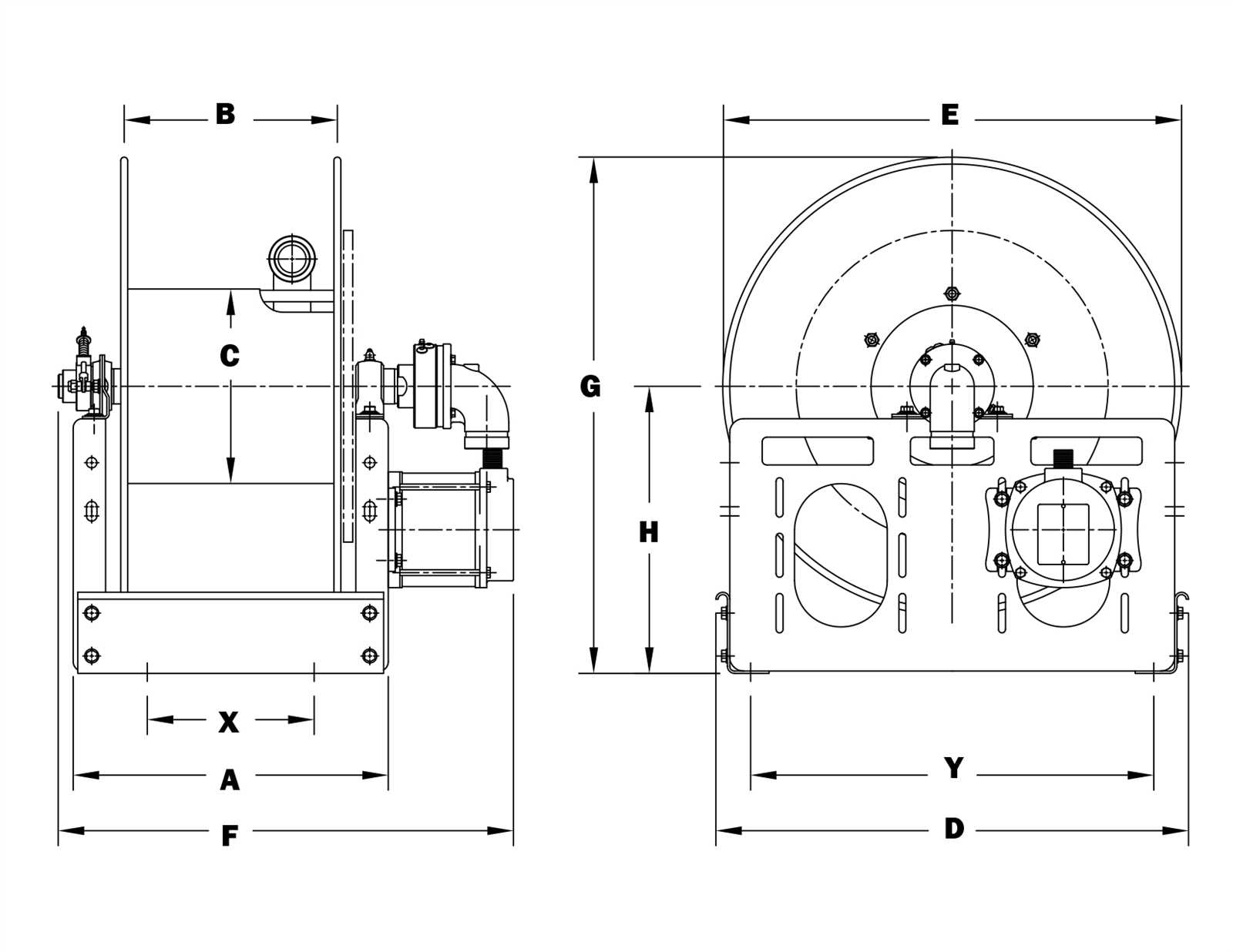

In today’s fast-paced world, having a reliable machine is essential for both personal and professional tasks. A thorough comprehension of the inner workings of your equipment can significantly enhance its functionality and lifespan. This section aims to provide a detailed overview of the various elements that contribute to the optimal performance of your device.

Identifying the Key Components is crucial for troubleshooting and maintenance. Each element plays a vital role in the overall efficiency, from the main circuitry to the auxiliary mechanisms. Gaining insight into how these parts interact can empower users to make informed decisions regarding repairs and upgrades.

