The equipment in question is a powerful and reliable tool designed to handle a wide range of outdoor tasks. Its internal structure is carefully crafted to ensure smooth performance and durability, offering users a dependable solution for various landscaping and maintenance needs. Understanding how each element interacts within the system can provide valuable insights into maintaining and optimizing this essential equipment.

In the following section, we will take a closer look at the detailed breakdown of its configuration. From key structural features to smaller elements, we’ll explore how everything works together, enabling the tool to function efficiently. By familiarizing yourself with these details, you can improve your maintenance routine and ensure long-term reliability.

Understanding the KM 94 R

The KM 94 R is a versatile and powerful tool designed to meet various needs in maintaining outdoor spaces. Known for its reliability and ease of use, this equipment provides a balance between performance and efficiency, making it ideal for both professionals and hobbyists.

Its lightweight design ensures extended use without fatigue, while the efficient engine technology allows for consistent operation in different conditions. Whether tackling heavy workloads or light tasks, the KM 94 R is engineered to deliver optimal results in a wide range of applications.

Another key aspect of the KM 94 R is its adaptability. It can handle multiple attachments, expanding its functionality and making it suitable for diverse tasks. This flexibility is what sets it apart as a preferred choice for those seeking an all-in-one solution for outdoor maintenance.

Essential Components of the KM 94 R

The KM 94 R is built with a variety of important elements that contribute to its performance and reliability. Each piece plays a vital role in ensuring smooth operation and efficiency. Understanding these core components helps users maintain and operate the machine with ease.

Key Mechanical Elements

- Power Unit: The heart of the machine, responsible for generating the necessary energy to drive various attachments.

- Throttle System: Allows for easy adjustment of power output, ensuring control over speed and performance.

- Fuel Delivery: Ensures a steady supply of fuel, crucial for consistent operation and power output.

Supportive Features

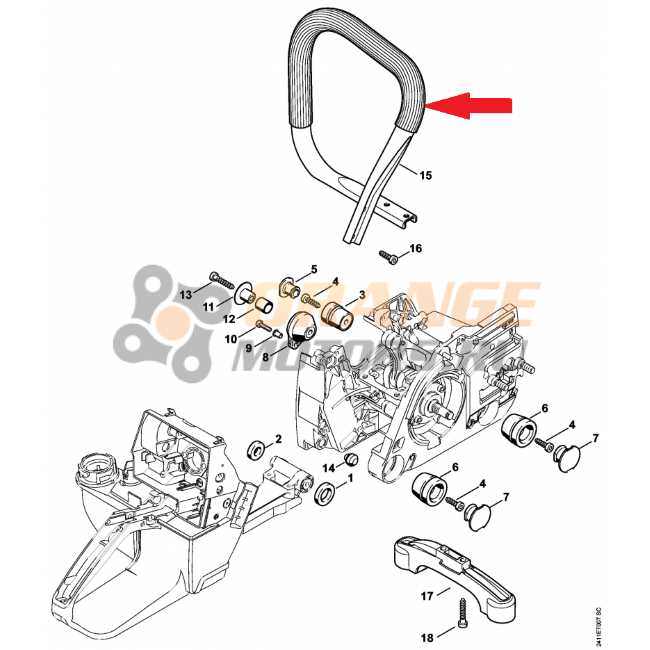

- Handlebar Assembly: Provides stability and comfort, allowing users to work efficiently over long periods.

