The intricate world of fluid-driven machinery plays a crucial role in various applications, from industrial settings to mobile equipment. These systems harness the power of pressurized liquid to generate motion and perform essential tasks. Understanding the various elements that comprise these systems is vital for effective maintenance and operation.

Within these assemblies, each component serves a specific function, contributing to the overall efficiency and performance of the system. By examining the relationships between these elements, one can gain insights into how they work together seamlessly to deliver reliable performance under demanding conditions.

Familiarity with the essential building blocks of these mechanisms allows operators and technicians to troubleshoot issues and optimize their functionality. As technology continues to advance, knowledge of these components becomes increasingly important for ensuring that equipment operates at peak efficiency.

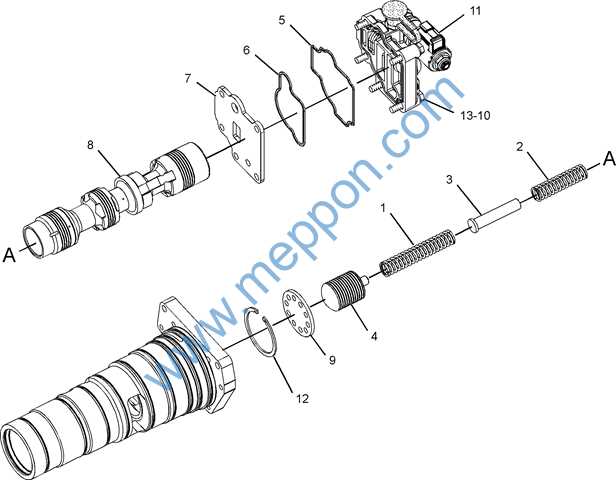

