The intricate workings of electronic devices rely heavily on the precise arrangement of their internal elements. Grasping the layout of these components is essential for effective troubleshooting, maintenance, and enhancement of functionality. A clear representation of these arrangements aids both enthusiasts and professionals in navigating complex systems.

In this section, we will explore the various elements that constitute the assembly, highlighting their roles and interconnections. By understanding how each piece contributes to the overall operation, one can gain valuable insights into optimizing performance and ensuring longevity. This knowledge is crucial for anyone looking to deepen their understanding of electronic assemblies.

Additionally, familiarity with the configuration of these components can significantly enhance repair and upgrade processes. A comprehensive overview provides the groundwork for informed decision-making, empowering individuals to tackle challenges with confidence and skill.

Key Components Explained

Understanding the essential elements of a system is crucial for effective maintenance and troubleshooting. Each component plays a significant role in the overall functionality and performance, contributing to the seamless operation of the entire assembly. Grasping the purpose and interconnection of these parts allows users to identify potential issues and implement appropriate solutions.

Power Supply Unit: This element serves as the heart of the setup, providing the necessary energy to all other components. Its reliability ensures that the entire system functions optimally without interruptions.

Control Board: Acting as the brain, the control board processes signals and coordinates the actions of various parts. It interprets user inputs and translates them into commands for other components to follow.

Display Interface: This part is responsible for visual output, allowing users to monitor system status and performance. It communicates vital information through various indicators, making it easy to understand operational conditions.

Connectivity Modules: These components enable communication between different elements of the system, facilitating data exchange and ensuring synchronized operation. Their functionality is crucial for maintaining overall efficiency.

In summary, a comprehensive understanding of these key components empowers users to manage their systems more effectively, enhancing performance and prolonging the lifespan of the entire assembly.

Assembly Process Breakdown

This section provides an overview of the assembly procedure, detailing the essential steps required to achieve a successful final product. Each phase plays a crucial role in ensuring that all components fit together seamlessly, leading to optimal functionality and performance.

The assembly process can be categorized into several key stages:

- Preparation of Components:

- Gather all necessary materials and tools.

- Inspect each item for quality and accuracy.

- Initial Assembly:

- Begin with the main framework, ensuring stability.

- Attach smaller elements to the main structure, following the specified order.

- Connection of Systems:

- Integrate electrical and mechanical components.

- Ensure all connections are secure and functional.

- Final Adjustments:

- Test the assembled unit for operational efficiency.

- Make necessary tweaks to enhance performance.

- Quality Assurance:

- Conduct a thorough inspection of the completed assembly.

- Document any issues and rectify them before final approval.

By following these steps meticulously, the assembly process can be completed effectively, ensuring that the final product meets all necessary specifications and standards.

Understanding Wiring Connections

Effective comprehension of electrical linkages is essential for ensuring the proper functioning of electronic devices. A clear understanding of how different components interact through wiring can prevent issues during installation and maintenance. This section will explore the critical aspects of these connections, focusing on the types, configurations, and best practices for achieving reliable performance.

Types of Electrical Connections

Wiring configurations can vary significantly based on the application and design of the system. Below are some common types of electrical connections:

| Connection Type | Description |

|---|---|

| Soldered | Permanent connections made by melting solder to join wires and terminals. |

| Crimped | Connections created by compressing a metal connector onto the wire using a crimping tool. |

| Plug and Socket | Interchangeable connections allowing easy assembly and disassembly. |

| Twisted Pair | Wires twisted together to minimize electromagnetic interference, commonly used in data transmission. |

Best Practices for Wiring

To ensure longevity and safety in electrical systems, adhering to best practices when establishing wiring connections is crucial. Here are key recommendations:

- Always use the appropriate gauge of wire for the application to prevent overheating.

- Secure connections properly to minimize resistance and ensure reliable performance.

- Utilize heat-shrink tubing or electrical tape to insulate exposed areas and prevent short circuits.

- Regularly inspect connections for signs of wear or corrosion, replacing any damaged components promptly.

