For those who rely on high-performance cleaning machinery, having a thorough understanding of its components is essential for optimal functioning and maintenance. Each element plays a critical role in ensuring efficiency and longevity, making it vital to grasp their interconnections and functions. This knowledge empowers users to troubleshoot issues and perform necessary repairs, enhancing the overall effectiveness of the equipment.

Within this guide, we delve into the intricate layout of essential components, highlighting their specific roles and how they contribute to the machine’s performance. By familiarizing yourself with the structure and organization of these elements, you can better appreciate how they interact to produce powerful cleaning results. This understanding can also prevent common problems and reduce downtime.

Whether you are a seasoned professional or a novice user, knowing the arrangement and function of each piece can significantly impact your experience. Armed with this information, you can confidently navigate repairs and maintenance tasks, ensuring your equipment remains in peak condition. Let’s explore the intricate details that make up this essential cleaning tool.

Understanding Mi-T-M Pressure Washers

High-performance cleaning machines have revolutionized the way we tackle tough stains and dirt in various environments. These powerful tools are designed for efficiency, offering users the ability to achieve sparkling results with minimal effort. With a blend of advanced technology and user-friendly features, they cater to both residential and commercial needs.

Key Features and Benefits

These cleaning units are equipped with robust engines that provide exceptional water flow and pressure, enabling them to handle diverse tasks. Users appreciate their durability and the ease with which they can switch between different cleaning attachments, making them versatile for numerous applications.

Maintenance and Care

Regular upkeep is essential for longevity and optimal performance. Familiarity with essential components and maintenance routines will ensure that these machines remain in peak condition, delivering outstanding results every time.

Importance of Pressure Washer Parts

Understanding the significance of various components in a cleaning device is crucial for ensuring optimal performance and longevity. Each element plays a vital role in the overall functionality, contributing to efficiency and effectiveness during operation. Neglecting any single part can lead to diminished results or even equipment failure, emphasizing the need for awareness and maintenance.

Maintaining these essential elements not only enhances the machine’s ability to perform tasks effectively but also prevents costly repairs and replacements. A comprehensive knowledge of how these components interact can lead to better decision-making when it comes to upgrades or repairs.

| Component | Function | Impact of Neglect |

|---|---|---|

| Motor | Powers the unit and generates pressure | Failure can halt operation entirely |

| Pump | Maintains water flow and pressure | Leakage or failure leads to inefficiency |

| Nozzle | Controls the spray pattern and intensity | Clogging can reduce cleaning effectiveness |

| Hose | Transfers water from the source to the application area | Wear can cause leaks and hinder flow |

| Trigger Gun | Regulates the flow of water | Malfunction can lead to unsafe operation |

By prioritizing the upkeep and understanding of these critical components, users can ensure that their cleaning equipment remains efficient, reliable, and safe for various tasks. Regular inspections and timely replacements are key to maintaining high performance and achieving satisfactory results.

Common Components in Pressure Washers

Understanding the key elements of these cleaning machines is essential for effective use and maintenance. Each component plays a crucial role in delivering powerful cleaning performance.

- Motor: The heart of the machine, responsible for generating the necessary power.

- Pump: Converts the motor’s energy into high-pressure flow, essential for effective cleaning.

- Hose: Transports the water from the unit to the nozzle, influencing reach and flexibility.

- Nozzle: Directs the water spray, allowing for various cleaning applications.

- Trigger Gun: Provides user control over water flow, enhancing safety and efficiency.

Each of these components can impact the ultimate effectiveness and longevity of the cleaning device.