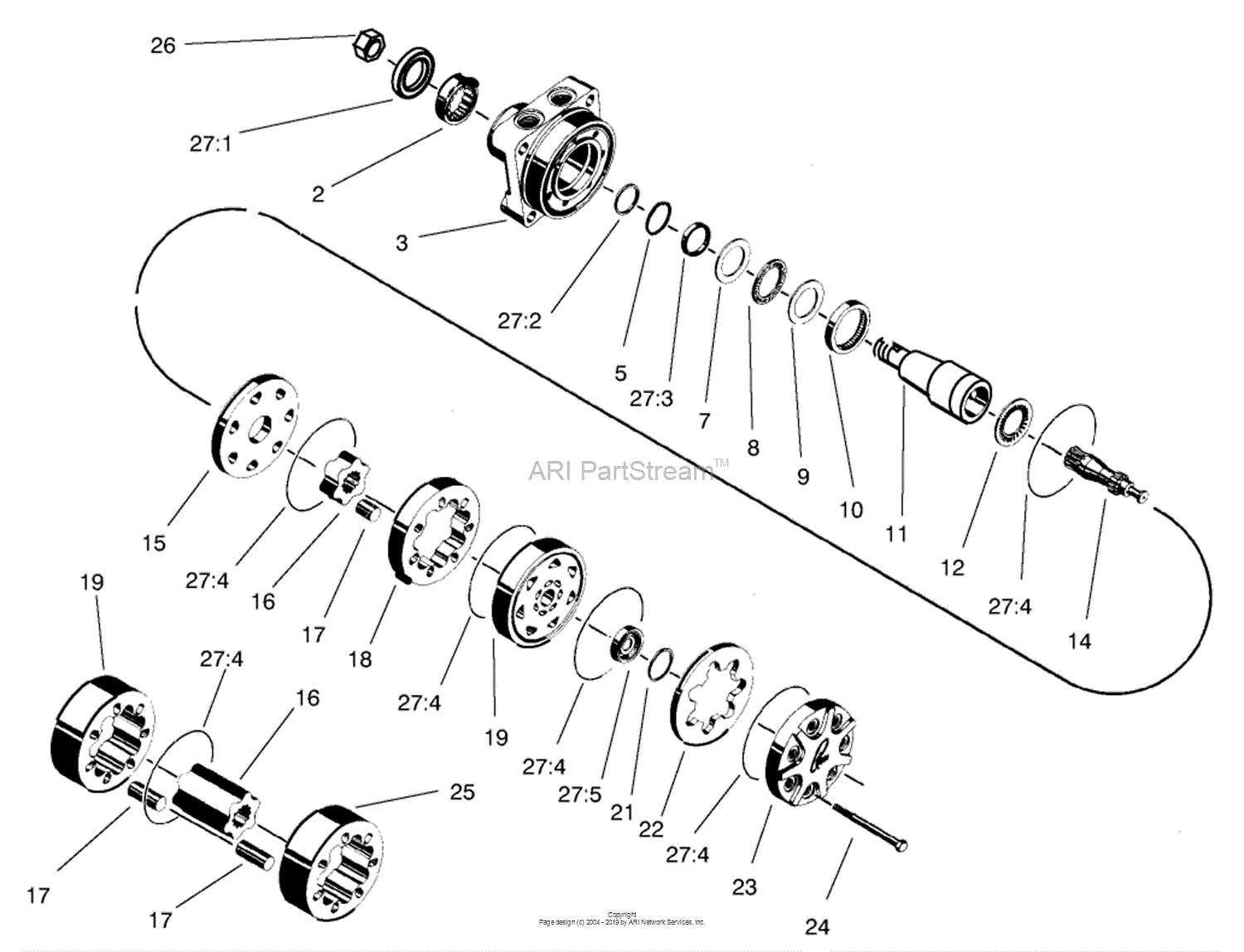

This section provides an in-depth examination of the components involved in a fluid-driven system, highlighting their individual functions and significance. Understanding these elements is essential for grasping the overall operation and efficiency of the mechanism.

| Component | Description | Function |

|---|---|---|

| Housing | The outer shell that encases all internal elements. | Provides structural integrity and protection against external factors. |

| Piston | A cylindrical piece that moves within the chamber. | Translates hydraulic pressure into mechanical work. |

| Valve | A mechanism that regulates fluid flow. | Controls the direction and pressure of the fluid within the system. |

| Seal | A material that prevents fluid leakage. | Ensures a tight fit between moving parts to maintain pressure. |

| Connecting Rod | A link between the piston and the crankshaft. | Transfers motion from the piston to the output shaft. |

