Engine systems designed for various outdoor power equipment are known for their reliability and efficiency. These systems incorporate advanced technologies that ensure smooth operation, ease of maintenance, and long-lasting performance in different environments. The combination of innovative engineering and durable components makes them a preferred choice for powering various machines.

- Heavy-duty materials used in construction increase the system’s lifespan.

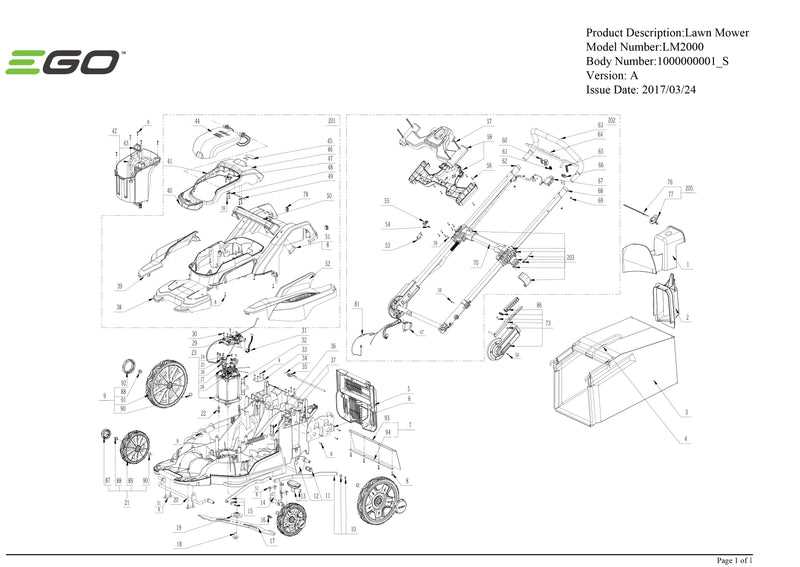

Blade Assembly Overview for Efficient Cutting

The blade system plays a crucial role in ensuring smooth and effective trimming of surfaces. Understanding the components and how they work together is essential for maintaining optimal performance. By keeping the cutting mechanism in proper alignment and condition, you can enhance the precision and quality of each use.

Key Components of the Cutting Mechanism

The cutting system typically consists of several essential parts that must function together seamlessly. The main blade, known for its sharpness and durability, is supported by bolts and washers that secure it firmly in place. These elements work in harmony to provide a consistent and clean result during operation.

Maintaining Blade Efficiency

To ensure continuous effectiveness, regular maintenance of the cutting system is necessary. Sharpening the blade, inspecting for wear, and replacing any damaged components will help prolong the lifespan of the cutting assembly and guarantee

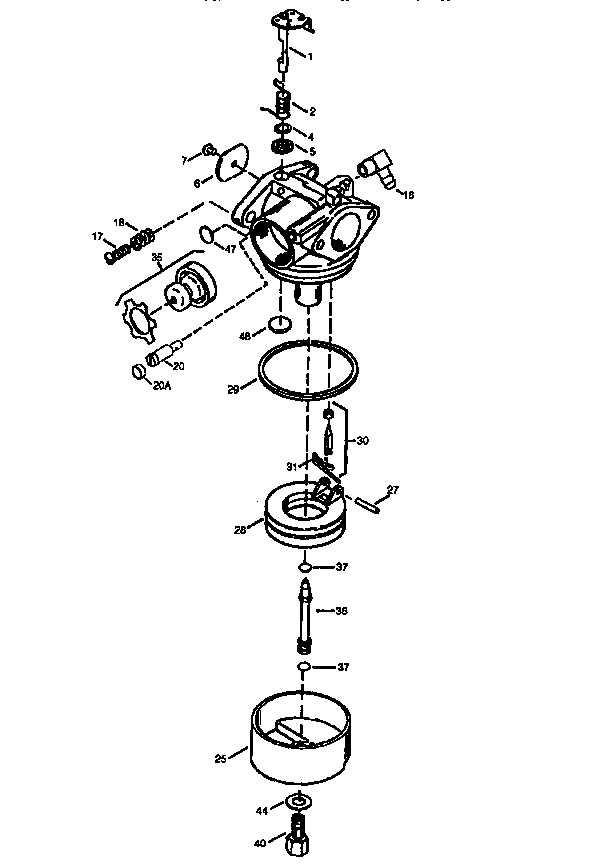

Fuel System Components and Maintenance Tips

The section on Fuel System Components and Maintenance Tips discusses essential elements of the engine’s fuel delivery system and offers practical advice for upkeep. Understanding the components responsible for delivering fuel efficiently is crucial for maintaining optimal engine performance.

