Maintaining your outdoor equipment in peak condition is essential for ensuring consistent and efficient performance. When it comes to lawn care tools, knowing the structure and functionality of each component allows for smoother operation and easier maintenance. Understanding how these elements fit together can help users quickly address any mechanical issues and improve the longevity of their equipment.

In this guide, we will explore the detailed breakdown of the essential elements that make up your outdoor cutting tool. Whether you’re dealing with routine upkeep or more complex repairs, having a clear view of the inner workings will save you time and effort. This comprehensive look into the different sections of your machine provides clarity and ensures you have the right knowledge when you need to replace or maintain any specific part.

Understanding the Lawn Cutting Attachment

The cutting attachment is a critical component of any lawn tractor, ensuring efficient and precise trimming of grass. This section delves into the key aspects of this attachment, highlighting its design, functionality, and how it contributes to the overall performance of the machine. By understanding its role, you can maintain and optimize the system for long-term use.

Key Features

- Adjustable blade height for versatile cutting

- Heavy-duty construction to withstand tough terrain

- Multiple cutting blades for even and efficient grass trimming

Maintenance Tips

- Regularly inspect the blades for sharpness and damage

- Ensure the attachment is properly aligned

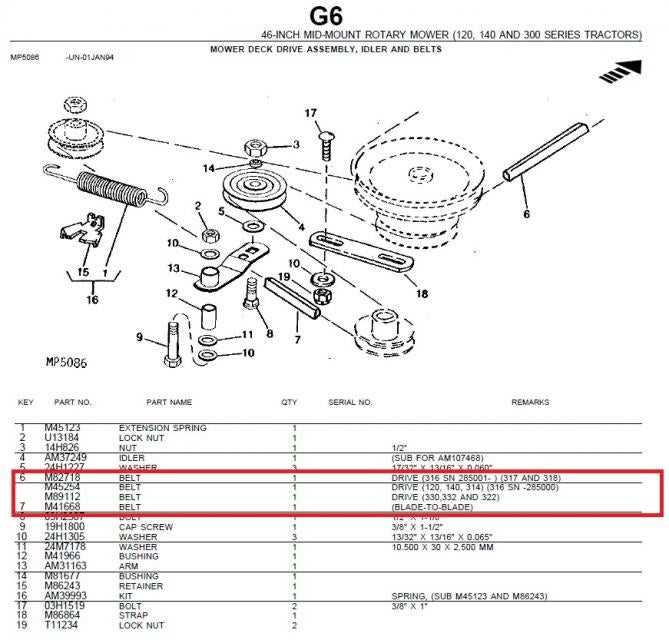

Key Components of the 46-Inch Deck

The cutting system is composed of several essential elements, all working together to ensure optimal performance and precision. Understanding these individual parts is crucial for maintaining efficiency and extending the longevity of the equipment. Each component plays a unique role in delivering a clean, even cut on the lawn.

Blades are central to the cutting function, responsible for trimming grass evenly and effectively. Regular inspection and sharpening of these components are necessary to maintain their functionality and avoid uneven results.

The spindles are crucial as they connect the blades to the mechanical system, allowing them to rotate at the necessary speeds

Mower Deck Assembly Overview

The assembly of a cutting mechanism is a critical aspect in ensuring efficient and precise grass trimming. Understanding how the various components fit together allows for smooth operation and optimal performance during maintenance activities. This section will provide an insightful look into the main components and their interaction within the system, focusing on ease of setup and alignment.

Component Description Function Blades Sharp, rotating elements responsible for cutting vegetation. Ensures an even cut and efficient grass collection. Blade Configuration for Optimal Cutting

The arrangement of cutting blades plays a crucial role in ensuring efficient and even grass trimming. A well-optimized blade setup not only improves the quality of the cut but also extends the lifespan of the equipment by reducing strain. Understanding how to position and maintain the blades properly is essential for achieving a uniform result, minimizing missed patches, and reducing wear.

Key Factors to Consider

- Blade Sharpness: Regular sharpening is vital for maintaining a clean and precise cut. Dull edges can tear grass, leaving jagged ends that are more susceptible to disease.

- Blade Height: Adjusting the height according to grass type and season helps promote healthy growth. Lower settings work best for shorter grass, while higher settings protect taller varieties from damage.

