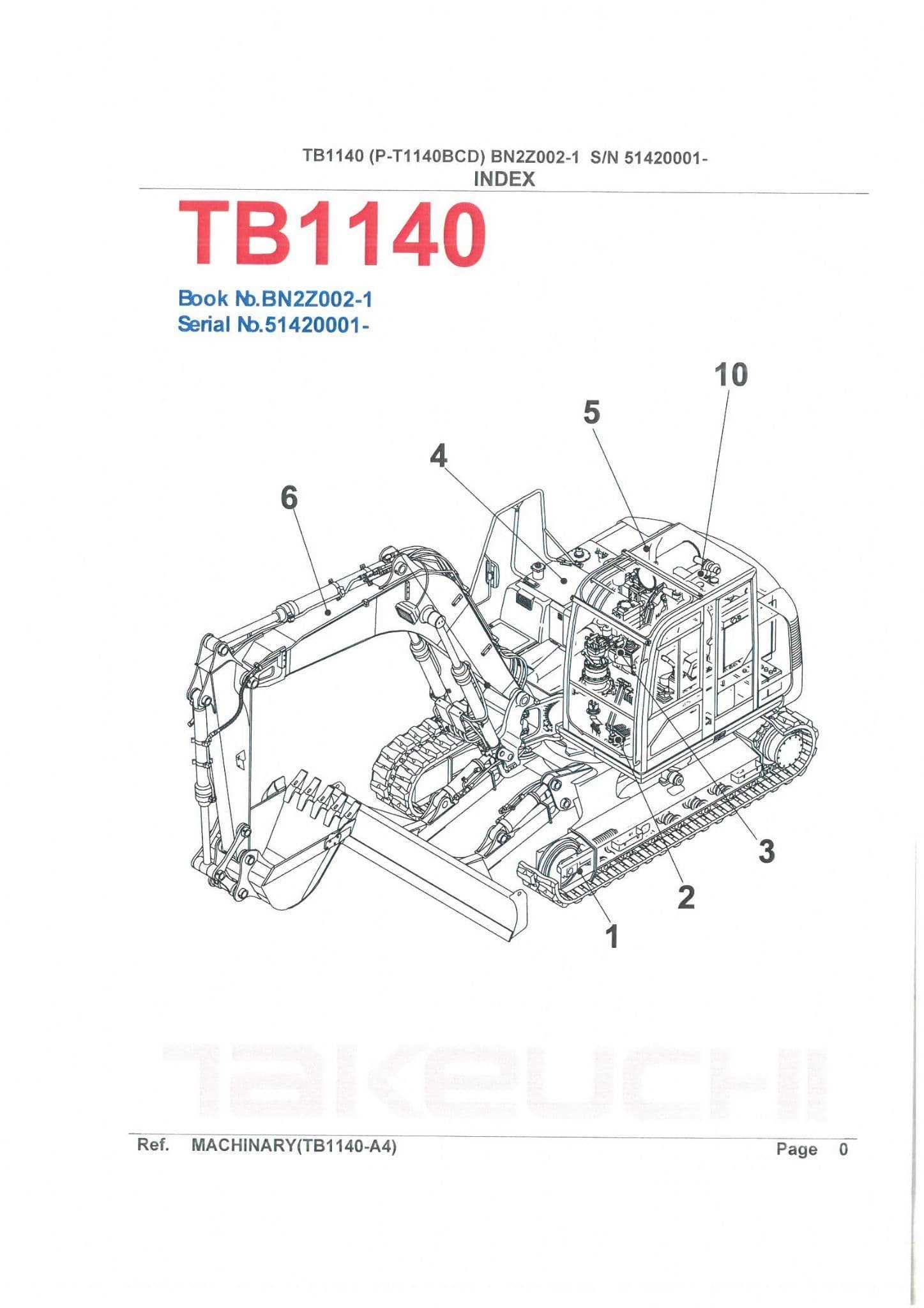

When it comes to heavy machinery, having a clear understanding of the various elements and their arrangements is crucial for effective maintenance and repairs. This section aims to provide insights into the intricate configurations of essential machine components. By familiarizing oneself with these layouts, operators and technicians can enhance their ability to identify issues and implement solutions more efficiently.