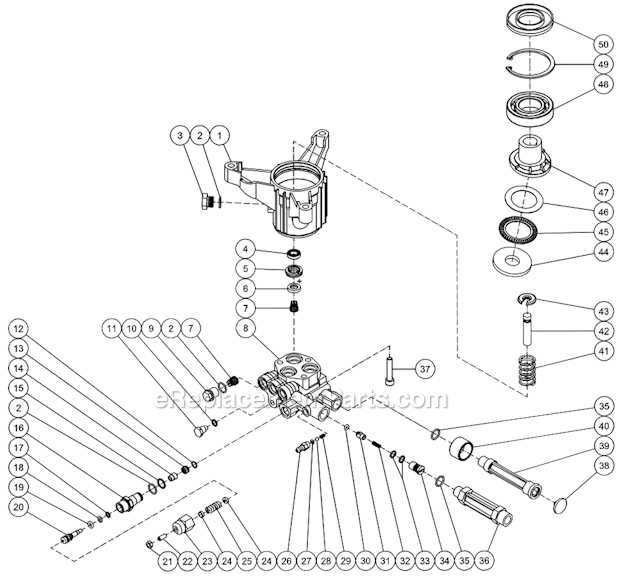

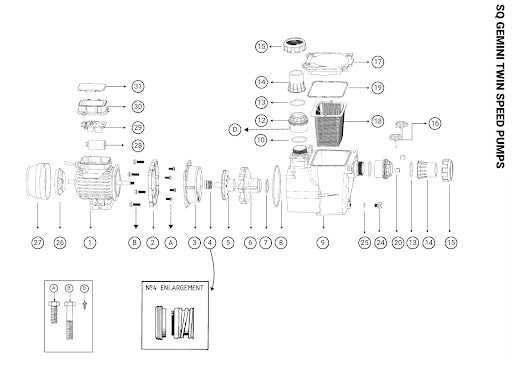

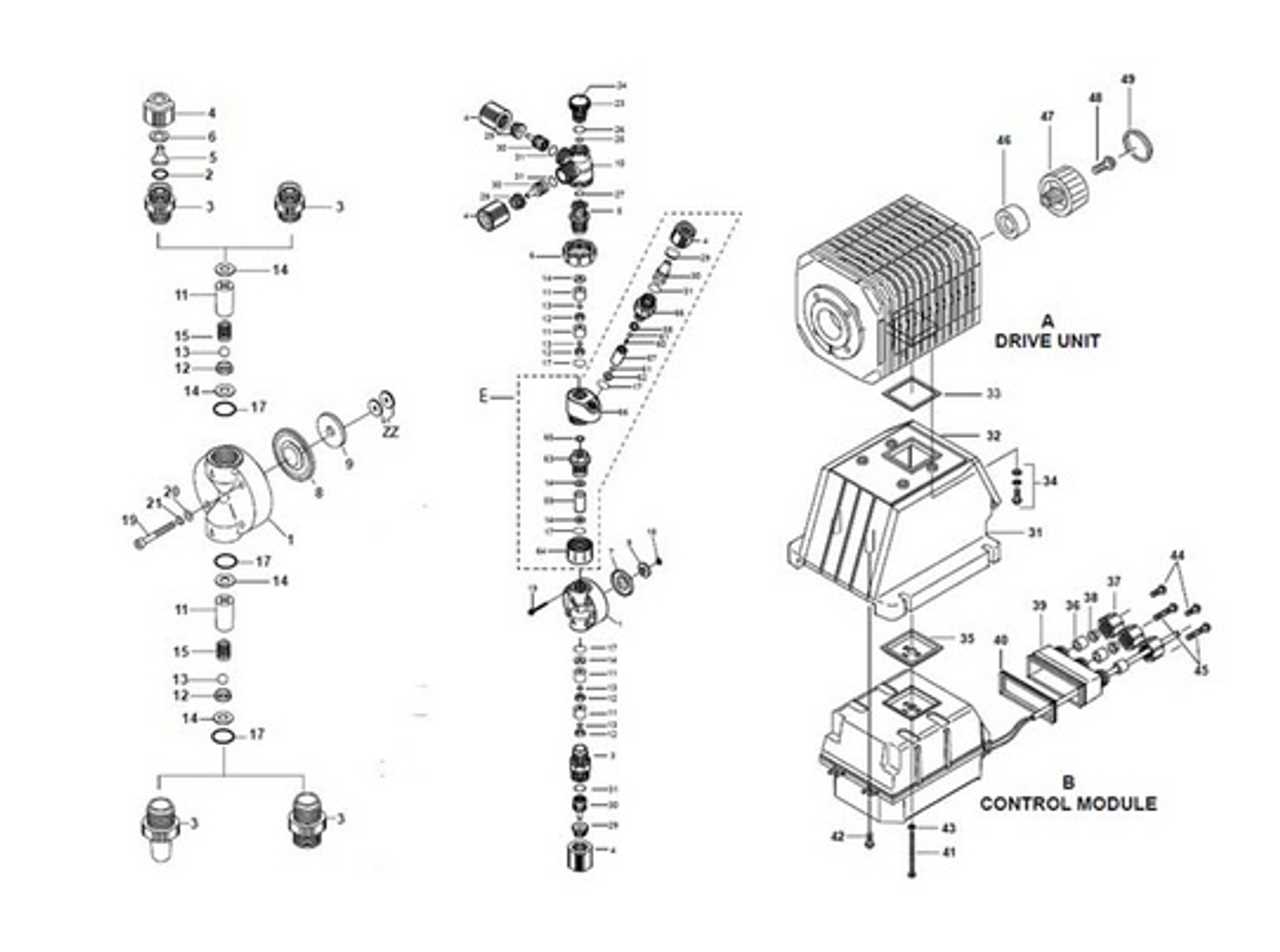

Interpreting the Parts Diagram

Understanding the layout of components is essential for efficient maintenance and repair. A well-structured visual representation allows users to identify and locate each element, facilitating quicker problem-solving and replacement. Grasping this layout can significantly enhance your experience and effectiveness in managing equipment.

Key elements of the illustration include labels and connections, which guide users in recognizing the relationships between different components. Each section often highlights critical areas, making it easier to pinpoint issues and carry out necessary tasks.

By analyzing the visual cues presented, one can develop a deeper comprehension of the overall assembly. This knowledge empowers users to make informed decisions, ensuring that their maintenance efforts lead to optimal functionality and longevity of the machinery.

Identifying Key Components

Understanding the main elements of your equipment is crucial for effective maintenance and optimal performance. Familiarity with these components allows for efficient troubleshooting and ensures longevity. Below are the essential parts that contribute to the overall functionality.

Core Elements to Recognize

- Motor: Powers the entire system, converting electrical energy into mechanical motion.

- Pump: Responsible for generating the necessary pressure to propel water, essential for cleaning tasks.

- Hoses: Facilitate the flow of water, connecting various parts while withstanding high pressure.

- Nozzle: Directs the water stream, allowing for different spray patterns to suit various cleaning needs.

- Trigger Handle: Controls the release of water, providing user convenience and safety.

Additional Supporting Components

- Filter: Prevents debris from entering the system, protecting internal parts.

- Wheels: Enhance mobility, making the equipment easier to transport.

- Frame: Provides structural support, housing all components securely.