Fuel Delivery Components

Fuel Pump: This vital component ensures a steady flow of fuel from the tank to the engine, operating under high pressure to meet the engine’s demands. Regular inspection and cleaning of the fuel pump can prevent clogs and ensure consistent performance.

Fuel Filter: Positioned between the fuel tank and the engine, the fuel filter traps contaminants such as dirt and rust particles before they reach sensitive engine parts. Replacing the fuel filter at recommended intervals helps maintain fuel quality and prevents engine damage.

Maintenance Tips

Regular Inspection: Routinely inspecting fuel lines, connections, and components for leaks or wear is essential. Addressing issues promptly can prevent fuel system malfunctions and extend the life of engine components.

Fuel Quality: Using clean, high-quality fuel and additives recommended by the manufacturer ensures optimal engine performance and reduces the risk of fuel system corrosion.

By understanding fuel system components and following maintenance tips, you can enhance the longevity and efficiency of your engine’s fuel delivery system, ensuring reliable operation season after season.

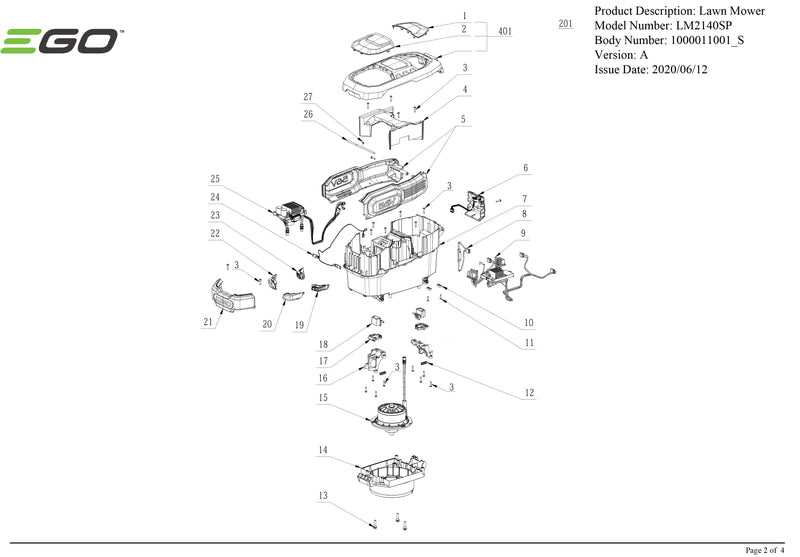

Air Filter Location and Replacement Guide

The air filter plays a crucial role in maintaining the efficiency of outdoor power equipment. It prevents dirt and debris from entering the engine, ensuring smooth operation. Regular inspection and timely replacement of this component are essential to prolong the lifespan of the machinery.

Locating the Air Filter: To find the air filter, begin by identifying the engine cover. Typically, the filter is enclosed in a protective housing on the side of the engine. This cover can usually be opened by removing a few screws or clips, revealing the filter inside.

Replacing the Air Filter: Once the cover is removed, carefully take out the old filter. Examine it for any visible signs of wear or clogging. If it appears dirty or damaged, it’s time for a new one. Insert the replacement filter into the housing, ensuring it fits snugly, and reattach the cover securely.

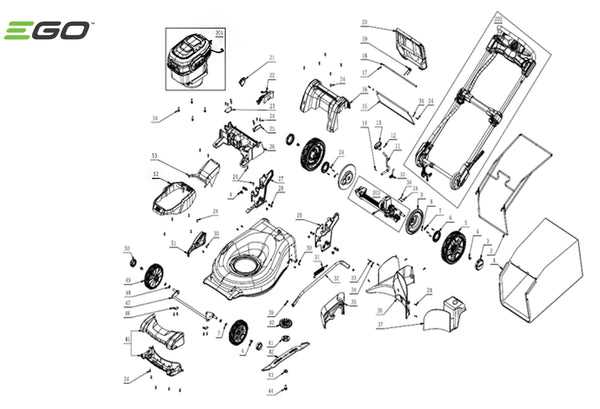

Exploring the Drive Mechanism in Detail

The drive mechanism plays a crucial role in ensuring smooth and efficient movement. By distributing power effectively, this system allows for consistent forward motion. Understanding its structure and operation helps in diagnosing issues and performing necessary adjustments. In this section, we will dive into how the components interact and contribute to the overall function of the system.

