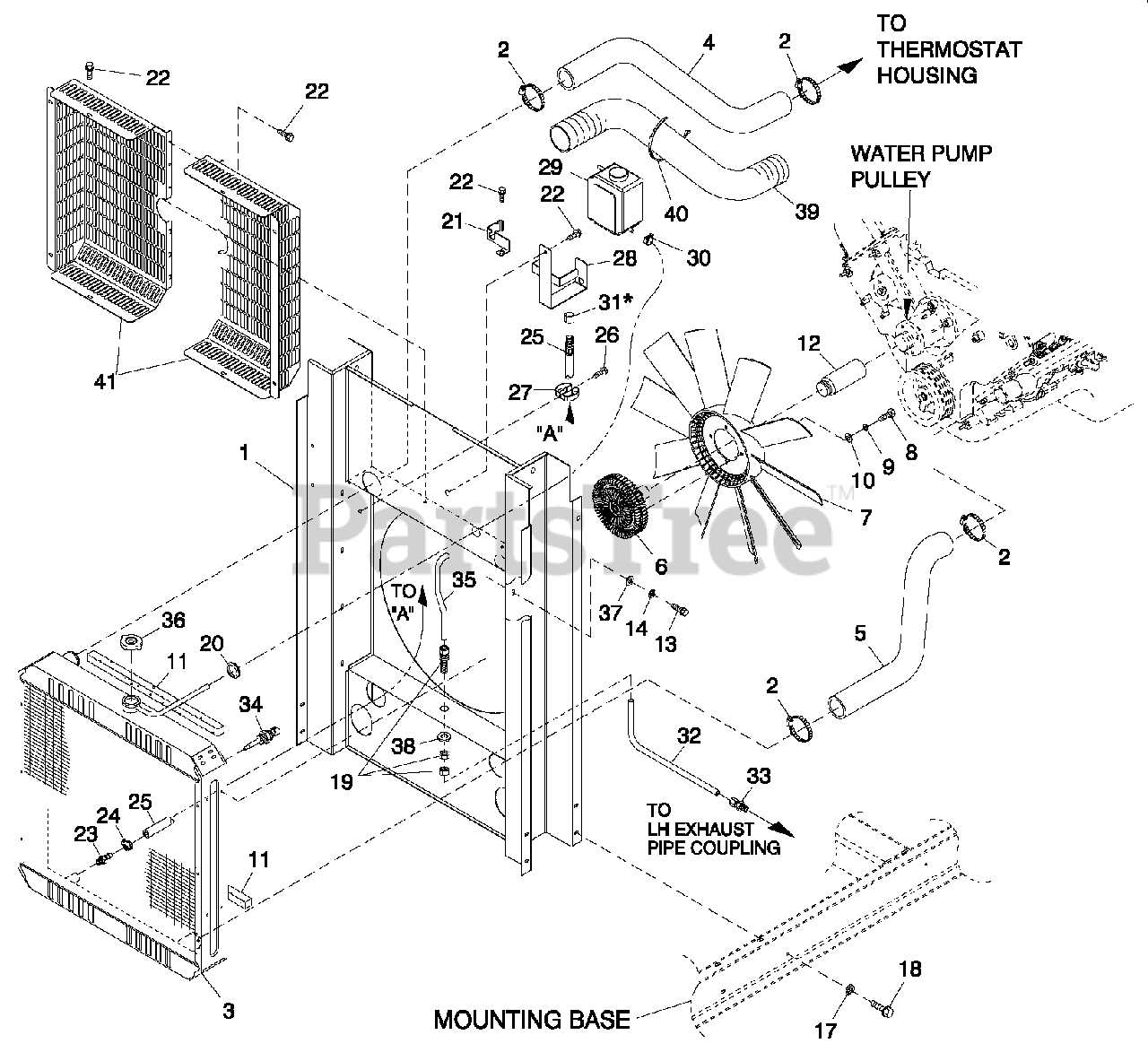

When exploring the internal mechanisms of any complex appliance, it’s essential to have a clear view of how different elements interact and perform. Each component plays a crucial role in ensuring smooth operation and functionality. Without a clear understanding of these elements, maintenance or troubleshooting can become challenging and inefficient.

