In the realm of outdoor machinery, mastering the intricacies of a specific model can significantly enhance both performance and longevity. Grasping how various elements work together provides valuable insights for users looking to optimize their equipment. A comprehensive exploration of the individual components can lead to more effective maintenance and improved operational efficiency.

Visual representations play a crucial role in understanding how each part fits into the overall assembly. By examining these detailed illustrations, users can identify essential elements, troubleshoot issues, and even upgrade their devices with confidence. Analyzing these visuals allows for a deeper appreciation of the tool’s design and functionality.

Whether you are a seasoned professional or an enthusiastic hobbyist, delving into the intricacies of your machine’s structure will ultimately empower you. Knowledge of each component enables informed decisions regarding repairs and enhancements, ensuring your tool remains a reliable asset for years to come.

Understanding Stihl FS250R Parts

Exploring the components of a grass trimmer is essential for effective maintenance and optimal performance. Each element plays a crucial role in the functionality of the machine, ensuring it operates smoothly and efficiently. A thorough grasp of these elements allows users to identify issues, perform repairs, and enhance the longevity of the equipment.

Key components include:

- Engine: The heart of the machine, responsible for powering the tool.

- Cutting Head: Where the trimming action takes place, utilizing various types of lines or blades.

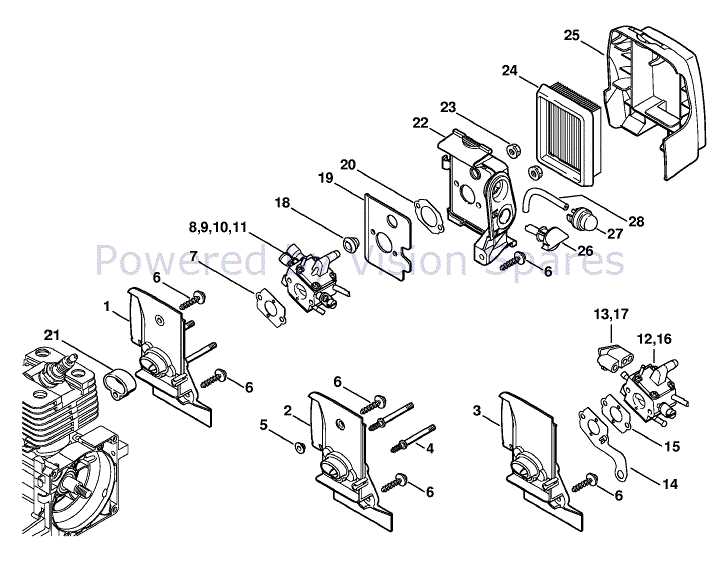

- Fuel System: Essential for delivering the necessary energy to the engine.

