Understanding the components of an advanced fuel system is crucial for maintaining efficiency and ensuring long-term reliability. This section delves into the intricate design and functionality of key elements within a modern fuel delivery mechanism, offering insights into their roles and interactions.

Each element within this system plays a vital role in ensuring precise control and smooth operation. From intricate valves to resilient seals, the arrangement ensures optimal performance under various conditions. A deeper exploration of the internal structure allows for better diagnostics and maintenance, helping to identify potential points of wear or failure.

This article provides a detailed breakdown, focusing on individual mechanisms and their interconnected functions. The aim is to equip professionals and enthusiasts with the knowledge required to handle upgrades, repairs, and troubleshooting with confidence.

Overview of Common Pump Components

In modern machinery, fluid transport systems rely on precision-built assemblies that ensure smooth operation and efficient performance. These systems contain multiple interconnected elements, each with a specific role in regulating flow, pressure, and stability under various operating conditions.

Key components include chambers that manage fluid intake and discharge, mechanical structures responsible for maintaining flow direction, and seals that prevent leakage and contamination. Internal moving parts synchronize to sustain consistent operation, while sensors and valves adjust to changing requirements in real time. Each element works in harmony to achieve optimal functionality, contributing to the reliability and durability of the system as a whole.

Main Elements in Fuel Delivery

The process of delivering fuel efficiently relies on several interconnected components working in harmony. Each element plays a crucial role in regulating, measuring, and supplying fuel to the engine with precision, ensuring optimal performance. These systems must handle high pressure and maintain reliability under varying conditions, preventing disruptions in the flow.

Fuel Regulation Components

One of the key aspects involves maintaining a consistent flow by using mechanisms that monitor pressure and adjust supply rates. Valves and regulators ensure that fuel is delivered smoothly without abrupt changes, safeguarding the engine from potential damage caused by excess or insufficient supply.

Precision Flow Control and Monitoring

Advanced sensors and control modules are responsible for tracking the delivery process. These elements provide real-time data to the system, enabling precise adjustments to meet the engine’s requirements. This constant feedback loop ensures efficiency and helps in reducing emissions by optimizing fuel consumption.

Internal Mechanisms and Their Roles

The functionality of complex mechanical systems relies on the precise coordination of multiple internal elements. Each component plays a specific role to ensure smooth performance, working together in a synchronized manner to manage pressure, flow, and energy transfer effectively.

Key Components Overview

- Main Chamber: Central to regulating flow dynamics, this section handles the distribution of fluid within the system.

- Control Valves: These parts adjust internal pressure levels, ensuring proper functionality by reacting to input signals.

- Plungers: Responsible for creating necessary movement, converting energy into mechanical force.

Sequence of Operations

- The system initiates with the movement of internal shafts, creating the primary driving force.

- Valves open and close at precise intervals, maintaining optimal pressure levels.

- The final stage involves the release of energy, ensuring consistent flow through output channels.

Each internal mechanism contributes uniquely to overall efficiency. Their combined operation ensures a stable and balanced process, minimizing disruptions and enhancing performance under varying conditions.

How Precision Parts Operate Together

Mechanical assemblies rely on the seamless interaction of finely crafted components to ensure efficient and reliable operation. Every element, from the smallest fastener to the most complex mechanism, is designed to fit within strict tolerances, promoting smooth performance and minimizing wear. The harmony between these elements allows the entire system to function effectively under varying conditions.

Key Elements and Their Roles

- Housing: Encases and protects internal components, ensuring stability and alignment.

- Shafts: Transfer rotational or linear motion, maintaining precise movement throughout the system.

- Bearings: Reduce friction, enhancing durability and efficiency by supporting rotational elements.

- Seals: Prevent fluid or air leakage, ensuring optimal pressure and reducing contamination risks.

- Fasteners: Secure components, keeping the structure intact even under high stress.

The Importance of Synchronization

- Alignment: Proper alignment ensures all components work in unison, avoiding imbalances or unnecessary strain.

- Lubrication: A well-maintained lubrication system minimizes friction and protects against excessive heat buildup.

- Material Compatibility: Selecting compatible materials prevents premature wear and extends service life.

- Timely Maintenance: Regular inspections help detect early signs of wear, preventing failures.

The synergy between these precision components allows the entire mechanism to operate consistently, even under challenging conditions. When every part functions as intended, the system achieves high levels of reliability and performance

Differences Between CP4 and CP3 Systems

Fuel delivery technologies have evolved over time, offering enhanced performance and efficiency for internal combustion engines. Two prominent systems, often compared, reflect different design approaches and are tailored to meet varying engine demands. Understanding their distinctions helps users select the right configuration for specific applications.

Design and Operational Efficiency

One of the key differences lies in how these systems regulate the flow of fuel. The earlier model is known for its robust construction and reliability under heavy loads, making it a popular choice for engines requiring durability. In contrast, the more recent version introduces design optimizations aimed at reducing friction and improving efficiency, particularly under varying pressure conditions.