Main Components of the Drive Mechanism

Several elements come together to form the drive mechanism. These components work in unison to transfer energy from the engine to the wheels, maintaining steady propulsion. Below is an overview of the key parts involved in the process:

| Component |

Function |

| Transmission |

Converts engine power into rotational force for movement. |

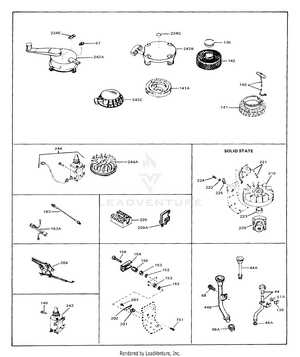

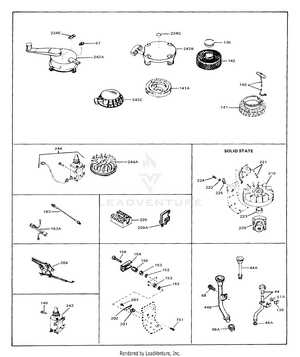

Ignition System Parts and Troubleshooting

The ignition system is crucial for the proper functioning of small engine equipment, as it ensures reliable starting and optimal performance. Understanding the components involved in this system can help diagnose issues effectively and maintain efficiency. Various elements, such as the ignition coil, spark plug, and wiring, play significant roles in the ignition process.

When troubleshooting ignition problems, it is essential to examine each component systematically. Begin by inspecting the spark plug for wear or carbon buildup, which can prevent a strong spark from igniting the fuel-air mixture. If the spark plug appears damaged, replacing it is often a straightforward solution. Next, check the ignition coil and associated wiring for any signs of damage or loose connections that could disrupt the electrical flow necessary for ignition.

Additionally, ensure that the electrical connections are secure and free from corrosion, as this can hinder performance. If issues persist, testing the ignition system with a multimeter can help identify faults in the electrical components. By methodically addressing these aspects, users can effectively troubleshoot ignition-related challenges and restore reliable operation.

Muffler and Exhaust Components for Noise Control

Effective noise management is crucial in maintaining a pleasant environment while operating outdoor machinery. The components responsible for sound reduction play a vital role in ensuring that devices operate quietly, contributing to both user comfort and compliance with noise regulations. Understanding these elements can help users appreciate their function and importance.

Key Components of Exhaust Systems

- Mufflers: These devices are specifically designed to minimize sound levels generated during operation. They work by dissipating the energy of sound waves, allowing for quieter performance.

- Exhaust Pipes: These channels direct exhaust gases away from the engine and reduce noise. Their design can significantly impact overall sound output.

- Silencers: Similar to mufflers, silencers further enhance noise control by filtering sound waves before they exit the machine.

Benefits of Efficient Noise Control

- Improved comfort for users and surrounding individuals.

- Compliance with local noise ordinances, reducing the risk of fines.

- Enhanced performance, as quieter machinery can lead to longer operational periods without fatigue.

Incorporating high-quality components for noise control not only benefits the environment but also extends the lifespan of equipment by reducing wear associated with excessive vibrations and sound levels.