Moreover, understanding the layout and connections of these crucial elements can facilitate a smoother user experience. Whether you’re a seasoned technician or a curious user, familiarizing yourself with the intricate details of your machine will undoubtedly contribute to a better understanding of its capabilities and limitations.

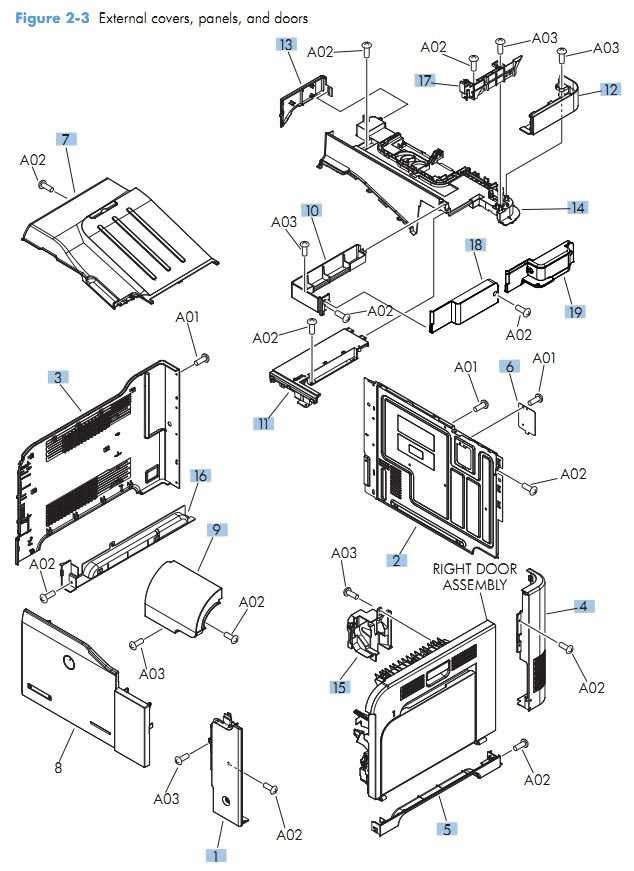

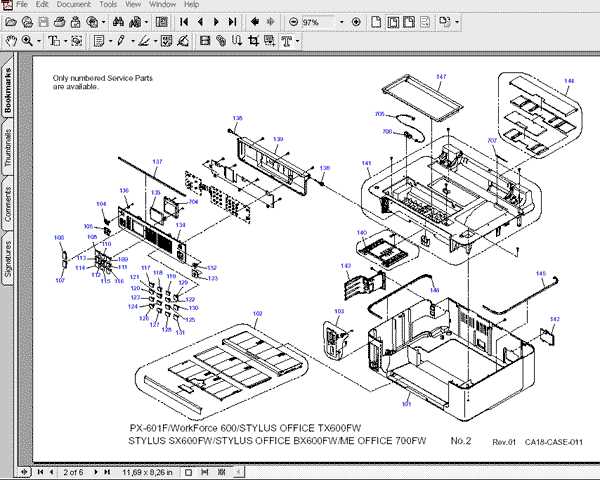

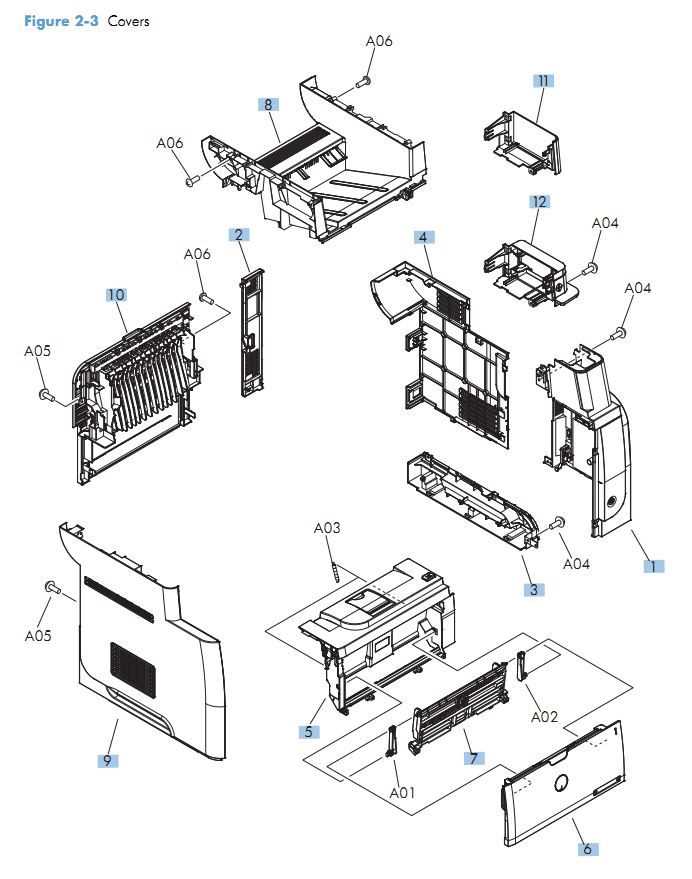

Understanding the HP 7520 Structure

The design of this multifunctional printing device reflects a meticulous arrangement of various components, each serving a specific role in ensuring efficient operation. A comprehensive understanding of this configuration can enhance both maintenance and troubleshooting processes.

Main Components

- Printing Mechanism: Central to functionality, this section encompasses the print head and ink delivery system.

- Control System: This unit manages all operations, allowing users to interact with the machine through a user-friendly interface.

- Paper Handling: This includes trays, rollers, and feeders designed to manage various paper sizes and types.

- Power Supply: Essential for the operation of all electronic components, ensuring stable energy delivery.

Structural Features

- Modular Design: Each segment can be independently serviced or replaced, simplifying repairs.

- Compact Layout: Optimized for space efficiency, allowing the device to fit seamlessly in various environments.

- Durability: Constructed with high-quality materials to withstand frequent use while maintaining performance.

Key Components of HP 7520 Printer

The effectiveness of a printing device relies on its fundamental elements, each contributing to its overall performance and functionality. Understanding these critical components can help users optimize their printing experience and troubleshoot issues that may arise during operation.

Printing Mechanism

At the heart of any printing device is the printing mechanism, which plays a vital role in transferring ink onto the paper. This mechanism includes the printhead, which precisely applies ink to create sharp images and text. Regular maintenance of this component ensures consistent output quality and longevity.

Paper Handling System

The paper handling system is essential for managing the loading, feeding, and ejection of media. It consists of input trays, output trays, and rollers that work together to ensure smooth operation. Proper configuration and management of this system are crucial for preventing jams and ensuring that prints are delivered without errors.