The layout of essential elements in any system highlights how these individual components are organized and connected. Understanding these connections is vital for anyone looking to repair or enhance performance. In this guide, we will look at the major elements and their roles, emphasizing their significance in the overall functioning of the appliance.

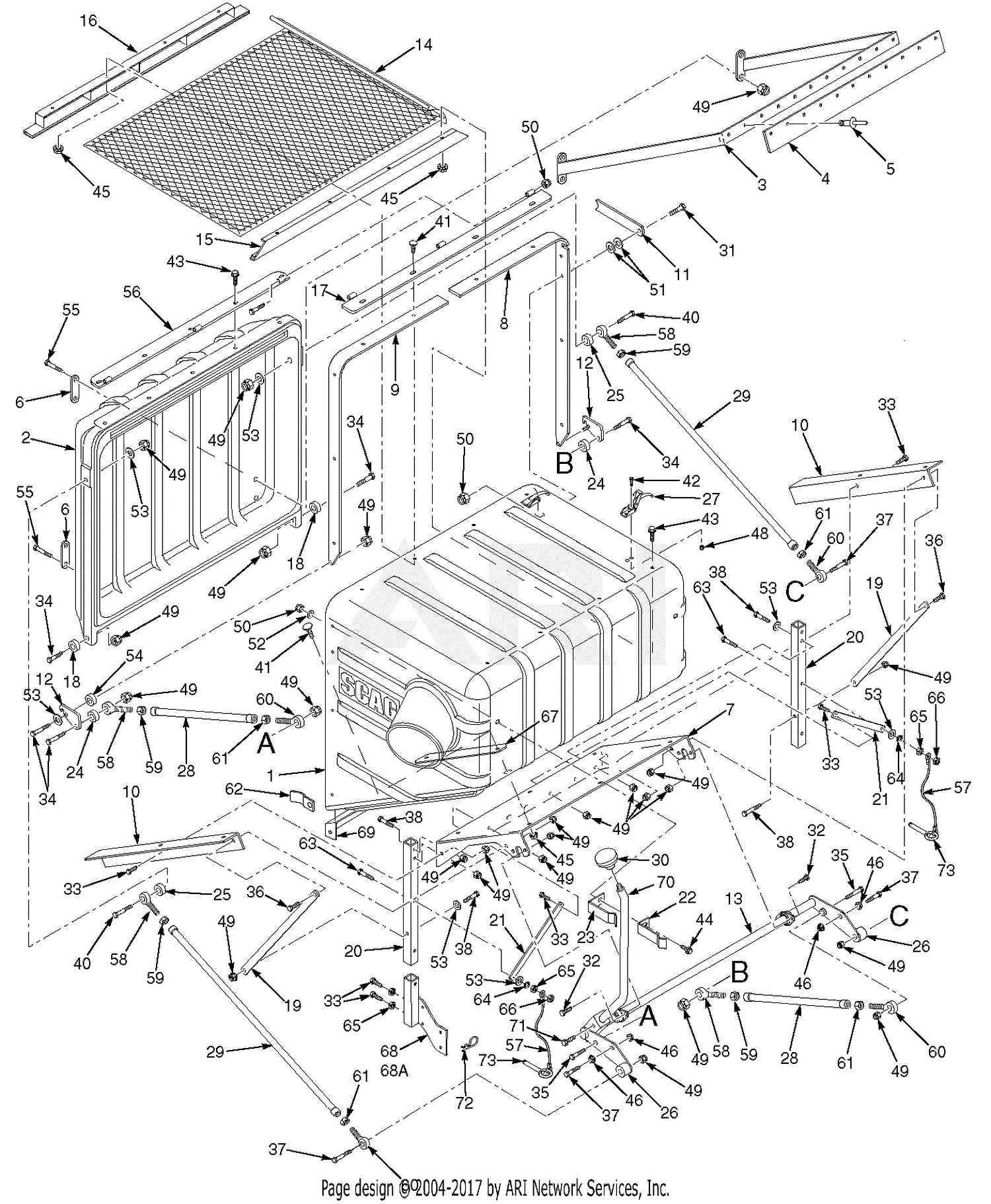

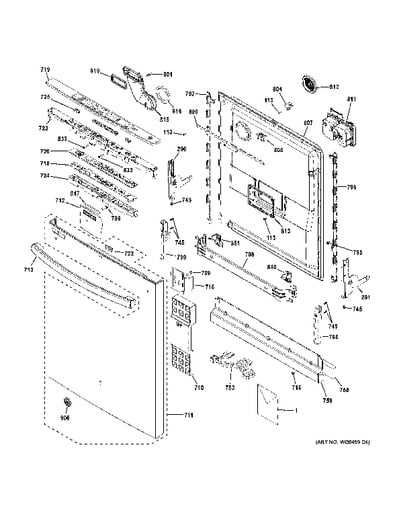

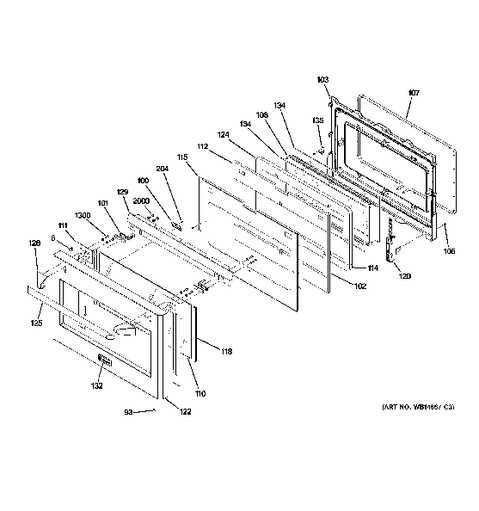

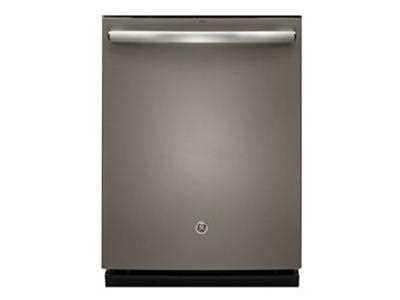

Understanding Gbt632ssmss Component Layout

The organization of elements within a system is crucial for ensuring smooth functionality and easy maintenance. When examining the internal structure, it’s important to understand how various elements are positioned in relation to each other and their specific roles. This knowledge allows for better troubleshooting and efficient upgrades.

Core Structural Elements

The central framework consists of key elements that drive the main operations. These components are arranged in a manner that ensures optimal interaction and minimizes interference. Recognizing these essential parts helps in identifying performance issues or potential areas for improvement.

Peripheral Connections and Interfaces

The outer components and interfaces are designed to connect the internal system with external devices. Their arrangement is strategic, allowing seamless communication between different modules. Proper understanding of these connections is essential for maintaining stability and avoiding technical malfunctions.

Key Features of Gbt632ssmss Model

This model stands out due to its versatile functionality, making it a preferred choice in various environments. It offers a combination of robust performance and innovative design that caters to different needs. Below are the most significant attributes that define its structure and usability.

Durability and Design

- Constructed with high-quality materials to ensure longevity.

- Modern and sleek appearance that fits seamlessly into various setups.

Performance Capabilities

- Efficient operation, even under demanding conditions.

- Advanced technology for optimized functionality.

Common Parts in Gbt632ssmss Units

Each unit is composed of several essential components that work together to ensure smooth operation and reliability. These elements are key to the system’s functionality, providing both control and support to various subsystems. Understanding their roles can help identify potential issues and maintain the equipment efficiently.

Key Structural Elements

- Frame: Provides the necessary support and structure for the entire unit.

- Fasteners: Ensure the secure assembly of different sections, allowing for stability during operation.

- Covers and Panels: Protect internal mechanisms from external damage or interference.

Operational Components

- Control Modules: Regulate the unit’s performance and ensure proper function across subsystems.

