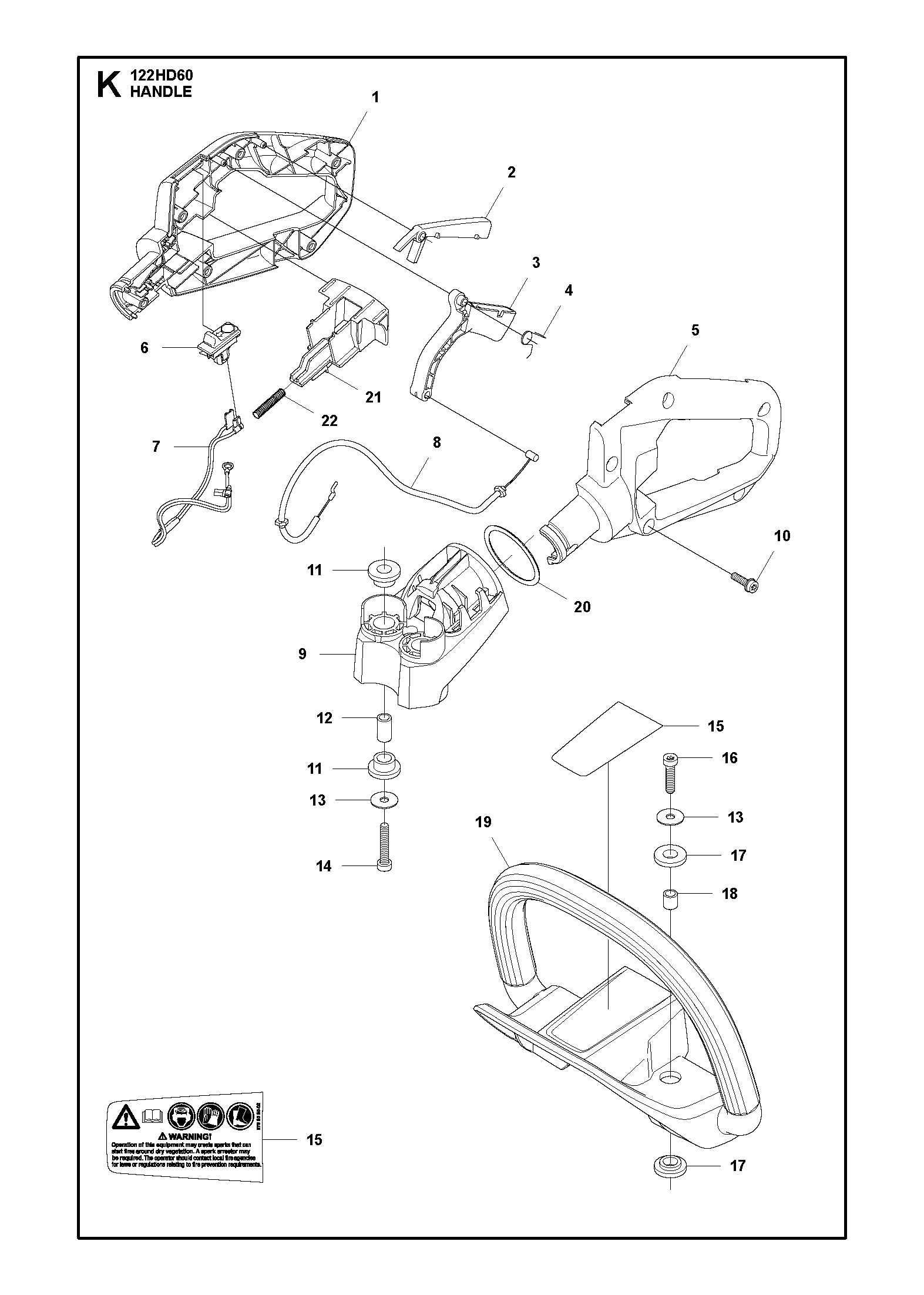

Understanding the inner workings of any mechanical tool can greatly enhance its efficiency and lifespan. For those looking to maintain their hedge trimmer, having a detailed view of its assembly is crucial. Knowing where each element fits and how it contributes to the overall function helps ensure smooth operation and easy troubleshooting.

Each piece within the machine serves a specific role in delivering optimal performance. From the smallest screws to the major engine components, familiarity with these elements not only aids in repairs but also promotes preventive care, reducing the likelihood of unexpected malfunctions.

