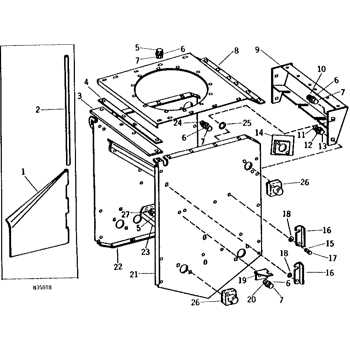

In the realm of mechanical systems, comprehending the arrangement of various elements is crucial for effective maintenance and troubleshooting. A detailed visual representation serves as a roadmap, guiding users through the intricate relationships and functions of each piece. This understanding not only enhances operational efficiency but also aids in diagnosing potential issues before they escalate.

Analyzing these layouts allows for a deeper appreciation of the design’s intricacies. Each segment plays a pivotal role, contributing to the overall performance and reliability of the system. By exploring these connections, one can ultimately enhance their skill set and foster a more profound knowledge base in their field.

Ultimately, being well-versed in component arrangements not only empowers individuals in their work but also inspires confidence in handling complex machinery.

Understanding Gud27essj0ww Components

Grasping the intricacies of various elements within a mechanical system is essential for effective functionality and maintenance. Each component plays a critical role, contributing to the overall performance and efficiency of the device. This section delves into the different parts that make up this system, exploring their functions and interrelationships.

Key Elements and Their Functions

- Core Unit: The primary section that houses the main operational mechanisms.

- Control Interface: The user-accessible part that allows interaction with the system, enabling settings and adjustments.

- Power Source: The component responsible for supplying energy, crucial for the entire operation.

- Support Structures: Elements that provide stability and alignment, ensuring all parts work harmoniously.

- Feedback Sensors: Devices that monitor performance, providing data to optimize functionality.

Interconnectivity of Components

Understanding how these elements work together is vital for troubleshooting and optimization. The interdependencies between each part can significantly affect overall performance.

- The core unit relies on the power source to function effectively.

- Control interfaces provide the user with the ability to modify operations based on feedback from sensors.

- Support structures ensure that all components maintain proper alignment, preventing operational issues.

By familiarizing oneself with these critical elements and their interactions, one can enhance the longevity and efficiency of the entire system.

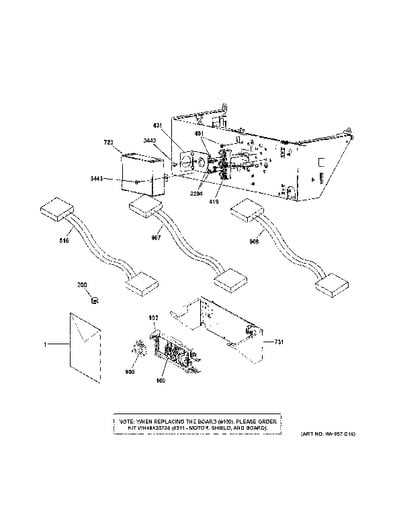

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex systems. They provide clarity and insight into how individual elements interact and contribute to overall functionality.

Here are several reasons why these illustrations are essential:

- Enhanced Understanding: They simplify intricate details, making it easier to grasp the structure and relationships.

- Efficient Troubleshooting: Identifying specific elements helps in diagnosing issues quickly.

- Streamlined Assembly: Clear visuals guide users in correctly assembling or disassembling systems.

- Improved Communication: They serve as a universal language, bridging gaps between different stakeholders.

- Documentation: These visuals are vital for maintaining accurate records of components and configurations.

Ultimately, a well-crafted illustration serves as an indispensable tool in both education and practical applications, facilitating a deeper comprehension of mechanical systems.

Key Features of Gud27essj0ww

This section highlights the essential attributes that define the functionality and appeal of the subject in question. Understanding these characteristics can help users appreciate its design and usability, ensuring they can maximize its potential in various applications.

