Understanding the inner workings of a complex mechanical system can greatly enhance its maintenance and performance. By exploring the intricate assembly and connections between various elements, one can gain a clearer perspective on how each piece contributes to the overall functionality of the machine.

Each element plays a vital role, and learning how these pieces interlock ensures smoother operation and easier troubleshooting. Identifying the placement and function of these components helps in maintaining the system’s longevity and efficiency.

This guide aims to provide a detailed look at the essential components, offering insight into how they fit together and contribute to the machine’s overall structure. Whether you are making repairs or performing routine maintenance, this breakdown will serve as a valuable resource.

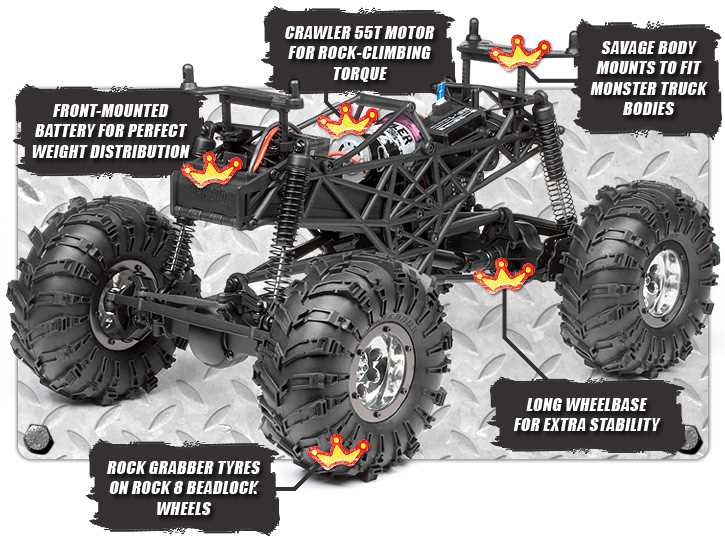

Hpi Wheely King Parts Overview

Understanding the components of this popular off-road vehicle can enhance your ability to maintain and upgrade it efficiently. Each element of the machine plays a crucial role in its overall performance, ensuring that it runs smoothly across challenging terrains. By becoming familiar with the structure and design, users can optimize their vehicle for better control, speed, and endurance.

Key Mechanical Components

Among the most essential mechanical elements are the drivetrain and suspension systems. These systems work together to provide power and stability. The drivetrain transfers energy from the motor to the wheels, while the suspension absorbs shock and keeps the vehicle stable during off-road adventures. Both require regular inspection to maintain top performance.

Chassis and Electrical Elements

The chassis forms the backbone of the vehicle, offering structural integrity and housing important electrical

Understanding Key Components

The structure of any mechanical model relies on several essential elements that work together to ensure proper function. Recognizing these primary units helps to grasp how the system operates and what roles each piece plays in its performance. By understanding these critical elements, you can maintain and optimize the model more effectively.

Each section of the system is designed to handle specific tasks, from controlling movement to stabilizing the overall structure. It’s important to familiarize yourself with these individual pieces, as their interaction is crucial to achieving the desired outcome.