- Blade Type: Selecting the right blade for mulching, bagging, or side discharge can drastically impact performance. Each type is designed

Belt System and Pulley Placement

The arrangement of belts and pulleys plays a crucial role in ensuring smooth and efficient operation of the cutting mechanism. By correctly positioning the belts and ensuring proper tension, the system functions seamlessly, transferring power from the engine to the blades. A well-maintained system improves performance and longevity.

Belt Routing

Proper belt routing is essential for maintaining tension and preventing slippage. Each belt follows a specific path across the pulleys, ensuring optimal power transfer. It is important to regularly check for wear and adjust the belts to avoid disruptions in performance.

Pulley Configuration

The pulleys are strategically placed to guide the belts and provide the necessary power distribution. They must be aligned correctly to avoid unnecessary strain on the belts and to ensure consistent cutting action

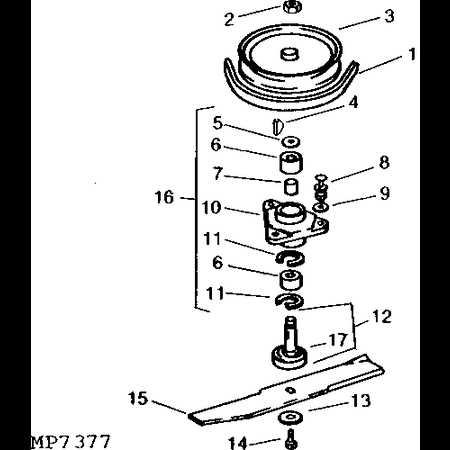

Spindle Housing and Maintenance Tips

The spindle housing is a crucial component of any lawn care equipment, ensuring the smooth operation of the cutting system. Regular maintenance of this element is essential for optimal performance and longevity. Proper attention to the spindle housing not only enhances the efficiency of the machinery but also prevents costly repairs down the line.

Inspecting the Spindle Housing: Regular inspections should be conducted to identify any signs of wear or damage. Look for cracks, excessive play, or corrosion that may compromise the housing’s integrity. If any issues are detected, it is advisable to address them promptly to avoid further complications.

Lubrication: Keeping the spindle housing well-lubricated is vital for smooth operation. Utilize the manufacturer’s recommended lubricant to ensure optimal performance. Periodic lubrication helps reduce friction and heat buildup, prolonging the lifespan of the spindle assembly.

Cleaning: Debris accumulation can impede the functioning of the spindle housing. Regularly clean the area to remove grass clippings, dirt, and other contaminants. Use a soft brush or cloth to avoid scratching the surface while ensuring all buildup is eliminated.

Replacement: In cases where the spindle housing is severely damaged or worn, replacement may be necessary. It is crucial to choose high-quality components that match the specifications of your equipment to ensure compatibility and performance.

By following these maintenance tips, operators can ensure their lawn care equipment remains in top condition, providing effective and efficient service for many seasons to come.

How to Align the Cutting Deck

Proper alignment of the cutting mechanism is essential for achieving an even and efficient cut. Ensuring that the blades are positioned correctly can enhance performance and prolong the life of the equipment. This process typically involves adjusting the height and angle of the blades to match the manufacturer’s specifications.

Step 1: Gather Necessary Tools

Step 2: Measure Blade Height

Begin by measuring the height of the blades from the ground. Use a tape measure to check the height at multiple points to ensure consistency. Adjust the height as necessary, ensuring both sides are even for optimal performance.

Step 3: Check for Levelness

Using a level, check if the cutting component is horizontal. If it is not level, make adjustments using the leveling bolts. This step is crucial as it affects how well the blades engage with the grass.

Step 4: Test Cutting Performance

After making adjustments, perform a test cut on a small patch of grass. Observe the results and make any further adjustments if needed. A well-aligned cutting mechanism will result in a clean cut without scalping or unevenness.

Step 5: Regular Maintenance

Regularly check the alignment of the cutting apparatus to maintain peak performance. Routine inspections can prevent issues before they arise, ensuring that your equipment remains in optimal condition for longer periods.

Identifying Wear and Tear on Parts

Recognizing deterioration in components is crucial for maintaining optimal performance and longevity of your equipment. Regular inspections can help identify signs of wear that may affect functionality. Understanding what to look for ensures timely repairs and prevents further damage.

Common Indicators of Damage

Several signs can indicate that components are beginning to fail. Look for visible cracks, excessive rust, or any discoloration on metallic surfaces. Additionally, worn-out belts often exhibit fraying or a shiny appearance, signaling the need for replacement. Be vigilant for unusual noises during operation, which may suggest internal issues.

