Understanding how various elements within a complex machine interact is crucial for anyone looking to maintain or enhance performance. Each component plays a vital role in the overall system’s functionality, and recognizing their relationships can be the key to resolving issues or improving efficiency.

By delving into the specific characteristics and connections of the core elements, users can gain insight into how these systems operate. This knowledge not only aids in troubleshooting but also empowers individuals to make informed decisions when it comes to repairs or upgrades.

In the following sections, we will take a closer look at the intricate setup, examining how different elements are aligned and contribute to the overall functionality. This exploration will help demystify the structure, making it easier to understand and work with.

Understanding the Components of CMXGIAC2500

To comprehend the structure and function of this system, it’s important to break down the various elements that contribute to its overall performance. Each section is designed with a specific purpose in mind, ensuring the efficiency and reliability of the entire unit.

Main Elements

- Control Unit: This core element manages the coordination of all operations, ensuring that everything runs smoothly and in sync.

- Power Source: Provides the necessary energy for all components, ensuring continuous operation under different conditions.

- Input Channels: Responsible for receiving data or signals, these pathways allow for interaction and processing of external inputs.

- Output Mechanism: Delivers the final result, whether it’s an action or signal, based on the processed information from the unit.

Supporting Mechanisms

- Cooling System: Maintains optimal temperatures by preventing overheating during prolonged use.

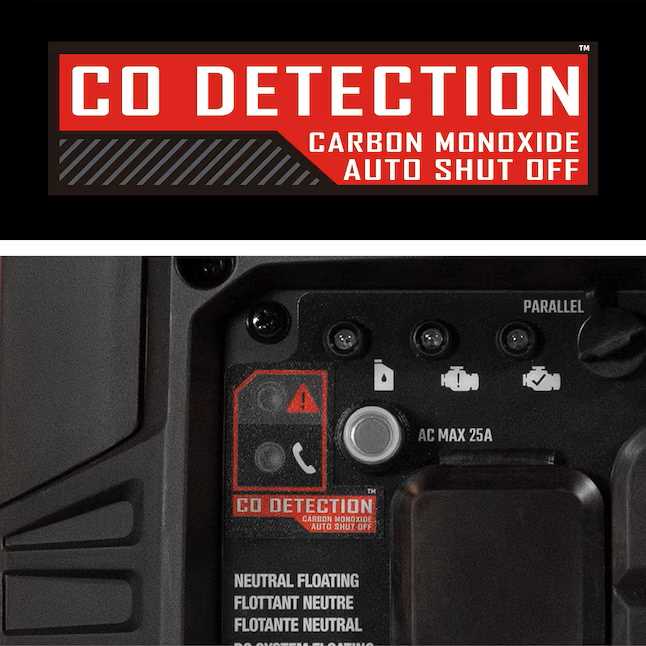

- Safety Features: Integrated protections

Key Elements in CMXGIAC2500 Structure

The composition of this device is based on a variety of essential components that work in harmony to deliver optimal performance. Each element plays a distinct role, ensuring that the system operates smoothly and efficiently. Understanding the key building blocks provides insights into its overall function and potential areas for maintenance or upgrades.

Core framework is the foundation upon which all other elements are organized. It provides stability and ensures the correct alignment of interconnected parts.

The processing unit serves as the central hub, managing all operational commands and data flow. Its performance greatly influences the efficiency and speed of the entire system.

Power management is critical for reliable operation, distributing energy to various sections while preventing overloads or malfunctions.

Additional components like the control interface and communication modules allow for user interaction and external connectivity, enabling seamless integration with other systems and devices.

Detailed Breakdown of Main Assemblies

The following section provides a comprehensive analysis of the key structural components and their individual elements, ensuring a clear understanding of how they function together. This breakdown highlights the core units that are essential for the overall operation, giving insight into their arrangement and interrelation.

Primary Structural Components

Each major unit plays a pivotal role in the overall system, designed to support functionality and durability. Below is a concise overview of the primary structural components and their specific elements, emphasizing their importance in the system’s operation.