Being knowledgeable about these critical elements enables you to maintain your equipment effectively, ensuring it operates smoothly and reliably. Regular inspection and care of these components will lead to better performance and durability.

How to Read Pressure Washer Schematics

Understanding the layout of a cleaning machine’s components is essential for effective troubleshooting and maintenance. By familiarizing yourself with the visual representation of the device’s structure, you can easily identify parts, their functions, and how they interact with one another. This knowledge empowers you to make informed decisions when repairs or replacements are necessary.

Key Elements to Identify

- Symbols: Recognize the various icons used to represent different components, such as motors, hoses, and valves.

- Lines: Pay attention to the connections between parts, which indicate how they are linked and their flow direction.

- Labels: Look for names or numbers that describe each component for easy reference during maintenance.

Steps to Analyze a Schematic

- Start by examining the overall layout, noting the primary assembly and major components.

- Identify individual parts and familiarize yourself with their functions within the system.

- Trace the lines connecting the components to understand the flow of operations.

- Use the labels to cross-reference with the user manual for detailed information on each part.

- Make notes of any potential issues that arise from the schematic, such as wear or faulty connections.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your cleaning equipment operates efficiently and lasts for years. By implementing a few straightforward practices, you can significantly extend the lifespan of your machine and maintain optimal performance.

Here are some key maintenance tips to consider:

- Clean After Use: Always remove debris and residues after each session to prevent build-up.

- Check Fluid Levels: Regularly inspect and replenish necessary fluids to ensure smooth operation.

- Inspect Hoses: Look for cracks or wear in hoses and replace them as needed to avoid leaks.

- Change Filters: Keep filters clean and replace them periodically to maintain efficiency.

