitating maintenance, repairs, and upgrades. By having a clear visual reference, users can navigate through intricate systems with greater ease, ensuring efficient operation and longevity of the equipment.

Enhanced Understanding

Utilizing visual aids allows users to grasp the relationships between various elements within a machine. This understanding can lead to more effective troubleshooting and the ability to identify potential issues before they escalate. With a comprehensive overview, operators can approach their tasks with confidence, reducing the likelihood of errors during assembly or disassembly.

Efficient Repairs and Maintenance

Having a detailed visual reference significantly streamlines the repair process. Technicians can quickly locate and replace faulty components without wasting time searching for them. This efficiency not only minimizes downtime but also helps maintain the overall performance of the equipment. Moreover, clear illustrations reduce the risk of miscommunication, ensuring that everyone involved in maintenance is on the same page.

Identifying Key Parts of SR450

Understanding the essential components of your equipment is crucial for effective maintenance and operation. Each element plays a specific role, contributing to the overall functionality and efficiency. Familiarity with these parts not only aids in troubleshooting but also enhances performance and longevity.

The engine serves as the heart of the machine, providing the necessary power to drive various functions. The fuel system is vital for ensuring the engine receives the right mixture for optimal performance. Additionally, the air intake and exhaust components are essential for proper airflow, impacting both power output and emission control.

Other significant elements include the ignition system, which is responsible for starting the engine, and the drive mechanism that facilitates movement. Understanding the relationships between these components will help users recognize any signs of wear or malfunction, allowing for timely repairs and adjustments.

Lastly, familiarity with the housing and frame is important, as they protect internal mechanisms while contributing to the overall stability and balance of the equipment. By identifying and understanding these key elements, operators can ensure their machinery remains in peak condition for years to come.

Maintenance Tips for SR450 Users

Proper upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Regular maintenance not only enhances performance but also prevents costly repairs in the future. Here are some key practices to keep in mind.

Routine Checks

- Inspect air filters regularly and clean or replace them as needed.

- Check fuel lines for wear or leaks to maintain optimal performance.

- Examine the spark plug for signs of damage or buildup.

Cleaning and Lubrication

- Clean the exterior to prevent dirt accumulation.

- Lubricate moving parts to reduce friction and wear.

- Ensure that all safety mechanisms are functional and clean.

Common Issues and Solutions

Understanding potential challenges with outdoor power equipment can greatly enhance its performance and longevity. This section focuses on frequently encountered problems, offering practical solutions to help users maintain their machinery efficiently.

Engine Starting Difficulties

One of the most common challenges is when the engine fails to start. This issue may stem from a variety of factors, such as fuel quality, spark plug condition, or air filter blockage. Ensuring that fresh, high-quality fuel is used, replacing worn spark plugs, and regularly cleaning or replacing the air filter can significantly improve starting performance.

Overheating Concerns

Overheating can lead to severe damage if not addressed promptly. This problem is often caused by insufficient cooling, which can result from debris obstructing air vents or a malfunctioning cooling system. Regularly checking for blockages and ensuring that the cooling system is functioning properly can help prevent overheating and prolong the life of the equipment.

Where to Find Replacement Parts

When seeking components for outdoor power equipment, it’s essential to explore various avenues to ensure quality and compatibility. Different sources can provide reliable options to maintain your machinery in peak condition.

Authorized Dealers are often the best choice for obtaining genuine components, offering products specifically designed for your model. They can also provide expert advice and assistance in identifying the right items you need.

Online Retailers offer a vast selection, allowing you to compare prices and find specific items from the comfort of your home. Websites that specialize in outdoor equipment can be particularly useful for locating hard-to-find components.

Local Repair Shops can also be a valuable resource, as they may stock commonly needed components and can help you with installation. Their expertise ensures you get the right fit for your equipment.

Second-Hand Markets, such as auctions or classifieds, can yield great finds, especially if you’re looking for discontinued or rare items. Just be sure to check the condition before making a purchase.