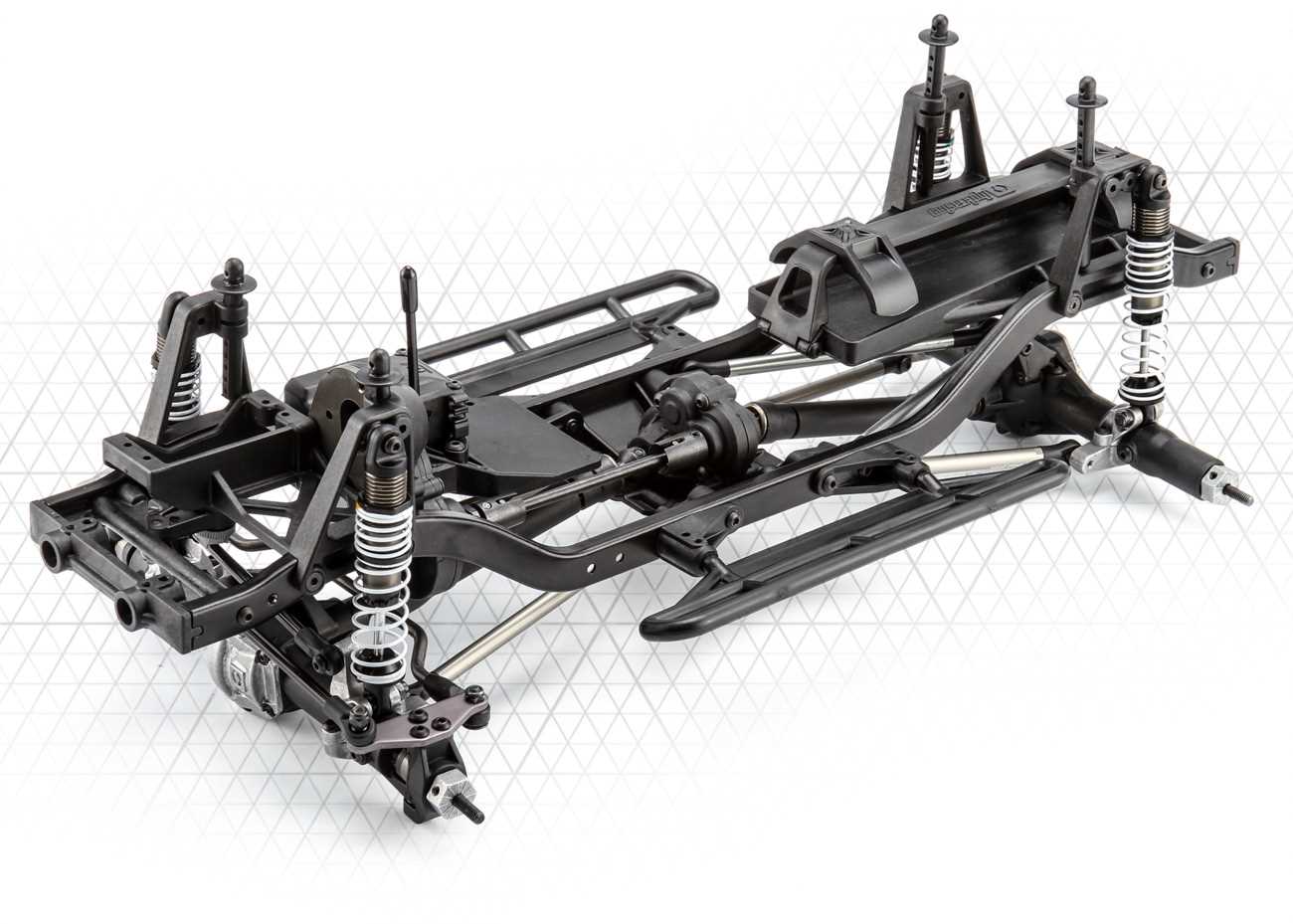

Chassis Design and Structure

The chassis serves as the backbone of any vehicle, providing a solid foundation that supports all the essential components. Its design ensures stability, durability, and the ability to handle stress during movement. This section focuses on the structural layout and its key functions in maintaining the integrity of the vehicle’s overall performance.

Material Composition

The material chosen for the chassis plays a crucial role in its performance. High-strength metals or specialized composites are often selected to ensure both lightweight properties and sufficient durability. This combination allows for better maneuverability while keeping the chassis resistant to impacts and wear over time.

Structural Integrity and Reinforcement

Reinforcements are strategically integrated into the chassis to strengthen areas exposed to higher stress levels. These reinforcements, along with the overall design, contribute to the balance and handling characteristics of the vehicle, ensuring it can withstand various terrains and conditions without compromising stability

Suspension System Breakdown

The suspension system plays a crucial role in ensuring smooth performance and handling during various driving conditions. It is responsible for maintaining stability and control, particularly when navigating uneven terrain or making sharp turns. Understanding the individual components and how they interact can help identify potential issues and improve overall functionality.

Main Components of the Suspension

Key elements of the suspension include springs, shock absorbers, and control arms. Each part contributes to absorbing impact and providing a balanced ride. The springs bear the vehicle’s weight, while the shock absorbers control the movement, reducing bouncing. Control arms, meanwhile, connect the wheels to the

