In the realm of sanitation technology, various elements work in unison to ensure efficient water management and waste disposal. These intricate systems are designed to optimize functionality while maintaining user comfort and hygiene. By examining the individual components, one can gain insights into their roles and contributions.

Each component serves a specific purpose, enhancing the overall efficiency of the mechanism. Recognizing how these elements interact can lead to better maintenance and troubleshooting, ensuring longevity and reliability in daily use. Additionally, understanding the configuration aids in informed decision-making during upgrades or repairs.

As we delve deeper into this subject, we will explore the various elements that contribute to effective operation. This knowledge not only empowers users but also fosters an appreciation for the engineering behind everyday conveniences.

Understanding Valve Functionality

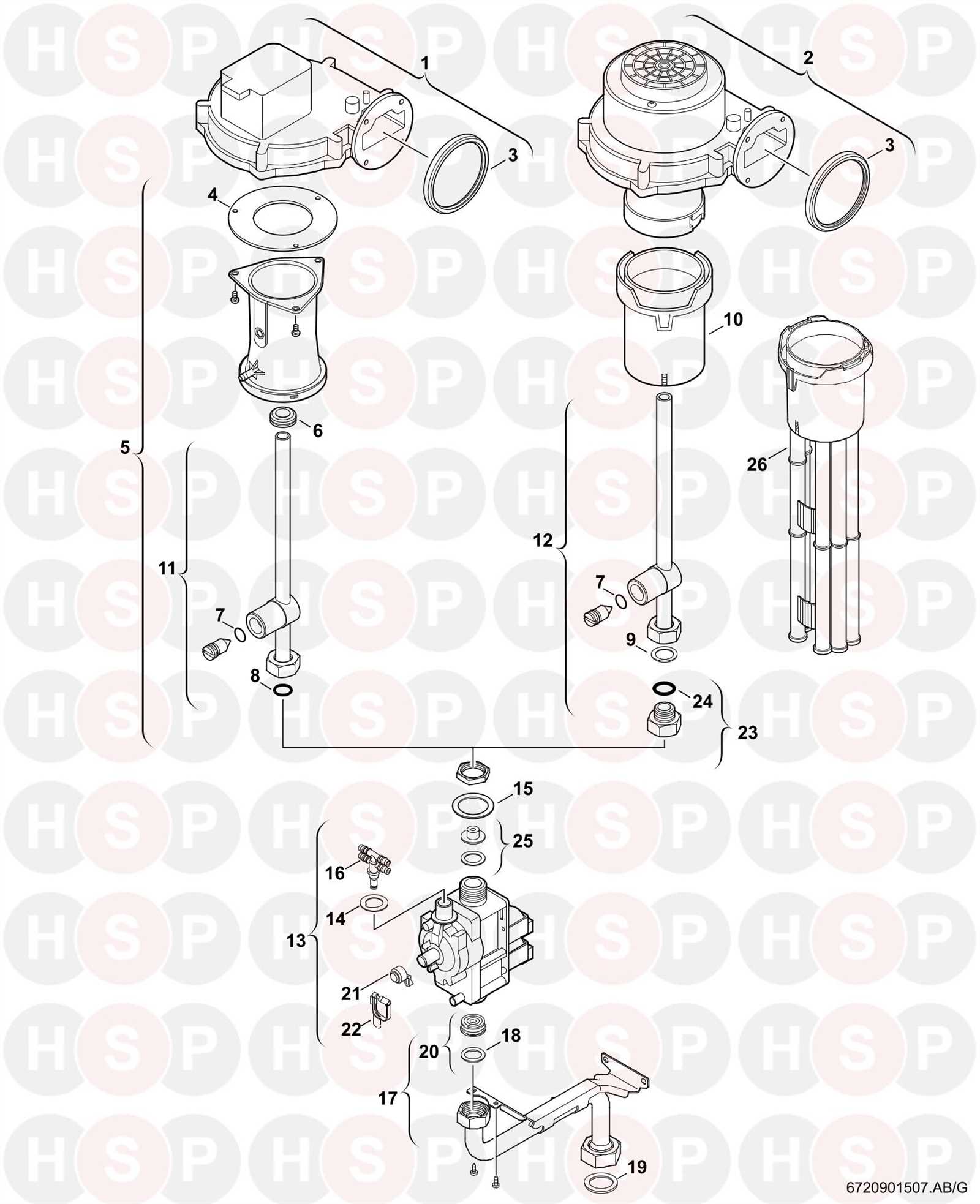

The operation of flow control mechanisms is crucial for ensuring efficient management of liquids and gases within various systems. These mechanisms play a significant role in regulating the movement and pressure of fluids, making them essential components in plumbing and industrial applications.

Key Components of Flow Control Mechanisms

Each flow control mechanism consists of several essential elements that work together to achieve desired outcomes. Understanding these components can enhance efficiency and facilitate troubleshooting when issues arise.

| Component | Function |

|---|---|

| Body | Holds internal parts and connects to plumbing |

| Actuator | Controls the movement for opening or closing |

| Seal | Prevents leaks and maintains pressure |

| Spring | Provides tension to return to a closed position |

Operational Mechanisms

The functionality of these devices can be based on various principles, including pressure differentials and manual control. By understanding the operational mechanisms, users can effectively manage and optimize fluid flow.

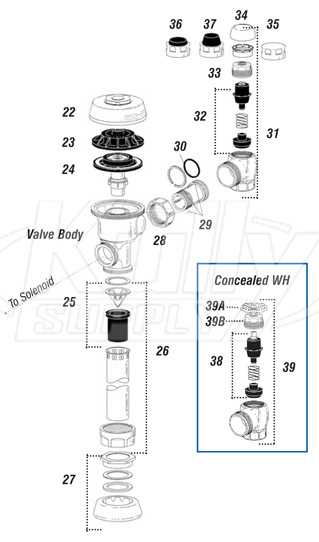

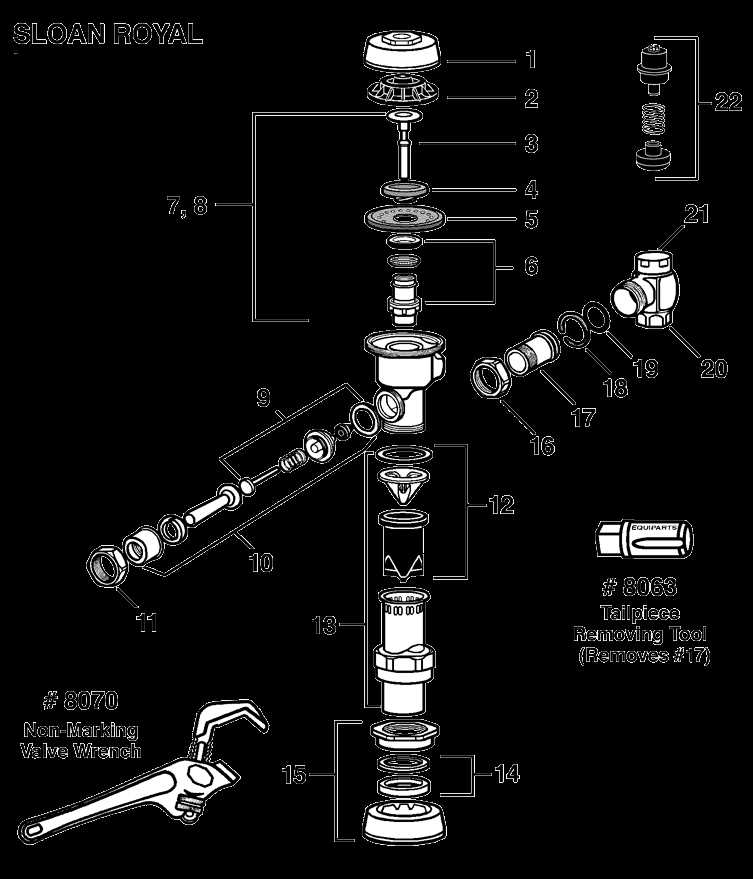

Key Parts of Sloan Valves

The essential components of these fixtures play a crucial role in their functionality and efficiency. Understanding these elements allows for better maintenance and troubleshooting, ensuring optimal performance over time.

1. Actuator: This mechanism initiates the flushing process, responding to user interaction. Its design is critical for smooth operation.

2. Diaphragm: Acting as a seal, this element controls water flow, ensuring precise delivery during each cycle. Its durability is vital for longevity.

3. Control Stop: This component regulates the amount of water used, contributing to water conservation efforts while maintaining performance standards.

4. Supply Connection: This part links the fixture to the water source, facilitating efficient water delivery necessary for proper operation.

5. Trim Kit: This assembly includes various small parts that enhance functionality and user experience, often contributing to aesthetic considerations as well.

Common Issues with Valve Components

Various complications can arise with components used in plumbing systems. Understanding these challenges can lead to better maintenance and efficiency.

- Wear and Tear: Components may degrade over time, leading to leaks or malfunctions.

- Corrosion: Exposure to moisture can cause parts to rust, affecting their functionality.

- Clogging: Debris can obstruct flow, resulting in reduced performance.

- Misalignment: Improper installation can lead to operational issues.

- Seal Failures: Gaskets and seals may wear out, causing leaks.

Addressing these issues promptly ensures optimal performance and extends the lifespan of the system.

Maintenance Tips for Sloan Valves

Regular upkeep is essential for ensuring the optimal performance of these devices. Proper maintenance not only extends their lifespan but also enhances their efficiency, preventing common issues that may arise over time.

1. Routine Inspections: Conduct frequent checks to identify any signs of wear or malfunction. Look for leaks, unusual noises, or inconsistent operation, as these can indicate underlying problems.

2. Cleaning Components: Regularly clean the various elements to prevent buildup that could hinder functionality. Use appropriate cleaning agents that won’t damage materials.

3. Replace Worn Parts: Monitor parts for signs of degradation and replace them as necessary. This proactive approach helps maintain seamless operation and reduces the risk of breakdowns.

4. Check Seals and Gaskets: Ensure that all seals and gaskets are intact and functioning properly. Damaged seals can lead to leaks and inefficiencies, so it’s vital to address any issues promptly.

5. Consult Professional Services: For complex repairs or if you’re uncertain about maintenance tasks, consider seeking help from experienced professionals. Their expertise can save time and ensure that repairs are done correctly.

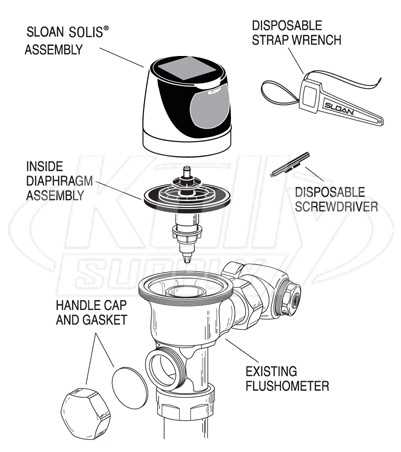

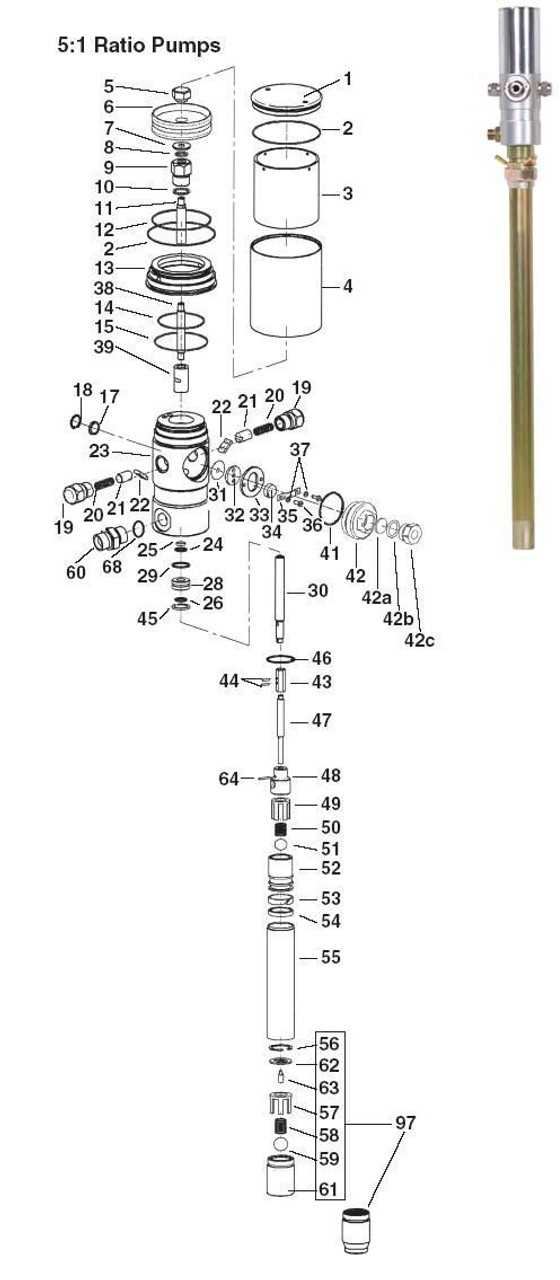

Identifying Components in Diagrams

Understanding the various elements in technical illustrations is crucial for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall functionality of the system. By recognizing these elements, one can ensure proper assembly and identify potential issues quickly.

Common Elements to Recognize

Typically, illustrations include symbols that represent different mechanisms, such as switches, connectors, and sensors. Familiarity with these symbols can greatly enhance one’s ability to interpret the visuals accurately, making it easier to navigate complex setups.