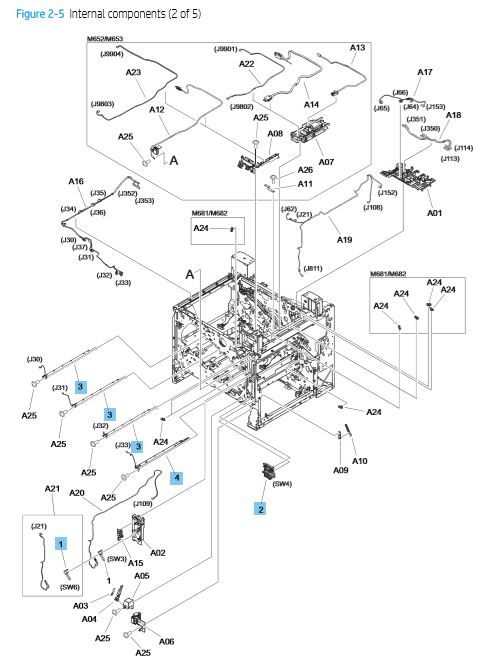

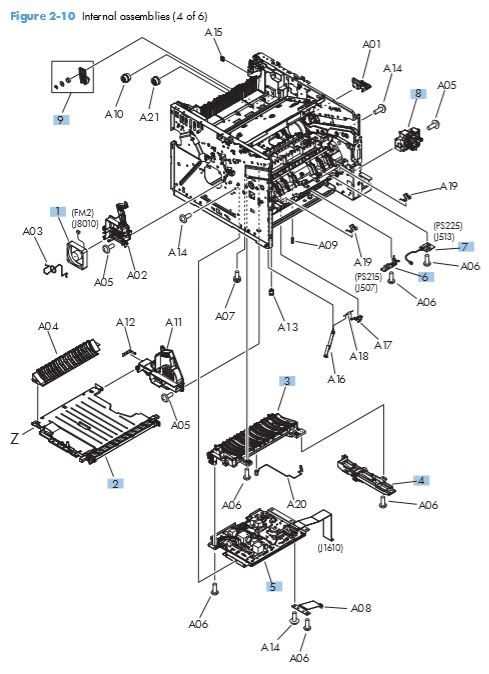

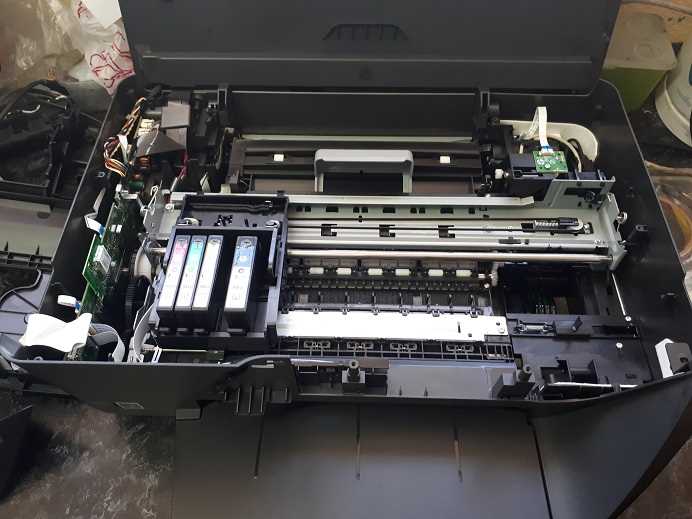

Exploring the Internal Layout

This section delves into the intricate design and organization of the internal components of the multifunction device. Understanding the layout is essential for comprehending how each element contributes to overall functionality and efficiency.

Within the device, several key components work in harmony to ensure optimal performance. These elements can be categorized into distinct sections:

- Print Mechanism: The core assembly responsible for producing high-quality prints. This section includes the print head, cartridges, and the associated drive systems.

- Paper Handling: This area encompasses all parts involved in feeding and managing media, including input trays, rollers, and output trays.

- Control System: The electronic components that manage operations, including the main circuit board, display panel, and control buttons.

- Power Supply: This crucial component converts electrical energy to power the device, ensuring all systems operate smoothly.

- Connectivity Modules: This section facilitates communication with other devices, incorporating Wi-Fi and USB interfaces.

Each of these sections plays a vital role in the device’s operation. Understanding their functions and interconnections helps in diagnosing issues and performing maintenance effectively.

In conclusion, the internal layout reveals the complexity and precision involved in designing such an advanced piece of technology, highlighting the importance of each component in delivering reliable performance.

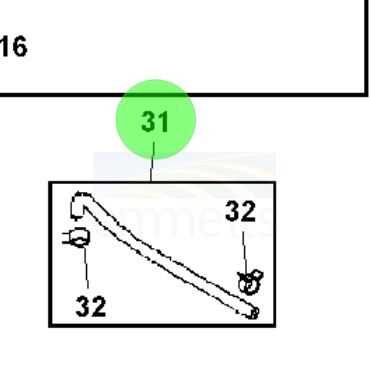

Common Replacement Parts Overview

In understanding the essential components needed for maintaining your HP 7520, it’s crucial to identify the key elements that often require replacement over time. These components play pivotal roles in ensuring the printer’s functionality and longevity, addressing various operational needs without delving into intricate specifics.

- Primary components for regular upkeep, catering to foundational aspects of printer operation.

- Necessary items ensuring sustained performance and operational consistency.

- Parts integral to the smooth operation and durability of the printing device.

- Essential elements that contribute significantly to the printer’s overall functionality.

By recognizing these critical parts and their roles within the printer’s ecosystem, you can effectively manage maintenance and optimize performance over the printer’s lifecycle.

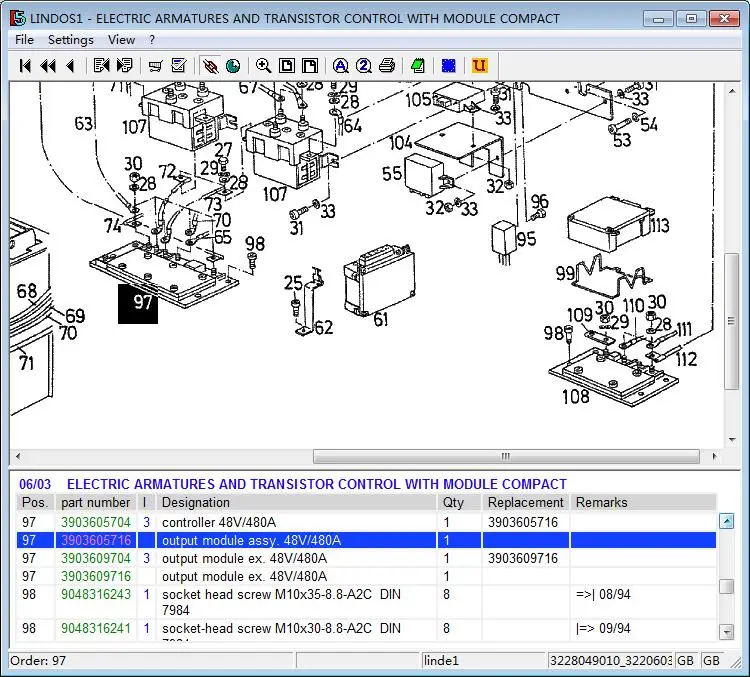

Identifying Major Assemblies

Understanding the primary components of a printing device is crucial for effective maintenance and troubleshooting. These assemblies work together to ensure the device operates smoothly, and recognizing their roles can aid users in diagnosing issues or performing upgrades. Each assembly serves a unique function, contributing to the overall performance of the machine.

One key assembly is the print head, responsible for transferring ink onto the medium. This component is essential for achieving high-quality output and can affect print speed and clarity. Another significant part is the paper feed mechanism, which controls the movement of media through the device. It ensures accurate alignment and prevents jams during operation.

Additionally, the control board acts as the brain of the machine, coordinating the actions of various components and managing user commands. Recognizing these major assemblies allows users to better understand their device’s functionality and enhances their ability to troubleshoot effectively.

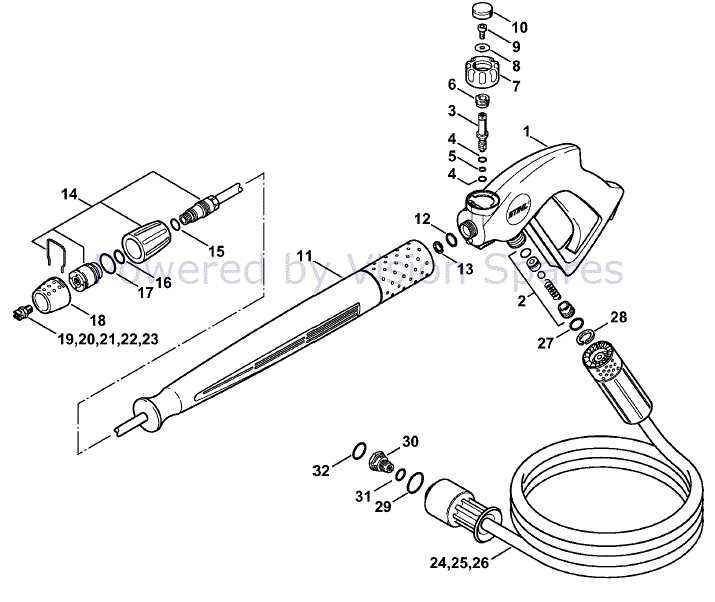

Troubleshooting with Parts Diagram

Effective resolution of issues in complex devices often hinges on understanding their internal structure. A visual reference showcasing the components can significantly aid in identifying malfunctioning elements, making it easier to conduct repairs or replacements. By leveraging such a reference, users can streamline the troubleshooting process and enhance their ability to maintain optimal device performance.

Identifying Problematic Components

When encountering operational difficulties, the first step is to locate the specific section of the device that may be causing the problem. Utilizing a visual guide allows users to pinpoint exact locations of each element, facilitating a more efficient assessment. Recognizing symptoms associated with particular components can also expedite the diagnosis, ensuring that interventions target the root cause rather than merely addressing symptoms.

Enhancing Repair Efficiency

Once the issue has been identified, understanding how each element interacts within the device can inform repair strategies. A comprehensive visual reference not only clarifies the arrangement of parts but also highlights potential vulnerabilities. By following the connections and dependencies outlined in such a guide, users can execute repairs with greater confidence and accuracy, ultimately restoring functionality more effectively.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your equipment, regular maintenance is essential. Implementing a routine can help prevent common issues and keep your device running smoothly. Here are some effective practices to consider:

- Regular Cleaning: Dust and debris can accumulate inside and outside the unit, affecting its functionality. Use a soft, lint-free cloth to wipe surfaces and a gentle vacuum to remove particles from vents.

- Check Connections: Ensure all cables and connectors are secure and free from wear. Loose connections can lead to performance issues.

- Software Updates: Keeping your device’s software up to date can enhance performance and fix bugs. Regularly check for updates from the manufacturer.

- Proper Usage: Follow the manufacturer’s guidelines for usage to avoid overworking the machine. Adhering to recommended settings can prevent strain and damage.

- Environment Considerations: Place the equipment in a well-ventilated area, away from direct sunlight and extreme temperatures, to prevent overheating and damage.

By following these maintenance tips, you can enhance the reliability of your device and ensure it serves you well for years to come.

Where to Find Replacement Parts

Finding suitable components for your printing device can significantly enhance its performance and longevity. This section outlines various reliable sources where you can acquire essential elements, ensuring your equipment remains in optimal condition.

Authorized Retailers

One of the most dependable options for sourcing components is through authorized retailers. They typically provide high-quality replacements that meet the manufacturer’s specifications. Consider the following:

- Check the official website of the manufacturer for a list of certified retailers.

- Visit local electronics or office supply stores that specialize in printing devices.

- Inquire about warranties or guarantees on the items purchased.

Online Marketplaces

Online platforms offer a vast selection of components, often at competitive prices. When shopping online, keep these tips in mind:

- Use reputable websites, such as Amazon or eBay, to find a variety of options.

- Read customer reviews to assess the quality and reliability of the products.

- Look for sellers that offer return policies for added security.

By exploring these avenues, you can ensure that you find the right elements for your device, enhancing its functionality and efficiency.

Comparative Analysis of Printer Models

This section presents a comprehensive examination of various printer models, highlighting their functionalities, features, and usability. By comparing distinct aspects, users can make informed decisions based on their specific needs and preferences.

Key Features to Consider

- Print Quality: Evaluate the clarity and precision of print outputs across different models.

- Speed: Analyze the pages per minute (PPM) rate to determine efficiency during high-volume printing tasks.

- Connectivity Options: Consider the available wireless and wired connections, including USB, Wi-Fi, and Ethernet capabilities.

- Cost of Consumables: Assess the price and lifespan of ink or toner cartridges, as well as paper compatibility.

- User Interface: Review the ease of navigation and accessibility of settings through control panels or mobile applications.

Model Comparisons

-

Model A:

- Excellent print quality with vibrant colors.

- Moderate speed, suitable for home office use.

- Supports wireless printing and mobile applications.

-

Model B:

- High-speed printing ideal for small businesses.

- Cost-effective in terms of ink consumption.

- Limited connectivity options; primarily USB and Ethernet.

-

Model C:

- User-friendly interface with touchscreen controls.

- Offers advanced scanning and copying features.

- Higher upfront cost but lower long-term maintenance expenses.

By analyzing these factors, users can select a model that aligns with their operational demands and budget, ensuring optimal performance in their printing tasks.

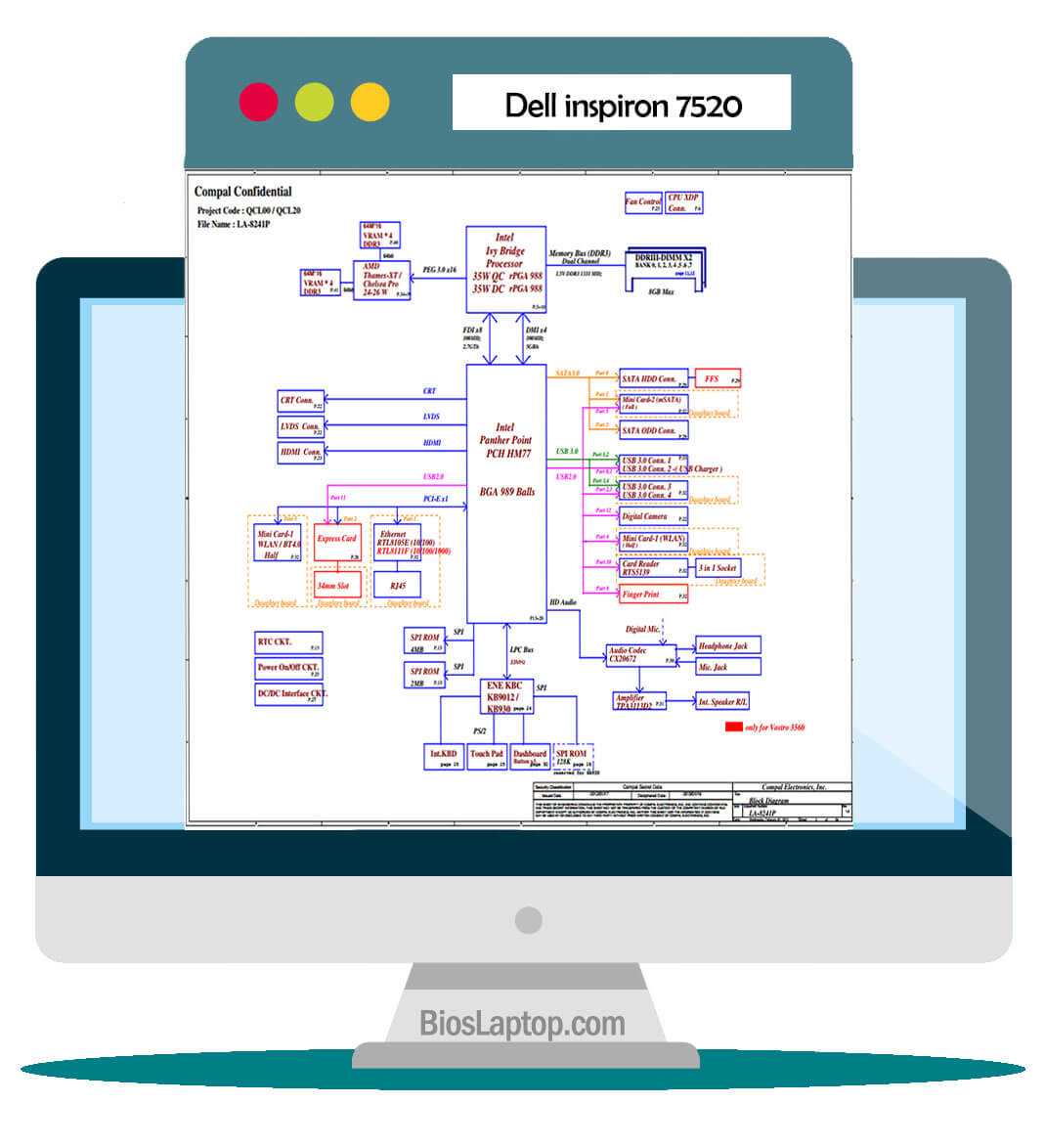

Upgrading Components for Better Performance

Enhancing the functionality of your device often involves the strategic replacement of its internal elements. By focusing on key components, users can significantly boost efficiency, speed, and overall performance. This process can help to eliminate bottlenecks and ensure a smoother operation, making the device more capable of handling demanding tasks.

One effective approach is to upgrade the memory modules. Increasing the RAM allows for more applications to run simultaneously, enhancing multitasking capabilities. This is particularly beneficial for users who frequently work with resource-intensive programs.

Another crucial aspect to consider is the storage solution. Replacing traditional hard drives with solid-state drives (SSDs) can lead to faster data access and improved boot times. The speed increase not only enhances user experience but also contributes to the longevity of the device by reducing mechanical wear.

Additionally, upgrading the power supply unit can support the new components, ensuring that they operate optimally. A more robust power supply can accommodate additional upgrades in the future, providing flexibility for further enhancements.

Finally, keeping the firmware up to date is essential. Regular updates can optimize the performance of both existing and upgraded components, ensuring compatibility and stability. By focusing on these areas, users can effectively elevate their device’s capabilities, leading to a more productive and enjoyable experience.

Utilizing the Diagram for Repairs

When addressing issues within a specific model, a visual representation of its components can serve as an invaluable tool. This graphical layout aids in identifying the location and function of each element, streamlining the repair process and enhancing efficiency.

By examining the illustration, technicians can quickly pinpoint problematic areas and assess whether certain components require maintenance or replacement. This method not only saves time but also minimizes the risk of overlooking crucial elements that might contribute to malfunctioning.

Furthermore, the visual guide fosters a deeper understanding of the overall system, allowing for more informed decision-making during repairs. Knowing how each piece interacts with others empowers individuals to approach repairs with greater confidence and accuracy.

In conclusion, leveraging such a resource can significantly improve the repair experience, transforming a potentially daunting task into a more manageable one.