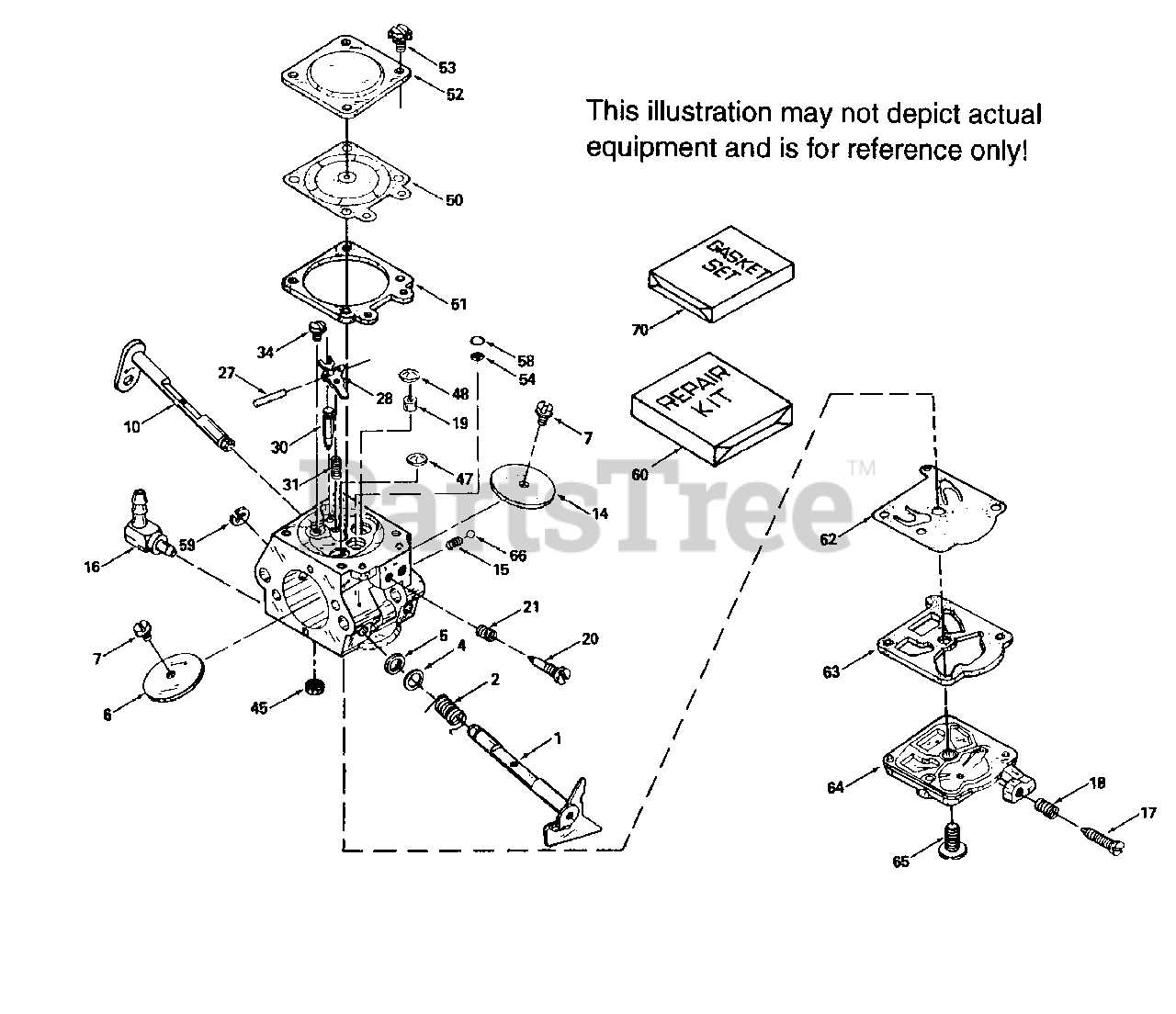

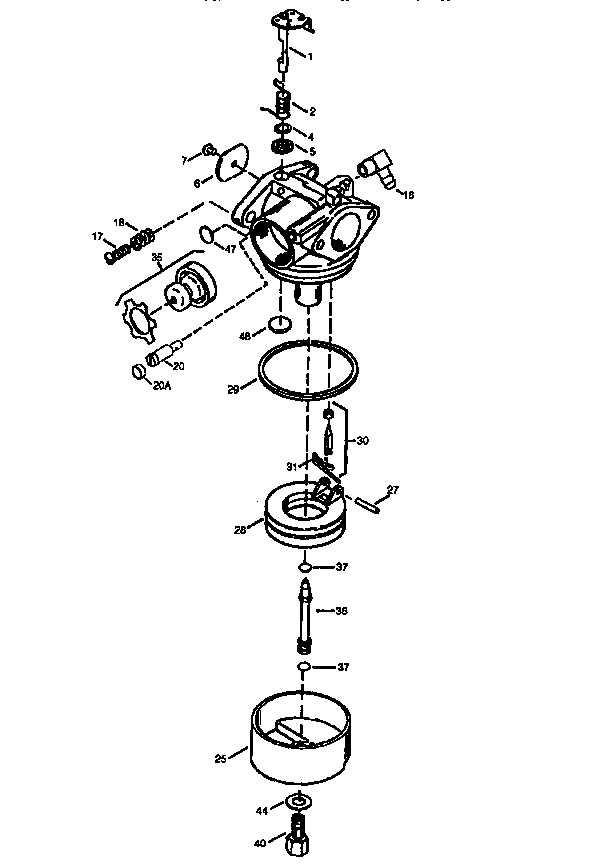

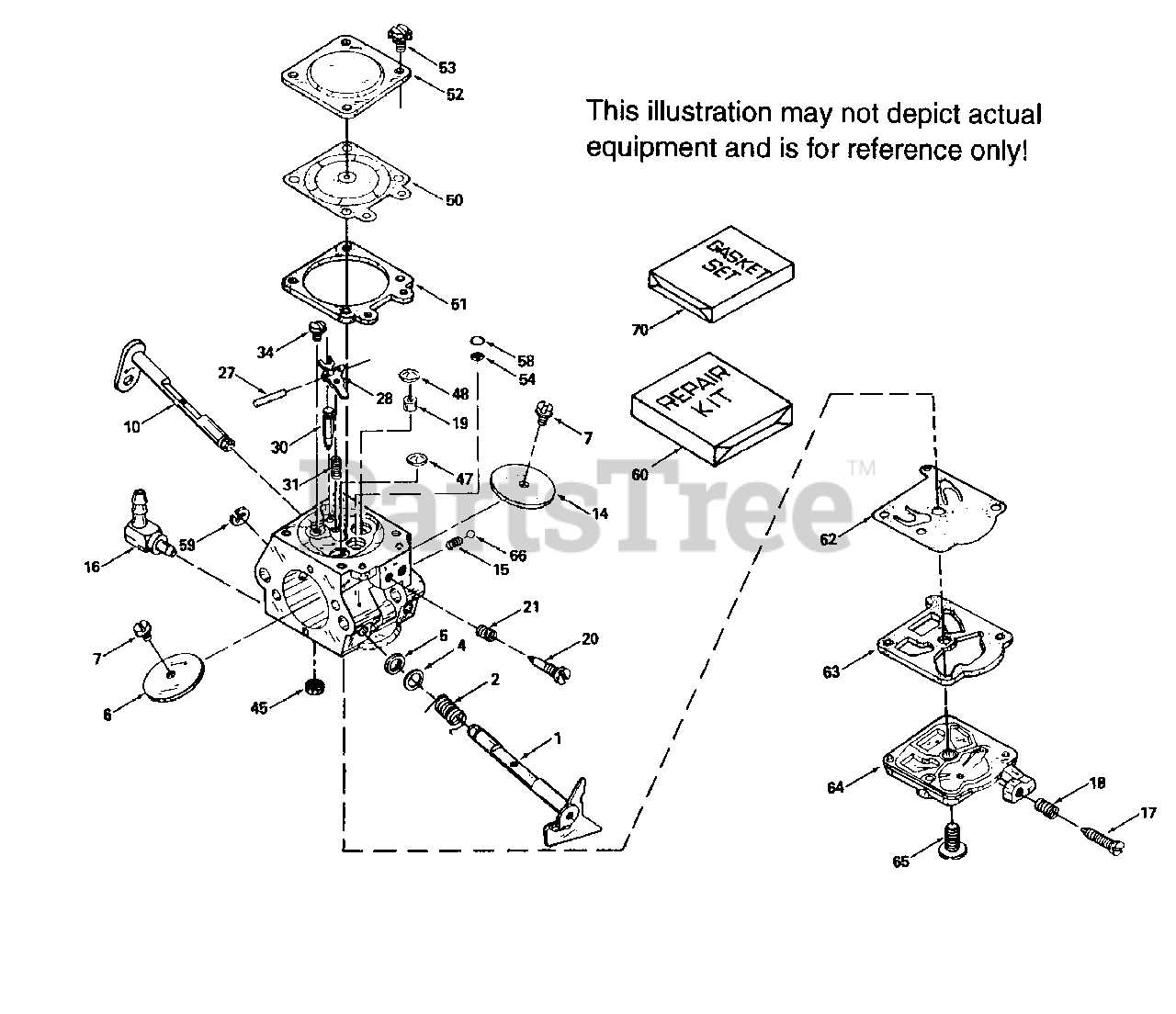

How to Identify the Carburetor and Its Functions

The carburetor is a crucial component in many engines, playing a vital role in the mixture of air and fuel necessary for combustion. Understanding its characteristics and functionality can greatly enhance maintenance and troubleshooting efforts.

