Exploring the intricate design of lawn maintenance machinery reveals a fascinating array of elements working in harmony. Each section of these machines is crafted to optimize performance, ensuring that users can achieve their desired results with efficiency and ease. The importance of familiarizing oneself with the various components cannot be overstated, as it enhances both the maintenance and operation experience.

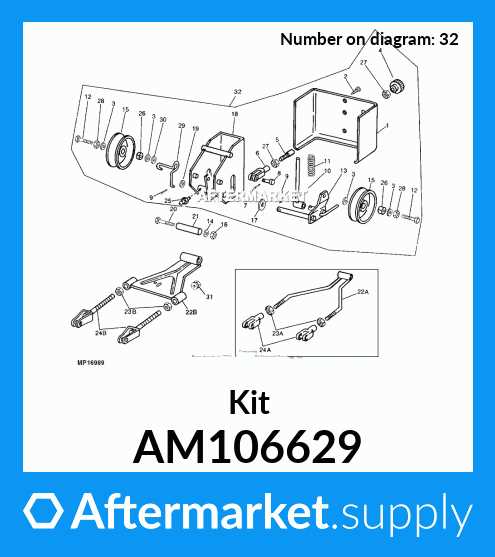

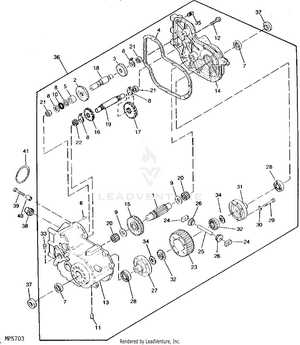

Within the realm of this particular equipment, a detailed illustration of its structure serves as a vital resource. Such visual representations allow operators and enthusiasts to identify specific pieces, facilitating informed decision-making during repairs or upgrades. The clarity provided by these diagrams is indispensable, especially for those who value hands-on engagement with their tools.

Whether one is a seasoned professional or a casual user, understanding the relationship between these components is essential. By diving into the specifics, individuals can not only improve their operational skills but also extend the lifespan of their machinery. Engaging with the comprehensive layout fosters a deeper appreciation for the technology that simplifies outdoor tasks.

Understanding the John Deere 318 Mule Drive

This section explores the mechanics and functionality of a specific system used in outdoor equipment, focusing on its role in power transmission and accessory attachment. The design is critical for optimizing performance and ensuring smooth operation across various tasks.