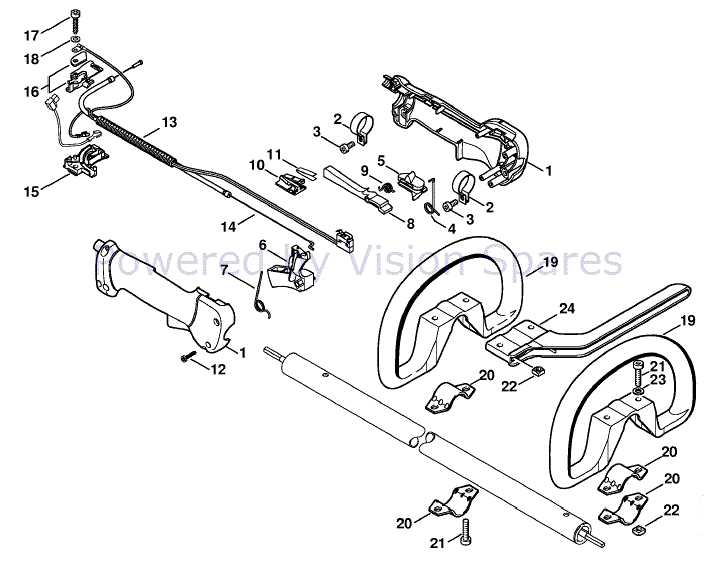

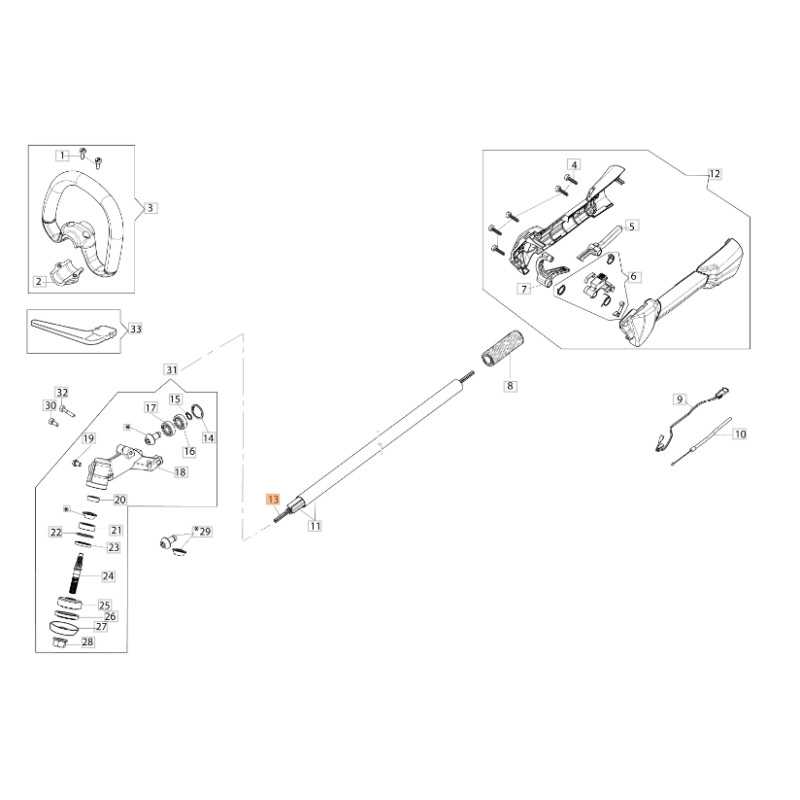

- Handle and Harness: Provide comfort and control during operation.

- Starter Mechanism: Enables the user to ignite the engine easily.

Understanding the function and interaction of these elements helps users make informed decisions about repairs and upgrades. Regular inspection and maintenance can prevent common issues and enhance the tool’s overall efficiency.

For anyone looking to maintain their equipment, familiarizing oneself with these critical components is invaluable. By doing so, users can ensure their machines remain reliable and effective for all their trimming tasks.

Importance of a Parts Diagram

Understanding the layout and components of a machine is crucial for effective maintenance and repair. A visual representation of its elements allows users to quickly identify each part, facilitating troubleshooting and enhancing overall efficiency. This clarity can prevent costly errors and reduce downtime.

Having access to such visuals not only empowers users to perform their own repairs but also aids in communication with service professionals. When discussing issues, being able to reference specific components ensures that everyone is on the same page, ultimately leading to faster resolutions.

Moreover, these representations are invaluable for ordering replacements. Knowing exactly what is needed streamlines the procurement process, minimizing the risk of ordering incorrect items. This efficiency is vital for anyone relying on machinery for their work or hobbies.