Recognizing the Carburetor

Typically, the carburetor is situated between the air filter and the intake manifold. It features a distinctive shape, often cylindrical, and may include multiple adjustment screws. Look for components such as a float chamber, throttle plate, and choke, which are indicative of its structure.

Functions of the Carburetor

This device regulates the flow of air and fuel into the engine, ensuring optimal performance. It adjusts the fuel mixture based on engine demands, which is essential for efficient operation. The carburetor’s ability to manage airflow contributes to the engine’s responsiveness and overall power output.

Deck Belt Diagram and Adjustment Instructions

The following section provides essential information on the configuration of the belt system and how to properly adjust it for optimal performance. Understanding the layout and functionality of this component is crucial for maintaining effective operation and prolonging the life of your equipment.

Understanding the Belt Configuration

The belt system connects various elements of the machinery, facilitating motion and ensuring smooth operation. Here’s a brief overview of the components involved:

- Driving mechanism

- Idler pulley

- Attachment points

- Adjustment levers

Adjustment Instructions

Proper adjustment of the belt is vital for ensuring efficiency and preventing wear. Follow these steps for accurate calibration:

- Begin by turning off the engine and disconnecting the spark plug for safety.

- Locate the adjustment levers or bolts on the system.

- Loosen the tension by turning the adjustment mechanism counterclockwise.

- Ensure that the belt sits securely on all pulleys without excessive slack.

- Tighten the adjustment mechanism while checking the alignment of the belt.

- Reconnect the spark plug and start the engine to test the adjustment.

By adhering to these guidelines, users can effectively maintain the belt system, ensuring reliable and efficient operation of the equipment.

Throttle Linkage and Governor Parts Explained

The throttle linkage and governor components play a crucial role in controlling engine performance and efficiency. Understanding how these elements function together can help ensure optimal operation of your machinery.

The throttle linkage connects the control mechanism to the engine, allowing the operator to adjust the engine speed according to needs. This system involves several key elements:

- Throttle Cable: This flexible cable transmits the operator’s input from the control handle to the throttle plate.

- Linkage Rods: These rods connect the throttle control to the carburetor, facilitating smooth movement and precise adjustments.

- Return Spring: This component ensures that the throttle returns to its idle position when not engaged, maintaining a safe operating state.

On the other hand, the governor regulates the engine speed by adjusting the throttle position based on load demands. Its main components include:

- Governor Gear: This gear interacts with the engine to monitor speed and adjust throttle response accordingly.

- Weights: These are critical for sensing changes in engine speed and provide feedback to the governor to maintain desired performance.

- Governor Spring: This spring adjusts the tension based on engine load, influencing how quickly the governor reacts to changes.

By familiarizing yourself with the functions and interactions of these components, you can ensure that your equipment operates efficiently and effectively, prolonging its lifespan and enhancing performance.

