Understanding the structure and arrangement of individual elements within a system is crucial for efficient maintenance and troubleshooting. Each element has a specific role, contributing to the overall functionality, making it important to clearly visualize their relationships and functions. This helps not only in identifying potential issues but also in planning regular upkeep.

In this section, we will explore the detailed breakdown of essential components, highlighting how they connect and operate together. By focusing on the arrangement, you can gain a deeper insight into the system’s internal workings, ensuring smoother handling of any technical tasks.

Whether you are looking to replace or maintain specific elements, this guide provides a clear and concise view of the layout and how each piece interacts with the others to maintain overall system integrity.

Overview of Watts HY 420 Model

The product discussed in this section is a versatile solution designed for regulating and managing the flow of liquid in various systems. Known for its reliability and efficiency, this model is commonly used in both commercial and residential settings. Its robust construction and thoughtful design make it a popular choice for applications requiring precise control and durability.

Main Features

This device offers a range of essential features that ensure optimal performance under different conditions. It is built with high-quality materials, allowing it to withstand regular use in demanding environments. Additionally, the model incorporates advanced technology that enhances its responsiveness and adaptability, making it suitable for various system configurations.

Key Components of the HY 420 System

The system in question is built around several crucial elements that work together to ensure optimal functionality. These components are meticulously designed to interact seamlessly, contributing to the system’s overall performance and efficiency. Below is an overview of the most significant parts that play a role in its operation.

Primary Control Unit

The main control unit serves as the brain of the system, managing and coordinating the operations of other components. It ensures that all elements function in harmony and respond to changing conditions. This unit is vital for maintaining a balanced and efficient performance.

Flow Regulation Mechanism

Another key element is the

Installation Tips for the HY System

Setting up your new system requires attention to detail to ensure proper function and longevity. Following the correct steps during installation can help prevent potential issues and guarantee smooth operation for years to come.

Prepare the Installation Area

Before starting, make sure the location where the unit will be installed is clean, dry, and free from obstructions. Verify that all necessary tools and materials are on hand to avoid unnecessary delays.

Follow Manufacturer’s Guidelines

It’s essential to adhere to the manufacturer’s instructions closely. Each component should be fitted carefully according to the provided specifications to avoid leaks or other malfunctions. Tighten all connections securely but avoid overtightening, which could damage fittings.

Maintenance Guide for Optimal Performance

Regular maintenance is essential to ensure that your device operates at peak efficiency. By adhering to a consistent upkeep routine, you can prevent potential issues and extend the lifespan of your equipment. Following simple yet effective steps will help you maintain reliable operation over time.

Check for Wear and Tear: Periodically inspect all components for signs of deterioration. Replacing any worn-out elements early will prevent larger complications and ensure continued functionality.

Keep Components Clean: Dust and debris can accumulate over time, impacting performance. Make sure to clean the internal and external parts regularly to avoid overheating or blockages.

Perform Regular Adjustments: Over time, minor shifts in alignment or settings may occur. By making periodic adjustments

Understanding the Function of Each Part

Each element in a system plays a crucial role in ensuring optimal performance. By understanding the purpose and interaction of individual components, it becomes easier to maintain and troubleshoot the entire setup. The functionality of every piece is interconnected, and even minor issues in one section can affect the overall operation. Therefore, recognizing the role of each element is essential for both efficient use and long-term durability.

Main Components and Their Roles

The system consists of several key units, each responsible for a specific task. The primary unit ensures the flow and regulation of essential

Common Issues and Troubleshooting Solutions

When dealing with mechanical systems, users may encounter various challenges that can hinder performance. Identifying these problems early on and knowing how to address them is crucial for maintaining efficiency and functionality.

-

Leaking Components:

If you notice any dripping or pooling of fluid around the system, it may indicate a faulty seal or connection. Inspect all joints and seals for wear or damage, and replace any defective parts to prevent further leakage.

-

Inconsistent Pressure:

Fluctuations in pressure can disrupt the normal operation of the unit. Check the pressure gauge and ensure that the system is properly calibrated. If issues persist, examine the valves and regulators for any malfunctions.

-

Noisy Operation:

Unusual sounds can signify problems such as loose fittings or worn bearings. Conduct a thorough inspection of all mechanical parts and tighten or replace any components that seem to be causing excessive noise.

By recognizing these common issues and applying the suggested solutions, users can enhance the longevity and reliability of their equipment.

How to Replace Worn-Out Components

Replacing aged or damaged elements in any device is essential for maintaining optimal functionality and performance. This process not only enhances efficiency but also extends the lifespan of your equipment. Understanding the necessary steps and precautions can significantly streamline the replacement process, ensuring that the task is completed safely and effectively.

Identifying the Components

Before proceeding with replacements, it is crucial to identify the components that require attention. Regular inspection can help detect wear and tear, allowing for timely intervention. Below is a list of common indicators that suggest the need for replacement:

| Indicator | Description |

|---|---|

| Visual Damage | Cracks, breaks, or discoloration on the surface. |

| Performance Issues | Unusual noises, decreased efficiency, or malfunctioning parts. |

| Age | Components that have been in use for a prolonged period may require replacement. |

Replacement Process

Once the necessary components have been identified, follow these general steps for replacement:

1. Power Off the Device: Ensure that the equipment is completely turned off and unplugged to avoid accidents.

2. Gather Tools: Collect all necessary tools, such as screwdrivers, pliers, and replacement components.

3. Carefully Remove the Old Component: Take out the damaged part with caution to prevent further damage to surrounding areas.