- Store Properly: Keep the equipment in a dry and sheltered location when not in use to protect it from the elements.

In addition to these practices, always consult the manufacturer’s guidelines for specific maintenance recommendations tailored to your model. Consistent attention to these details will lead to better performance and a longer operational life.

Common Issues and Solutions

When operating cleaning equipment, users often encounter various challenges that can hinder performance. Understanding these common problems and their corresponding solutions is essential for maintaining efficiency and prolonging the lifespan of the machine. Below, we explore frequent issues and practical fixes that can help users get back to work swiftly.

Problem: Low Water Pressure

A frequent complaint among users is insufficient water flow. This can result from clogged filters or hoses. To address this issue, first check for blockages in the intake and discharge lines. Cleaning or replacing filters can significantly improve flow. Additionally, ensure that all connections are secure and that the water source is adequate.

Problem: Engine Fails to Start

If the engine refuses to ignite, several factors may be at play. Start by inspecting the fuel system. Ensure that the fuel is fresh and that there are no leaks in the lines. If the fuel appears contaminated, consider draining the tank and refilling it with new fuel. Also, examine the ignition system, including spark plugs and electrical connections, for any signs of wear or damage.

By recognizing these common challenges and applying the appropriate solutions, users can maintain optimal functionality and enjoy effective cleaning results.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward task if you know where to look. There are various sources available that cater specifically to enthusiasts and professionals alike, ensuring you can maintain optimal performance and longevity.

Online Retailers often offer a wide selection of components, making it easy to compare prices and availability. Websites dedicated to machinery supplies can provide detailed catalogs, helping you identify the exact items you need.

Local Dealers can be invaluable resources as well. Visiting a nearby supplier allows you to see the components firsthand and receive expert advice on compatibility and installation.

Manufacturer Websites typically have sections dedicated to support, where you can find genuine components. This option ensures that you are using original items that fit perfectly with your machine.

Community Forums and social media groups are also excellent places to seek recommendations and advice. Fellow users often share their experiences, directing you to reliable sources for your specific needs.

DIY Repairs vs. Professional Help

When it comes to fixing equipment, individuals often face a choice between tackling the job themselves or seeking outside expertise. Each approach has its own set of benefits and drawbacks, making it essential to evaluate the situation carefully.

Consider the following factors when deciding:

- Cost: DIY repairs can save money on labor, but unexpected issues may lead to additional expenses.

- Time: Assess how much time you can dedicate. Professionals often work faster due to experience.

- Skill Level: Consider your comfort and familiarity with the equipment. Lack of experience can lead to mistakes.

- Tools Required: Some repairs may need specialized tools that you may not have on hand.

- Complexity: For intricate problems, professional assistance might be the safest option.

Ultimately, weighing these elements will guide you in making an informed decision that aligns with your needs and capabilities.

Comparing Models and Their Features

This section aims to explore the various models available on the market, highlighting their distinct characteristics and functionalities. By understanding the differences among them, consumers can make informed choices that align with their specific needs and preferences.

| Model | Power (HP) | Flow Rate (GPM) | Weight (lbs) | Special Features |

|---|---|---|---|---|

| Model A | 2.5 | 2.0 | 30 | Adjustable nozzle, compact design |

| Model B | 3.0 | 2.5 | 35 | Heavy-duty motor, extended hose |

| Model C | 2.0 | 1.8 | 28 | Eco-friendly mode, lightweight |

| Model D | 3.5 | 3.0 | 40 | High-performance pump, quick-connect accessories |

Upgrading Components for Better Performance

Enhancing various elements of your cleaning device can significantly improve its efficiency and effectiveness. By selecting superior alternatives, you can achieve better results and extend the lifespan of your equipment.

- High-Quality Nozzles: Opt for nozzles designed for specific tasks to maximize cleaning power.

- Durable Hoses: Upgrade to reinforced hoses that resist kinks and abrasions.

- Efficient Pumps: Consider replacing the pump with a model that offers higher flow rates.

- Enhanced Motors: A more powerful motor can provide the ultimate boost in performance.

Ultimately, investing in these upgrades not only enhances functionality but also contributes to a more satisfying user experience.