When it comes to maintaining your home devices, having a clear picture of how each component fits together is essential. This knowledge can save both time and money by helping you address issues without professional intervention. Every element within the system plays a role in ensuring optimal performance, and understanding this intricate structure allows for more effective troubleshooting.

In this section, we’ll explore the detailed layout of the device, focusing on how various mechanisms interact. By gaining a deeper insight into the system’s architecture, you can easily identify potential points of failure and handle replacements or repairs with greater confidence. Whether you’re looking to solve a specific issue or just want to become more familiar with your appliance, the following information will provide a clear and concise overview.

Comprehensive Breakdown of the Kdte254ess2 Appliance

This section provides a detailed exploration of the internal components and key elements that contribute to the efficient operation of the appliance. Understanding the individual mechanisms and their functionality is essential for anyone looking to troubleshoot or maintain this model. Each element plays a crucial role in ensuring smooth performance, and in this breakdown, we will focus on the critical areas that enhance the overall usability and durability of the unit.

The core systems within the device work together to handle the primary tasks it is designed for, with a focus on delivering optimal results in daily use. From the mechanical structures to the electrical connections, every aspect of this model has been designed for reliability and longevity. This overview will provide insights into the essential mechanisms, helping users get familiar with its most important features.

Identifying Key Components of the Kdte254ess2

Understanding the primary elements that make up this appliance is crucial for both maintenance and troubleshooting. Each section serves a distinct function, contributing to the overall operation of the system. By recognizing these essential features, users can better assess the condition of their unit and address potential issues effectively.

Internal Mechanisms

The internal assembly consists of various units designed to handle the main functions. This includes components responsible for managing water flow, heating elements, and motorized systems. These internal parts work together to ensure efficient operation, with each playing a specific role in maintaining functionality.

External Controls

The external interface allows for interaction with the machine, featuring a range of settings and buttons that control various modes and options. These controls are designed for user convenience, providing easy access to the system’s full capabilities while also offering diagnostic feedback in case of malfunctions.

Understanding the Internal Structure of the Device

The internal design of this particular appliance is crafted to ensure both efficiency and durability. Each component is meticulously positioned to contribute to the overall functionality, working together to complete specific tasks. By examining the layout and arrangement of the elements, we can gain valuable insight into how the unit operates as a whole.

Below is a closer look at some of the key components found within the system:

- Control mechanisms responsible for regulating performance.

- Pumps and valves that handle the flow of water and ensure proper cleaning cycles.

- Heating elements that help maintain optimal temperature levels during operation.

- Filtration systems designed to keep the device free from debris and ensure smooth functionality.

- Electrical wiring that connects all components and enables seamless communication between different parts.

Understanding how these sections are organized helps in troubleshooting and maintaining the appliance for long-term use.

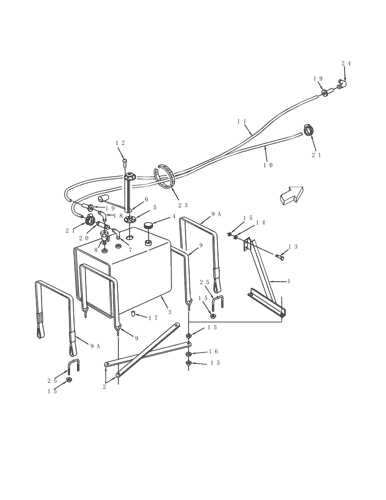

Exploring the Electrical System Layout

The electrical configuration within any appliance plays a vital role in its functionality. Understanding how the various components interconnect can help diagnose issues, optimize performance, and ensure proper maintenance. This section offers insights into the arrangement and connectivity of the system, allowing a clearer perspective on how the power is distributed throughout the entire structure.

The network of wires, connectors, and circuits is designed to deliver energy to each functional element efficiently. Key areas of focus include the routing of electrical lines, the placement of critical control units, and how different elements are powered and interact with each other. This comprehensive overview provides a deeper understanding of the system’s internal framework.

Functions of Major Control Units

The central components within this system play an essential role in ensuring the seamless operation of various functions. These control units manage and regulate the entire workflow, coordinating multiple tasks to maintain efficiency and effectiveness. By understanding how these core elements interact, one can better appreciate the intricate balance required for smooth performance.

Main Control Module: This is the brain of the system, overseeing the execution of all commands. It processes inputs and adjusts outputs accordingly, ensuring that the entire system functions optimally.

Temperature Control Unit: This section regulates the heat levels, crucial for maintaining operational stability. It adjusts the temperature based on real-time needs, ensuring proper conditions throughout the process.

Flow Management System: Responsible for monitoring and controlling the flow of resources, this unit ensures that the right amount is delivered at the correct time, preventing any disruptions in the cycle.

Sensor Array: A network of sensors continuously provides feedback to the main module. These inputs help adjust operations in real-time, ensuring that performance is always at peak efficiency.

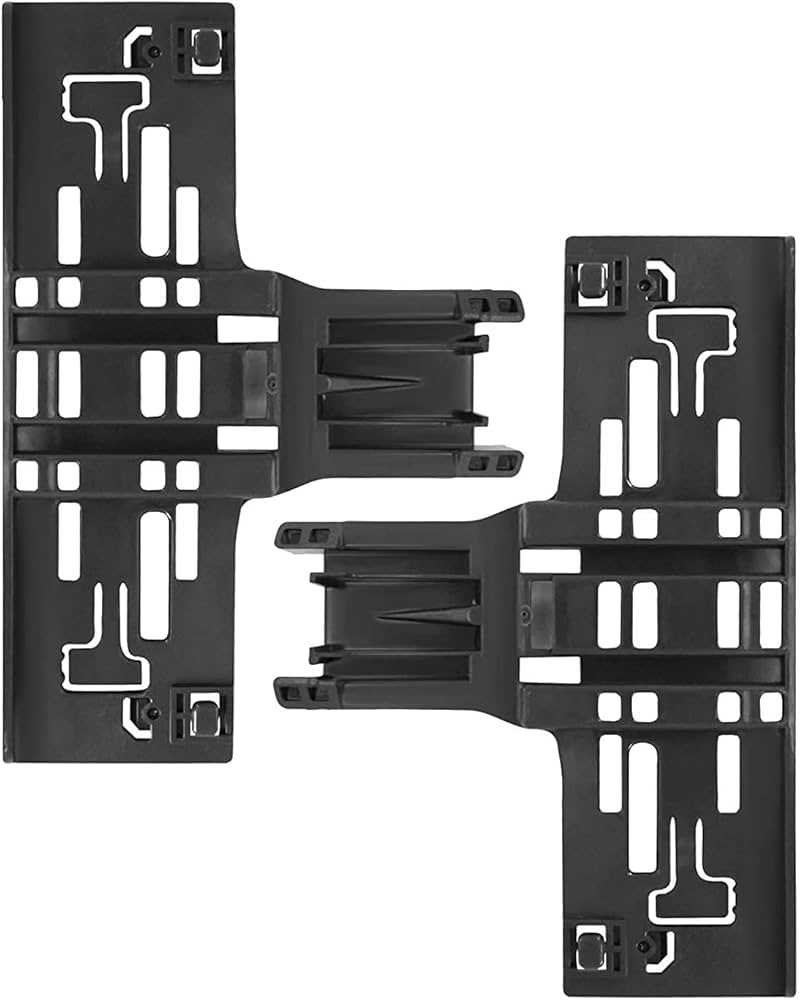

Detailed Look at the Pump Assembly

The pump assembly is a critical component in any appliance, responsible for fluid movement and efficient operation. Understanding its structure and function is essential for effective maintenance and troubleshooting. This section provides an in-depth exploration of the various elements that comprise this assembly, highlighting their roles and interactions within the system.

Key Components of the Pump Assembly

At the heart of the pump assembly lies the motor, which drives the entire mechanism. This element is typically connected to an impeller, a rotating part designed to propel fluid through the system. Additionally, seals and gaskets are employed to prevent leaks and ensure optimal performance. Each of these components works in harmony, contributing to the assembly’s overall efficiency.

Maintenance Considerations

Regular upkeep of the pump assembly is crucial to prevent potential issues. Routine checks for wear and tear on the seals can help avoid leaks, while ensuring that the motor is clean and free from debris will enhance its longevity. By understanding the individual parts and their functions, users can perform effective maintenance and ensure reliable operation.

How to Replace Water Filtration Parts

Maintaining clean and fresh water in your appliance is essential for optimal performance and taste. This guide will walk you through the process of swapping out filtration components, ensuring your unit operates efficiently.

Identifying the Necessary Components

Before starting the replacement process, it’s important to know which elements need to be changed. Common filtration components include:

- Carbon filters

- Water inlet valves

- Hoses and connectors

- O-rings and seals

Steps for Replacement

Follow these steps to successfully replace the filtration components:

- Ensure the appliance is turned off and unplugged to prevent any accidents.