Every machine is composed of numerous interconnected parts, each playing a vital role in its overall function. Recognizing how these components work together not only aids in troubleshooting but also contributes to better operational practices. Additionally, a well-organized reference of these layouts can serve as a valuable tool for training new personnel and ensuring that everyone involved is well-informed about the equipment’s intricacies.

In summary, understanding the arrangement of machinery elements is fundamental for maintaining performance and reliability. This knowledge empowers users to perform their tasks with confidence and precision, ultimately leading to improved productivity and reduced downtime.

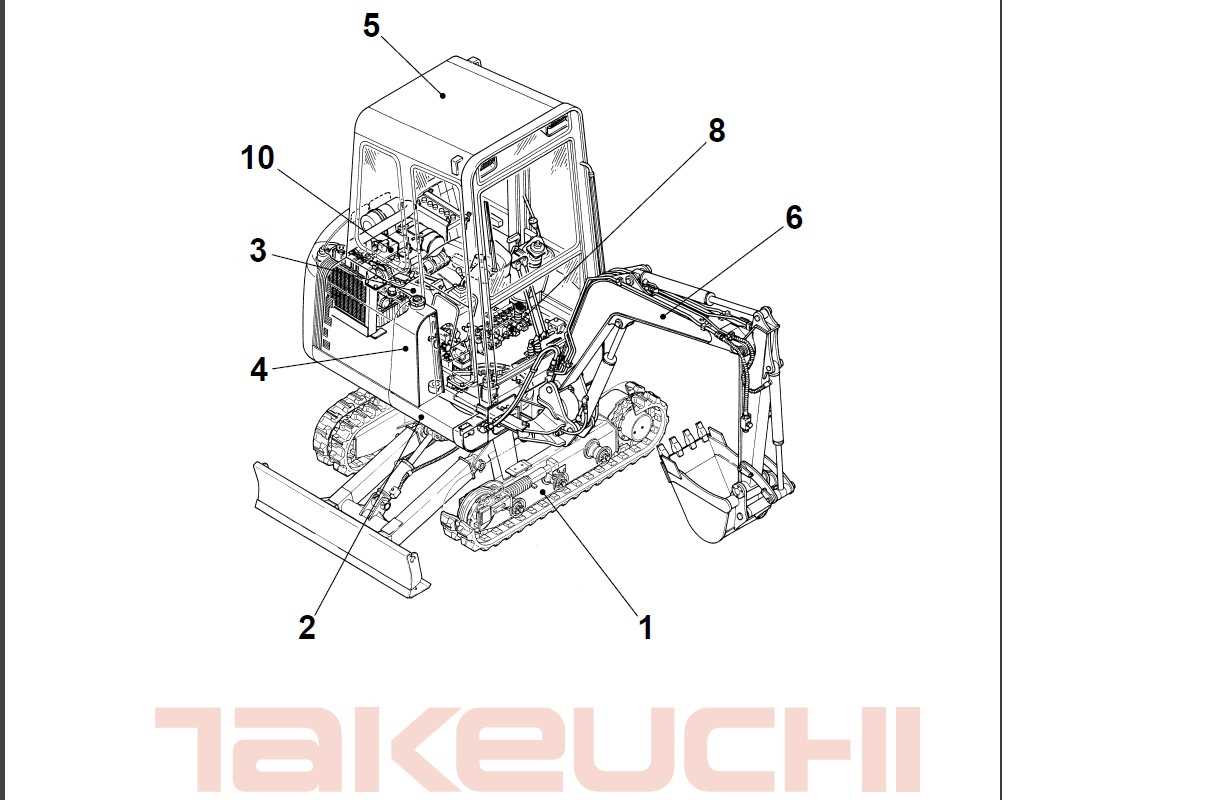

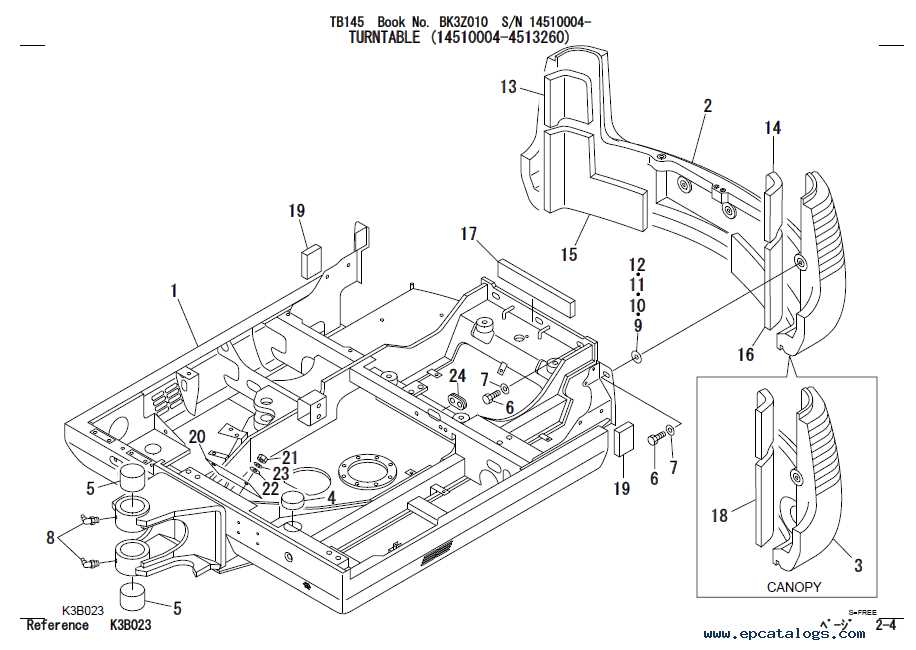

This section provides an in-depth look at the essential elements of a specific compact machine, focusing on their roles and relationships within the system. Understanding these components is crucial for effective maintenance and operation, as well as for troubleshooting potential issues that may arise during usage.

Key Elements of the Machine

The following list highlights some of the critical components that play a vital role in the functionality of the equipment:

- Hydraulic system

- Engine assembly

- Transmission unit

- Chassis structure

- Control mechanisms

- Fuel system

Importance of Component Knowledge

Familiarity with each element enhances the operator’s ability to conduct maintenance efficiently and identify wear or failure signs. Regular inspections and knowledge of part functions lead to improved performance and longevity of the machinery.