Innovative Design

The innovative approach to design enhances efficiency and user experience. The streamlined aesthetics not only contribute to a modern look but also ensure that every component is easily accessible for maintenance and operation.

Enhanced Performance

Performance metrics indicate significant improvements over previous models. This includes faster processing capabilities and greater reliability, which are critical for demanding tasks.

| Feature | Description |

|---|---|

| Efficiency | Optimized for minimal energy consumption without compromising power. |

| Durability | Built with high-quality materials for long-lasting use under various conditions. |

| Versatility | Adaptable to multiple environments, catering to diverse user needs. |

| Safety | Equipped with advanced safety features to ensure user protection during operation. |

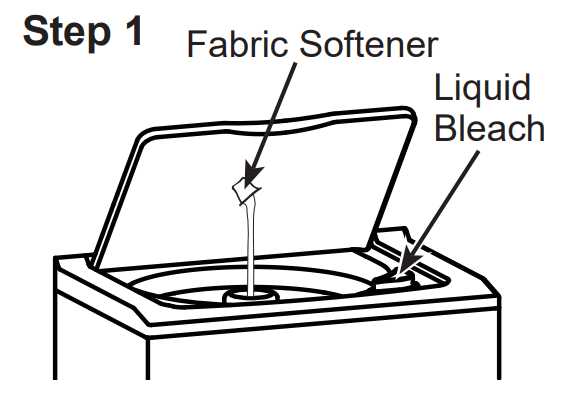

How to Interpret Diagrams

Understanding visual representations requires familiarity with their structure and components. These graphical tools can convey complex information efficiently, making it essential to grasp their meanings and relationships.

To effectively analyze these visuals, follow these steps:

| Step | Description |

|---|---|

| 1 | Examine the overall layout to identify key elements. |

| 2 | Look for symbols and labels that denote specific functions. |

| 3 | Trace connections to understand the relationships between parts. |

| 4 | Consult any accompanying legends for clarification. |

| 5 | Practice with different examples to enhance your skills. |

Common Issues and Fixes

In the realm of machinery and equipment, users often encounter various challenges that can impede functionality. Identifying these problems early and understanding effective solutions can greatly enhance performance and longevity.

Frequent Problems

Many users face similar obstacles, such as operational failures, unusual noises, or performance drops. Recognizing these issues is the first step towards resolution.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Operational Failure | Power supply issues, internal blockages | Check connections, clear obstructions |

| Unusual Noises | Worn components, lack of lubrication | Inspect parts, apply lubricant |

| Performance Drop | Dirty filters, improper settings | Replace filters, adjust settings |

Maintenance Tips

Regular inspections and timely interventions can prevent many issues. Staying proactive ensures optimal operation and helps avoid costly repairs.

Best Practices for Maintenance

Effective upkeep is essential for ensuring longevity and optimal performance of any equipment. Adhering to a systematic approach not only enhances reliability but also minimizes the risk of unexpected failures. By implementing a series of best practices, users can maintain their devices in peak condition.

Routine Checks

Regular inspections can help identify potential issues before they escalate. Consider the following:

- Establish a schedule for periodic reviews.

- Inspect components for signs of wear or damage.

- Clean surfaces to prevent the buildup of debris.

Documentation and Record Keeping

Keeping detailed records of maintenance activities is vital for tracking performance and making informed decisions. Focus on these aspects:

- Log dates and details of each maintenance task.

- Document any repairs or replacements made.

- Review historical data to identify patterns or recurring issues.

Tools Needed for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. The correct tools not only streamline the repair process but also ensure safety and efficiency. This section outlines essential instruments that every technician should have on hand for successful interventions.

Essential Instruments

Wrenches are fundamental for loosening and tightening various components. Different sizes and types, such as adjustable or socket wrenches, provide flexibility for diverse tasks.