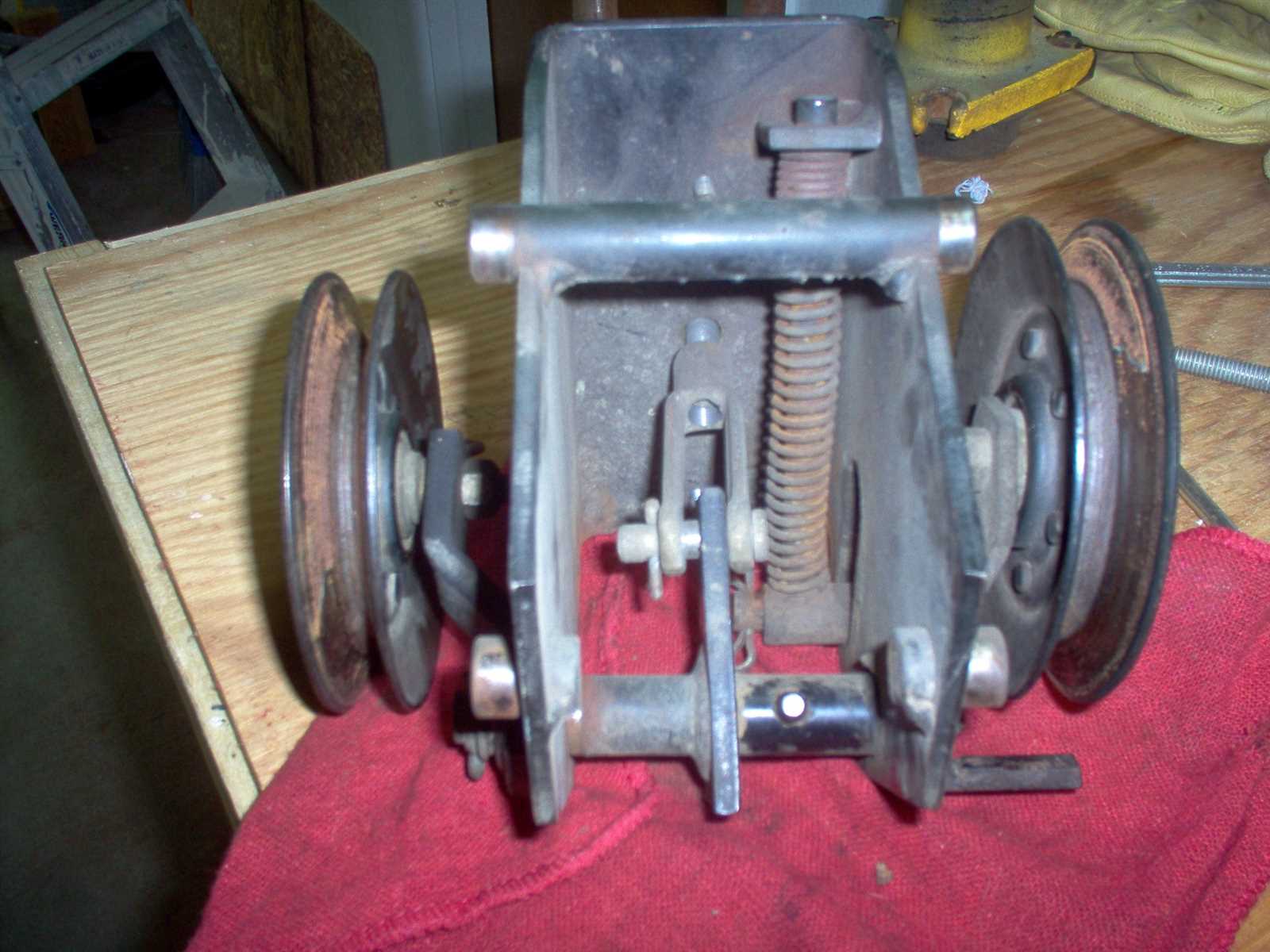

Key Components: Essential elements of this system work together to provide stability and efficiency. Each component plays a vital role in facilitating the connection between the main unit and additional implements, ensuring seamless functionality.

Maintenance Tips: Regular inspection and maintenance of this system can significantly enhance longevity and reliability. Identifying wear and tear early on can prevent more extensive damage, ensuring that the equipment remains operational for years to come.

Importance of Mule Drive Components

The efficiency and performance of any outdoor machinery significantly depend on the various integral elements that facilitate its operation. Understanding these components is essential for maintenance, repair, and overall functionality. These parts not only enhance productivity but also ensure safety and reliability in use.

Key Functions of Drive Elements

- Power Transmission: Essential for transferring energy from the engine to the cutting implements, ensuring optimal performance.

- Stability: Provides a stable framework that supports the entire mechanism during operation, preventing potential malfunctions.

- Adjustability: Allows for modifications based on specific tasks, enhancing versatility across various applications.

Maintenance and Longevity

Regular inspection and timely replacement of these components play a critical role in extending the lifespan of the equipment. Neglecting to address wear and tear can lead to:

- Increased operational costs due to inefficiencies.

- Higher risk of mechanical failure, resulting in downtime.

- Potential safety hazards for the user and surrounding environment.

Ultimately, understanding the significance of these essential components is crucial for anyone involved in the upkeep and operation of outdoor machinery. Prioritizing their care and maintenance will lead to improved functionality and greater reliability in the long run.