- Wiring

Maintenance Tips for Gbt632ssmss Parts

Proper upkeep of key components is essential to ensure the long-term functionality and efficiency of your equipment. Consistent care prevents breakdowns and enhances performance, prolonging the lifespan of critical elements. Below are recommendations to help maintain your device’s core features effectively.

Regular Cleaning Practices

Maintaining cleanliness is one of the simplest yet most effective ways to preserve functionality. Dust and debris can accumulate and cause various issues over time. Follow these steps to ensure optimal care:

- Wipe surfaces with a soft, dry cloth regularly to avoid dust buildup.

- Use a gentle cleaning solution for deeper cleaning, ensuring no moisture enters sensitive areas.

- Check for any blockages in key sections to prevent damage or overheating.

Inspection and Replacement

Identifying Gbt632ssmss Essential Components

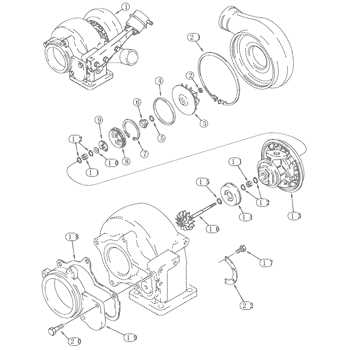

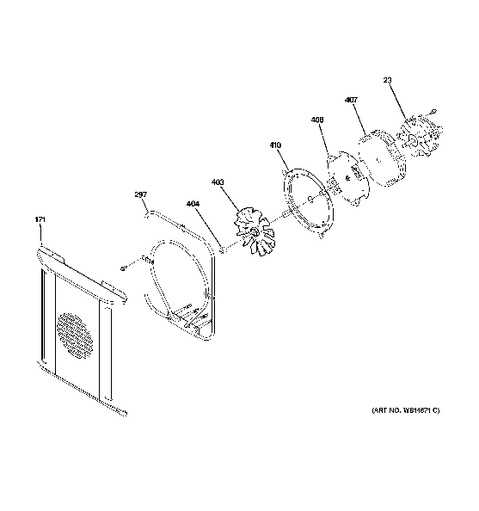

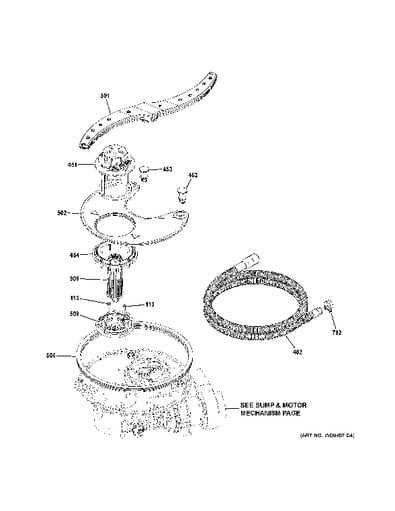

Understanding the key elements of a complex system is crucial for ensuring its proper functioning and maintenance. By examining the main sections and their roles, one can gain insight into how the overall mechanism operates.

Main Structural Elements

- Core Framework: The foundational support that holds all other elements in place.

- Connection Interfaces: Pathways that allow communication and data transfer between various sections.

- Power Distribution Unit: Responsible for supplying energy to the entire system, ensuring efficient performance.

Supporting Mechanisms

- Stabilizing Fixtures: Help in securing the setup and preventing any unwanted shifts or instability.

- Replacing Gbt632ssmss System Elements

Replacing components within a complex system is essential for maintaining optimal functionality and performance. This process involves careful assessment and selection of suitable replacements to ensure seamless integration and continued operation. Understanding the specifications and requirements of each element is crucial to achieving desired results.