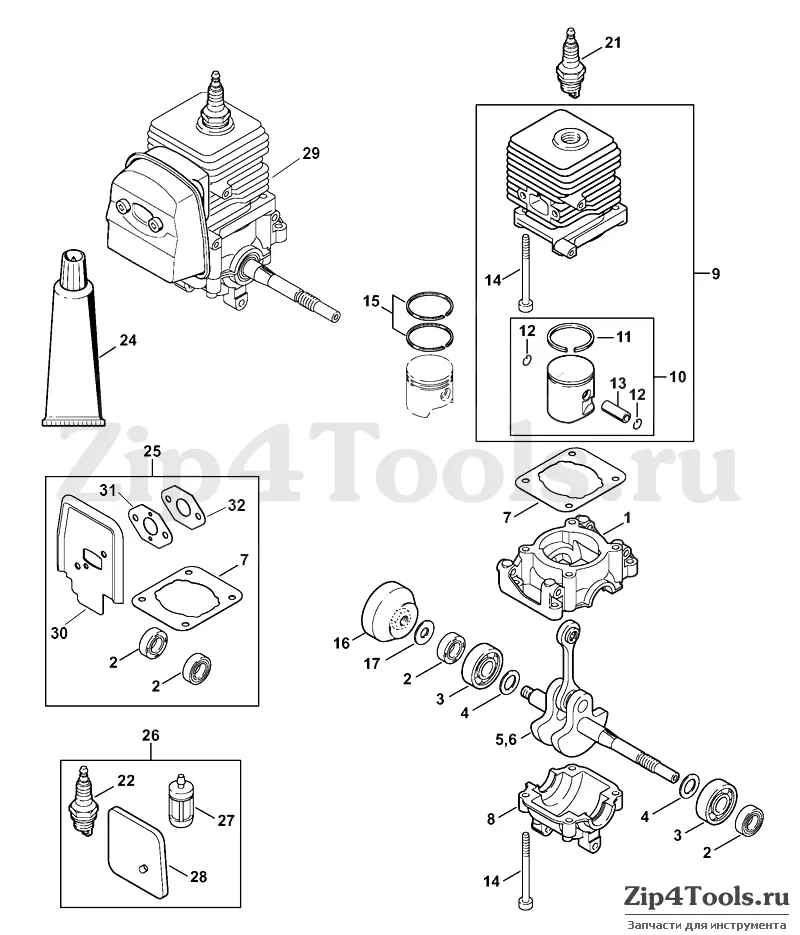

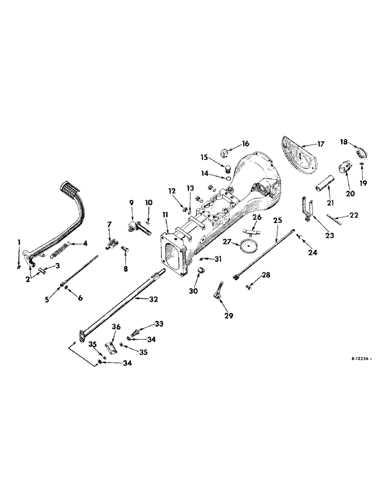

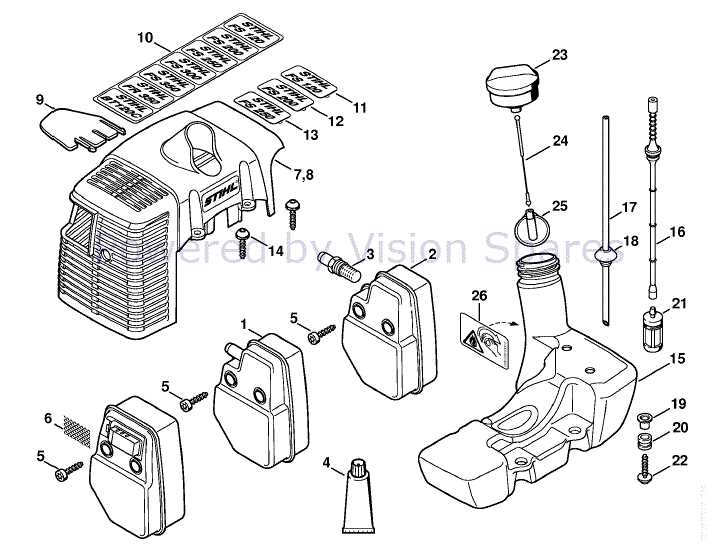

Key Components of FS250R

Understanding the essential elements of this powerful cutting tool is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and durability during operation, making it important for users to familiarize themselves with these components.