Maintenance Tips for Longevity

To ensure the extended lifespan of your equipment, regular upkeep is essential. Implementing effective maintenance practices not only enhances performance but also minimizes the likelihood of unexpected failures. Adopting a proactive approach can significantly contribute to the durability and reliability of your devices.

Routine Inspections: Conduct periodic assessments to identify any signs of wear or potential issues. This practice allows for early detection and timely intervention, preventing more significant problems down the line.

Proper Cleaning: Keeping your devices clean is crucial for optimal functionality. Dust and debris can accumulate over time, leading to overheating and reduced efficiency. Regularly cleaning surfaces and internal components helps maintain performance.

Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedules and procedures outlined by the manufacturer. This ensures that your equipment receives the necessary attention and care it requires for optimal operation.

Utilize Quality Parts: When replacements are needed, opt for high-quality components. Using reliable parts not only enhances performance but also extends the overall life of your equipment.

Monitor Operating Conditions: Keep an eye on environmental factors that may affect performance, such as temperature and humidity. Operating equipment within recommended conditions can prevent undue stress and wear.

By implementing these practices, you can significantly increase the longevity of your equipment, ensuring that it remains functional and efficient for years to come.

Common Issues and Solutions

In any mechanical system, certain challenges may arise that hinder optimal performance. Understanding these common problems and their resolutions is crucial for maintaining efficiency and longevity. This section explores typical complications encountered and offers practical solutions to address them effectively.

Frequent Challenges

- Power Failures: Interruption in electrical supply can lead to system malfunctions.

- Overheating: Excessive heat build-up may cause components to fail.

- Connection Issues: Loose or damaged connectors can disrupt communication between parts.

- Wear and Tear: Regular use can lead to degradation of critical components.

Effective Solutions

- Ensure Proper Power Supply: Regularly check electrical connections and use surge protectors.

- Implement Cooling Measures: Install cooling fans or heat sinks to manage temperatures.

- Inspect and Replace Connectors: Routinely examine connections and replace any faulty parts.

- Perform Regular Maintenance: Schedule inspections to identify and address wear early.

Compatibility with Other Models

Understanding the interchangeability of components across various models is essential for ensuring optimal performance and functionality. This section delves into how certain assemblies can be utilized in conjunction with other devices, enhancing versatility and user experience.

Key Features of Compatibility

Several elements play a crucial role in determining whether a component can be effectively paired with other systems. These features include physical dimensions, electrical specifications, and overall design. By evaluating these attributes, users can make informed decisions regarding compatibility.

Comparison of Compatible Systems

| Model | Compatibility Status | Notes |

|---|---|---|

| Model A | Fully Compatible | All specifications match perfectly. |

| Model B | Partially Compatible | Requires slight modifications for optimal use. |

| Model C | Not Compatible | Significant differences in electrical specifications. |

Tools Needed for Repair

When embarking on a repair project, having the right equipment is essential for achieving optimal results. Utilizing the appropriate tools not only enhances efficiency but also ensures safety throughout the process. Below is a list of essential implements that can facilitate successful repairs.

Essential Hand Tools

- Screwdrivers: Various sizes and types, including Phillips and flathead.

- Wrenches: Adjustable and socket varieties for different bolt sizes.

- Pliers: Needle-nose and standard for gripping and twisting.

- Utility Knife: For cutting materials as needed.

Specialized Equipment

- Multimeter: To measure voltage, current, and resistance.

- Soldering Iron: For making electrical connections.

- Heat Gun: Useful for shrinking tubing or softening adhesives.

- Safety Gear: Goggles and gloves to protect during the repair process.

Safety Precautions to Consider

When working with complex systems, it is essential to prioritize safety to prevent accidents and ensure a secure environment. Understanding the various risks associated with handling intricate components can significantly minimize potential hazards. Proper awareness and adherence to safety measures not only protect individuals but also extend the longevity of the equipment involved.

Proper Handling Techniques

Utilizing appropriate handling techniques is crucial when managing sensitive elements. Always wear suitable protective gear, such as gloves and goggles, to shield yourself from any potential harm. Ensure that your workspace is well-organized, and avoid overcrowding to reduce the risk of accidents. Additionally, maintain a clear understanding of each component’s function and placement to prevent mistakes during assembly or disassembly.

Electrical Safety Considerations

Electrical components can pose significant risks if not handled properly. Always disconnect power sources before starting any work to prevent electric shock. Be mindful of static electricity, as it can damage sensitive electronic parts. Using anti-static wrist straps and mats can help mitigate this risk. Regularly inspect tools and equipment for wear and tear, ensuring they are in optimal condition before use.

Disassembly Instructions for Beginners

Understanding how to carefully disassemble electronic devices can be an essential skill for anyone interested in repair or modification. This section aims to provide a straightforward guide for newcomers to navigate the process of taking apart various components effectively and safely.

Before starting, ensure that you have a clean workspace and the necessary tools, such as screwdrivers, pliers, and a container for small parts. Always disconnect the device from any power source to avoid electrical hazards. Begin by examining the exterior for screws or clips that may need to be removed. Take note of the order and type of each fastener as you work, as this will aid in reassembly.

As you proceed, gently pry apart sections without applying excessive force, as this can damage internal components. Use appropriate tools designed for disassembly to minimize the risk of scratches or breaks. If you encounter resistance, double-check for any hidden fasteners or locks that may still be securing the pieces together.

Documenting the process with notes or pictures can be incredibly beneficial, especially for beginners. This practice not only helps in reassembly but also reinforces learning about the structure and function of the device. Once all parts are successfully separated, take a moment to assess and clean them before any repair or upgrade tasks.

Following these simple steps can make the disassembly process more manageable and enjoyable, paving the way for a deeper understanding of how electronic devices operate.