Safety Gear

Investing in protective equipment is vital. Safety goggles and gloves should be standard to protect against potential hazards during repairs, ensuring a secure working environment.

Where to Find Replacement Parts

When seeking components for your machinery, it’s essential to explore various reliable sources. Numerous outlets specialize in providing high-quality alternatives, ensuring that you can maintain optimal performance without compromising on reliability.

Online Retailers: The internet is a treasure trove of options. Websites dedicated to industrial supplies often carry a wide range of replacements. Be sure to check user reviews to gauge the quality and reliability of the components.

Local Distributors: Visiting local shops can yield immediate solutions. Many distributors offer personalized service and can assist in identifying the correct items you need.

Manufacturer’s Website: Always consider checking the official website of the manufacturer. They often provide a comprehensive catalog of available replacements, ensuring authenticity and compatibility.

Forums and Community Groups: Engaging with online communities can be invaluable. Members frequently share insights on where to procure specific components and may even offer second-hand options.

Ultimately, a combination of these avenues can help you find the right alternatives to keep your equipment running smoothly.

Manufacturer Specifications Explained

Understanding the technical details provided by a producer is essential for optimal usage and maintenance of any equipment. These specifications serve as a foundation for performance expectations, guiding users in making informed decisions. By delving into these details, one can appreciate the ultimate capabilities and limitations of the product.

Key Elements of Specifications

Manufacturer specifications typically include vital information such as dimensions, weight, material composition, and performance metrics. Each of these aspects plays a crucial role in determining the suitability of the product for specific tasks. Dimensions, for instance, ensure compatibility with existing systems, while performance metrics inform users about efficiency and reliability.

Importance of Compliance

Adhering to manufacturer guidelines is critical for safety and longevity. By following these recommendations, users can avoid potential issues that may arise from misuse or improper installation. Ultimately, understanding these specifications not only enhances the user experience but also maximizes the product’s lifespan.

Benefits of Regular Inspection

Conducting frequent assessments is crucial for maintaining optimal performance and longevity of equipment. These evaluations help identify potential issues before they escalate, ensuring smooth operations and minimizing downtime.

Early Problem Detection

- Identifies wear and tear before it becomes critical.

- Reduces the risk of unexpected failures.

- Facilitates timely repairs, preventing larger expenses.

Enhanced Safety

- Ensures compliance with safety standards.

- Reduces the likelihood of accidents and injuries.

- Promotes a safer working environment for all personnel.

Upgrades and Modifications

Enhancing performance and functionality is a common pursuit among enthusiasts. Whether for improved efficiency or personalized aesthetics, exploring various enhancements can lead to an ultimate transformation of your setup. These modifications can range from simple tweaks to extensive overhauls, tailored to meet individual needs and preferences.

Performance Boosts: Upgrading key components can significantly elevate your system’s efficiency. Consider options such as advanced motors or optimized control units that provide greater responsiveness and speed.

Aesthetic Changes: Personalization is crucial for many users. From custom paint jobs to unique accessories, these visual upgrades allow for self-expression while enhancing the overall appeal.

Functionality Enhancements: Incorporating additional features, such as improved lighting or integrated technology, can enrich the user experience. These modifications not only make operations smoother but also add a layer of sophistication.

By carefully selecting upgrades and modifications, users can delve deeper into their projects, achieving a balance between performance, aesthetics, and functionality.

Community Resources and Forums

This section highlights various platforms where enthusiasts can connect, share knowledge, and seek assistance related to their interests. These spaces foster collaboration and provide valuable insights, making them essential for both beginners and experts.

Engaging with these resources can enhance understanding and skill development:

- Online forums dedicated to specific topics.

- Social media groups focused on related themes.

- Websites offering tutorials and guides.

Participating in discussions can lead to:

- Access to expert advice.

- Networking opportunities with like-minded individuals.

- Discovery of new tools and resources.

By delving into these community-driven platforms, users can significantly enrich their experiences and knowledge base.