Tips for Effective Identification

When analyzing technical visuals, focus on the legend or key provided. This will help clarify the meaning behind each symbol. Additionally, cross-referencing with manuals or guides can reinforce understanding and aid in recognizing any unfamiliar components.

Replacement Procedures for Valve Parts

Understanding the process of swapping out components is essential for maintaining the functionality of your plumbing systems. Proper replacement ensures efficient operation and prevents further issues down the line.

1. Gather Necessary Tools

Before starting the replacement, ensure you have all required tools at hand. Common tools include wrenches, screwdrivers, and replacement components specific to your system.

2. Shut Off Water Supply

Begin by turning off the water supply to prevent any leaks or spills during the process. This step is crucial for avoiding unnecessary mess and potential damage.

3. Remove the Old Component

Carefully detach the old component using your tools. Take note of how it is installed to aid in correctly positioning the new part.

4. Install the New Component

Position the new component in the same manner as the old one. Ensure all connections are secure to prevent leaks.

5. Restore Water Supply

Once everything is in place, restore the water supply. Check for any leaks and ensure everything is functioning properly before concluding the process.

Tools Required for Repair Tasks

When undertaking maintenance or fixing mechanisms, having the right instruments is crucial for achieving efficient results. The necessary tools ensure that tasks are executed smoothly, minimizing potential complications during the process.

Basic equipment typically includes wrenches, screwdrivers, and pliers, which are essential for loosening or tightening components. Additionally, specialized tools such as pipe cutters and seals may be needed for more complex repairs, ensuring that all connections are secure and functioning properly.

It’s also wise to have safety gear on hand, such as gloves and goggles, to protect oneself while performing repairs. Overall, equipping oneself with the appropriate tools not only facilitates the repair process but also enhances safety and effectiveness.

Safety Precautions When Servicing

Ensuring safety during maintenance is crucial for both the technician and the equipment involved. Proper precautions minimize risks and promote an efficient working environment. Adhering to safety guidelines helps prevent accidents and ensures effective operation.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks. This gear protects against potential hazards such as sharp components and harmful substances. Prioritize your safety to maintain a secure workspace.

Work Area Considerations

Keep the service area clean and organized. Remove unnecessary tools and materials to avoid tripping hazards. Adequate lighting is essential for visibility, allowing for detailed inspection and maintenance. A clutter-free environment contributes significantly to overall safety.

Benefits of Regular Maintenance

Conducting consistent upkeep on your fixtures and systems is essential for ensuring optimal performance and longevity. Regular care not only enhances functionality but also prevents unexpected breakdowns that can lead to costly repairs.

Improved Efficiency: When components are properly maintained, they operate more effectively. This leads to reduced energy consumption and lower utility bills, benefiting both the environment and your finances.

Extended Lifespan: Just like any machinery, routine maintenance can significantly prolong the life of your installations. Addressing minor issues promptly helps avoid major malfunctions that could necessitate complete replacements.

Increased Safety: Regular checks help identify potential hazards before they escalate. This proactive approach ensures that everything is functioning as intended, providing a safer environment for users.

Cost Savings: Investing time and resources into regular upkeep can save substantial amounts in the long run. Preventive measures reduce the likelihood of emergency repairs and minimize downtime, keeping operations smooth and uninterrupted.

Frequently Asked Questions About Valves

This section addresses common inquiries regarding mechanical flow control devices, their functionality, and maintenance practices. Understanding these components is essential for effective usage and troubleshooting.

What are the main types of flow control devices?

There are several varieties designed for specific applications, including but not limited to: globe, ball, gate, and check mechanisms. Each type has unique characteristics that influence its performance in various situations.

How can I maintain my flow control device?

Regular maintenance involves inspecting for leaks, ensuring seals are intact, and cleaning any build-up that may affect operation. Proper upkeep extends the lifespan of these components and ensures optimal performance.

| Type | Function | Common Use |

|---|---|---|

| Ball | On/off control | Water systems |

| Gate | Full flow control | Oil pipelines |

| Globe | Flow regulation | Steam applications |

| Check | Prevent backflow | Heating systems |

Where to Find Replacement Parts

Finding the right components for your plumbing fixtures can be a straightforward process if you know where to look. Numerous resources are available, making it easier to acquire the necessary items without much hassle.

Online Retailers

Many online stores specialize in plumbing supplies. Websites dedicated to home improvement often have extensive catalogs. Ensure you check customer reviews and product descriptions for quality assurance.

Local Hardware Stores

Visiting nearby hardware stores can provide immediate access to needed components. Knowledgeable staff can assist in identifying the correct items, making your shopping experience efficient.

Tip: Always have the old component on hand or a clear description of what you need to ensure compatibility.