Identifying Key Parts in Diagrams

Understanding the essential components in visual representations is crucial for effective maintenance and repairs. Clear identification of these elements enhances comprehension and aids in troubleshooting processes.

Common Components to Recognize

Familiarizing oneself with frequently encountered elements can streamline efforts. Look for connectors, supports, and other structural features that play pivotal roles in the assembly.

Utilizing Diagrams Effectively

Employing these visuals correctly can significantly improve efficiency. Ensure to cross-reference labels and references to achieve the ultimate understanding of each part’s function.

Maintenance Tips for Mule Drive Systems

Proper upkeep of towing mechanisms is crucial for ensuring optimal performance and longevity. Regular attention to these systems can prevent breakdowns and enhance efficiency, making tasks smoother and more manageable.

Regular Inspection

Conduct frequent examinations of the assembly to identify any signs of wear or damage. Pay close attention to connection points and moving parts, as these are prone to issues over time.

Lubrication and Cleaning

Keep all components well-lubricated to minimize friction and reduce the risk of corrosion. Additionally, clean the system regularly to remove debris and buildup that could impair functionality.

Common Issues with John Deere 318

Understanding the frequent challenges faced by owners of this popular model is essential for maintaining its longevity and performance. From mechanical failures to electrical glitches, various factors can lead to suboptimal operation. Addressing these concerns promptly can save time and resources.

One notable issue is related to the ignition system, where faulty components can prevent the engine from starting. Additionally, hydraulic leaks are common and can affect the overall functionality of attachments. Regular inspection of belts and pulleys is also advisable, as wear and tear can lead to performance degradation.

Moreover, owners often report problems with the cutting deck, including uneven cuts and difficulty in height adjustment. Ensuring proper maintenance and timely repairs can greatly enhance the efficiency and reliability of the machine.

Step-by-Step Assembly Instructions

This section provides a clear and concise guide to help you piece together essential components efficiently. Following these instructions will ensure a smooth assembly process, allowing you to achieve optimal functionality.

Before you begin, gather all necessary tools and components. Refer to the following table for an overview of the assembly steps:

| Step | Description |

|---|---|

| 1 | Start by aligning the main bracket with the designated mounting area. Ensure all holes are unobstructed. |

| 2 | Secure the bracket using bolts. Tighten them evenly to maintain stability. |

| 3 | Attach the secondary components, ensuring they fit snugly against the primary assembly. |

| 4 | Install any necessary spacers to avoid friction during operation. |

| 5 | Double-check all connections for tightness and alignment before proceeding. |

| 6 | Finally, perform a test run to ensure everything functions as intended. Adjust any components if necessary. |

By adhering to these steps, you will achieve a successful assembly, ensuring all elements operate seamlessly together.

Where to Buy Replacement Parts

Finding suitable components for your equipment can greatly enhance its performance and longevity. Numerous options exist for sourcing these essential items, ensuring you can restore functionality efficiently. From local retailers to online marketplaces, there are various avenues to explore that cater to different preferences and needs.

Local hardware stores often carry a selection of components, allowing you to inspect items in person. Additionally, specialty shops focused on outdoor machinery may provide specific solutions tailored to your equipment. For those seeking convenience, online platforms offer a vast inventory, often with user-friendly search tools to help you locate the exact items needed.

Manufacturer websites can also serve as reliable sources, frequently providing original components along with detailed information regarding compatibility. Moreover, forums and community groups dedicated to equipment enthusiasts may offer insights on where to find hard-to-get items, along with recommendations for trustworthy suppliers.

Differences Between Models and Variants

This section explores the distinctions among various designs and iterations of equipment, highlighting how specific features and functionalities can vary significantly. Understanding these differences is crucial for users seeking the most suitable version for their needs.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 20 HP | 22 HP | 25 HP |

| Weight | 500 lbs | 550 lbs | 600 lbs |

| Transmission Type | Automatic | Manual | Hydrostatic |

| Deck Size | 42 inches | 48 inches | 54 inches |

Upgrades for Enhanced Performance

Enhancing the efficiency and capability of your equipment can lead to significant improvements in productivity. By focusing on key modifications, operators can achieve optimal results and extend the lifespan of their machinery. These upgrades not only boost performance but also ensure that your tools remain competitive in demanding tasks.