Importance of Regular Maintenance

Conducting routine checks not only prolongs the lifespan of components but also enhances overall efficiency. Establish a maintenance schedule that includes cleaning, lubrication, and part replacement as needed. By prioritizing upkeep, you can ensure reliable performance and reduce the risk of unexpected breakdowns.

Replacing the Blades on a 318 Deck

Maintaining optimal performance of your cutting equipment is crucial for achieving a clean and precise finish in your lawn care tasks. One of the most important aspects of this maintenance involves the regular replacement of the cutting edges. This process not only ensures efficient operation but also enhances the longevity of your machinery.

Tools and Preparation

Before starting the blade replacement procedure, gather the necessary tools to facilitate a smooth operation. You will need a socket wrench, a replacement set of cutting edges, and safety gear, including gloves and goggles. Ensure that your equipment is parked on a level surface and that the engine is turned off to prevent any accidents.

Step-by-Step Replacement Process

Begin by lifting the unit using a jack or appropriate lift, ensuring it is stable and secure. Locate the fastening bolts on the cutting edges and use your socket wrench to remove them carefully. Once the old blades are detached, inspect the mounting area for any debris or damage. Clean the area thoroughly before installing the new cutting edges. Align the new blades with the mounting holes and secure them tightly with the bolts. Finally, lower the unit back to the ground and check for proper blade alignment before starting the engine.

Troubleshooting Common Deck Issues

Maintaining optimal performance is essential for any lawn care equipment, and addressing typical problems can ensure longevity and efficiency. Common complications often arise during operation, affecting the overall functionality. Understanding these issues allows for quick resolutions, saving time and enhancing productivity.

Uneven Cutting

One of the most frequent challenges is uneven cutting. This can be caused by a variety of factors including blade dullness, incorrect height settings, or uneven tire pressure. To resolve this, first inspect the blades for wear and replace them if necessary. Adjust the height settings according to the manufacturer’s recommendations, and check tire pressure to ensure they are evenly inflated.

Clogging

Clogging can hinder performance, particularly in damp conditions. Debris accumulation can obstruct the flow, leading to inefficient cutting. Regularly clear any buildup of grass or debris from the underside. Additionally, operating the equipment at the recommended speed can help prevent this issue. If clogging persists, consider adjusting the cutting height to a higher level during wet conditions.

John Deere 318 Deck Maintenance Schedule

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance routines help prevent unexpected breakdowns and promote efficient operation. Adhering to a well-structured schedule allows for timely interventions, ensuring that every component functions effectively.

Below is a recommended maintenance schedule to keep your equipment running smoothly:

- Daily Tasks:

- Inspect for loose bolts and nuts.

- Check the sharpness of the blades.

- Clean debris from the underside.

- Weekly Tasks:

- Lubricate all moving parts.

- Examine belts for wear and tear.

- Inspect the battery and connections.

- Monthly Tasks:

- Replace the oil and oil filter.

- Clean or replace the air filter as needed.

- Sharpen or replace blades if necessary.

- Seasonal Tasks:

- Conduct a thorough inspection before the start of the mowing season.

- Winterize the equipment at the end of the season.

- Check tire pressure and condition regularly.

Following this maintenance plan will help ensure that your machinery remains in top condition, allowing for a more enjoyable and efficient experience.

Where to Find Replacement Parts

Maintaining your equipment in optimal condition requires access to quality components. Whether you’re seeking original replacements or aftermarket alternatives, knowing where to look is essential for efficiency and cost-effectiveness.

Authorized Dealers

One of the most reliable sources for authentic components is authorized dealerships. These locations often provide:

- Genuine items directly from the manufacturer.

- Expert advice and support from knowledgeable staff.

- Access to specific manuals and installation guides.

Online Retailers

With the growth of e-commerce, numerous online platforms offer a wide selection of components. Here are some advantages:

- Convenience of shopping from home.

- Ability to compare prices and read customer reviews.

- Options for expedited shipping.

Be sure to choose reputable sites to ensure quality and reliability.

Local Repair Shops

For hands-on assistance, local repair shops can be invaluable. They often have access to a variety of components and can help with:

- Identifying the correct items for your equipment.

- Providing installation services if needed.

- Offering used or refurbished options at lower prices.

Whether you opt for a dealer, an online shop, or a local repair service, make sure to verify compatibility and quality before making a purchase.

- Daily Tasks: