In the world of outdoor equipment, comprehending the various elements of a lawn maintenance machine is crucial for optimal performance. Each individual component plays a significant role in ensuring the efficiency and longevity of the entire system. This knowledge aids in troubleshooting and maintenance, making it essential for both professionals and enthusiasts.

Exploring the intricacies of the various elements reveals how they interconnect and contribute to the overall functionality. Familiarity with these components not only enhances operational understanding but also empowers users to make informed decisions regarding repairs and upgrades.

Additionally, recognizing the specific configurations and arrangements of these parts can lead to improved performance and satisfaction. Whether for routine maintenance or complex repairs, a thorough understanding of the inner workings enhances the user experience and promotes effective lawn care.

Understanding John Deere Z720A Components

This section delves into the essential elements that contribute to the efficient functioning of a specific model in the landscape maintenance category. Recognizing the various components is vital for effective maintenance and troubleshooting.

- Engine: The heart of the machine, responsible for providing the necessary power.

- Transmission: Facilitates the transfer of power from the engine to the wheels, enabling movement.

- Deck: The area where cutting blades are located, crucial for achieving a clean cut.

- Wheels: Provide mobility and stability, essential for maneuvering across different terrains.

- Control System: The interface that allows the operator to manage the machine’s functions.

Understanding these components helps in identifying issues and ensuring optimal performance during operation.

Overview of Key Parts

This section provides a comprehensive look at the essential components that contribute to the functionality of a specific mowing machine. Understanding these elements is crucial for maintenance and performance enhancement.

Engine: The powerhouse of the machine, responsible for providing the necessary energy for operation.

Transmission: A critical system that facilitates the transfer of power from the engine to the wheels, enabling smooth movement.

Cutting Deck: This assembly houses the blades and is vital for achieving an even cut while managing grass discharge.

Wheels: These components ensure mobility and stability, allowing the operator to maneuver efficiently across various terrains.

Control Panel: The interface that allows the user to manage functions, providing an intuitive experience during operation.

Maintenance Tips for Z720A

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a consistent maintenance schedule, you can prevent costly repairs and enhance efficiency.

1. Check Fluid Levels: Regularly inspect and replenish all essential fluids, including oil, coolant, and fuel. This practice helps maintain smooth operation and prevents overheating.

2. Clean Air Filters: Ensure that air intake filters are clean and free of debris. Clean filters facilitate proper airflow, improving engine performance and fuel efficiency.

3. Inspect Blades: Periodically examine cutting implements for sharpness and damage. Keeping blades sharp ensures clean cuts and reduces strain on the motor.

4. Battery Maintenance: Inspect battery connections and clean any corrosion. A well-maintained battery ensures reliable starting and operation.

5. Tire Pressure: Regularly check and adjust tire pressure to the recommended levels. Properly inflated tires enhance traction and reduce wear.

6. Lubrication: Apply lubricant to all moving parts as specified in the user manual. This reduces friction and prolongs the life of components.

By following these simple yet effective maintenance practices, you can enhance the functionality and lifespan of your machinery.

Identifying Common Issues

Understanding typical problems that may arise with machinery can significantly enhance maintenance and repair efficiency. Recognizing these challenges early on allows for prompt action, minimizing downtime and ensuring optimal performance. Users should familiarize themselves with the most frequent concerns encountered in similar models.

Mechanical failures often stem from wear and tear on components, which can lead to reduced functionality. Regular inspections are crucial to identify signs of deterioration, such as unusual noises or vibrations.

Electrical malfunctions are another common issue, often caused by loose connections or faulty wiring. Ensuring that all electrical systems are properly maintained can prevent unexpected failures during operation.

Additionally, fuel system problems, including blockages or leaks, can hinder performance. Keeping the fuel lines and filters clean is essential for uninterrupted operation.

Lastly, hydraulic issues can arise, typically related to leaks or air in the system. Monitoring fluid levels and ensuring proper sealing can mitigate these complications effectively.

Replacement Parts Availability

Ensuring access to suitable components is essential for maintaining the efficiency and longevity of any machine. Availability of these elements can significantly impact operational performance, making it crucial for owners to be informed about where to find the right replacements.

Sources for Components

- Authorized dealers offer genuine items tailored for optimal compatibility.

- Online retailers provide a wide selection, often at competitive prices.

- Local repair shops may stock common components and can assist in sourcing less common ones.

Considerations When Purchasing

- Verify compatibility with your specific model to avoid fitment issues.

- Compare prices across different sources to ensure you receive a fair deal.