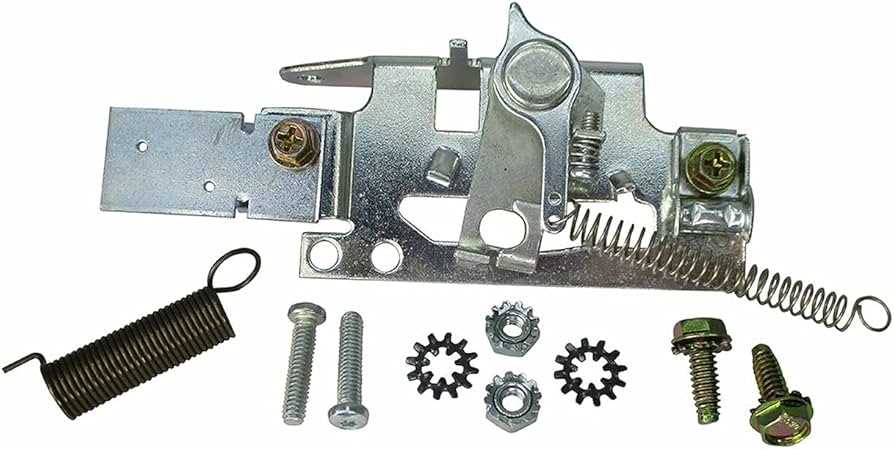

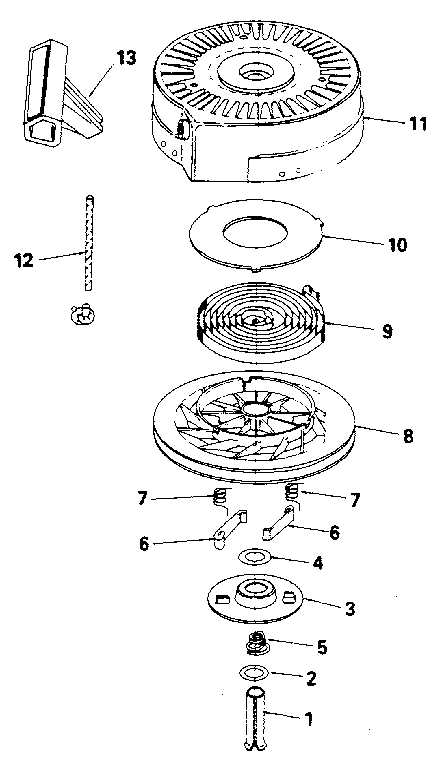

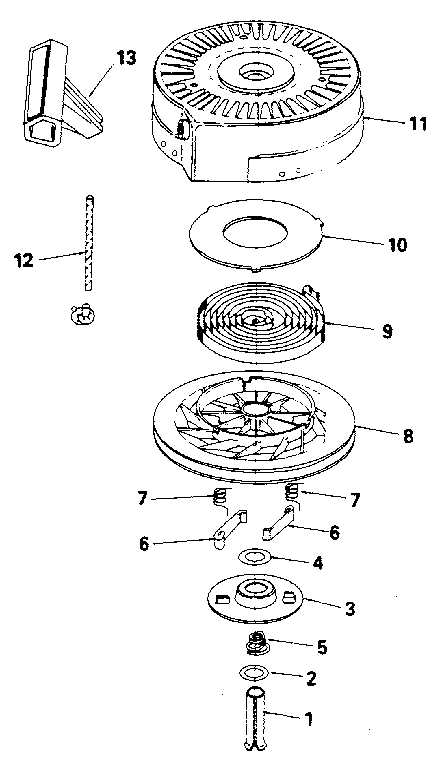

Starter Mechanism and Repair Tips

The starter system is a crucial component in initiating the operation of small engines. Understanding its functionality and potential issues can significantly enhance maintenance and ensure optimal performance. This section provides insights into common problems and effective repair strategies to help users troubleshoot and fix their starter mechanisms.

Here are some common issues and corresponding repair tips:

- Failure to Engage: If the starter does not engage, check the battery voltage and connections. Ensure all wires are secure and free from corrosion.

- Sticky Starter Gear: If the gear is stuck, apply a light lubricant to the moving parts. This can help restore smooth operation.

- Rope Snapping: A frayed or damaged starting rope should be replaced immediately. Ensure the new rope is of the correct length and strength.

- Excessive Wear: Regularly inspect the starter for signs of wear. Replace any worn-out components, such as springs or gears, to maintain functionality.

Regular maintenance and prompt repairs can extend the life of the starter system. Familiarity with these components can empower users to address issues proactively and enhance the reliability of their equipment.

Safety Switches and Their Role in Operation

Safety switches are critical components in various machinery, ensuring that the equipment operates under safe conditions. Their primary function is to prevent accidental activation, which could lead to injuries or damage. By understanding the importance of these devices, operators can enhance both their safety and the longevity of the equipment.

These switches serve as a protective mechanism that interrupts the power supply when certain conditions are not met. For instance, if the operator is not in the correct position or if safety guards are not in place, the switch will disable the machine. This feature is crucial for maintaining a safe working environment and protecting the user from potential hazards.

Regular inspection and maintenance of safety switches are essential for ensuring their proper functioning. Over time, wear and tear can affect their reliability. By keeping these components in good condition, operators can ensure that their equipment remains safe and efficient.