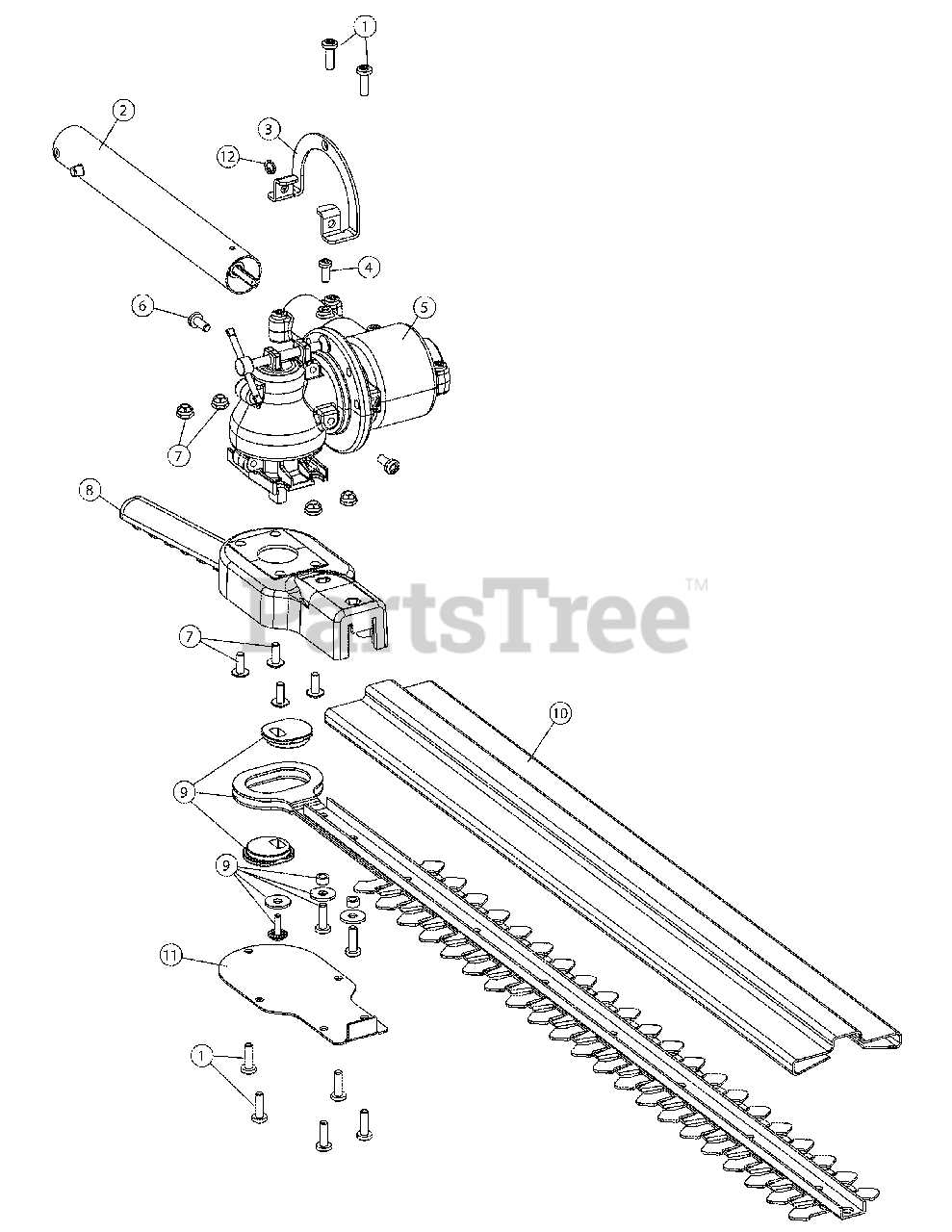

- Attachment Mechanism: Facilitates easy swapping of different functional tools, enhancing the machine’s versatility.

- Air Filtration: Protects internal systems from debris, extending the lifespan of the equipment.

