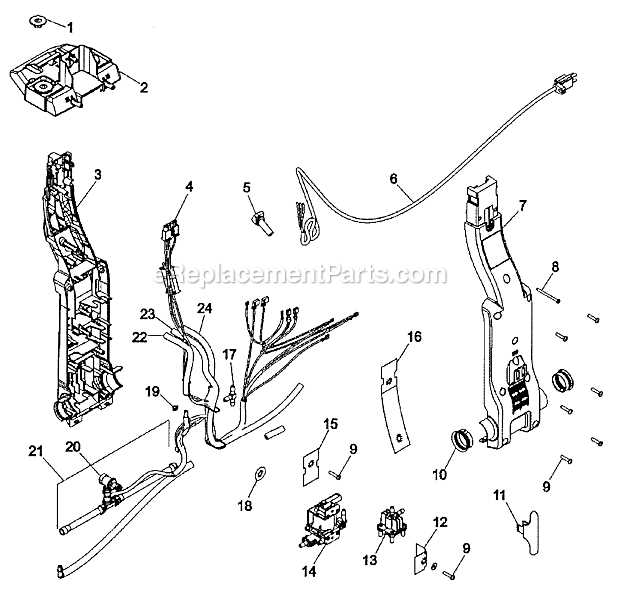

The internal mechanisms of a cleaning device play a crucial role in ensuring its effective operation. Each element within the machine is designed to perform a specific function, contributing to the overall cleaning process. By examining the structure of these elements, users can better understand how their equipment works and identify any potential issues that may arise during use.

Learning about the layout and structure of the device’s key mechanisms helps in maintaining and troubleshooting the equipment. Understanding the placement and connection of various components can provide valuable insights into enhancing the device’s performance and prolonging its lifespan. This knowledge also aids in timely maintenance, ensuring the device continues to function optimally for years to come.

Whether you are dealing with filters, nozzles, or internal connections, knowing the structure and functionality of these components is essential. This allows for smoother operation and easier replacement of worn-out or malfunctioning elements, ensuring your cleaning tas

Understanding the Internal Components of Hoover Max Extract

The efficient operation of this cleaning device relies on the intricate interaction of various internal mechanisms. Each component plays a crucial role in ensuring thorough cleaning performance, contributing to the effective handling of different surfaces and types of dirt. These elements work together seamlessly to provide a powerful and reliable cleaning experience.

Water Distribution System: A key mechanism that ensures proper liquid flow throughout the cleaning cycle. This system manages both the distribution of water and the cleaning solution, enabling efficient cleaning and rinsing functions.

Suction Mechanism: Essential for removing moisture and debris from surfaces, this feature is designed to maximize the extraction of liquids, leaving surfaces cleaner and drier. It is crucial for achieving optimal drying times and preventing excess water from being left behind.

Brush Assembly: A pivotal part that agitates the surface

Key Features of Hoover Max Extract Machine

The cleaning equipment offers advanced technology for deep cleaning and restoring various types of surfaces. It is designed to efficiently tackle both routine and more intensive tasks, providing a solution that helps maintain hygiene and freshness. With its powerful functions and thoughtful design, the system is well-suited for users looking for both effectiveness and ease of use.

Powerful Performance: Equipped with a robust system that delivers a thorough clean, this machine ensures that even stubborn dirt and stains are lifted. The enhanced performance contributes to its ability to handle demanding cleaning scenarios with ease.

Versatile Application: This machine is capable of cleaning a wide range of surfaces, making it suitable for carpets, upholstery, and hard floors. The flexibility