Component Function Main Housing Provides structural integrity and protection for internal mechanisms. Drive Mechanism Responsible for initiating and sustaining motion within the system Exploring the Internal Layout

The internal structure of the unit is designed to ensure optimal functionality and longevity. Various interconnected components work in unison to manage the device’s operations efficiently. Understanding how these elements are arranged provides insight into the mechanics behind its reliable performance.

Key Structural Components

The internal arrangement includes essential modules that control power distribution, processing functions, and user interaction. These components are strategically positioned to maximize space and enhance operational flow, ensuring smooth and uninterrupted performance.

Layout Overview

Component Function Location Power Module Regulates electrical input to maintain stable operation Upper left section Control Unit Oversees Connection Points and Their Functions

When assembling complex systems, understanding the various interaction zones is essential for ensuring proper functionality. Each zone is responsible for handling specific tasks, and the efficiency of the entire setup depends on how well these areas perform their designated roles. The ability to identify these points and their purposes can significantly enhance the overall operation and troubleshooting process.

Power Input Area: This section provides the necessary energy to drive the system. Proper connection here is vital for maintaining stability and preventing malfunctions.

Control Interface: Serving as the communication hub, this area allows for the regulation of various system parameters. Clear and secure links ensure accurate command transmission.

Data Transfer Path: Responsible for the flow of information, this zone manages how data is exchanged between components. Proper alignment ensures smooth and efficient communication within the system.

Understanding how these areas work together is key to ensuring optimal system performance.

Mechanical Parts Overview

The intricate assembly of a mechanical system encompasses various components that work in harmony to achieve optimal functionality. Understanding these elements is essential for effective maintenance and troubleshooting. Each unit serves a specific purpose, contributing to the overall efficiency of the machinery.

Key Components: At the heart of the assembly are the essential elements, including gears, shafts, and bearings. These pieces facilitate movement and support the structure, ensuring stability under operational stress. The integration of high-quality materials enhances durability, reducing the risk of failure during use.

Gears play a crucial role in transmitting torque and controlling speed. Their design and arrangement determine the mechanical advantage and efficiency of the system. Similarly, shafts provide the necessary support for rotating parts, allowing for smooth motion and alignment. Bearings, on the other hand, minimize friction, enabling seamless operation while protecting against wear and tear.

Additionally, the incorporation of fasteners ensures that all components remain securely attached, promoting longevity and reliability. Regular inspection of these crucial elements is vital to maintaining the integrity of the assembly, preventing unexpected breakdowns and ensuring continued performance.

Power System and Associated Elements

The power system within this equipment plays a critical role in ensuring efficient operation and reliability. It encompasses various components that work together to deliver the necessary energy while maintaining optimal performance levels. Understanding these elements is essential for troubleshooting and enhancing the overall functionality of the device.

At the heart of the power infrastructure, several key components contribute to its effective operation:

Component Description Power Supply Unit Converts electrical energy from the source to usable levels for the system’s components. Voltage Regulator Maintains a constant voltage level to ensure stable operation of sensitive components. Capacitors Store and release electrical energy to smooth out fluctuations in voltage and provide stability. Connectors Facilitate electrical connections between various components, ensuring reliable power distribution. Fuses Protect the system from overcurrent situations by breaking the circuit when excessive current flows. Each of these elements is integral to the overall functionality of the power framework, and their proper maintenance is vital for the longevity and efficiency of the entire system.

Control Modules and Their Roles

Control units play a pivotal role in the functionality and efficiency of various systems. They serve as the brain, interpreting data and ensuring that different components work in harmony. By coordinating signals and commands, these units help maintain optimal performance and safety in numerous applications.

Key Functions of Control Units

- Data Processing: Control units receive inputs from sensors, process this information, and execute appropriate actions.

- Signal Coordination: They manage communication between various system elements, ensuring they operate smoothly together.

- Error Detection: Many units are equipped with diagnostic capabilities to identify and alert users to potential issues.

Types of Control Units

- Central Processing Units (CPUs): These are the main control units responsible for processing instructions and managing operations.