Performance and Longevity

The older generation system tends to be more forgiving with fuel quality, offering a longer lifespan when maintained properly. However, the newer system provides higher precision, which can lead to improved combustion and lower emissions. It is, however, more sensitive to contaminants, requiring stricter fuel management to prevent wear.

In summary, the two systems reflect a shift in focus: from raw endurance to a more refined balance of power and efficiency. Choosing between them depends on the engine’s workload, maintenance practices, and the desired performance outcome.

Key Design Improvements and Trade-offs

In the realm of advanced fuel delivery systems, several innovations have emerged to enhance performance and reliability. These enhancements often focus on improving efficiency, reducing emissions, and optimizing durability. However, each improvement comes with its own set of compromises that must be carefully evaluated to ensure overall effectiveness.

Innovative Features

Recent advancements have introduced new features that significantly boost operational efficiency. These include refined component geometries, enhanced materials, and advanced control algorithms. Such modifications allow for improved fuel atomization and better pressure regulation, leading to enhanced combustion and power output.

Considerations and Challenges

While these innovations present substantial benefits, they also introduce challenges. For example, the use of lightweight materials can reduce wear but may compromise structural integrity under extreme conditions. Additionally, sophisticated control mechanisms may enhance responsiveness but could complicate maintenance and repair processes.

| Improvement | Benefit | Trade-off |

|---|---|---|

| Enhanced Efficiency | Better fuel consumption | Higher manufacturing costs |

| Durable Materials | Increased lifespan | Potential weight increase |

| Advanced Control Systems | Improved responsiveness | Complexity in repair |

Understanding High-Pressure Sealing Systems

In various industrial applications, the integrity of fluid management is critical, particularly in environments characterized by elevated pressures. Effective sealing mechanisms are essential to prevent leakage and ensure the efficient operation of machinery. A robust sealing system not only enhances performance but also contributes to the longevity of equipment.

High-pressure sealing solutions are designed to withstand extreme conditions, including significant temperature variations and aggressive fluids. These systems often incorporate specialized materials and engineering techniques to provide reliable seals that maintain operational efficiency. Understanding the components and functionality of these systems is vital for anyone involved in maintenance or engineering roles.

| Component | Description |

|---|---|

| Seals | Elements that provide a barrier against fluid leakage, often made from elastomers or advanced polymers. |

| Retaining Rings | Components that secure seals in place, preventing them from dislodging under high pressure. |

| Compression Elements | Used to maintain the appropriate force on seals, ensuring a tight fit even under fluctuating pressures. |

| Gaskets | Flat seals placed between mating surfaces to prevent fluid escape, typically made from flexible materials. |

In summary, understanding high-pressure sealing mechanisms is crucial for ensuring the operational reliability of systems exposed to challenging conditions. Proper selection and maintenance of sealing components are key factors that significantly influence performance and durability.

Importance of Leak Prevention

Effective management of fluid systems is crucial for maintaining operational efficiency and safety. One of the most significant aspects of this management is the prevention of leaks, which can lead to substantial losses, environmental hazards, and safety concerns. Implementing robust leak prevention measures is essential to ensure the reliability of the entire system.

Consequences of Leaks

Leaks can have far-reaching consequences, including equipment damage, increased operational costs, and potential regulatory penalties. Fluid loss not only affects performance but can also lead to hazardous situations that compromise safety. Addressing leaks promptly and effectively is vital to avoid these adverse outcomes.

Strategies for Leak Prevention

Employing proactive strategies such as regular inspections, maintenance routines, and the use of high-quality components can significantly mitigate the risk of leaks. Monitoring systems and advanced sealing technologies also play a crucial role in identifying potential issues before they escalate. By prioritizing leak prevention, organizations can enhance efficiency and prolong the lifespan of their systems.

Key Materials for Durability and Efficiency

In the pursuit of enhanced performance and longevity, the selection of superior materials plays a pivotal role. High-quality components are essential for ensuring optimal functionality in mechanical systems, reducing wear and tear, and maintaining efficiency over time. The right choice of substances can significantly impact overall operation and reliability, leading to improved outcomes.

Various materials are utilized in the construction of these systems, each offering distinct benefits. Below is a summary of key materials commonly employed to enhance durability and efficiency:

| Material Type | Properties | Applications |

|---|---|---|

| Stainless Steel | Corrosion-resistant, high tensile strength | Structural components, housings |

| Aluminum Alloys | Lightweight, good thermal conductivity | Frameworks, support structures |

| Composite Materials | High strength-to-weight ratio, resistant to fatigue | Internal components, protective covers |

| Rubber Compounds | Elasticity, excellent sealing capabilities | Seals, gaskets, and dampers |

Choosing the appropriate materials is crucial for enhancing both the longevity and performance of mechanical systems. The right combination not only improves efficiency but also minimizes maintenance needs, thereby ensuring a more sustainable operation.

Material Selection in Pump Construction

The choice of materials in the assembly of hydraulic devices plays a crucial role in ensuring efficiency, durability, and reliability. Various factors influence this decision, including the operating environment, pressure requirements, and fluid characteristics. Selecting appropriate materials is essential for optimal performance and longevity of the system.