Engine Enhancements

One of the most effective ways to improve overall functionality is by upgrading the engine components. Options such as high-performance air filters and exhaust systems can increase airflow and power output. Additionally, tuning the engine for better fuel efficiency can provide both economic and environmental benefits.

Attachment Improvements

Investing in advanced attachments can greatly enhance versatility. Options like improved blades, plows, and specialized implements allow for a wider range of applications. These modifications enable operators to tackle various tasks with greater ease and efficiency, making equipment more valuable in diverse settings.

How to Troubleshoot Mule Drive Problems

When facing issues with the towing mechanism of your equipment, it’s essential to approach the problem methodically. By identifying common symptoms and applying systematic checks, you can effectively diagnose and resolve malfunctions. This section will guide you through the troubleshooting process, ensuring optimal performance.

Common Symptoms and Their Solutions

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No engagement | Worn components | Inspect and replace any damaged parts |

| Unusual noises | Misalignment | Check for proper alignment and adjust accordingly |

| Excessive vibration | Loose connections | Tighten all bolts and fasteners |

| Slipping | Worn belts | Replace with new, compatible belts |

Step-by-Step Diagnostic Process

To efficiently troubleshoot, follow these steps:

- Begin with a visual inspection of the entire assembly.

- Check for any signs of wear or damage on the visible components.

- Test the operation by engaging the mechanism while observing for irregularities.

- Refer to the manufacturer’s manual for specific guidance on adjustments and specifications.

By adhering to this structured approach, you can identify and rectify issues effectively, ensuring your equipment remains functional and reliable.

Historical Context of John Deere 318

The evolution of agricultural machinery reflects significant advancements in technology and changing farming practices. This particular model played a pivotal role during a transformative era in the industry, showcasing the blend of innovation and tradition. Its design and functionality were tailored to meet the needs of farmers, enhancing productivity and efficiency on various terrains.

As agricultural demands grew, the introduction of versatile machines became crucial. This model emerged as a solution, symbolizing the shift towards mechanization in farming. Its reliability and ease of use established it as a favorite among many, influencing subsequent designs and contributing to the legacy of modern farming equipment.

The historical significance of this machinery extends beyond its practical applications. It embodies a period where advancements in engineering intersected with the everyday lives of farmers, ultimately shaping agricultural landscapes and practices for generations to come.

Resources for DIY Repairs and Guides

Engaging in do-it-yourself maintenance can be a rewarding experience, allowing individuals to save money while gaining valuable skills. Whether you are troubleshooting machinery or looking to enhance its performance, numerous resources can assist you on your journey.

Here are some essential resources for effective DIY repairs:

- Online Forums: Communities dedicated to equipment enthusiasts often provide valuable insights and shared experiences. Participating in discussions can lead to helpful tips and advice.

- YouTube Channels: Visual learners can benefit from instructional videos that guide you through various repair processes step by step. Look for channels focusing on your specific type of equipment.

- Manufacturer Websites: Official websites often contain downloadable manuals and troubleshooting guides, ensuring you have access to accurate information.

- Social Media Groups: Joining groups on platforms like Facebook can connect you with other DIYers who share similar interests and challenges.

Additionally, consider the following options for detailed guidance:

- Repair Manuals: These publications often include comprehensive instructions and diagrams, making them invaluable for complex repairs.

- Local Workshops: Hands-on classes can provide practical knowledge and the chance to learn from experienced instructors.

- Tool Rental Services: Many home improvement stores offer tools for rent, allowing you to tackle repairs without the need for a large initial investment.

By leveraging these resources, you can enhance your DIY skills and confidently undertake maintenance tasks. Happy repairing!