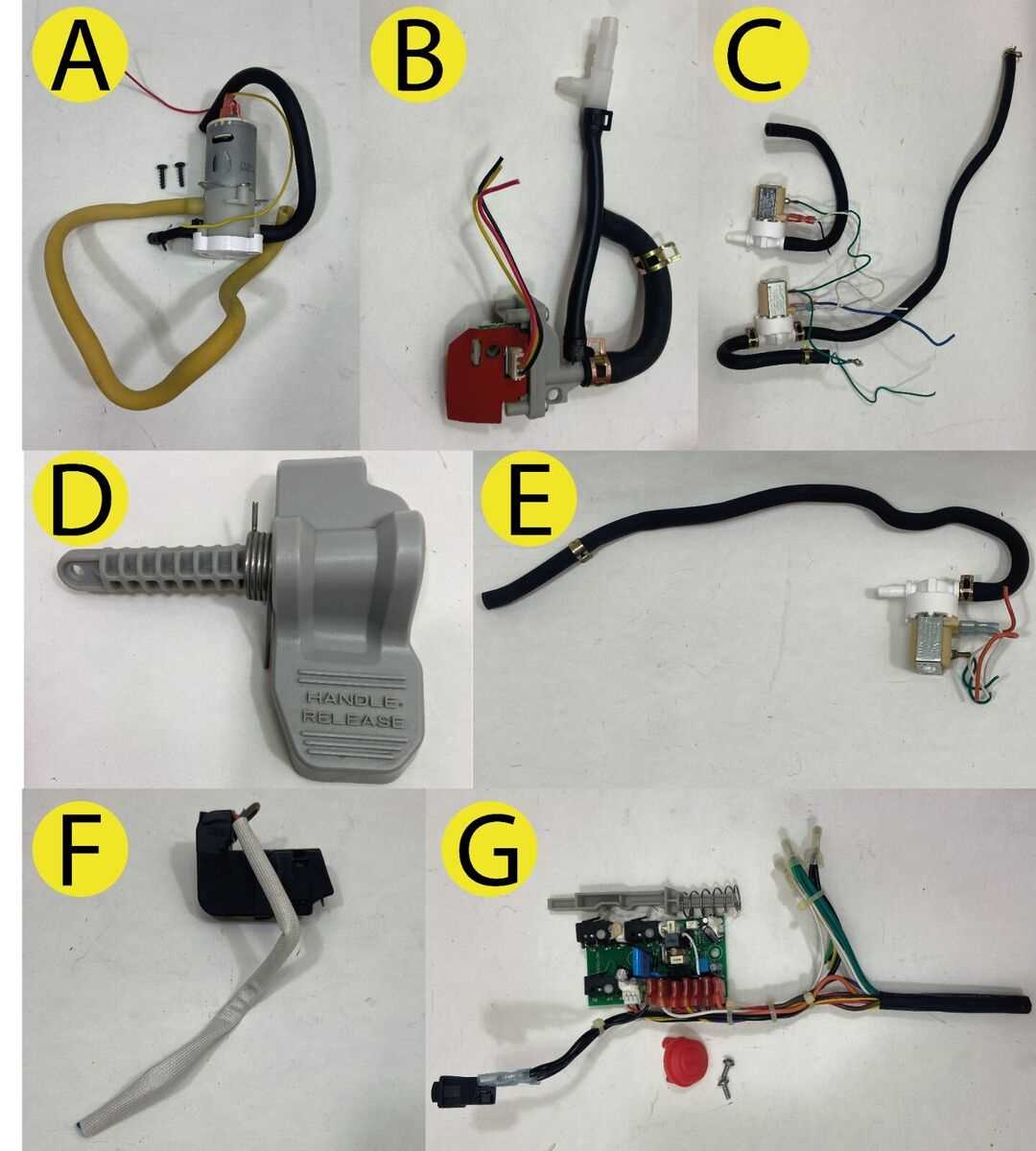

Breakdown of the Water Pump Assembly

The water pump assembly plays a crucial role in the overall functioning of the cleaning system by controlling the flow and pressure of liquids. Understanding the structure of this component is essential for maintaining efficient performance and ensuring smooth operation. This section will guide you through the key elements that make up the assembly, helping you identify its core functions and mechanisms.

Main Components of the Water Pump

- Pump Housing: The outer shell that contains and protects the internal mechanisms of the system.

- Impeller: A rotating part responsible for moving the liquid through the system, generating the necessary pressure.

- Inlet and Outlet Valves: These regulate the entry and exit points for the liquid, ensuring controlled flow during operation.

Functions of the Key Elements

How the Suction Mechanism Operates

The suction system is a vital component in efficient cleaning devices, ensuring that dirt, water, and debris are effectively drawn into the collection chamber. This process involves a series of interconnected elements that work in harmony to create the necessary force for pulling substances from various surfaces.

Main Components Involved

- Airflow generator

- Intake pathway

- Filtration system

- Collection tank

These parts collaborate to produce the required airflow, capturing unwanted materials and directing them to a designated container.

Operational Process

Exploring the Brush Roll Configuration

Understanding how the brush roll is structured and operates is essential for maintaining efficient cleaning performance. The rotating mechanism is responsible for agitating the surface and loosening debris, ensuring thorough results during each cleaning cycle. To delve deeper into this component, it’s crucial to examine its layout and how its elements interact with one another.

Main Components and Their Role

- Bristles: The bristles are the most visible part and are designed to lift dirt from various surfaces, ensuring a deep clean.

- Roller Shaft: This central piece allows the bristles to rotate smoothly, providing consistent contact with the floor.

- End Bearings: These help to reduce friction during rotation, extending the lifespan of the system.

Identifying the Role of the Cleaning Solution System

The cleaning solution system plays a pivotal role in maintaining optimal performance in various cleaning machines. This component is crucial for delivering a mixture of water and cleaning agents to the surface being treated, ensuring effective dirt and stain removal. Understanding how this system functions is essential for achieving the best results and prolonging the life of the equipment.

Functionality of the Solution Delivery Mechanism

At the heart of this system lies the mechanism responsible for distributing the cleaning mixture. It operates by pumping the solution through a series of tubes and nozzles, applying it evenly across the targeted area. This functionality is vital for loosening embedded dirt and grime, allowing for a more thorough cleaning process.