By exploring these avenues, you can ultimately find the necessary items to keep your equipment running smoothly and efficiently.

Benefits of Using Genuine Parts

Using authentic components for your equipment ensures optimal performance and longevity. Genuine items are designed specifically for your model, offering precise fit and functionality. This can prevent potential issues that may arise from inferior alternatives, ultimately saving time and money in the long run.

Here are some key advantages of utilizing original components:

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic components meet strict manufacturing standards, ensuring reliability and durability. |

| Perfect Compatibility | Designed for a specific model, these items guarantee a precise fit, reducing the risk of malfunction. |

| Enhanced Performance | Original components optimize the efficiency of your machinery, contributing to better overall performance. |

| Long-Term Savings | Investing in quality parts minimizes maintenance costs and extends the lifespan of your equipment. |

| Warranty Protection | Using authentic components helps maintain the warranty coverage provided by the manufacturer. |

In conclusion, opting for genuine components is a smart choice that pays off through improved performance, durability, and overall satisfaction with your equipment.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to the assembly process of your equipment, ensuring that each component is correctly positioned for optimal functionality. Following these instructions will help you avoid common pitfalls and ensure a smooth operation.

Required Tools

| Tool | Purpose |

|---|---|

| Screwdriver | For securing screws |

| Wrench | For tightening bolts |

| Lubricant | To ensure smooth movement |

Assembly Steps

Begin by gathering all components and tools. Follow the sequence outlined in the instruction manual, ensuring each piece is aligned properly. Secure all fasteners without overtightening, and apply lubricant where indicated to enhance performance. Finally, double-check your work to ensure everything is assembled correctly before use.

Comparing SR450 with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. By examining features, performance metrics, and user experiences, we can understand what sets this particular unit apart and why it might be the ultimate choice for certain users.

Performance Comparison

When analyzing performance, key factors such as power output and efficiency come into play. The model in question typically offers robust capabilities that rival other leading products. Users often report that its design allows for superior handling and lower operational fatigue during extended use.

Features and Usability

Feature sets can significantly impact usability. While some alternatives may provide additional accessories, the focus on simplicity and reliability in this model often leads to a more streamlined experience. Users appreciate the straightforward maintenance and ease of operation, which are crucial for both professionals and casual users.

Frequently Asked Questions

This section addresses common inquiries that users may have regarding maintenance and repair components for their equipment. Here, we provide concise answers to assist with troubleshooting and understanding essential features.

What should I do if a component is damaged?

If a piece is broken, it’s crucial to identify the specific part and consult the user manual for guidance on replacement procedures. Additionally, consider sourcing compatible alternatives to ensure optimal performance.

How can I find the correct replacement for my device?

To locate the right substitute, refer to the model specifications and part numbers listed in the documentation. Online resources and authorized dealers can also provide valuable information.

Are there any tips for proper maintenance?

Regular upkeep is essential. Keep the equipment clean, inspect components for wear, and adhere to the recommended service schedule to prolong its lifespan.

What are the signs of a malfunctioning part?

Indicators may include unusual noises, reduced efficiency, or visible wear. Promptly addressing these symptoms can prevent further damage and costly repairs.

Where can I purchase spare components?

Spare items can typically be found at authorized retailers, specialty shops, or online marketplaces that cater to equipment maintenance needs.

Resources for Stihl Enthusiasts

For those passionate about outdoor power equipment, a wealth of information and tools is readily available. These resources can enhance your understanding, assist in maintenance, and support your projects, ultimately elevating your experience with these machines.

Online Communities

- Forums dedicated to equipment enthusiasts

- Social media groups for sharing tips and experiences

- Dedicated YouTube channels featuring tutorials and reviews

Technical Guides and Manuals

- Manufacturer’s official manuals for reference

- Repair guides and maintenance tips from experts

- Online resources for troubleshooting common issues