In this section, we will take a closer look at the essential features that make up this

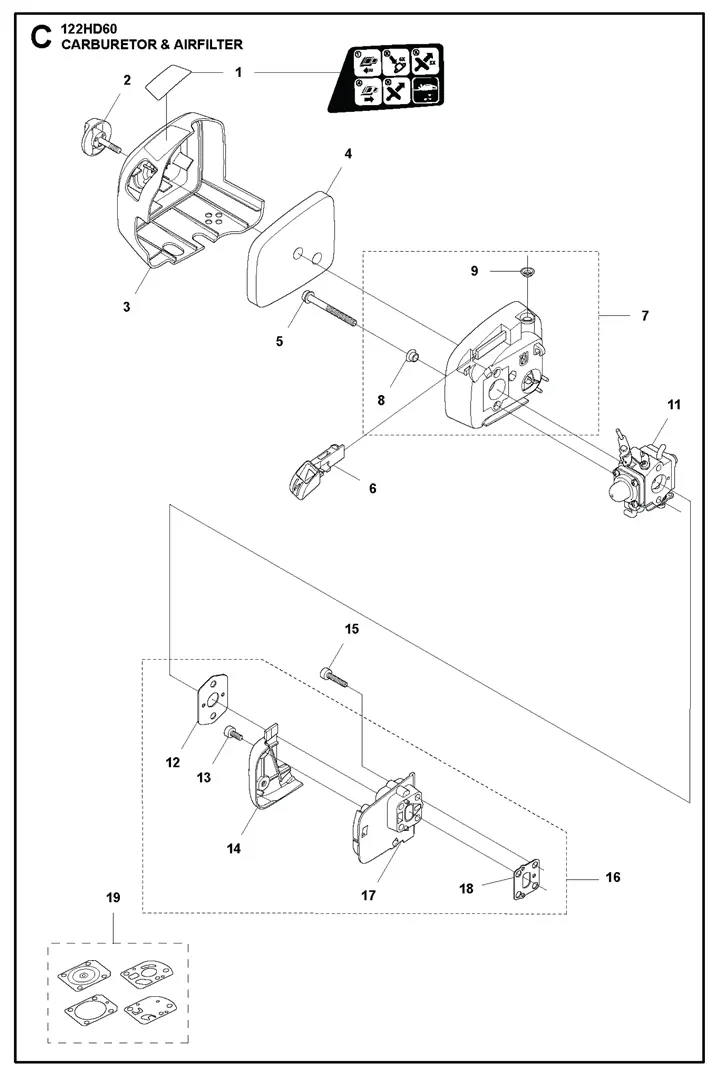

Understanding the Components of 122HD60

Every machine consists of various elements that work together to ensure its smooth operation. In this section, we will explore the key structural elements that make up the core functionality of this model. Recognizing the purpose of each individual component helps in maintaining and troubleshooting the equipment effectively.

