The intricacies of mechanical systems play a vital role in enhancing the efficiency of various operations. A thorough understanding of these elements is essential for anyone looking to optimize functionality and ensure longevity. By breaking down each component, users can gain insight into how these systems work and the significance of each element in the overall mechanism.

In this section, we will explore the different elements that contribute to the operation of these systems. Each piece has a specific function, and recognizing these roles will help in troubleshooting and maintenance. Familiarity with the individual components enables users to identify issues swiftly and implement effective solutions.

Moreover, a comprehensive grasp of these components can lead to improved performance and reliability. Whether for personal use or professional applications, understanding the mechanics involved can empower users to make informed decisions regarding repairs and upgrades. This knowledge fosters a deeper appreciation for the engineering behind these essential tools.

Understanding Lewmar Winch Functionality

To fully appreciate the operation of a mechanical device used for handling lines and sails, it is essential to grasp its fundamental principles. This type of mechanism efficiently manages the tension and movement of ropes, enabling smooth adjustments and control on the water.

The core functionality revolves around a combination of gears and levers that work in harmony. By applying force to the handle or motor, the internal system converts this effort into rotational movement, allowing the line to be wound or unwound as needed. This transformation of energy is critical for effective sailing maneuvers.

Furthermore, various components play a significant role in ensuring reliability and ease of use. These elements include the drum, which stores the rope, and the clutch, which allows for seamless engagement and disengagement. Understanding how each part interacts contributes to better maintenance and optimal performance.

In summary, a clear comprehension of this mechanical system’s operation enhances both its functionality and the user experience, making it a vital aspect for any sailing enthusiast.

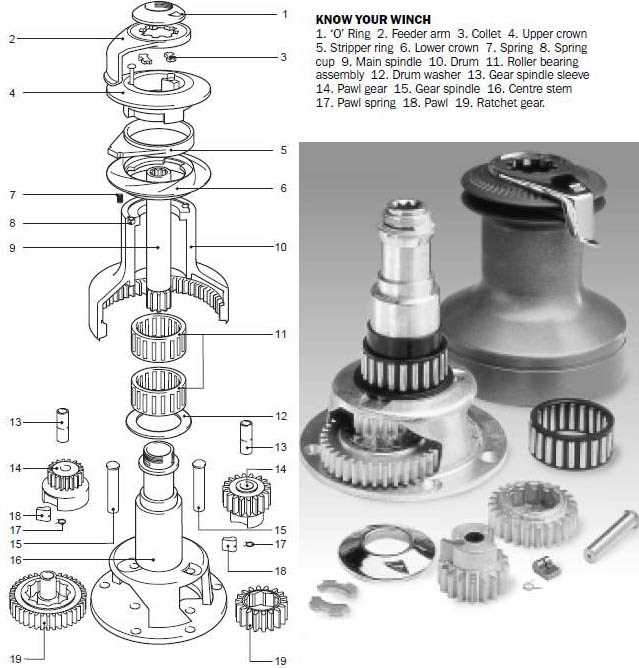

Essential Components of Lewmar Winches

Understanding the fundamental elements of these mechanisms is crucial for both maintenance and performance optimization. Each component plays a vital role in ensuring smooth operation and efficiency. Below, we explore the key components that contribute to the overall functionality.

Main Elements

- Drum: This is where the line is wound and stored. Its design affects the capacity and the type of line that can be used.

- Gear System: The arrangement of gears determines the mechanical advantage, allowing for easier operation with heavy loads.

- Brake Mechanism: This feature secures the line when tension is applied, preventing slippage and enhancing control.

- Motor: Powering the system, the motor can be manual or electric, influencing speed and ease of use.

Additional Components

- Handle: Essential for manual operation, providing the user with leverage to operate the device efficiently.

- Base Plate: This supports the entire assembly, ensuring stability during operation.

- Clutch: Allows the user to disengage the drum from the drive system, facilitating easier line handling.

- Sheaves: These guide the line and help manage the direction of the load, reducing wear on the line.

Each of these components contributes to the reliable performance of the device, making it important to understand their roles and maintenance requirements.

Types of Lewmar Winch Models

When exploring the various options available for sailing enthusiasts, it’s essential to understand the distinct categories of mechanical devices designed to assist with line handling. Each model is tailored to specific requirements and applications, offering unique features that enhance functionality and performance on the water.

The diverse range includes models suitable for different vessel sizes, from smaller crafts to larger yachts, ensuring that sailors can select the most appropriate mechanism for their needs. Additionally, these devices can vary in operation type, such as manual or electric, each providing its own advantages in terms of ease of use and efficiency.

Another important aspect is the load capacity, which determines how much weight each device can handle effectively. Higher capacity models are ideal for those engaging in more demanding sailing conditions, while lighter versions cater to recreational use. Understanding these differences helps sailors make informed decisions based on their specific sailing activities and preferences.

Maintenance Tips for Winch Longevity

Ensuring the durability and efficiency of your marine equipment requires regular care and attention. Proper upkeep not only enhances performance but also extends the lifespan of essential components. By following some straightforward maintenance practices, you can avoid costly repairs and ensure that your equipment operates smoothly for years to come.

Regular Cleaning

Keeping your equipment clean is crucial to preventing the buildup of dirt and salt, which can lead to corrosion and mechanical failures. After each use, rinse the components with fresh water to eliminate any residues. For deeper cleaning, consider using mild soap and a soft brush to remove stubborn grime, ensuring that you reach all crevices.

Lubrication and Inspection

Routine lubrication is vital for maintaining smooth operation. Apply appropriate grease or oil to moving parts according to the manufacturer’s guidelines. Additionally, conduct periodic inspections to identify signs of wear or damage. Pay special attention to seals and gears, replacing any compromised components promptly to prevent further issues.

Common Issues with Winch Components

Understanding frequent challenges associated with lifting mechanisms is essential for maintaining their functionality and performance. Various factors can contribute to these complications, affecting both efficiency and safety. By identifying these issues early, operators can ensure smoother operations and prolong the lifespan of their equipment.

Wear and Tear

Degradation of components is a common concern, often resulting from prolonged use or exposure to harsh conditions. Friction and environmental elements can lead to cracks, rust, or overall weakness in materials. Regular inspection and timely replacements can help mitigate these problems, ensuring optimal performance.

Misalignment

Improper alignment of gears and moving parts can hinder the operation of lifting systems. This misconfiguration can cause increased strain on components, leading to premature failure. Ensuring that all parts are correctly positioned and securely fastened is vital for maintaining the integrity and reliability of the mechanism.

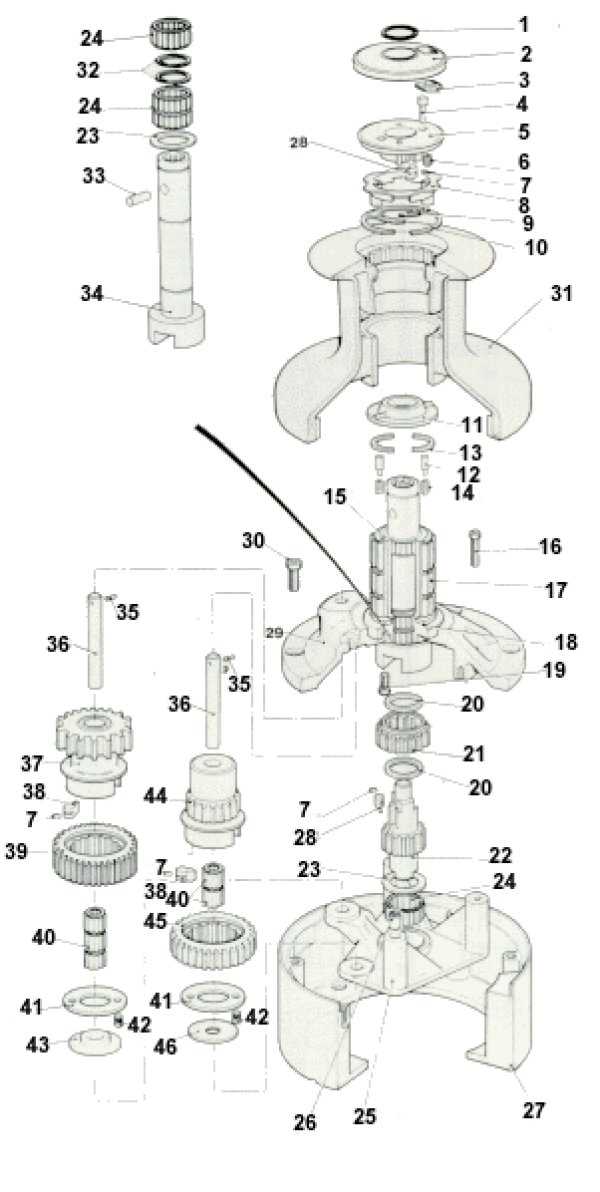

Identifying Winch Components for Repair

Understanding the individual elements of a mechanical hoisting device is crucial for effective maintenance and troubleshooting. Each component plays a vital role in the overall function and performance of the assembly, making it essential to recognize their characteristics and relationships.

First and foremost, familiarize yourself with the main functional units, such as the drive mechanism, gearing system, and control elements. These segments work in unison to ensure smooth operation. Take note of the various shapes, sizes, and materials that characterize these components, as they can indicate their specific purpose.

Additionally, pay attention to the auxiliary parts that support the primary function, including fasteners, bearings, and seals. Identifying wear and tear in these areas can significantly impact the efficiency of the entire mechanism. Inspecting each piece thoroughly allows for timely replacements and adjustments, prolonging the life of the device.

Finally, keep a detailed record of any observations and discrepancies found during your examination. This practice not only aids in organizing repair efforts but also enhances understanding for future maintenance tasks. Through careful analysis, you can ensure the reliable operation of your equipment for years to come.

Choosing the Right Winch Accessories

Selecting the appropriate accessories for your equipment is crucial for optimal performance and safety. Various components enhance the efficiency of your system, ensuring a seamless operation while you are engaged in outdoor activities. Understanding the different types of accessories available can help you make informed decisions tailored to your needs.

Essential Components

When considering which accessories to invest in, it’s important to identify the essentials that will complement your setup. Factors such as durability, compatibility, and intended usage play a significant role in your choices. Here are some key accessories you might consider:

| Accessory | Description | Benefits |

|---|---|---|

| Sheaves | These pulleys guide the line and reduce friction. | Improves efficiency and extends line life. |

| Blocks | Used to change the direction of the line for easier handling. | Increases control and reduces effort. |

| Lines | Strong cords that connect and secure your gear. | Ensures reliability and strength during use. |

Factors to Consider

To ensure you select the right accessories, consider the following factors:

- Compatibility: Ensure the components work well with your existing setup.

- Material: Choose high-quality materials that can withstand various environmental conditions.

- Purpose: Identify your specific needs based on the activities you plan to undertake.

Safety Practices for Winch Use

Ensuring safe operation during lifting and lowering activities is crucial for avoiding accidents and injuries. Implementing effective safety measures can significantly enhance the experience for everyone involved, promoting a secure working environment. Familiarizing oneself with best practices is the first step toward achieving optimal safety when handling equipment for hoisting and hauling tasks.

Here are some essential guidelines to consider:

| Practice | Description |

|---|---|

| Regular Inspection | Perform thorough checks of all equipment before use, looking for signs of wear or damage. |

| Proper Training | Ensure all operators are adequately trained in equipment handling and safety protocols. |

| Use Personal Protective Equipment (PPE) | Wear appropriate safety gear, such as gloves, helmets, and steel-toed boots, during operations. |

| Clear Area | Maintain a safe workspace by keeping the area free from obstacles and bystanders. |

| Load Limits | Adhere to the manufacturer’s specifications regarding weight limits to prevent equipment failure. |

| Communication | Establish clear signals or verbal cues among team members to coordinate efforts effectively. |

By adhering to these guidelines, individuals can help ensure a safer environment while using equipment designed for lifting and hauling tasks.