- Check for warranty or return policies to safeguard your investment.

Where to Purchase Components

Finding reliable sources for essential machinery elements is crucial for maintenance and repair. Whether you’re looking for original or aftermarket items, various options are available to ensure your equipment remains in optimal condition.

- Authorized Dealers: These vendors offer genuine replacements and often provide warranty support.

- Online Retailers: Websites specializing in equipment supplies can be convenient for comparing prices and availability.

- Local Hardware Stores: Nearby suppliers may stock commonly needed items, allowing for quick access.

- Salvage Yards: For budget-friendly solutions, consider checking yards that sell refurbished components.

- Manufacturer Websites: Direct purchases from producers can ensure authenticity and quality.

Exploring these avenues will help you secure the necessary components efficiently, keeping your machinery running smoothly.

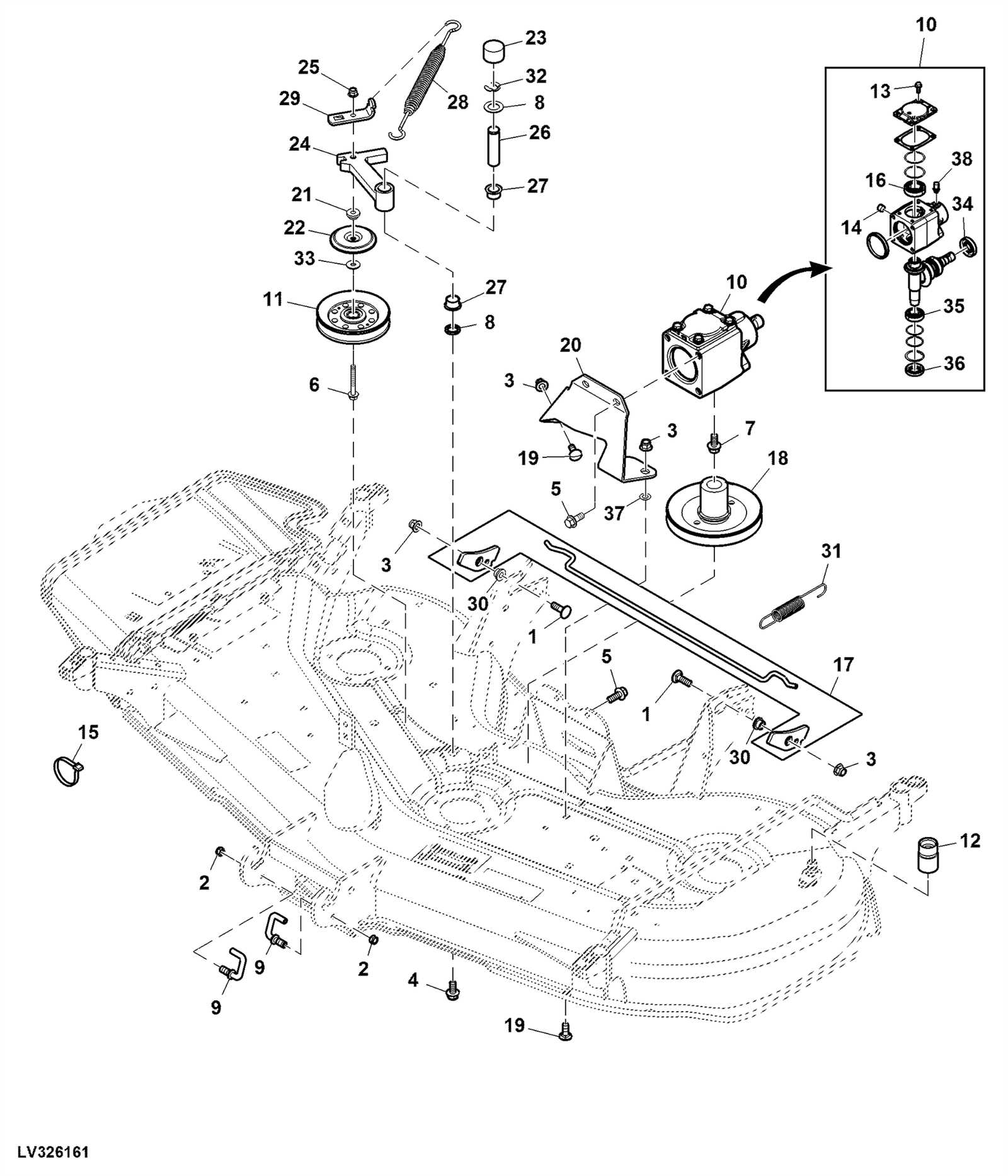

Assembly Process Explained

This section provides an overview of the procedure involved in bringing together various components for optimal functionality. Understanding the steps in the assembly process is crucial for ensuring efficiency and effectiveness in the final product.