| Component | Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

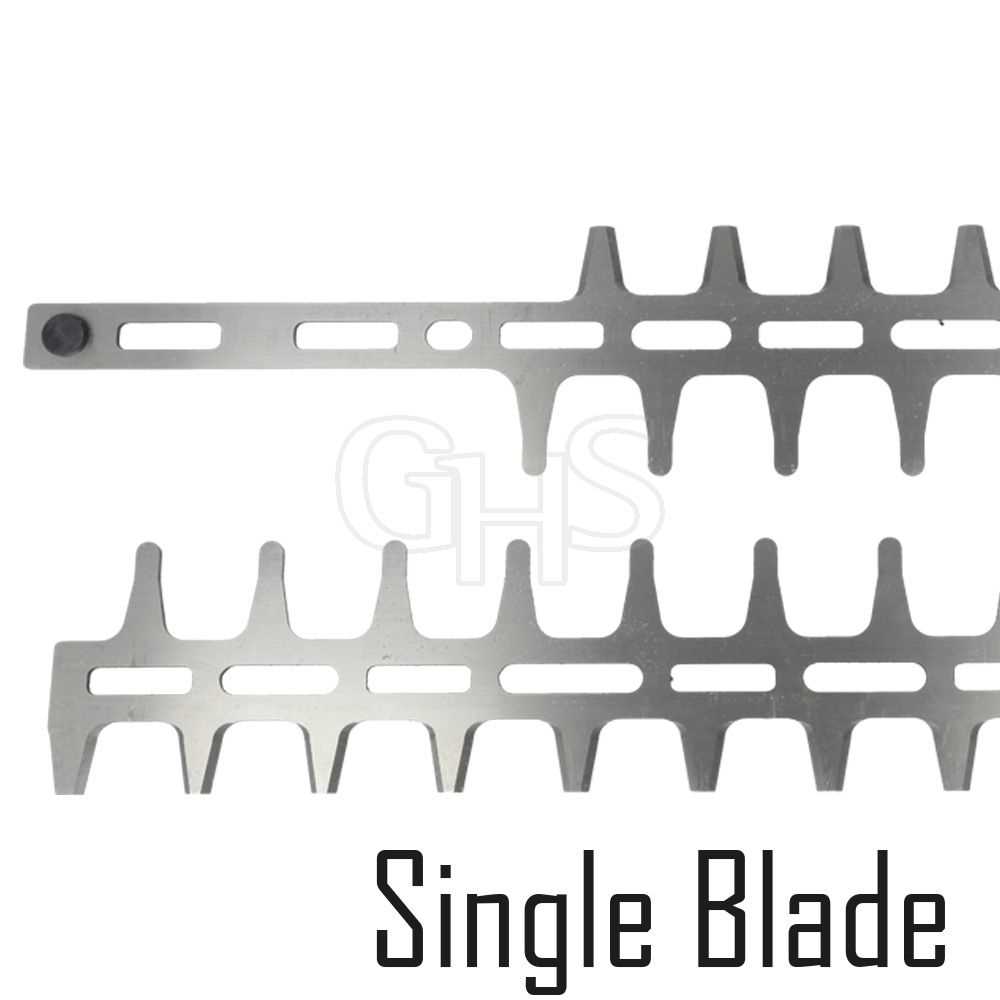

| Cutting Blades | Responsible for trimming and shaping vegetation with precision and efficiency. | ||||||||||||||||||

| Engine Unit | Provides the necessary power to drive the blades and ensure continuous performance. | ||||||||||||||||||

| Handle Assembly | Offers control

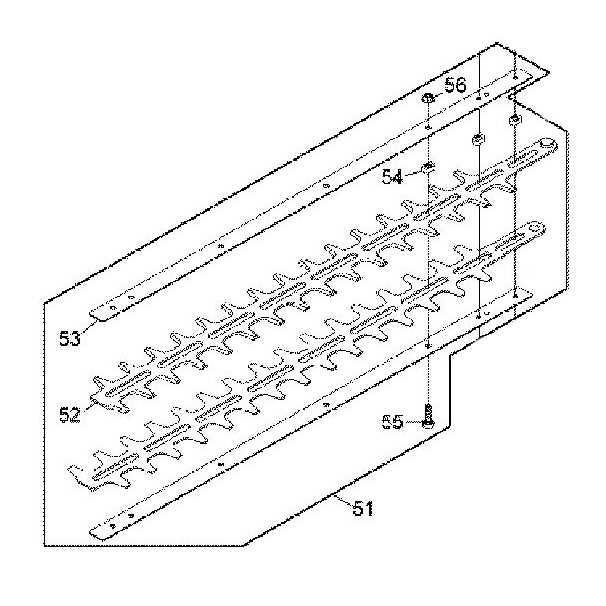

How the Blade Assembly Works

The cutting mechanism is an essential component in hedge trimmers, allowing for efficient and precise trimming. It operates through a coordinated movement of blades, ensuring sharp and clean cuts. The functionality of this assembly is designed to deliver high performance, ensuring the user can easily maintain hedges and shrubs. Main Components of the Cutting Mechanism

How the Motion is Generated

|

| Component | Function | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ignition Coil | Transforms low battery voltage

Throttle Mechanism BreakdownThe throttle system plays a crucial role in controlling the speed and power of the engine. Understanding its internal structure can help in identifying potential issues and maintaining optimal performance. In this section, we will explore the key components that make up the throttle control assembly. Key ComponentsThe throttle mechanism consists of several essential parts, each contributing to the overall operation. These elements work together to regulate the flow of fuel and air, allowing precise control over engine output. Below is a breakdown of the primary components involved in the throttle system:

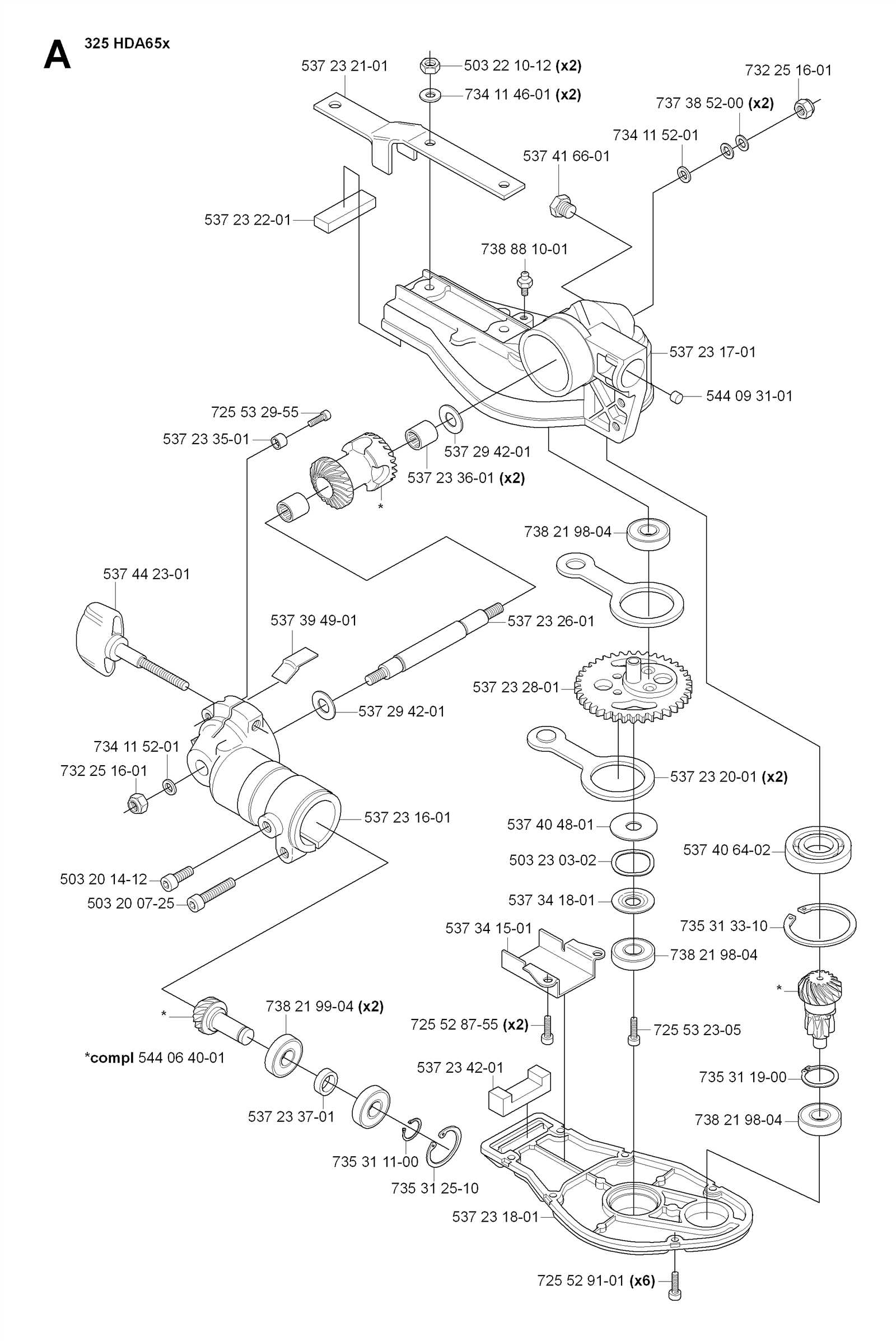

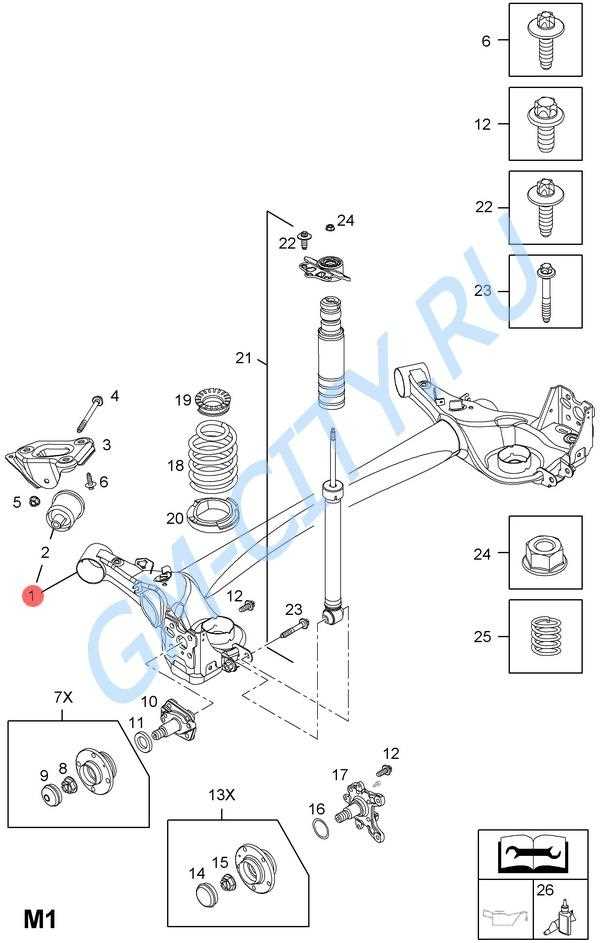

Importance of Proper MaintenanceRegular maintenance of the recoil starter components is crucial for optimal performance. Ensuring that the spring is tensioned correctly, the rope is intact, and the pulley functions smoothly can prevent starting issues and extend the lifespan of the engine. Proper care leads to efficient operation and reduces the risk of failure during use. How the Anti-Vibration System FunctionsThe anti-vibration mechanism plays a crucial role in enhancing the performance and durability of various equipment. Its primary function is to minimize the impact of vibrations generated during operation, which can lead to wear and tear over time. By effectively dampening these vibrations, the system ensures smoother operation and extends the lifespan of the machinery. This system typically utilizes a combination of springs and dampers, strategically positioned to absorb and dissipate energy. When the equipment is in motion, the springs compress and expand, counteracting the forces that cause vibrations. The dampers further enhance this effect by converting kinetic energy into thermal energy, effectively reducing the amplitude of vibrations. In addition to improving user comfort and safety, the anti-vibration system also contributes to maintaining precision and accuracy in operations. By stabilizing the equipment, it ensures consistent performance, reducing the likelihood of errors caused by excessive movement. Ultimately, the implementation of such a system is essential for achieving optimal functionality in various applications. Gearbox Assembly and MaintenanceThe assembly and upkeep of the transmission system are crucial for the overall performance and longevity of mechanical equipment. A well-maintained gearbox ensures smooth operation and reduces the risk of breakdowns. This section provides insights into the key aspects of assembling and maintaining this vital component. Assembly ProcessWhen assembling