Corrosion resistance is a primary consideration, particularly when dealing with aggressive fluids. Materials such as stainless steel and specialized alloys are often preferred for their ability to withstand harsh conditions without succumbing to degradation. Additionally, temperature stability is vital; components must maintain structural integrity under varying thermal conditions to prevent failures.

Another critical factor is weight considerations, as the overall mass can impact installation and operational efficiency. Lightweight composites or aluminum can be beneficial in certain applications, providing a balance between strength and reduced mass. Moreover, manufacturability also plays a significant role; materials must be easy to process and shape into the required components without compromising quality.

Finally, economic factors cannot be overlooked. While high-performance materials may offer superior functionality, their costs must align with project budgets. The ideal selection strikes a balance between performance and cost-effectiveness, ensuring the system meets its intended purpose without excessive expenditure.

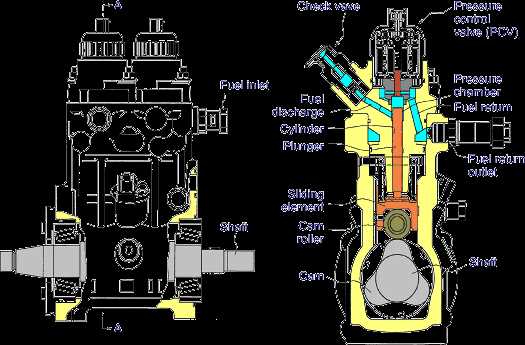

Visual Breakdown of Component Layout

This section provides an in-depth examination of the configuration of essential elements within a hydraulic mechanism. Understanding the arrangement and interaction of these components is crucial for effective maintenance and troubleshooting.

The layout typically consists of several key elements, each playing a vital role in the overall functionality. Here are the primary components to consider:

- Pressure Regulation Unit: Controls the pressure levels to ensure optimal performance.

- Fluid Inlet: Allows the intake of hydraulic fluid from the reservoir.

- High-Pressure Outlet: Facilitates the distribution of pressurized fluid to the system.

- Drive Mechanism: Provides the necessary motion to operate the assembly.

- Control Valves: Manage the flow direction and volume within the system.

Each of these components interacts seamlessly, contributing to the efficiency and reliability of the entire assembly. Proper understanding of their layout can greatly enhance repair and maintenance efforts.

To visualize the assembly, consider the following structure:

- The fluid enters through the inlet.

- It is then directed through the pressure regulation unit.

- Subsequently, the pressurized fluid is delivered through the outlet to the intended application.

- The drive mechanism ensures consistent operation.

- Control valves adjust the flow as necessary based on system demands.

By familiarizing oneself with this configuration, users can better appreciate the intricacies involved in the operation and maintenance of hydraulic systems.

Spatial Arrangement of Key Parts

The organization of essential components within a mechanical system is crucial for optimal performance and reliability. This arrangement ensures that each element functions effectively in conjunction with others, minimizing the risk of failure and enhancing operational efficiency. Understanding the layout of these integral sections is vital for both maintenance and troubleshooting tasks.

Component Layout Overview

In a well-designed assembly, the positioning of each section plays a significant role in facilitating fluid dynamics and mechanical interactions. The strategic placement of critical elements allows for efficient flow and minimizes wear and tear. Proper alignment contributes to the overall durability and functionality of the entire mechanism.

Importance of Spatial Configuration

The spatial configuration of components affects not only the operational efficiency but also the ease of access during maintenance procedures. A thoughtfully arranged setup can significantly reduce downtime, allowing for quicker repairs and adjustments. Consequently, this meticulous planning is essential for ensuring long-term reliability and performance.

Maintaining Consistent Fuel Pressure Output

Ensuring a stable delivery of fuel pressure is vital for the optimal performance of any internal combustion engine. Fluctuations in pressure can lead to subpar efficiency, increased emissions, and potential engine damage. This section focuses on methods and considerations for achieving and maintaining consistent fuel pressure within a system, emphasizing the importance of regular maintenance and component functionality.

Key Factors Affecting Fuel Pressure Stability

Multiple elements can influence the steadiness of fuel pressure, including component wear, temperature variations, and fuel quality. Regularly monitoring these factors can help in identifying potential issues before they escalate. Here are some critical aspects to consider:

| Factor | Impact on Pressure |

|---|---|

| Component Wear | Decreased efficiency and potential leaks, leading to pressure drops. |

| Temperature Variations | Can cause fuel expansion or contraction, affecting pressure readings. |

| Fuel Quality | Contaminated fuel can lead to blockages and inconsistent pressure. |

Maintenance Tips for Optimal Performance

To achieve reliable fuel pressure, routine maintenance is essential. Regular inspections and timely replacements of worn components can significantly enhance performance. Here are some recommended practices:

- Conduct periodic inspections of fuel lines and connections for leaks.

- Replace filters as per manufacturer guidelines to ensure clean fuel flow.

- Check and adjust the pressure regulator to maintain optimal settings.

- Monitor engine temperature and fuel characteristics regularly.