4. Install the New Component: Place the new part securely in position, ensuring all connections are tight.

5. Test the Device: After reassembly, power on the equipment to verify that the new component is functioning correctly.

By following these guidelines, you can effectively replace worn-out elements, ensuring the continued efficiency and reliability of your device.

Compatibility with Other Systems

Understanding the adaptability of various units is essential for seamless integration in diverse applications. Many devices share similarities in their components and functionalities, allowing for a more flexible approach to system design.

When considering compatibility, it is crucial to evaluate the following aspects:

- Component Interchangeability: Identifying parts that can be used across different units enhances the efficiency of maintenance and repairs.

- Functional Equivalence: Some systems are designed to perform similar tasks, making them suitable for interchangeable use in specific scenarios.

- Connection Standards: Ensuring that fittings and connections align with industry standards simplifies integration efforts and reduces installation time.

Overall, leveraging the compatibility of these systems can lead to improved operational efficiency and reduced downtime during repairs or upgrades.

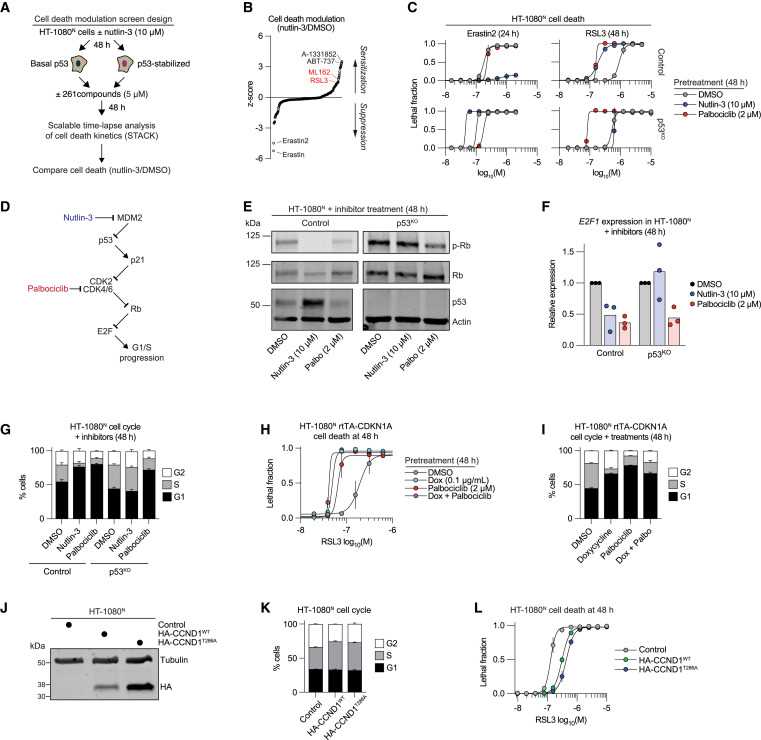

Detailed Diagram Explanation for Beginners

Understanding the intricate illustrations that represent the components of a device can be a valuable skill for those new to this field. These visual aids serve as guides to help users grasp how various elements fit together and function in harmony.

Key Components Overview

Familiarizing yourself with the main elements depicted in these visuals is essential for effective comprehension. Below are some of the critical parts typically represented:

- Power Source: This is where energy is supplied, enabling the entire system to operate.

- Control Unit: Often acts as the brain, managing the flow of energy and directing various functions.

- Functional Elements: These parts perform specific tasks, such as heating or cooling, depending on the intended use.

- Connecting Elements: These components link various parts together, ensuring a seamless operation.

Understanding Relationships Between Components

Recognizing how different parts interact is crucial for troubleshooting and maintenance. Consider the following relationships:

- Power Source and Control Unit: The efficiency of the control unit often depends on the quality of the power supplied.

- Functional Elements and Control Unit: The control unit determines how effectively these components carry out their designated tasks.

- Connecting Elements and Overall Functionality: Proper connections are vital for the system to function correctly, ensuring that all parts work in unison.

By studying these illustrations and understanding the roles of each part, beginners can develop a solid foundation in device mechanics, paving the way for more advanced knowledge in the future.

Choosing the Right Tools for Repairs

When embarking on maintenance tasks, selecting the appropriate instruments is crucial for achieving optimal results. The right tools not only streamline the repair process but also enhance safety and efficiency. Understanding the essential tools can make a significant difference in tackling various issues effectively.

Essential Tools for Repair Tasks

- Screwdrivers: A set of various screwdrivers is fundamental for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets are vital for gripping and turning nuts and bolts.

- Pliers: Needle-nose and slip-joint pliers are versatile for gripping, twisting, and cutting wires.

- Hammers: Different types of hammers, such as claw and rubber mallets, are useful for driving nails and shaping materials.

- Cutting Tools: Utility knives and scissors are essential for precise cutting tasks.

Safety Equipment to Consider

- Gloves: Protective gloves should be worn to prevent injuries while handling tools.

- Safety Glasses: Eye protection is essential when working with power tools or during demolition.

- Dust Masks: Masks help protect against inhaling dust and debris in confined spaces.

Investing in quality tools can significantly enhance your repair capabilities, ensuring tasks are completed efficiently and safely.