The assembly procedure typically includes several key stages:

- Preparation: Gather all necessary components and tools before beginning the process. This ensures a smooth workflow.

- Sorting: Organize parts based on their respective categories. This helps in easily locating each item during assembly.

- Assembly: Follow the sequence of assembly as outlined in the guide, ensuring that each component is fitted correctly.

- Inspection: After assembly, conduct a thorough examination to ensure all parts are properly installed and functioning as intended.

- Testing: Perform tests to verify the performance of the assembled unit, making adjustments if necessary.

By adhering to these stages, one can achieve a reliable and effective assembly, leading to a well-functioning unit that meets expectations.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your equipment efficiently. By following the outlined steps, you’ll ensure all components are correctly aligned and securely fitted for optimal performance.

Begin with a thorough inspection of all elements involved in the assembly process. Ensuring that you have everything at hand will streamline your work and minimize interruptions.

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools. |

| 2 | Organize parts according to the assembly sequence. |

| 3 | Start by securing the main framework. |

| 4 | Attach secondary elements, ensuring a snug fit. |

| 5 | Double-check all connections for stability. |

| 6 | Conduct a final inspection before operation. |

Following these steps will facilitate a smooth assembly, enhancing the longevity and efficiency of your machinery.

Benefits of Genuine Parts

Using authentic components for your equipment ensures optimal performance and longevity. These specialized items are designed to fit perfectly, enhancing the functionality of your machinery while reducing the risk of failures.

Quality Assurance: Genuine components undergo rigorous testing to meet high standards. This guarantees reliability and effectiveness, providing peace of mind for operators.

Enhanced Performance: Authentic items are crafted to work seamlessly with your machine, ensuring it operates at its best. This can lead to improved efficiency and reduced downtime.

Long-Term Savings: Investing in quality components can save money in the long run by minimizing maintenance needs and extending the lifespan of your equipment. It is a wise decision for those who prioritize durability and reliability.

Warranty Protection: Utilizing genuine items often helps maintain warranty coverage. Manufacturers typically require the use of authentic components to uphold service agreements, ensuring protection against unforeseen issues.

Why Quality Matters

In the world of machinery, the significance of high standards cannot be overstated. Quality components play a crucial role in ensuring longevity and optimal performance. When investing in equipment, understanding the impact of superior materials and craftsmanship is essential for achieving efficiency and reliability.

The Benefits of Durability

Durable elements contribute to the overall effectiveness of any mechanical system. They minimize the risk of breakdowns, leading to decreased maintenance costs and extended operational lifespans. Choosing robust materials means fewer replacements and repairs, ultimately saving time and resources.

Enhanced Performance and Safety

Top-notch components enhance the functionality of equipment, allowing it to perform at its best under various conditions. This not only boosts productivity but also ensures safety for users. Quality assurance in every part fosters trust and confidence in machinery, making it a wise choice for any operator.