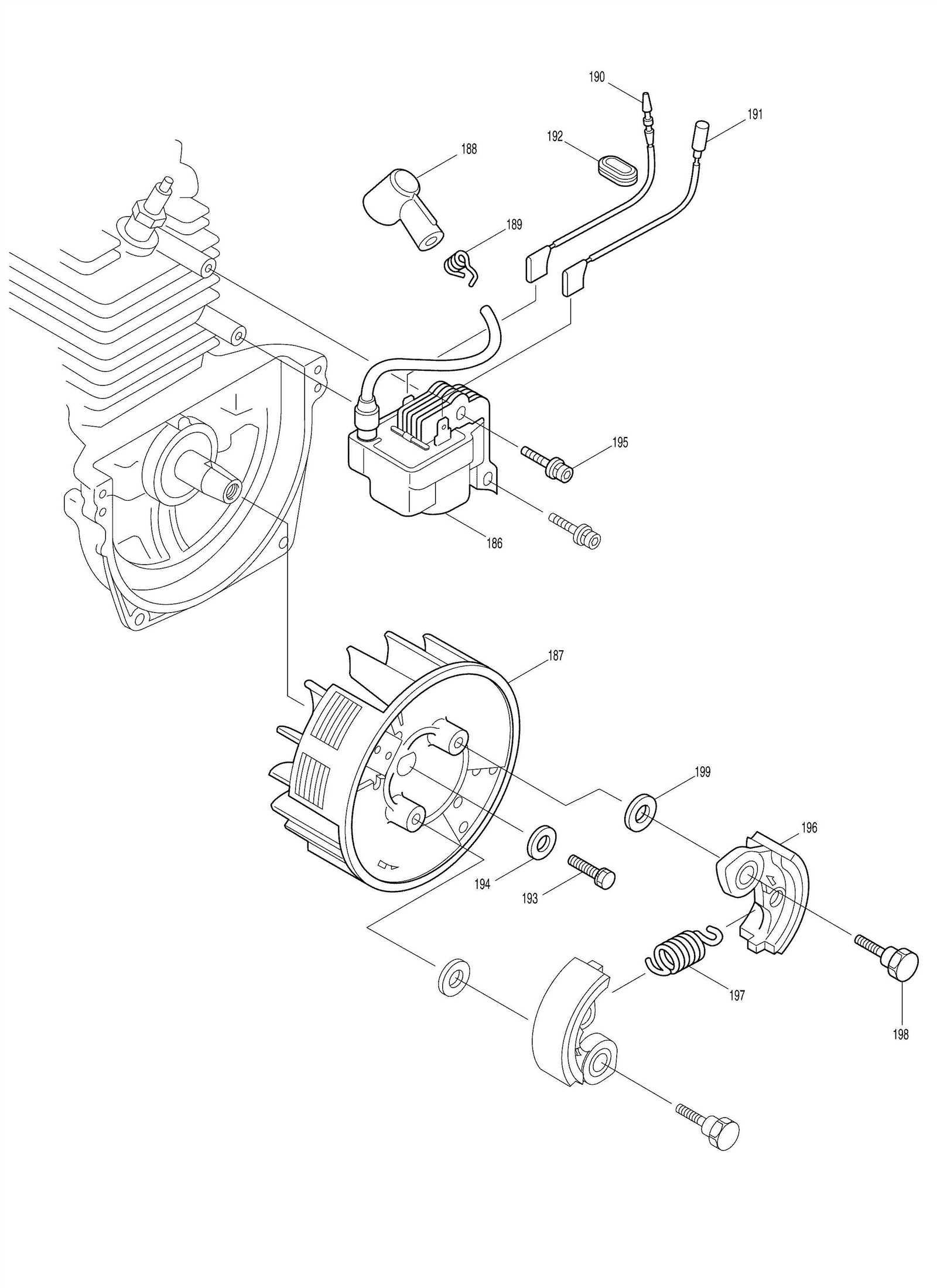

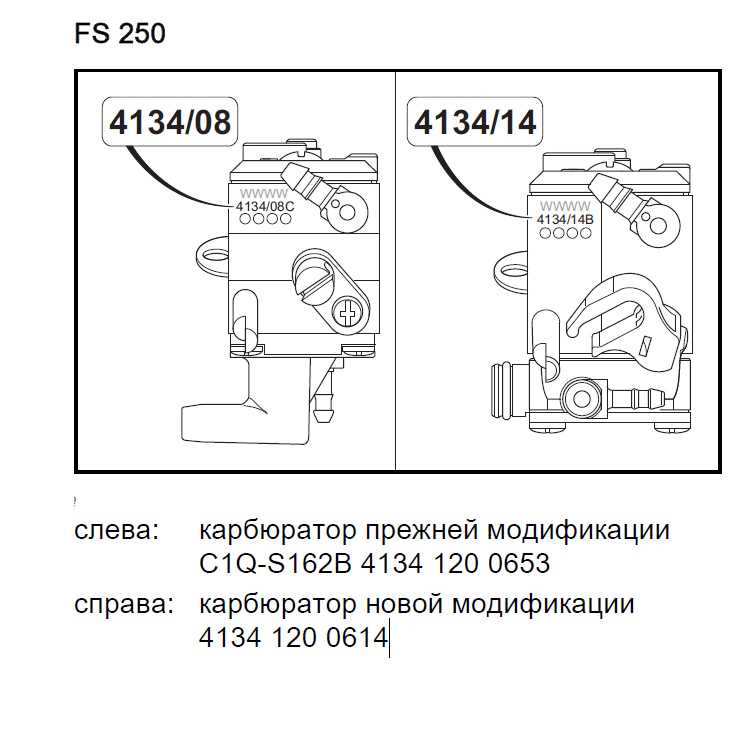

Engine Assembly

The heart of the machine, the engine assembly, delivers the necessary power for effective cutting. It includes vital features such as the spark plug, fuel system, and air filter, all of which work together to enhance performance. Regular checks and maintenance of these elements can lead to improved longevity and reliability.

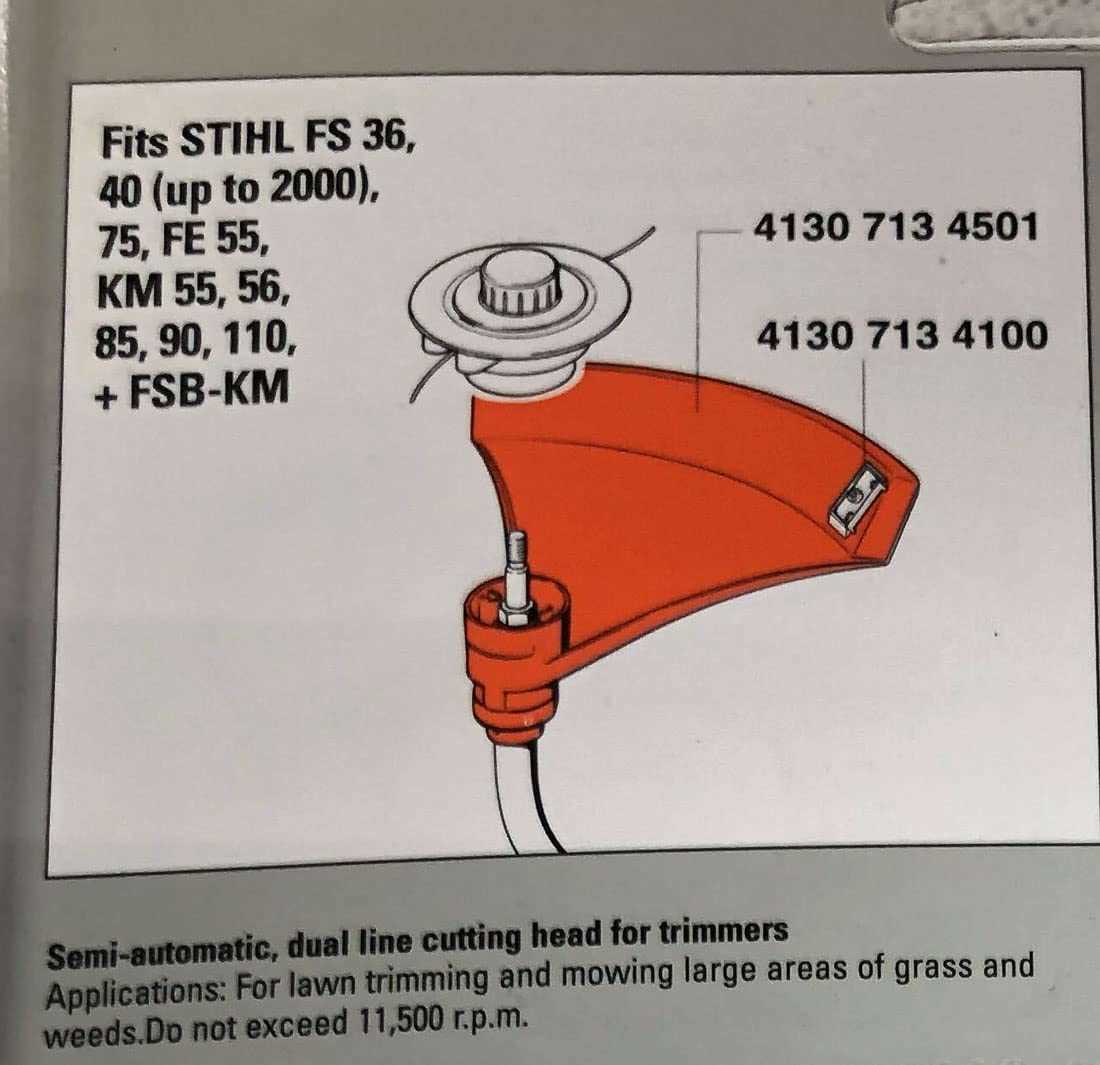

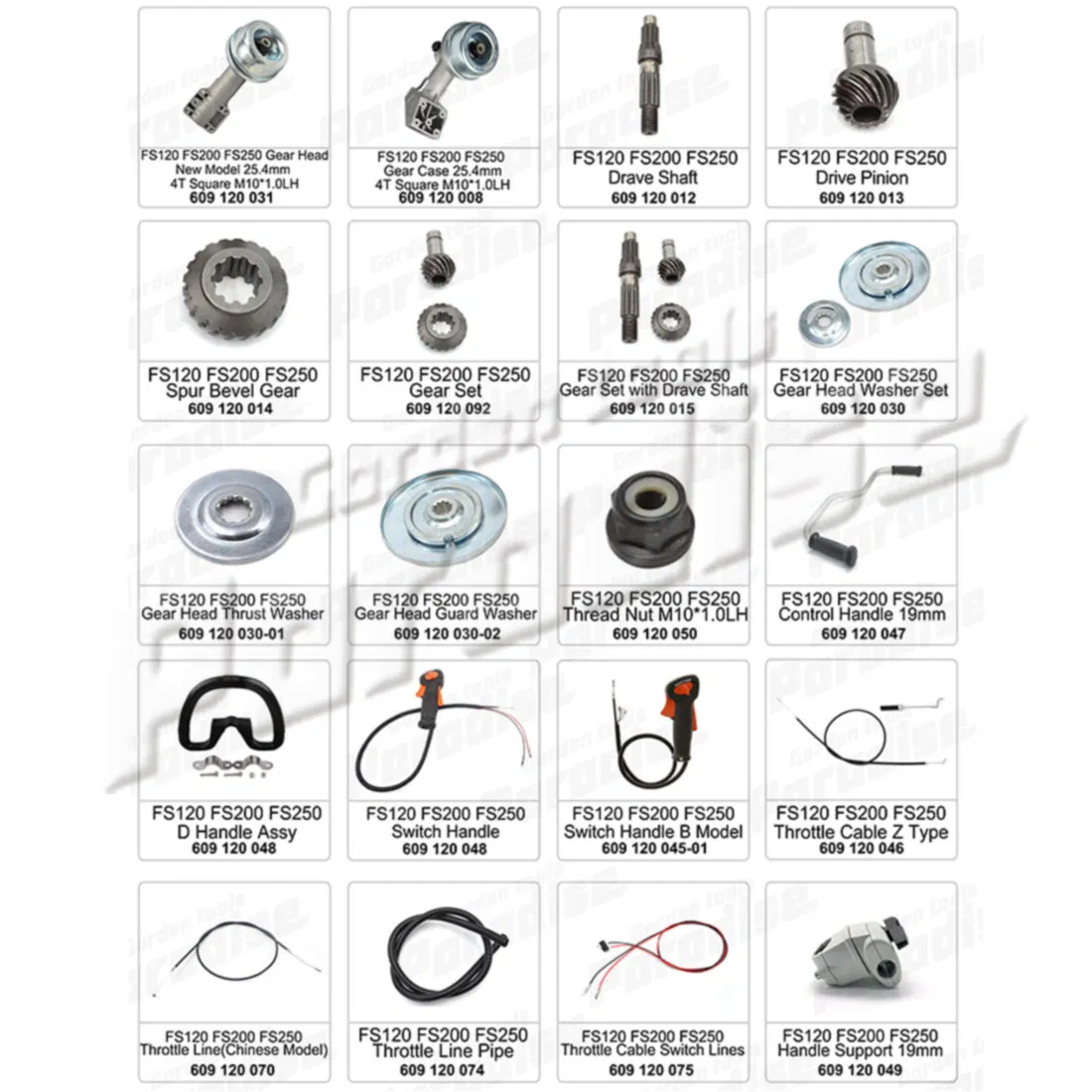

Cutting Mechanism

The cutting mechanism is designed for precision and efficiency. Key aspects include the blade attachment and gear head, which directly influence cutting quality. Proper alignment and timely replacements of these parts ensure the ultimate effectiveness of the tool in various landscaping tasks.

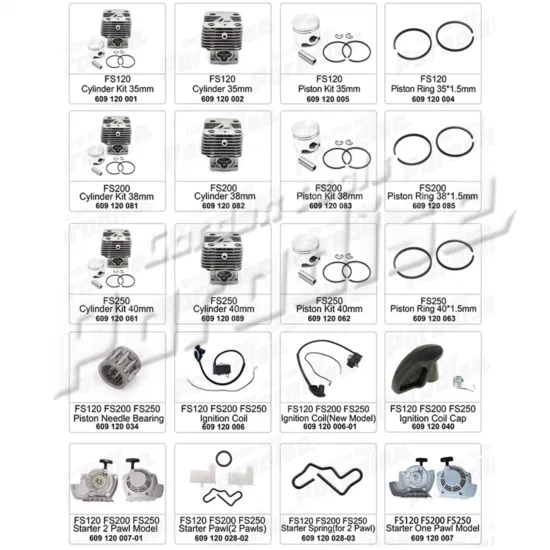

Common Replacement Parts Overview

Understanding the essential components of your outdoor power equipment is crucial for maintaining its efficiency and longevity. This section provides an overview of frequently needed elements that may require replacement over time. Proper upkeep not only enhances performance but also ensures safety during operation.

Key Components

Among the most critical elements are the cutting heads and trimmer lines, which endure significant wear and tear during use. Regularly checking and replacing these components can lead to more effective cutting performance. Additionally, filters and spark plugs play a vital role in the overall functionality of the machine. Ensuring these are clean and in good condition will enhance fuel efficiency and reduce emissions.

Maintenance Tips

Routine inspections of the equipment can help identify parts that need attention before they fail. Keeping spare components on hand is also advisable, as this allows for quick repairs and minimizes downtime. Always refer to the manufacturer’s guidelines for specific maintenance schedules and replacement recommendations.

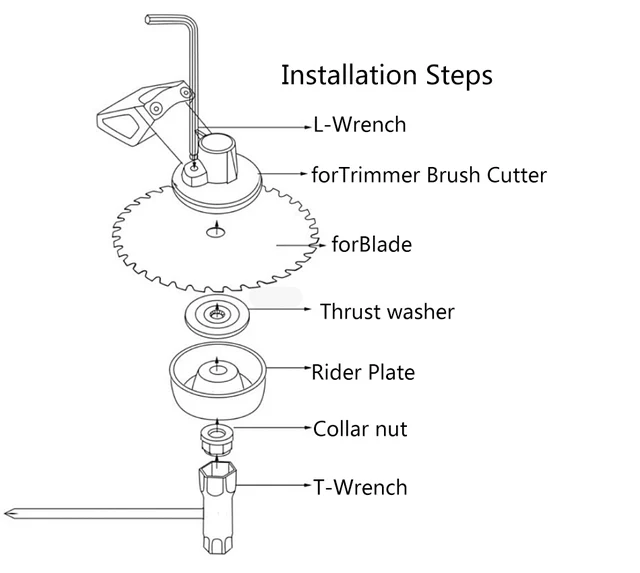

How to Use the Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. This guide will help you navigate the schematic to identify various elements and their relationships, ensuring a smoother process for any required work.

Identifying Components

Start by familiarizing yourself with each labeled section. Look for markings that indicate specific items, as these will assist in locating the necessary pieces when disassembling or reassembling equipment.

Following Assembly Instructions

Utilize the visual layout to follow assembly procedures. Referencing the illustration while working will help you ensure that everything is positioned correctly, reducing the risk of errors during the reassembly phase.

Maintenance Tips for Stihl FS250R

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following a few straightforward guidelines, you can keep your tool running smoothly and efficiently.

- Check the Air Filter: Inspect and clean the air filter regularly to prevent dirt buildup that can affect engine performance.

- Inspect the Spark Plug: Regularly examine the spark plug for wear and replace it as needed to maintain a reliable start.

- Maintain the Fuel System: Use fresh fuel and keep the fuel lines clear to avoid blockages and ensure proper fuel delivery.