Importance of Proper Maintenance

Maintaining the cleaning solution system is essential for ensuring its efficiency and longevity. Regular checks for clogs and leaks can prevent performance issues and extend the lifespan of the machine. Additionally, using the appropriate cleaning solutions will help to maintain the integrity of the system, ultimately enhancing the overall cleaning effectiveness.

The Function of the Motor and Belts

The core components responsible for driving the cleaning apparatus efficiently are the motor and belts. Together, they work in harmony to facilitate the machine’s operation, ensuring optimal performance during various cleaning tasks. Understanding their roles can enhance the user’s experience and maintain the device’s longevity.

Role of the Motor

The motor serves as the powerhouse of the equipment, converting electrical energy into mechanical energy. This transformation allows it to create the necessary force to drive the brushes and suction mechanism. A well-functioning motor is crucial for achieving the desired cleaning results, as it determines the effectiveness of dirt and debris removal from various surfaces.

Importance of Belts

Belts play a vital role in connecting the motor to other functional elements, facilitating the transfer of power. They ensure that the rotational energy produced by the motor is efficiently directed towards the brushes and other components. Proper maintenance of these belts is essential, as worn or damaged belts can hinder performance, leading to reduced efficiency and potential mechanical failure.

Common Issues with Hoover Max Extract Parts

When utilizing advanced cleaning machines, users may encounter various challenges related to their components. Recognizing these common problems can aid in timely maintenance and improve the overall efficiency of the device. Familiarity with the typical issues allows for quick identification and resolution, enhancing the longevity of the equipment.

Frequent Mechanical Failures

Mechanical components often experience wear and tear due to regular usage. This can lead to malfunctions, such as diminished suction power or leaks. Regular inspections can help identify worn-out elements that may require replacement. Addressing these issues promptly ensures that the cleaning process remains effective and prevents further damage.

Clogging and Blockages

Another prevalent issue is clogging, which can occur in hoses and filters. Accumulated debris and dirt can hinder performance, leading to overheating and reduced functionality. To avoid such blockages, it is essential to clean these areas routinely and check for obstructions. Proper maintenance practices not only enhance performance but also prolong the lifespan of the equipment.

How to Replace Hoover Max Extract Filters

Maintaining the efficiency of your cleaning appliance involves periodic replacement of its filtration components. Over time, these filters can become clogged with debris, which may reduce performance. This guide will walk you through the straightforward process of replacing the filtration elements to ensure optimal operation.

Before you begin, gather the necessary tools and replacement filters compatible with your device. It is recommended to consult the user manual for specific details regarding filter types and compatibility. Follow the steps below to successfully replace the filters:

| Step | Description |

|---|---|

| 1 | Unplug the appliance from the power source to ensure safety during the replacement process. |

| 2 | Locate the filter compartment. This is usually found at the rear or bottom of the unit. |

| 3 | Open the compartment cover by pressing the release button or unscrewing it, depending on the model. |

| 4 | Carefully remove the old filters. Be cautious of any accumulated dirt and debris. |

| 5 | Take the new filters and insert them into the compartment, ensuring they fit securely. |

| 6 | Close the compartment cover, making sure it is locked in place. |

| 7 | Plug the device back in and run a quick test to ensure it operates smoothly. |

Regularly checking and replacing these essential components will help maintain your machine’s effectiveness, prolong its lifespan, and enhance your cleaning experience.

Maintenance Tips for Prolonging Parts Lifespan

Ensuring the longevity of your cleaning equipment is crucial for maintaining its efficiency and performance. By following specific care routines and practices, you can significantly extend the life of various components and minimize the need for replacements. This section provides essential suggestions that focus on preserving functionality and durability.

Regular Cleaning: Consistently removing dirt, debris, and residues from your device will prevent buildup that can cause wear and tear. Utilize appropriate cleaning solutions and tools to maintain optimal performance.

Proper Storage: Store your equipment in a dry, cool area when not in use. Avoid exposing it to extreme temperatures or humidity, which can lead to deterioration of materials and components.

Routine Inspections: Regularly check for any signs of damage or wear. Identifying issues early can help prevent further complications and extend the lifespan of essential elements.

Follow Manufacturer Guidelines: Adhering to the care instructions provided by the manufacturer ensures that you are using the device correctly, which can significantly impact its longevity.

Use Quality Products: When replacing any components, choose high-quality alternatives that meet or exceed original specifications. This can enhance overall performance and durability.

Avoid Overuse: Do not push your equipment beyond its intended limits. Following recommended usage practices helps to prevent excessive strain on parts, thereby prolonging their lifespan.

By implementing these strategies, you can maximize the efficiency and durability of your cleaning apparatus, ensuring it remains a reliable tool for your maintenance needs.