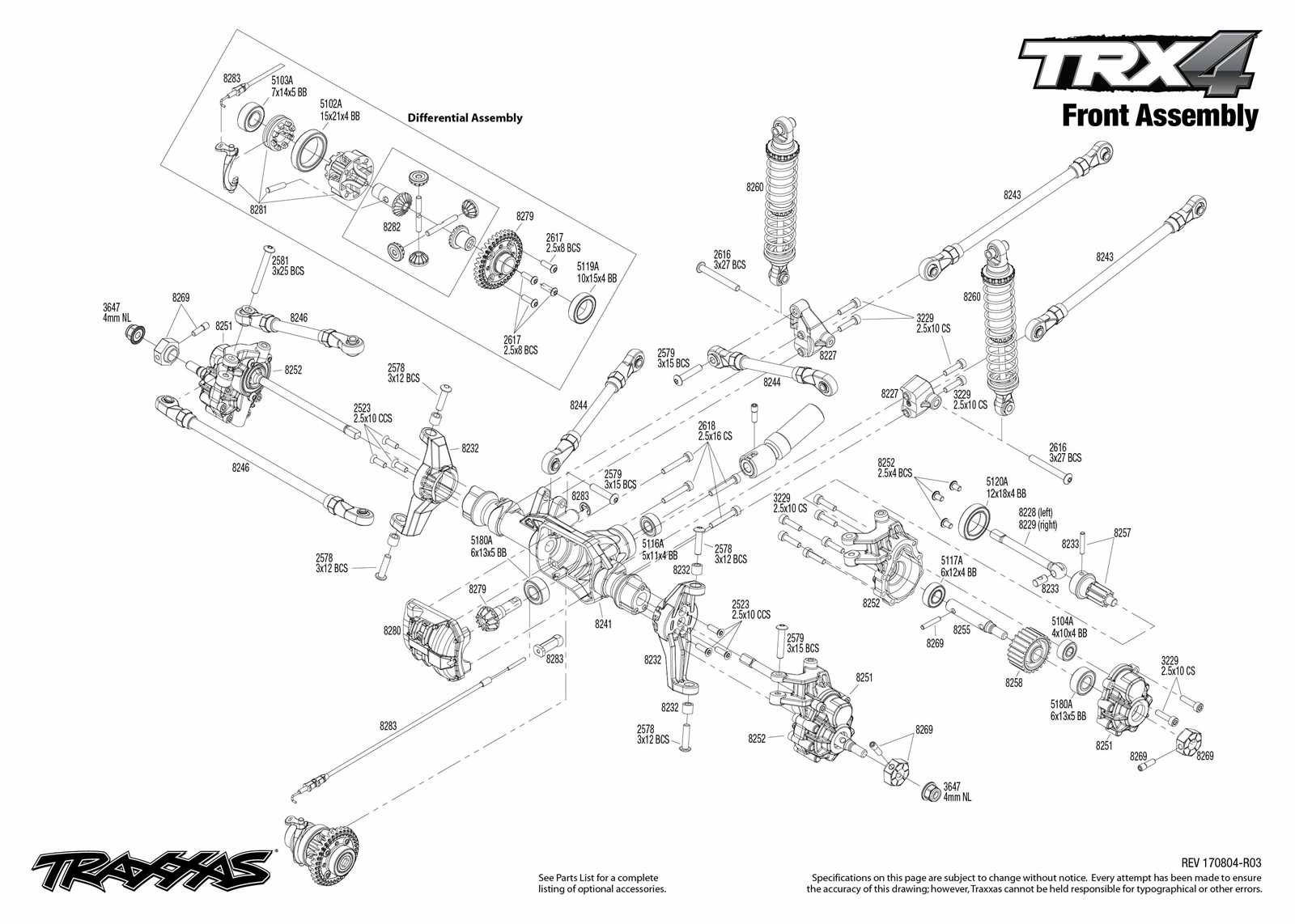

Transmission and Drive Assembly

The transmission and drive system are fundamental components that ensure efficient power transfer from the motor to the wheels. These interconnected parts work together to deliver motion, speed control, and torque management, enabling smooth operation across various terrains.

Main Components of the Drive System

The drive assembly consists of several key elements that collaborate to maintain functionality and stability. Each part contributes to the overall performance, ensuring the vehicle can handle different types of surfaces with ease.

- Gearbox: Responsible for adjusting the speed and torque to suit the driving conditions.

- Drive shafts: These components transfer rotational force from the gearbox to the wheels.

- Differentials

Motor and Electronics Layout

This section provides an overview of the arrangement and functionality of the propulsion system and electronic components within the vehicle. Understanding the layout is essential for optimizing performance and ensuring efficient operation.

Key Components

- Motor: The primary source of power that drives the wheels, responsible for converting electrical energy into mechanical motion.

- Electronic Speed Controller (ESC): A device that regulates the speed of the motor by controlling the power supplied, ensuring smooth acceleration and braking.

- Battery: The energy source that powers the entire system, typically rechargeable for prolonged use.

- Receiver: This component receives signals from the transmitter, enabling remote control of the vehicle’s movements.

- Servos: Mechanisms that control steering and other functions, responding to inputs from the remote control.

Wiring and Connectivity

Proper wiring is crucial for effective communication between components. Here are some essential tips:

- Ensure all connections are secure to prevent loss of power or signal.