When considering replacements, it is important to evaluate both compatibility and quality of the new components. Below is a table outlining key factors to consider during the replacement process:

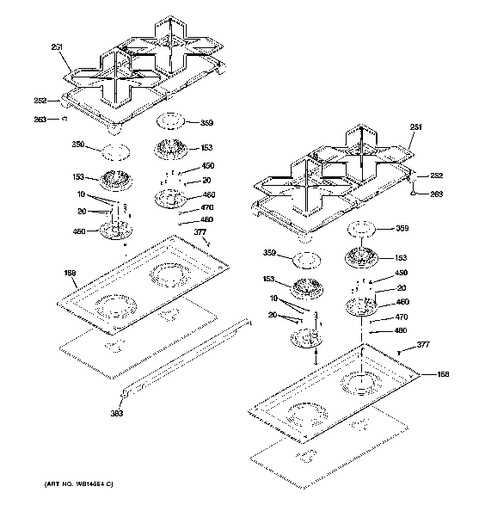

Factor Description Compatibility Ensure that the new components match the specifications of the existing system. Quality Opt for high-quality materials that guarantee durability and reliability. Cost Evaluate the cost-effectiveness of replacements while maintaining performance standards. Availability Check the availability of components to minimize downtime during replacement. Manufacturer Support Consider components from manufacturers that offer good customer support and warranty options. Detailed Breakdown of Gbt632ssmss Parts

This section provides an in-depth examination of the components associated with the specified model, highlighting their functions and interrelationships. Understanding these elements is essential for effective maintenance and troubleshooting.

Component Overview: Each element plays a crucial role in the overall operation of the system. From the main structure to the smaller attachments, every part contributes to the functionality and efficiency.

Functionality Insights: By dissecting the individual elements, one can gain a clearer understanding of how they interact. This knowledge not only aids in repairs but also enhances the user’s ability to optimize performance and longevity.