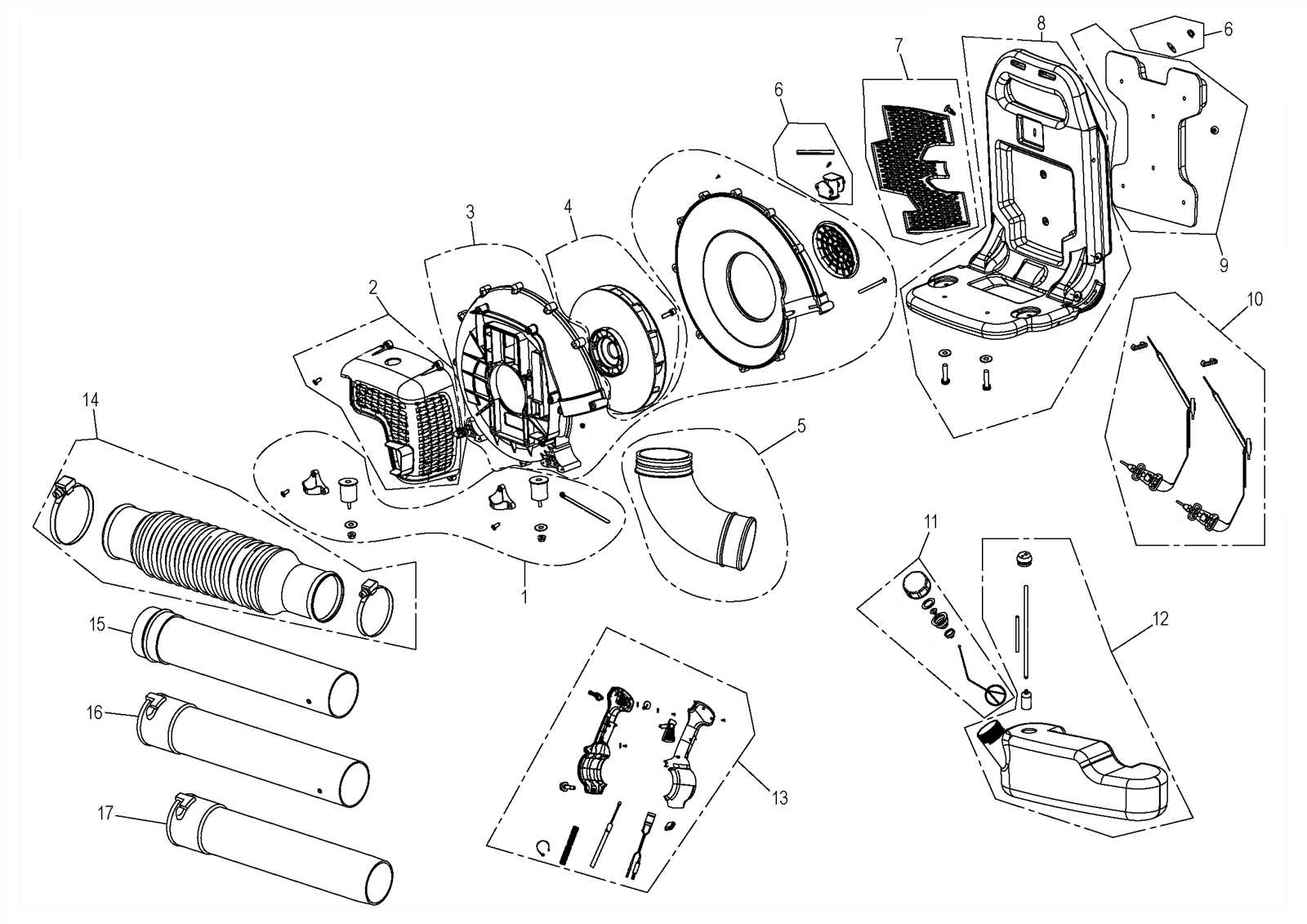

How to Interpret Diagrams

Understanding schematic representations is essential for anyone working with technical systems. These visual aids provide a structured way to convey complex information, making it easier to identify components, their relationships, and functionalities. By familiarizing yourself with the conventions used in these illustrations, you can enhance your ability to troubleshoot and optimize various systems effectively.

To successfully decode these visual guides, one must pay attention to several key aspects:

| Element | Description |

|---|---|

| Symbols | Each representation employs specific icons to denote different components, such as resistors, capacitors, and connectors. |

| Connections | Lines illustrate how elements are interconnected, indicating the flow of signals or power. |

| Labels | Annotations and identifiers provide crucial information about each element’s function and specifications. |

| Scale | Understanding the scale helps in comprehending the physical dimensions and relationships between components. |

Frequently Asked Questions

This section addresses common inquiries regarding components and their functionalities, providing insights that may enhance understanding. Here, we clarify prevalent concerns that users often encounter, facilitating a smoother experience with the equipment.

What should I do if I cannot identify a component?

If you find it challenging to recognize a specific element, consult the relevant documentation or resources that accompany your device. These materials typically include detailed descriptions and illustrations that can aid in identification. Additionally, online forums and communities can offer valuable insights and assistance from experienced users.

How can I ensure proper installation of components?

To guarantee accurate installation, follow the provided guidelines meticulously. It is advisable to verify compatibility with your model and utilize appropriate tools. If uncertainties arise, seeking professional assistance can prevent potential issues and ensure optimal performance.

Resources for Further Learning

Expanding your knowledge on intricate components and their functionalities can significantly enhance your understanding of complex systems. There are various avenues to explore, from online platforms to specialized literature, which can provide valuable insights into related subjects and improve your practical skills.

Online Courses and Tutorials

Numerous educational websites offer comprehensive courses and tutorials tailored to various expertise levels. Platforms like Coursera and Udemy feature classes focusing on technical skills, enabling learners to grasp essential concepts and applications through structured lessons.

Books and Manuals

Diving into well-reviewed books and manuals can offer in-depth knowledge and practical guidance. Look for titles that cover electronic systems, mechanical design, and troubleshooting techniques to broaden your understanding and apply your skills effectively in real-world situations.