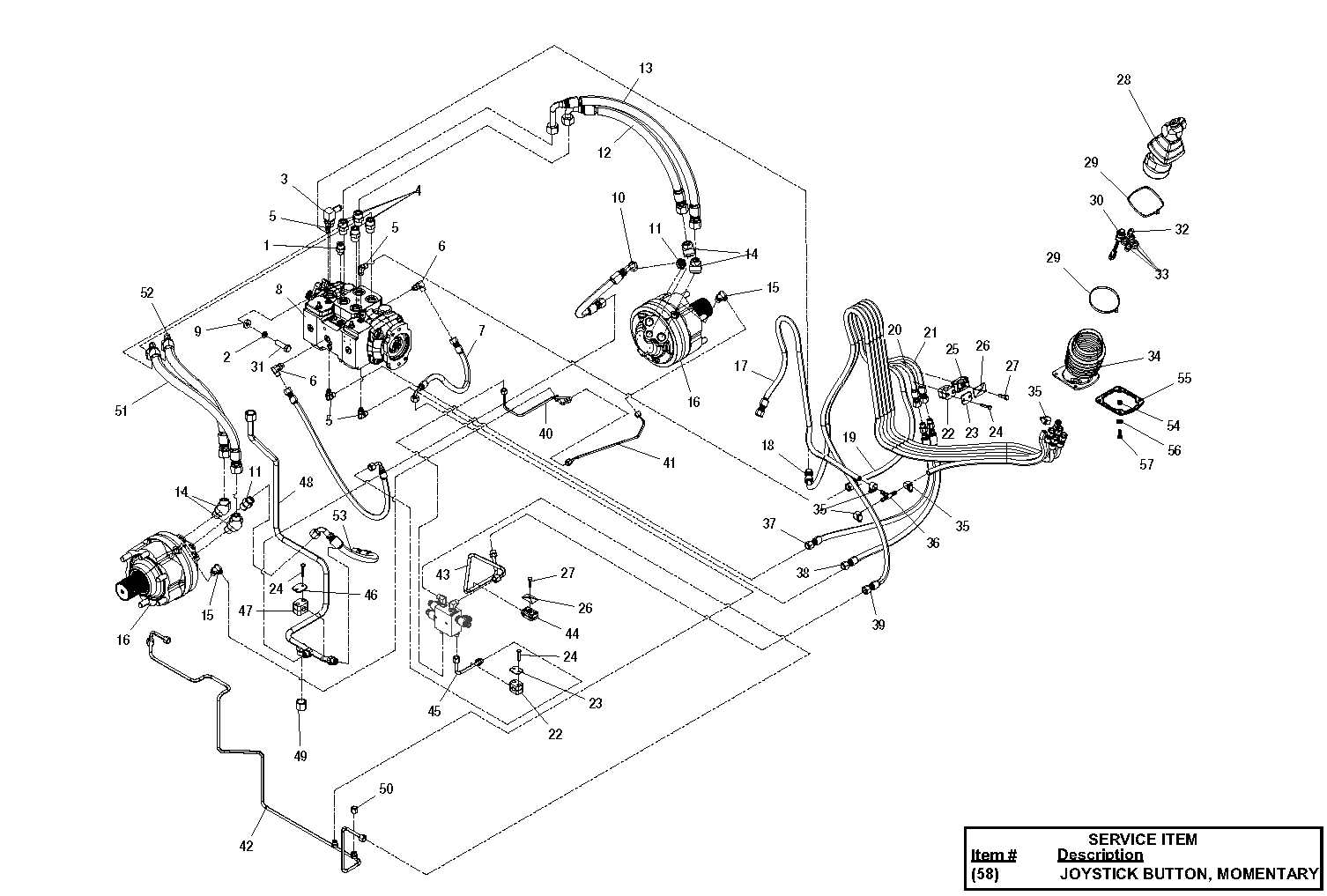

Understanding the Parts Diagram

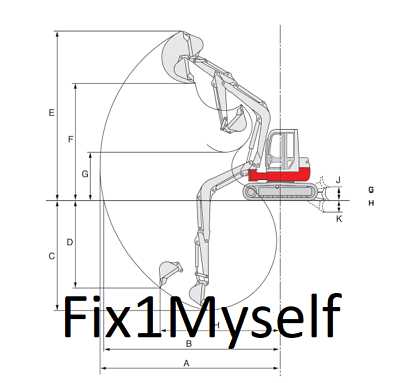

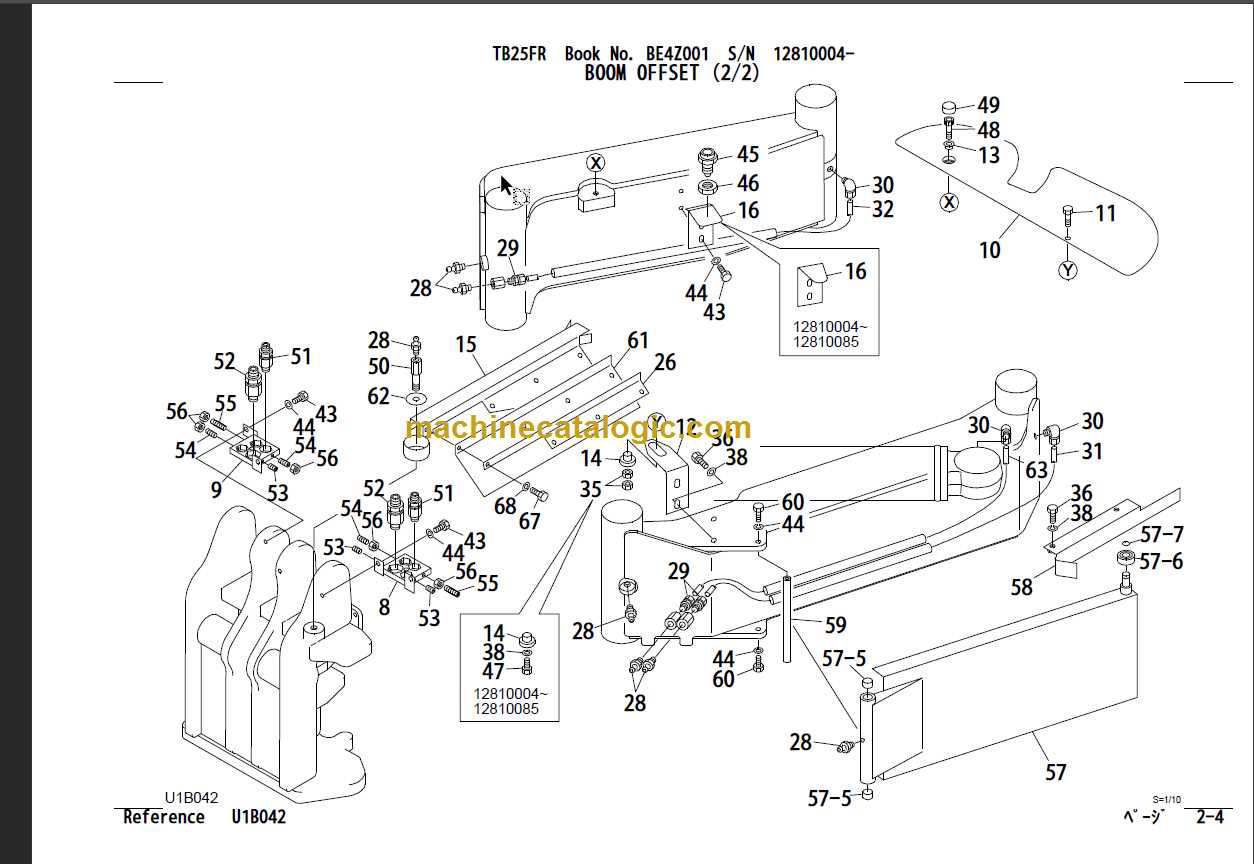

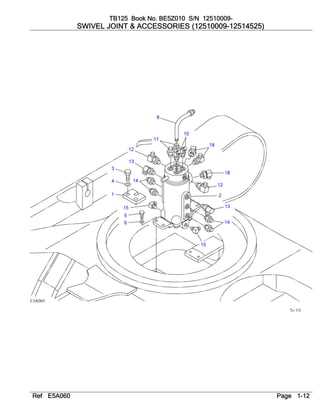

Comprehending the components of a machine is crucial for efficient operation and maintenance. A visual representation of the elements provides insight into their arrangement and functionality. This section aims to clarify how these illustrations serve as valuable tools for users and technicians alike.

These illustrations typically include:

- Identification of Components: Each part is labeled, allowing for easy recognition and reference.

- Arrangement Layout: The visual format shows how components fit together, highlighting their relationships.

- Functionality Explanation: Accompanying notes often detail the role of each part in the overall system.