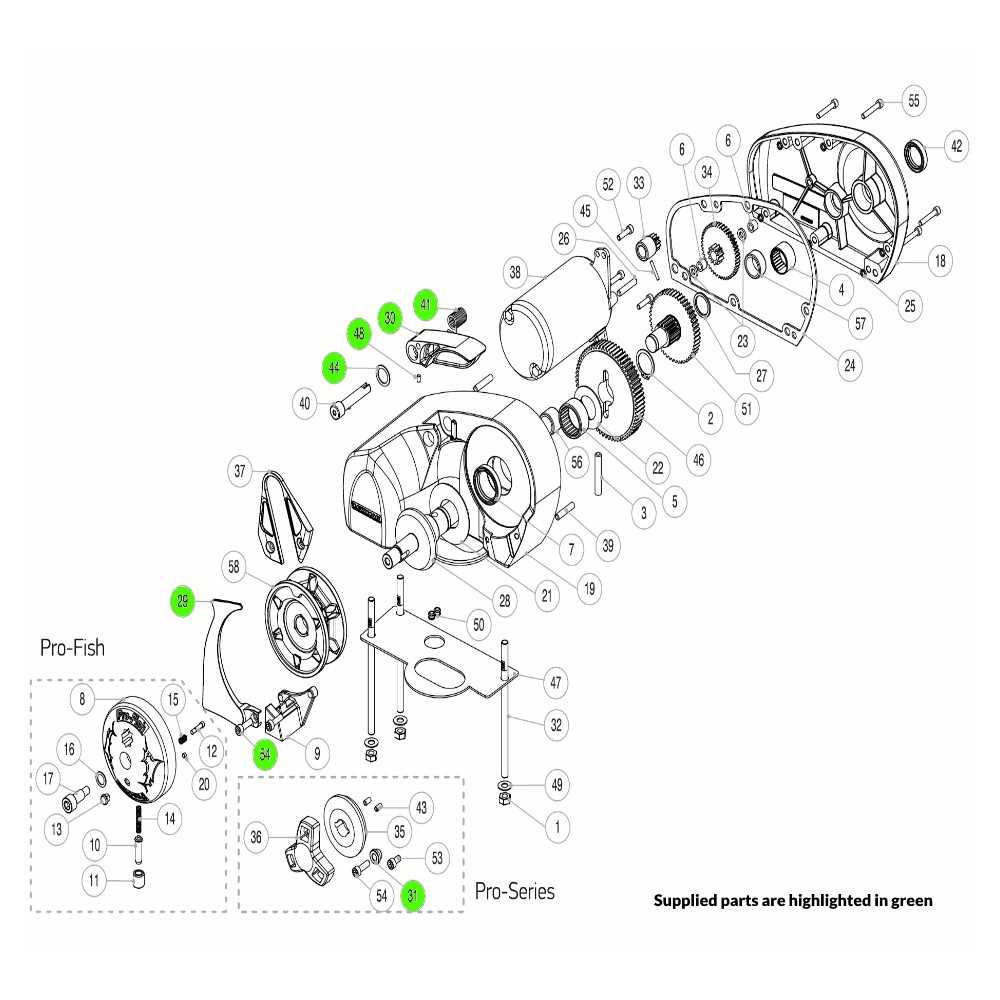

Upgrading Your Lewmar Winch System

Enhancing your mechanical hoisting system can significantly improve performance and efficiency, making your sailing experience more enjoyable. By carefully selecting the right enhancements, you can optimize functionality and ensure that your equipment operates smoothly under various conditions.

Assessing Your Current Setup

Before embarking on any upgrades, it is essential to evaluate your existing arrangement. Take note of the current components and their condition. This assessment will help you identify which elements may require replacement or enhancement to achieve your desired performance.

Choosing Compatible Enhancements

When considering upgrades, focus on components that align with your specific requirements. Look for items that offer improved durability and efficiency. Investing in high-quality replacements can lead to a more reliable system that withstands the rigors of the marine environment.

Remember to consult with experts or experienced sailors to gather insights on the most effective upgrades for your particular setup. Each improvement contributes to a more enjoyable and efficient sailing experience.

Where to Find Replacement Parts

Locating suitable components for your marine equipment can be crucial for maintaining its performance and ensuring safety. Various resources are available for acquiring high-quality replacements, whether for routine maintenance or urgent repairs. Exploring these options will help you find the right items to keep your apparatus in optimal condition.

Authorized Dealers

One of the most reliable sources for obtaining components is through authorized retailers. These vendors often stock genuine replacements and can provide expert advice on compatibility and installation. Additionally, they may offer warranties on the products, ensuring peace of mind with your purchase.

Online Marketplaces

The internet has revolutionized the way we shop for components, offering a plethora of online platforms where you can find a vast selection of options. Websites specializing in marine equipment often feature competitive pricing and customer reviews, helping you make informed decisions. Just ensure to check the seller’s reputation and return policy before finalizing your order.