How Hydraulic Motors Generate Motion

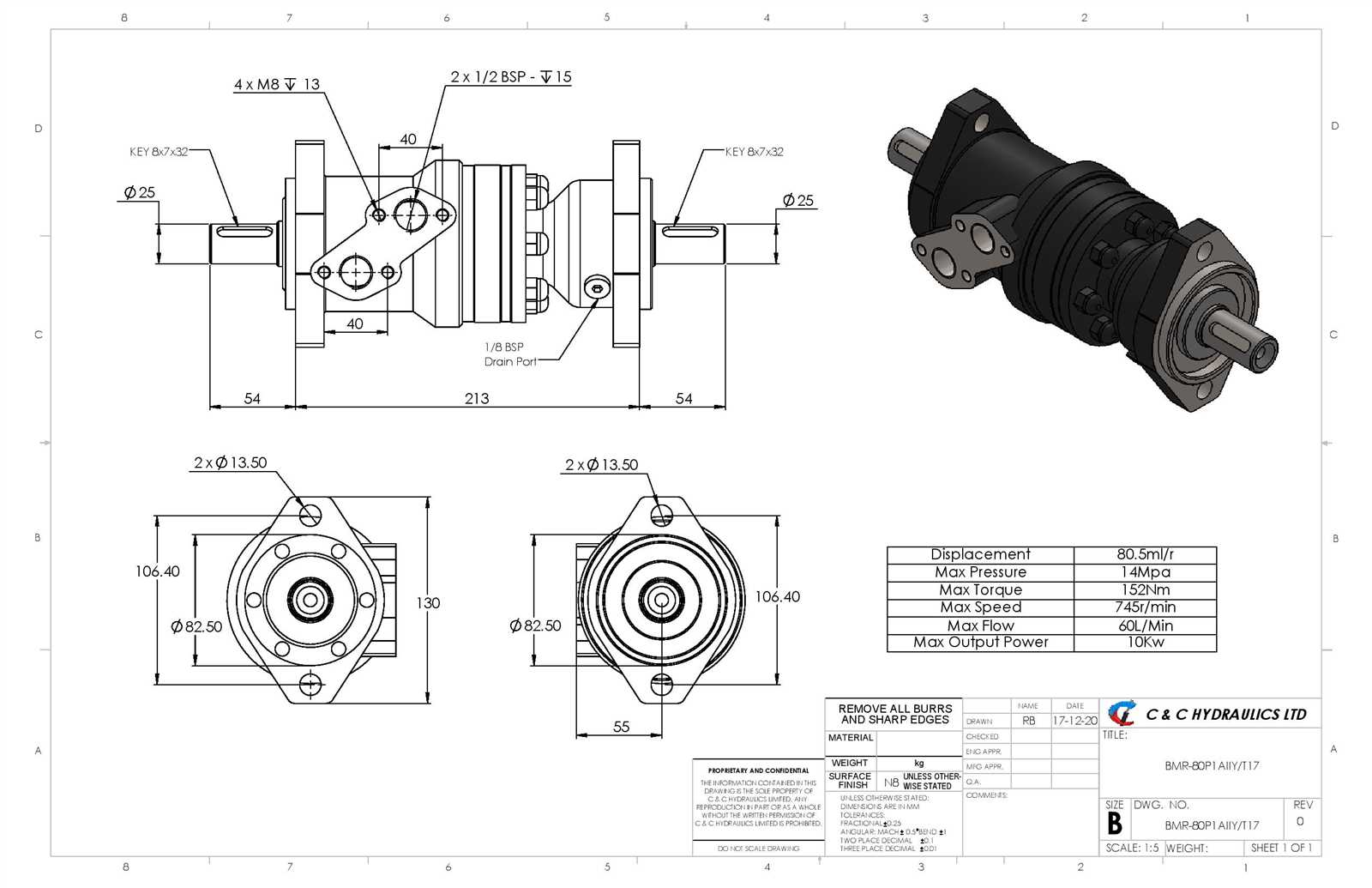

The conversion of fluid pressure into mechanical energy is a fundamental principle that drives many industrial applications. These devices utilize the movement of pressurized liquid to create a rotational force. By harnessing the power of fluid dynamics, they efficiently transform hydraulic energy into motion, enabling various machinery and equipment to operate smoothly.

The operation relies on the interaction between pressurized fluid and internal components. As the liquid enters the system, it pushes against specially designed surfaces, causing them to rotate. This rotational action generates kinetic energy, which can then be transferred to perform work. The design of these mechanisms allows for precise control over speed and torque, making them suitable for a wide range of tasks.

Common Applications of Hydraulic Motors

These powerful devices are essential in numerous fields, driving machinery and equipment to achieve various tasks efficiently. Their versatility allows them to operate in diverse environments, adapting to the specific needs of different applications.

One prevalent use is in construction machinery, where they provide the force necessary to operate heavy equipment like excavators and loaders. These systems enable precise control and enhance productivity on job sites.

Additionally, they play a crucial role in agricultural equipment, powering tractors and harvesters to perform demanding tasks. This ensures that farmers can cultivate and harvest crops effectively, contributing to improved yields and efficiency in food production.

Another significant area is in manufacturing processes, where these devices are utilized to drive conveyors and presses. This application enhances the automation of production lines, resulting in increased efficiency and reduced labor costs.

Lastly, they are found in various marine applications, assisting in the operation of winches and other deck machinery. Their reliability in challenging conditions makes them ideal for use in boats and ships, ensuring safe and efficient operations at sea.

Maintenance Tips for Hydraulic Motors

Ensuring the longevity and efficiency of these systems requires regular upkeep and attention. Proper maintenance not only prevents unexpected failures but also optimizes performance, saving time and resources in the long run. Here are some essential practices to follow for effective care.

Regular Inspections

Routine checks are vital for identifying potential issues before they escalate. Consider the following:

- Inspect for leaks: Look for any signs of fluid leakage around connections and seals.

- Monitor noise levels: Unusual sounds can indicate wear or damage that needs addressing.