Utilizing such visual guides enhances understanding, facilitating repairs and replacements. Users can quickly locate the necessary components when troubleshooting issues or performing routine maintenance, thereby streamlining the entire process.

Key Features of TB125 Model

This section highlights the essential attributes that define the efficiency and reliability of this compact machinery. Understanding these features can enhance the operator’s experience and ensure optimal performance in various applications.

Compact Design and Maneuverability

The machine’s compact structure allows for easy navigation in confined spaces, making it ideal for urban construction sites and landscaping tasks. Its low weight combined with a robust build provides excellent stability during operation.

Powerful Engine Performance

Equipped with a high-performance engine, this model delivers significant power while maintaining fuel efficiency. The innovative design minimizes emissions, contributing to a more environmentally friendly operation.

| Feature | Description |

|---|---|

| Operating Weight | Compact and lightweight for enhanced mobility. |

| Engine Power | Efficient and powerful engine for demanding tasks. |

| Maneuverability | Designed for easy navigation in tight spaces. |

| Emissions Control | Low emissions for a more eco-friendly operation. |

Identifying Essential Replacement Parts

Understanding the crucial components that may require substitution during maintenance is vital for ensuring the optimal performance of your machinery. Proper identification of these elements not only extends the lifespan of the equipment but also guarantees its efficient operation. This section focuses on how to recognize key components that need attention and potential replacement.

Commonly Replaced Components

- Hydraulic Filters: Essential for maintaining fluid cleanliness and preventing system damage.

- Belts: Often wear out due to constant use, affecting overall functionality.

- Seals and Gaskets: Critical for preventing leaks and maintaining pressure.

- Electrical Components: Fuses and wiring may degrade over time, leading to operational issues.

How to Identify the Need for Replacement

- Regular Inspections: Conduct frequent checks to spot signs of wear or damage.

- Performance Monitoring: Pay attention to any decrease in performance or unusual noises.

- Manufacturer Guidelines: Consult operational manuals for recommended replacement schedules.

Maintenance Tips for TB125 Equipment

Proper upkeep of construction machinery is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances the efficiency of the equipment but also prevents potential breakdowns and costly repairs. Implementing a structured maintenance routine can significantly extend the lifespan of your machinery.

Routine Inspections

Conducting regular inspections is crucial for identifying wear and tear early. Check all vital components, including hydraulic systems, filters, and belts. Addressing minor issues promptly can prevent them from escalating into major problems.

Lubrication and Fluid Checks

Ensure that all moving parts are adequately lubricated to reduce friction and prevent damage. Regularly check the levels of hydraulic fluid, oil, and coolant to maintain optimal functioning. Changing these fluids according to the manufacturer’s recommendations is vital for maintaining efficiency.

| Maintenance Task | Frequency |

|---|---|

| Inspect hydraulic systems | Monthly |

| Change oil and filters | Every 250 hours |

| Check belts and hoses | Every 500 hours |

| Lubricate moving parts | Weekly |

Common Issues and Solutions

In the operation of compact machines, various technical problems can arise over time. These can affect performance, efficiency, or even lead to mechanical failures if not addressed promptly. Understanding the root causes and how to effectively resolve them can help maintain smooth functionality.

| Issue | Cause | Solution |

|---|---|---|

| Engine overheating | Clogged cooling system | Clean the radiator and check coolant levels |

Hyd

Where to Purchase Spare Parts

When it comes to maintaining heavy machinery, finding reliable sources for replacement components is crucial. Many suppliers offer a wide range of items needed for upkeep, making it easier to keep your equipment running smoothly. It is essential to consider a few key factors when selecting a vendor for these items. Trusted Online RetailersOne of the most convenient options is shopping through reputable online platforms. Many websites specialize in providing components for various types of machinery. These retailers often offer quick delivery, competitive prices, and detailed product descriptions to ensure compatibility with your equipment.

|