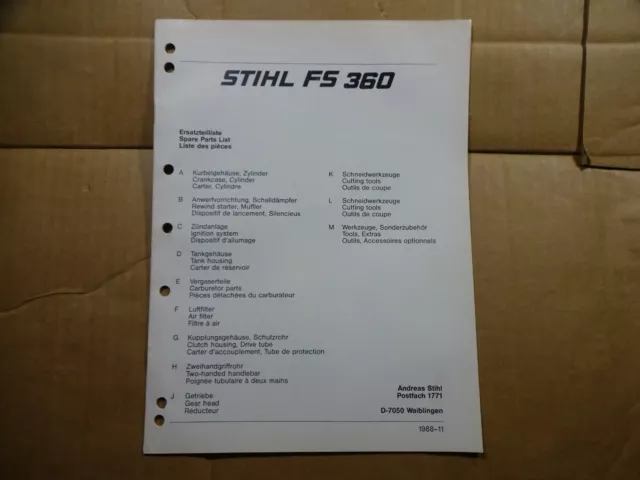

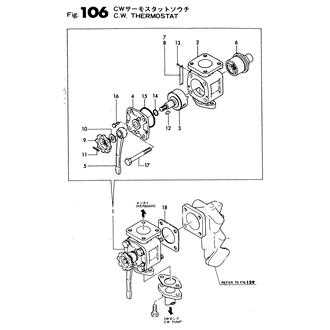

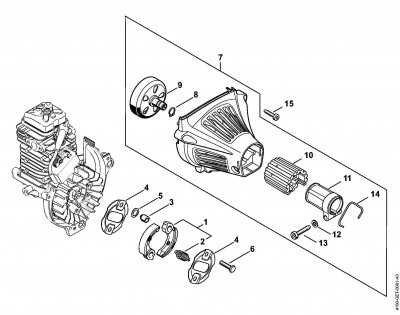

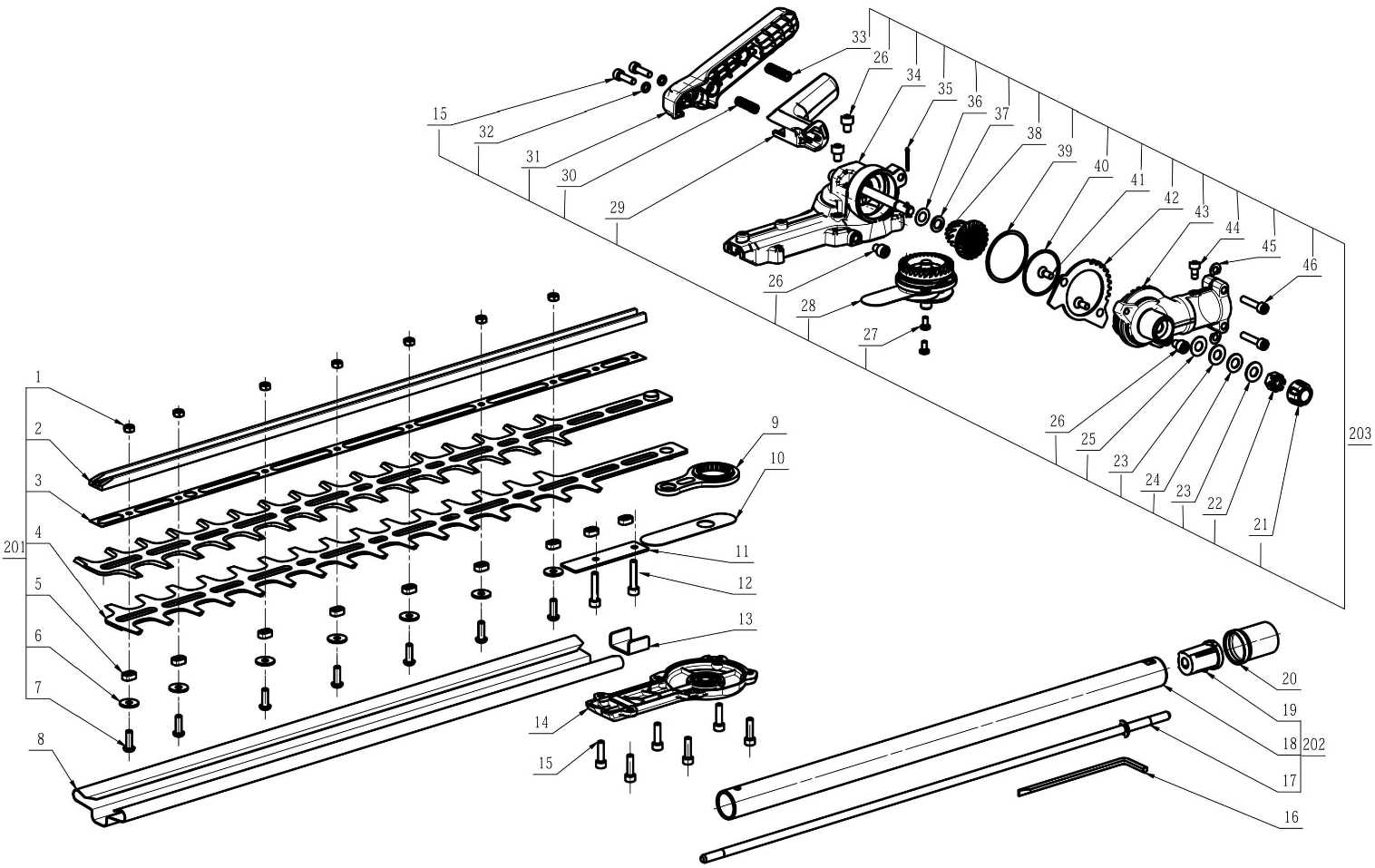

How to Read Parts Diagrams

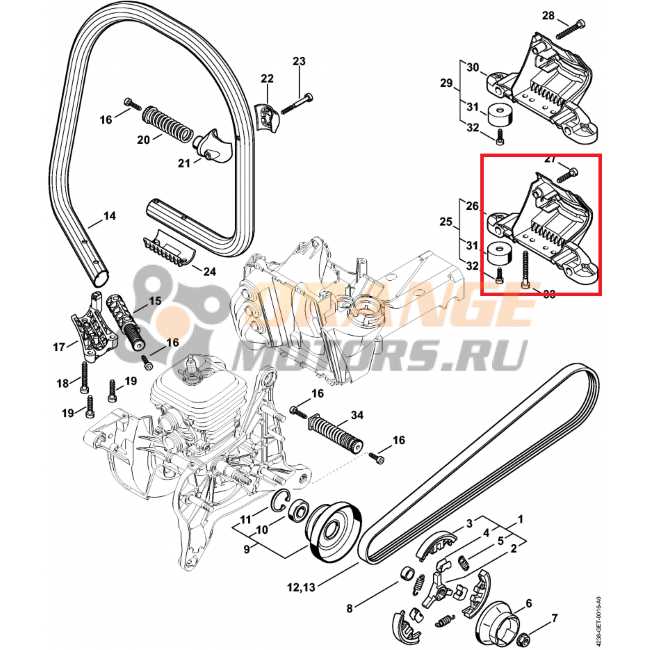

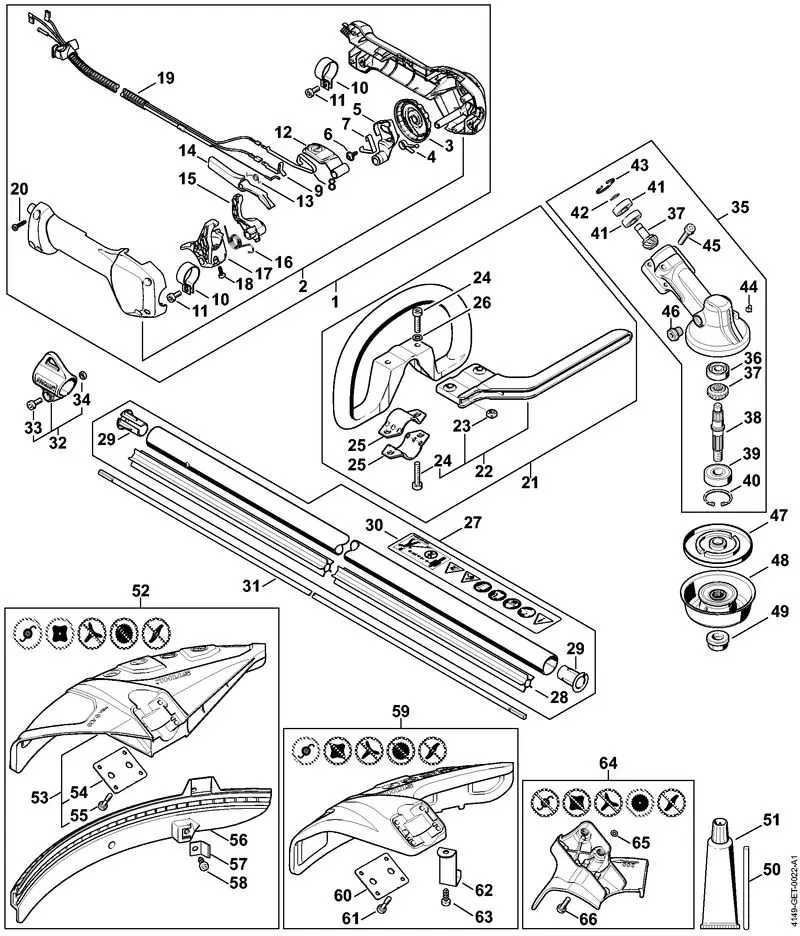

Understanding the layout of technical schematics can be crucial when working with various systems. These illustrations offer a clear visual guide, helping to identify and locate specific elements in a structured and easy-to-follow manner. With the right approach, these visual representations provide a deeper insight into how different components interact within a system, making maintenance and repairs more efficient.

Breaking Down the Visual Layout

Each illustration is typically divided into sections, each representing a specific part of the system. These sections are numbered or labeled, providing a quick reference that corresponds to the list of elements in the accompanying guide. The arrangement helps in pinpointing areas of interest and determining the sequence in which to disassemble or reassemble elements.