- Sharpen the Blades: Keep the cutting edges sharp for efficient operation and better results.

- Check for Loose Bolts: Periodically inspect all bolts and screws to ensure they are tight and secure.

By adhering to these maintenance tips, you can enhance the efficiency and lifespan of your equipment, ensuring it remains in top condition for all your tasks.

Where to Find Replacement Parts

Finding suitable components for your equipment can significantly enhance its performance and longevity. Whether you are looking for specific items to restore functionality or simply wish to upgrade, there are several reliable sources to consider.

Authorized Dealers: One of the best places to start is with authorized retailers. These vendors typically stock original components that meet the manufacturer’s standards, ensuring compatibility and quality.

Online Marketplaces: Numerous online platforms offer a vast selection of spare items. Websites such as eBay or specialized online stores often feature competitive prices and user reviews, making it easier to assess the reliability of sellers.

Local Repair Shops: Visiting a nearby repair shop can also be beneficial. Experienced technicians can assist in locating the right components, and they may have access to exclusive suppliers or even carry some items in stock.

Community Forums: Engaging with online communities or forums can provide valuable insights. Enthusiasts often share tips on where to find hard-to-get items and may offer recommendations based on their own experiences.

Aftermarket Options: If budget constraints are a concern, exploring aftermarket alternatives can be worthwhile. While these components may not be original, many are designed to provide satisfactory performance at a lower cost.

Identifying Parts by Diagram

Understanding the components of a machine can greatly enhance your ability to maintain and repair it. Visual representations serve as essential tools for recognizing each element’s function and placement. By studying these illustrations, users can gain clarity on how various sections interconnect, ensuring efficient troubleshooting and assembly.

These visual guides typically categorize components based on their roles and locations within the equipment. Labels and numbers often accompany each part, allowing for quick reference when ordering replacements or conducting maintenance tasks. Familiarity with these resources can significantly reduce downtime and improve the overall performance of your machinery.

Moreover, learning to navigate these visuals empowers users to take charge of their equipment’s upkeep. This knowledge not only fosters confidence in handling repairs but also promotes a deeper appreciation for the intricacies of the design. Ultimately, a well-informed operator can ensure longevity and reliability through proper care and timely interventions.

DIY Repair: Step-by-Step Guide

Embarking on a repair project can be both rewarding and cost-effective. By understanding the essential components and following a structured approach, you can address common issues with your equipment. This guide will provide clear, actionable steps to help you troubleshoot and fix your machine effectively.

Identifying the Problem

Start by observing the symptoms of the malfunction. Listen for unusual noises, check for leaks, or notice any performance drops. Make a list of these indicators, as they will help pinpoint the source of the issue. Research common problems associated with similar devices to gather insights on what to look for during your inspection.

Gathering Tools and Materials

Once you’ve identified potential issues, gather the necessary tools and replacement items. Basic tools like screwdrivers, wrenches, and pliers are essential for most repairs. Ensure you have safety equipment, such as gloves and goggles. If replacement parts are needed, consult reputable suppliers to obtain quality components that match your specifications.

Tools Needed for Maintenance

Proper upkeep of equipment requires a selection of essential tools to ensure optimal performance and longevity. Having the right instruments on hand not only simplifies the maintenance process but also enhances safety and efficiency.

Basic Hand Tools

Common hand tools such as wrenches, screwdrivers, and pliers are vital for routine checks and adjustments. These tools allow for easy access to various components, facilitating necessary repairs and replacements.

Specialized Equipment

In addition to basic tools, certain specialized equipment, like torque wrenches and blade sharpeners, can greatly improve maintenance efforts. Utilizing these instruments ensures precise adjustments and extends the lifespan of your machinery.

Benefits of Regular Parts Inspection

Conducting routine evaluations of essential components ensures optimal performance and longevity of your equipment. This proactive approach not only enhances efficiency but also minimizes the likelihood of unexpected breakdowns, leading to smoother operation.

Improved Performance

Regular checks help maintain peak functionality, allowing machines to operate at their best. When components are in top condition, the overall output is significantly enhanced, making tasks easier and faster.

Cost Efficiency

By identifying wear and tear early, you can avoid costly repairs or replacements down the line. Investing time in periodic inspections ultimately saves money and extends the lifespan of your machinery.