- Access the filtration area, which may require removing a cover or panel.

- Carefully detach the old filter or component from its housing.

- Inspect the surrounding area for any signs of wear or damage.

- Install the new filter or component, ensuring a secure fit.

- Reassemble any covers or panels that were removed.

- Plug in the appliance and turn it on to verify proper operation.

Regularly checking and replacing these filtration elements is key to maintaining the quality of water your appliance dispenses.

Maintenance Tips for the Heating Element

Ensuring the longevity and efficiency of the heating component is essential for optimal performance. Regular upkeep not only enhances functionality but also helps in preventing potential issues that may arise over time.

Begin by routinely checking for any signs of wear or damage. Look for discoloration or unusual deposits that could indicate a buildup of residue. Keeping the surface clean is crucial; use a soft cloth and appropriate cleaning agents to remove any grime that accumulates.

It’s advisable to inspect the electrical connections periodically. Loose or corroded connections can lead to inefficient heating or even failure. Make sure to tighten any loose screws and replace any corroded components as necessary.

Furthermore, consider the surrounding environment of the unit. Ensure proper ventilation to avoid overheating, as restricted airflow can lead to premature wear. Maintaining a clean area free from dust and debris will also contribute to the efficient functioning of the heating element.

Lastly, follow the manufacturer’s guidelines for routine maintenance schedules. Adhering to these recommendations will not only prolong the life of the component but also ensure safety and reliability during operation.

Guide to Spray Arm Mechanisms

The efficiency of any washing device largely depends on its ability to distribute water effectively. Central to this process is a pivotal component that ensures optimal cleaning performance. Understanding the operation and design of this mechanism can greatly enhance the user experience and maintenance of the appliance.

These systems typically feature a rotating arm equipped with multiple nozzles that spray water in various directions. The rotation allows for comprehensive coverage of the items being cleaned, ensuring that every surface is reached. Precision engineering in these components allows for adjustments in spray patterns and pressures, tailored to different cleaning needs.

Regular maintenance is essential for these mechanisms to function at peak efficiency. Clogs can hinder performance, leading to uneven cleaning results. By keeping the spray nozzles clear and inspecting the rotational mechanics, users can prolong the lifespan of their washing devices and maintain optimal cleaning results.

In summary, an understanding of the spraying mechanism is vital for anyone looking to improve their cleaning efficiency. By recognizing its importance and maintaining it properly, users can ensure their appliances operate smoothly and effectively.

Understanding Valve and Hose Connections

Connections between components play a crucial role in the efficiency and functionality of various systems. Properly designed junctions ensure seamless fluid movement, enhancing overall performance. This section delves into the intricacies of these links, emphasizing their significance in maintaining operational integrity.

The interaction between valves and hoses is essential for controlling the flow of fluids within a system. Valves regulate the passage of liquids or gases, while hoses provide the necessary pathways for transport. Understanding the types of connections and their applications can greatly influence system reliability and safety.

| Connection Type | Description | Common Uses |

|---|---|---|

| Threaded | Utilizes screw threads for secure attachment. | Pipes, hoses, and fittings in plumbing. |

| Quick Disconnect | Allows for fast separation and reattachment. | Automotive and hydraulic systems. |

| Flanged | Flat surfaces with bolts provide a sturdy connection. | Industrial piping systems. |

| Compression | Secured by compressing a fitting onto the hose. | Water supply lines and appliances. |

Recognizing the appropriate connection method is vital for ensuring the longevity and effectiveness of a system. Each type has its advantages and specific contexts in which it excels, thus making it imperative to choose wisely based on application needs.

Troubleshooting the Drain System Issues

Identifying and resolving problems within the drainage mechanism is essential for maintaining optimal performance. Various factors can contribute to inefficiencies, leading to poor drainage or leaks. Understanding these issues and their potential causes can facilitate effective solutions.

Common Symptoms: Users may notice water pooling, slow drainage, or unpleasant odors. These indicators often suggest blockages or malfunctions within the system.

Potential Causes: Accumulation of debris, improper installation, or wear and tear can obstruct flow. Regular inspections and maintenance are vital to prevent these issues from escalating.

Troubleshooting Steps: Start by examining visible components for any signs of obstruction. Remove any debris that may be hindering performance. If problems persist, check for proper alignment and connections. In some cases, it may be necessary to consult a professional for a thorough evaluation.

By addressing these concerns promptly, users can ensure the longevity and efficiency of the drainage system, ultimately enhancing the overall functionality of their appliance.