Using the Reference Guide

Alongside the visual layout, a reference table is often provided. This table gives additional details, including identification numbers, descriptions, and sometimes notes on the function or placement of each element. Cross-referencing this information ensures that you have the correct piece for each step of the process.

| Number | Description

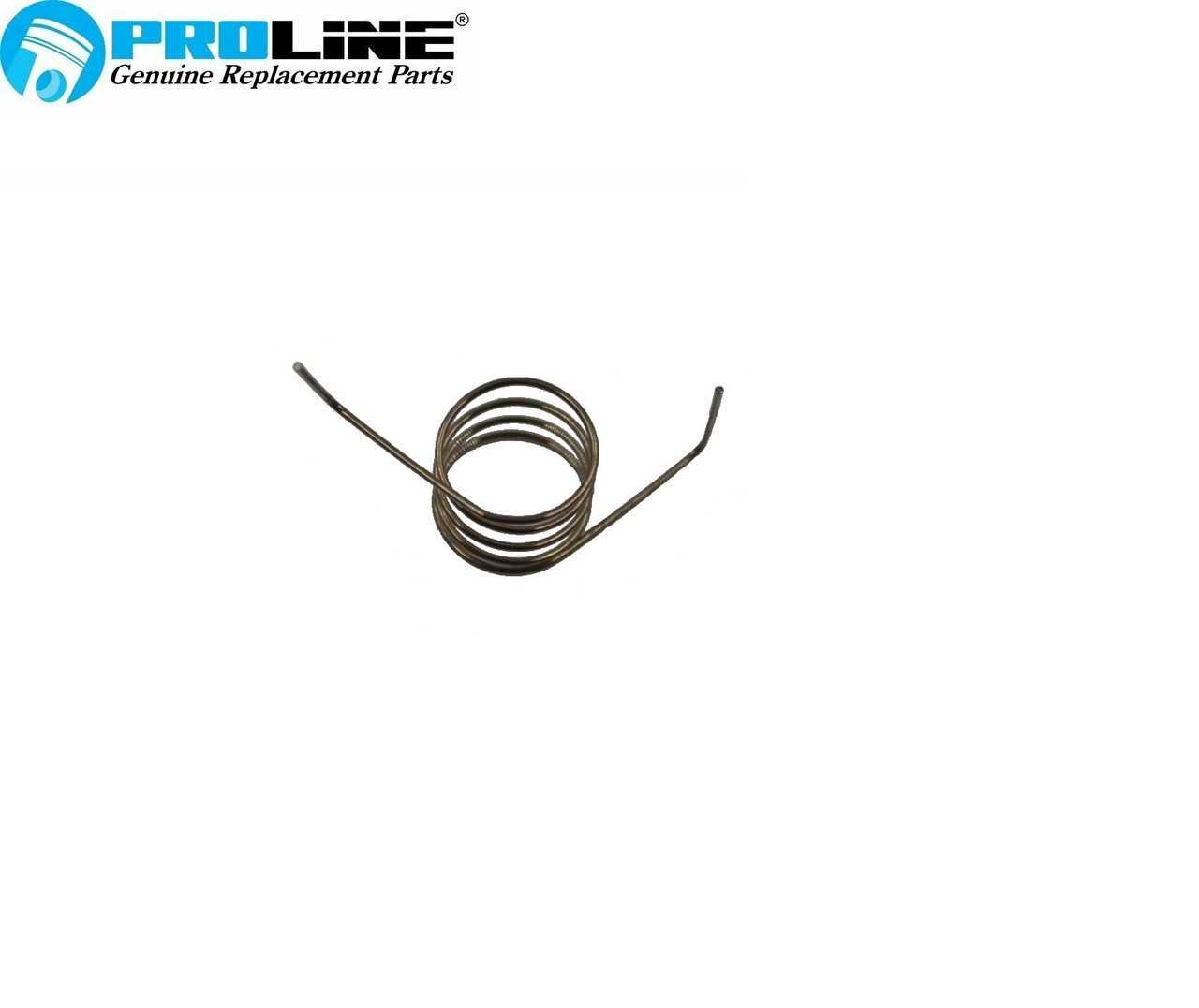

Common Replacement Parts ExplainedOver time, various components in power tools are prone to wear and tear due to regular use. Ensuring proper maintenance by replacing these elements can significantly extend the lifespan of the equipment and improve its overall efficiency. In this section, we will explore some of the most frequently swapped elements, shedding light on their importance and functionality. Engine Components

Drive and Cutting Elements

|

|---|