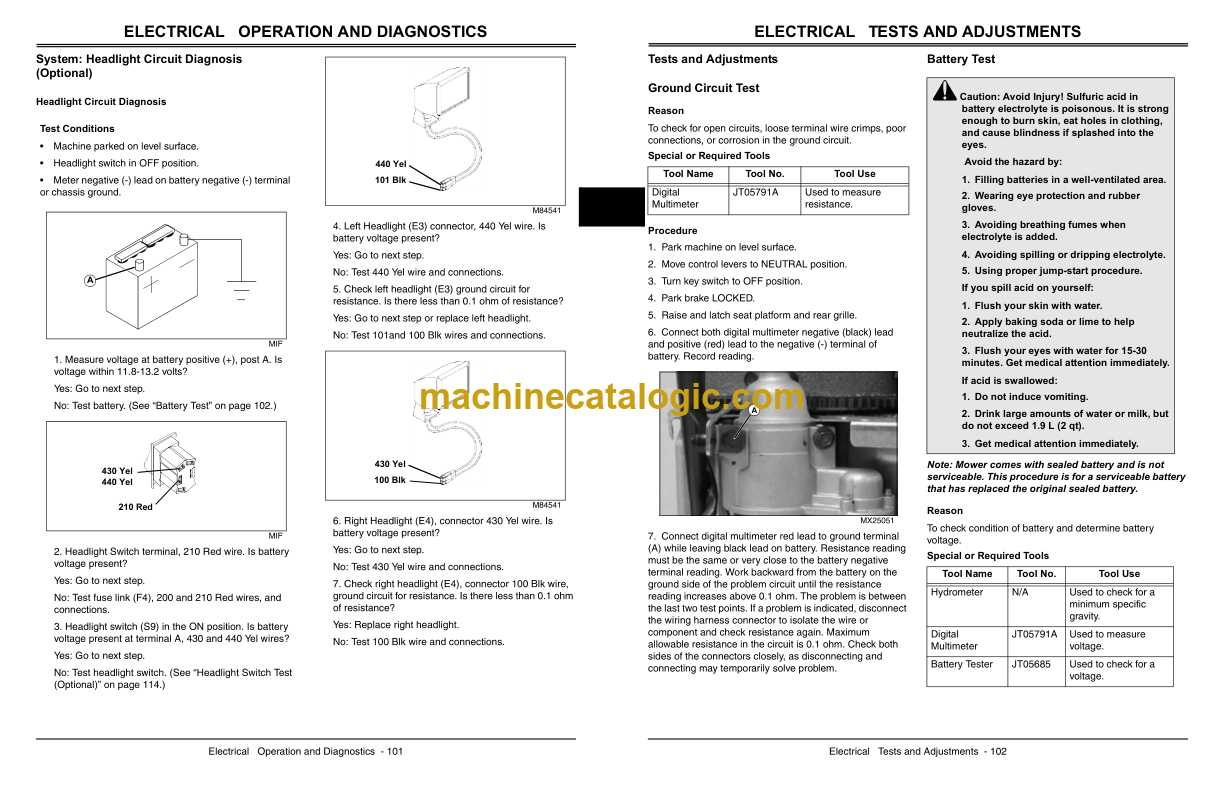

Wiring and Electrical Systems

The functionality of any machinery heavily relies on its wiring and electrical components. A well-organized electrical layout is crucial for ensuring optimal performance and safety. This section delves into the intricate network of circuits that power various systems, allowing for seamless operation.

Understanding the Basics of electrical systems involves recognizing how each component interacts within the overall framework. From the main power source to the smallest connectors, every element plays a vital role in maintaining efficiency.

Regular maintenance of wiring is essential to prevent malfunctions. Inspecting for wear, corrosion, and loose connections can significantly enhance longevity and reliability. Implementing a proactive approach ensures that the system remains robust and responsive to operational demands.

Furthermore, upgrading electrical components can lead to improved functionality and efficiency. Investing in high-quality parts and modern technologies can enhance the overall performance of the system, allowing for greater adaptability to changing requirements.

In conclusion, a comprehensive understanding of wiring and electrical systems is fundamental for maximizing the efficiency and safety of any mechanical setup. Attention to detail in both design and maintenance can lead to significant operational benefits.

Understanding the Circuit Diagrams

Circuit representations are essential for comprehending the electrical systems within machinery. These visual aids provide insights into how various components interact, allowing users to troubleshoot and maintain their equipment effectively.

Importance of Circuit Representations

These illustrations serve several purposes:

- Facilitate troubleshooting by showing connections and functions.

- Assist in understanding the flow of electricity throughout the system.

- Enable efficient planning for repairs and upgrades.

Key Components to Recognize

When examining circuit representations, it’s important to identify common elements:

- Power Sources: Indicate where electricity originates.

- Switches: Control the flow of current within the system.

- Load Devices: Represent the components that utilize electrical energy.

- Wires and Connections: Show how various parts are linked together.

By understanding these features, individuals can gain a clearer view of the electrical network, enhancing their ability to work with machinery effectively.

Safety Features of Z720A

The design of this mower incorporates various mechanisms aimed at enhancing user protection and minimizing accidents during operation. Understanding these features is crucial for ensuring a safe mowing experience.

Key Protective Mechanisms

- Operator Presence Control: This feature automatically shuts off the machine if the operator leaves the seat, preventing unintended movement.

- Safety Switches: Multiple switches are positioned throughout the equipment to halt operations when necessary, reducing the risk of injury.

- Emergency Brake: An easily accessible emergency brake allows for quick stops in case of unexpected situations.

Additional Safety Considerations

- Always wear appropriate protective gear when operating the equipment.

- Regularly inspect safety features to ensure they are functioning correctly.

- Follow the manufacturer’s guidelines for safe usage and maintenance.