- Check for overheating: Ensure that the operating temperature remains within the recommended range.

Fluid Quality Management

The fluid used in these systems plays a crucial role in performance. Follow these guidelines:

- Regularly change the fluid according to manufacturer recommendations.

- Use the appropriate type of fluid specified for your system.

- Perform periodic filtration to remove contaminants and debris.

Diagnosing Hydraulic Motor Issues

Identifying problems in fluid-driven machinery is crucial for maintaining operational efficiency. Understanding the common symptoms and their causes can help prevent costly repairs and downtime. This section will explore the key indicators of malfunctions and provide guidance on addressing them effectively.

Common Symptoms

- Unusual noises during operation, such as grinding or whining sounds.

- Decreased power or efficiency, resulting in slower performance.

- Leaks from seals or connections, leading to fluid loss.

- Increased temperature, which can indicate overheating or excessive friction.

Diagnostic Steps

- Inspect the system for any visible leaks or damage.

- Check fluid levels and quality; replace if contaminated or low.

- Listen for irregular sounds and note their frequency and intensity.

- Monitor operating temperatures and compare them to normal ranges.

- Conduct a pressure test to ensure the system is within operational specifications.

Efficiency Factors in Fluid Power Systems

Understanding the various elements that contribute to the effectiveness of fluid power systems is essential for optimizing their performance. Several key factors influence how well these systems convert energy into mechanical work, impacting overall productivity and energy consumption.

Design and Material Quality

The construction and materials used in the assembly play a crucial role in determining system efficiency. High-quality components reduce friction and wear, enhancing the overall energy transfer. Utilizing advanced materials can also withstand higher pressures, leading to improved performance under demanding conditions.

Operating Conditions and Maintenance

Maintaining optimal working conditions is vital for ensuring maximum efficiency. Factors such as temperature, pressure, and fluid cleanliness directly affect the functionality of the system. Regular upkeep and timely replacements of worn components are essential to prevent losses and maintain reliable operation.

Moreover, adjustments in control mechanisms can help fine-tune the energy output, ensuring that the system operates within its optimal range. Implementing best practices in operation can significantly enhance performance and extend the lifespan of the equipment.

Innovations in Hydraulic Motor Design

The evolution of fluid-driven machinery has ushered in remarkable advancements that enhance performance and efficiency. Engineers continuously explore novel approaches to optimize functionality, minimize energy loss, and improve reliability. This section highlights some of the most significant developments in the field, focusing on cutting-edge technologies and design enhancements.

Recent innovations emphasize the importance of materials and manufacturing techniques. By employing lightweight yet robust composites, designers can create units that are both powerful and compact. Additionally, the integration of smart technologies allows for real-time monitoring and adjustments, further enhancing overall system effectiveness.

| Innovation | Description |

|---|---|

| Smart Sensors | Implementation of real-time monitoring systems that provide data on performance and potential issues. |

| Advanced Materials | Utilization of high-strength composites that reduce weight while maintaining durability. |

| Variable Displacement | Technology allowing for adjustable flow rates, optimizing energy consumption. |

| Modular Designs | Components that can be easily customized or replaced to suit specific applications. |

Future Trends in Hydraulic Technology

The evolution of fluid-driven systems is steering towards innovative solutions that enhance efficiency and sustainability. As industries seek to optimize their operations, the integration of smart technologies and advanced materials is becoming increasingly prominent. This shift not only aims to improve performance but also addresses environmental concerns, paving the way for a more sustainable future.

Smart Integration

The emergence of intelligent systems is transforming how fluid-powered equipment is monitored and controlled. The incorporation of sensors and IoT technology allows for real-time data collection and analysis, facilitating predictive maintenance and minimizing downtime. This interconnectedness enhances operational efficiency and empowers users to make informed decisions.

Advanced Materials

Innovation in material science is leading to the development of lighter, stronger, and more durable components. These advancements contribute to reduced energy consumption and increased longevity of systems, ensuring that they meet the demands of modern applications. As industries continue to evolve, the focus on sustainable and high-performance materials will play a crucial role in shaping the future landscape.