- Use color-coded wires to simplify identification and troubleshooting.

- Organize wiring to minimize interference with moving parts and ensure airflow for cooling.

Steering Mechanism Explained

The steering system is a crucial component in maneuvering vehicles, allowing for precise control and direction changes. It plays a vital role in ensuring stability and responsiveness during movement.

Typically, the system comprises various interconnected parts that work together seamlessly. The main components include the steering wheel, linkage, and the actual steering gear, which translates the driver’s input into the movement of the wheels.

Linkage serves as the connection between the steering wheel and the wheels, facilitating the transfer of motion. Adjustment mechanisms are often incorporated to fine-tune responsiveness, ensuring optimal handling characteristics. Proper maintenance of this system is essential for safe operation and to enhance the overall driving experience.

In conclusion, understanding the steering mechanism is fundamental for anyone interested in vehicle operation or maintenance, as it directly affects control and handling.

Body Mounting and Customization

Proper attachment and

Shock Absorbers and Springs

Shock absorbers and springs play a crucial role in ensuring the stability and performance of any vehicle, especially in off-road environments. These components work together to manage the impact of uneven surfaces and provide a smooth driving experience.

Strong shock absorbers help minimize the effects of bumps and dips, enhancing the overall control and comfort of the ride. They reduce the amount of vertical movement by absorbing energy, preventing excessive bouncing. On the other hand, springs support the vehicle’s weight and help maintain appropriate ride height, enabling optimal handling and maneuverability.

Understanding the characteristics and functionality of these elements is essential for achieving peak performance. Proper maintenance and selection of suitable types can significantly impact traction, stability, and overall driving dynamics, making them integral to the vehicle’s setup.

Battery and Power Distribution

Effective energy management is crucial for the optimal performance of remote-controlled vehicles. This section delves into the components responsible for storing and distributing electrical power, ensuring that all systems operate smoothly and efficiently.

Energy Storage Solutions

The heart of any remote-operated model lies in its power source. Various types of batteries are available, each offering distinct advantages in terms of capacity, weight, and discharge rates. Selecting the appropriate energy storage solution is vital for achieving the desired run time and overall performance.

Power Distribution Mechanisms

Power distribution involves routing electricity from the battery to various components such as motors and servos. Efficient distribution systems reduce energy loss and enhance the responsiveness of the vehicle. Understanding the layout and connections can help users troubleshoot issues and optimize their setup for improved functionality.

Tire and Wheel Specifications

This section provides an overview of the essential characteristics related to tires and wheels, crucial for achieving optimal performance and stability in various applications. Understanding these specifications ensures compatibility and enhances the overall driving experience.

When selecting tires, it is vital to consider factors such as diameter, width, and aspect ratio. These measurements influence the handling, traction, and comfort of the vehicle. Additionally, tread patterns play a significant role in determining grip and wear characteristics, making them an important aspect of tire design.

Wheels also have their own set of specifications, including material, diameter, and offset. The choice of material affects durability and weight, while the offset impacts the positioning of the wheel relative to the vehicle’s body. Proper alignment of tires and wheels ensures efficient performance and reduces the risk of premature wear.

Axles and Gear Configuration

The arrangement of axles and gears plays a crucial role in the overall performance and functionality of a vehicle. Understanding how these components interact can enhance efficiency, stability, and handling capabilities. A well-designed system ensures smooth operation, allowing for optimal power transfer and maneuverability.

When examining the configurations, one must consider various factors such as gear ratios, axle lengths, and material quality. Each element contributes to the vehicle’s dynamics, influencing speed and torque. The following table outlines key specifications for different configurations:

Component Specification Function Front Axle Length: 100mm Provides steering and weight distribution Rear Axle Length: 120mm Supports the drive train and balance Gear Ratio 3:1 Affects acceleration and top speed Material Aluminum Offers lightweight and durable performance Maintenance Tips for Optimal Performance

To ensure the best functionality of your remote-controlled vehicle, regular upkeep is essential. Implementing effective maintenance practices can significantly enhance its longevity and performance. Below are key recommendations to keep your model running smoothly.

Routine Inspection

Conduct periodic checks of all components to identify any wear or damage. Look for loose screws, frayed wires, or any signs of deterioration. Timely detection of issues can prevent more significant problems down the line.

Cleaning and Lubrication

Keep your model clean by removing dirt and debris after each use. Utilize a soft brush and cloth for delicate areas. Additionally, apply appropriate lubricants to moving parts to reduce friction and enhance efficiency. This simple practice can lead to improved handling and speed.