- Embedded Control Modules: Often found in specific devices, these modules perform dedicated tasks tailored to their function.

- Distributed Control Systems: In complex setups, multiple control units communicate with one another to enhance overall efficiency.

Material Composition of Core Components

The selection of materials for essential elements in various mechanical systems plays a crucial role in determining their overall performance and durability. Understanding the composition of these key components not only influences their efficiency but also impacts their longevity and reliability in operation.

Metals are frequently utilized due to their strength and resistance to wear. Common choices include steel, which offers high tensile strength, and aluminum, valued for its lightweight properties. Both materials are often treated or alloyed to enhance their characteristics, making them suitable for diverse applications.

In addition to metals, polymers are employed in areas where flexibility and resistance to corrosion are paramount. These synthetic compounds can be engineered to possess specific properties, such as heat resistance or electrical insulation, making them ideal for various components.

Furthermore, composite materials are increasingly utilized for their unique benefits, combining the strengths of different substances. This integration allows for the creation of lightweight yet robust parts, optimizing performance while minimizing overall mass.

Ultimately, the careful consideration of material choices in core elements directly contributes to the efficiency, safety, and functionality of the entire system.

Wiring Setup and Circuitry

Establishing an efficient wiring framework is crucial for ensuring optimal performance and reliability in any electronic assembly. A well-organized layout not only facilitates easier troubleshooting but also enhances the overall functionality of the device. In this section, we will explore essential components and techniques for effectively arranging connections and circuitry.

Key Components

- Power Supply: Provides the necessary voltage and current to the system.

- Connectors: Enable secure and efficient connections between different parts.

- Resistors: Regulate current flow to protect sensitive components.

- Capacitors: Store and release electrical energy as needed.

- Microcontrollers: Serve as the brain of the operation, controlling various functions.

Wiring Techniques

- Plan the Layout: Before beginning, sketch a blueprint of the circuit to visualize connections.

- Use Color-Coded Wires: This helps in identifying connections quickly and prevents mistakes.

- Keep Wires Organized: Utilize cable ties or channels to manage and secure wiring.

- Test Connections: After setup, verify each connection with a multimeter to ensure proper functionality.

By following these guidelines, users can create a robust wiring structure that not only improves the efficiency of their device but also prolongs its lifespan.

Maintenance Guide for Critical Parts

Ensuring the longevity and optimal performance of vital components requires regular upkeep and attention. This section provides valuable insights into the best practices for maintaining essential elements of your equipment, ultimately enhancing efficiency and preventing costly breakdowns.

Regular Inspections

Conducting frequent assessments is crucial for identifying potential issues before they escalate. Examine each component for signs of wear and tear, corrosion, or misalignment. Implementing a routine inspection schedule can help catch problems early, allowing for timely interventions.

Cleaning and Lubrication

Keeping components clean is essential for maintaining functionality. Accumulation of dirt and debris can impede performance and lead to failures. Regularly wipe down surfaces and ensure all moving parts are properly lubricated to reduce friction and wear. Utilizing the right cleaning agents and lubricants can significantly extend the life of these critical elements.

Common Replacement Parts and Availability

When it comes to maintaining and servicing machinery, understanding which components may require replacement is crucial. Identifying frequently needed elements helps ensure optimal performance and prolongs the life of the equipment. Below, we discuss commonly replaced components and their availability in the market.

Component Description Availability Motor Essential for powering various functions, the motor is a critical element that may wear out over time. Widely available at local retailers and online stores. Control Unit This component regulates the operation of the system, and replacement may be necessary if it becomes unresponsive. Can be sourced from specialty electronic suppliers and authorized dealers. Seals and Gaskets These parts prevent leaks and ensure proper sealing between components, often requiring regular replacement. Readily available through maintenance supply companies and hardware stores. Filter Filters maintain clean operation by removing contaminants, and should be checked and replaced periodically. Commonly stocked in automotive and appliance parts retailers. Belt Belts are integral for motion transfer within the system and may require replacement due to wear and tear. Accessible from various industrial suppliers and online platforms.