the gearbox, it is essential to follow precise steps to ensure proper alignment and functionality. Begin by laying out all the components systematically. Pay attention to the positioning of gears, bearings, and seals, as improper placement can lead to operational inefficiencies. Utilizing the correct tools is also critical; this helps avoid damage to the components during assembly. Maintenance TipsRegular maintenance is vital for the gearbox’s efficiency. Check the lubricant levels frequently and replace any fluids that show signs of contamination. Additionally, inspect the seals and gaskets for wear and tear, as these can lead to leaks and further complications. Implementing a routine maintenance schedule will significantly enhance the durability and reliability of the transmission system. Understanding the Fuel Tank AssemblyThe fuel tank assembly is a crucial component of any internal combustion engine system. It serves as the primary reservoir for storing fuel, ensuring that the engine receives the necessary supply for optimal performance. Understanding its structure and function is essential for maintenance and troubleshooting, as any issues within this assembly can directly impact the overall efficiency of the machinery. Components of the Fuel TankThe assembly typically consists of various elements, including the tank itself, fuel lines, and a fuel pump. Each part plays a vital role in facilitating the movement and delivery of fuel from the tank to the engine. The tank must be durable and resistant to corrosion to prevent leaks, while the fuel lines must maintain a secure connection to ensure a consistent flow. Importance of Proper MaintenanceRegular inspection and maintenance of the fuel tank assembly are critical for ensuring reliable operation. This includes checking for leaks, ensuring all connections are tight, and verifying that the fuel pump is functioning correctly. Neglecting these aspects can lead to severe performance issues, making it essential to prioritize care for this component. |