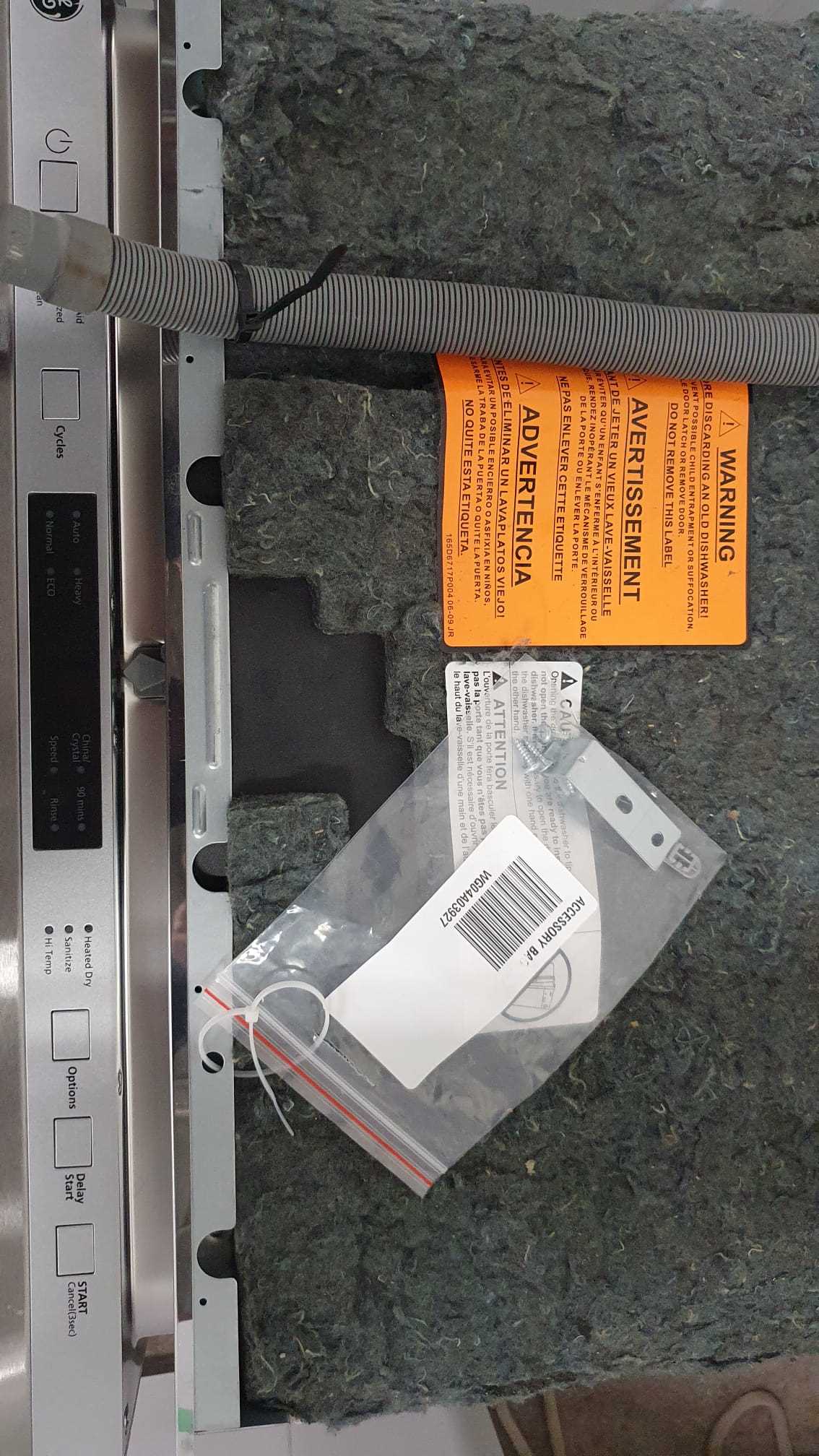

How to Assemble Gbt632ssmss Components

Assembling various components of a complex device requires careful attention to detail and a clear understanding of the overall structure. Each element plays a vital role in ensuring the functionality and reliability of the system. Proper assembly not only enhances performance but also extends the lifespan of the entire assembly.

Begin by gathering all necessary components and tools, ensuring you have a clean and organized workspace. Familiarize yourself with the connection points and interfaces between different elements. Pay close attention to any instructions or guidelines provided, as they will offer crucial information on the orientation and alignment of parts.

Next, start with the larger components, securing them in place before adding smaller elements. Use appropriate fasteners to ensure stability, but avoid overtightening, as this can damage delicate parts. After securing the major components, gradually incorporate the remaining elements, checking for proper fit and functionality at each step.

Once everything is assembled, perform a thorough inspection to confirm that all connections are secure and there are no loose components. Finally, conduct a functionality test to ensure that the assembly operates as intended.

Typical Issues with Gbt632ssmss Parts

When dealing with electronic components, several common challenges can arise, affecting their performance and reliability. Understanding these potential pitfalls is essential for ensuring optimal functionality and longevity. This section highlights prevalent concerns that users might encounter, providing insights into their causes and possible solutions.

One frequent issue is the improper alignment of elements, which can lead to connectivity problems or failures in signal transmission. Additionally, wear and tear over time may result in degraded performance, impacting the overall effectiveness of the system. Users should also be mindful of compatibility issues when integrating different components, as mismatched specifications can lead to malfunctions.

Moreover, environmental factors such as humidity and temperature fluctuations can adversely affect the integrity of these components. Regular maintenance and thorough inspections are crucial for identifying early signs of wear and addressing them before they escalate into more significant problems. By staying vigilant and informed, users can mitigate these issues and enhance the reliability of their systems.

Optimizing Performance of Gbt632ssmss Parts

Enhancing the functionality of components requires a strategic approach to ensure efficiency and reliability. By focusing on various aspects such as maintenance, configuration, and usage, users can significantly improve overall performance. This section explores effective strategies to achieve optimal outcomes.

Regular Maintenance Practices

Routine upkeep is essential for preserving the longevity and efficiency of equipment. Implementing a structured maintenance plan can yield substantial benefits:

- Conduct periodic inspections to identify wear and tear.

- Replace worn components promptly to prevent further damage.

- Clean parts regularly to remove debris and contaminants.

- Lubricate moving elements as per the manufacturer’s recommendations.

Efficient Configuration Techniques

Correctly setting up equipment can greatly influence its performance. Consider the following configuration tips:

- Ensure all connections are secure and properly aligned.

- Adjust settings according to the specific application requirements.

- Monitor operating conditions to maintain optimal performance levels.

- Utilize compatible accessories to enhance functionality.