When maintaining high-performance cleaning equipment, grasping the intricate layout of its components is essential. A thorough comprehension of how each piece fits together can significantly enhance both functionality and longevity. By familiarizing yourself with the inner workings, you empower yourself to troubleshoot effectively and optimize usage.

To maximize efficiency, it’s crucial to identify each element’s role within the system. Understanding the various sections allows users to pinpoint issues swiftly, facilitating timely repairs. This knowledge not only saves time but also ensures that the equipment operates at its peak performance.

In this guide, we will delve into the essential elements that comprise your cleaning device. With the ultimate goal of enhancing your cleaning experience, we aim to provide clear insights into the mechanical framework that supports effective operation. Whether you’re a novice or a seasoned user, this information will prove invaluable.

Karcher K2000 Overview

This section provides an insightful look into a high-performance cleaning device, designed to tackle a variety of tasks with ease and efficiency. The innovative technology incorporated into its design ensures thorough cleaning while maintaining user-friendly features that enhance the overall experience.

Features and Benefits

Equipped with a powerful motor, this unit delivers impressive cleaning capabilities, making it suitable for both residential and commercial use. The lightweight and compact structure allows for effortless maneuverability, ensuring that every nook and cranny can be reached without hassle. Additional attachments further extend its versatility, catering to diverse cleaning needs, from patios to vehicles.

Maintenance and Durability

Constructed with robust materials, this cleaning solution promises longevity and reliable performance. Regular upkeep is straightforward, with easy access to essential components. Users can expect not only efficiency in cleaning but also a long-lasting investment that withstands the rigors of frequent use. Attention to detail in design ensures that maintenance is minimal, allowing users to focus more on their tasks rather than repairs.

Key Features of Karcher K2000

This section explores the essential attributes of a leading cleaning device designed for efficiency and convenience. With a focus on user-friendly operation and effective cleaning performance, this model stands out in its category.

Power and Performance

- Robust motor for high-pressure output

- Effective in removing stubborn dirt and grime

- Energy-efficient design for reduced consumption

User Convenience

- Lightweight and portable for easy maneuverability

- Intuitive controls for effortless operation

- Versatile attachments for various cleaning tasks

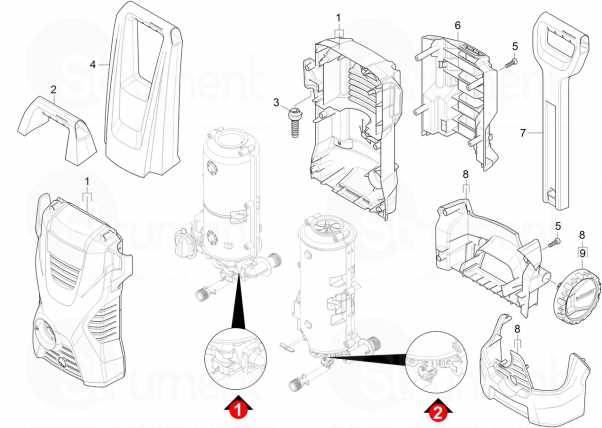

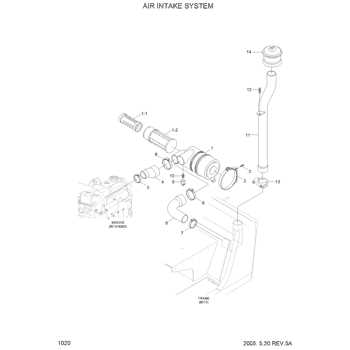

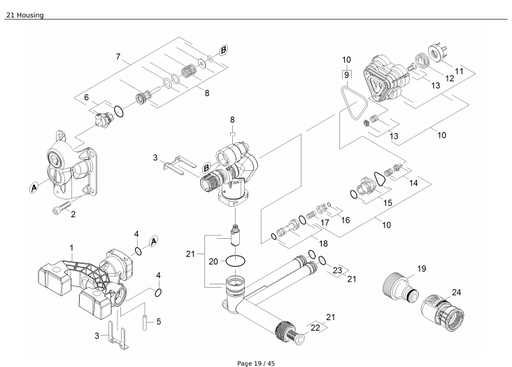

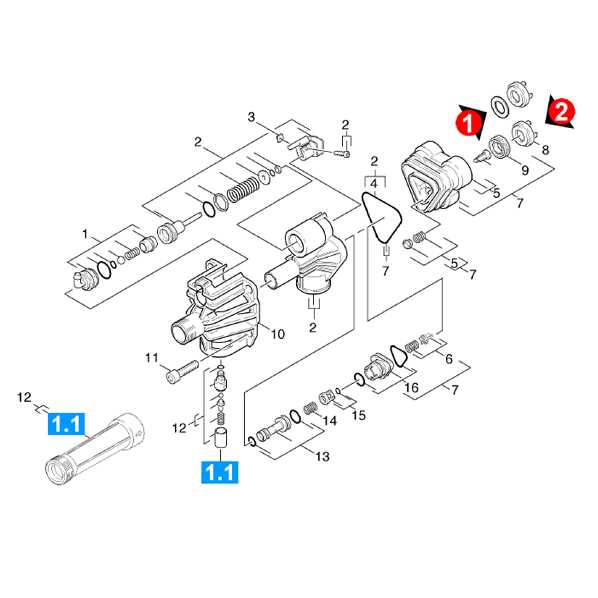

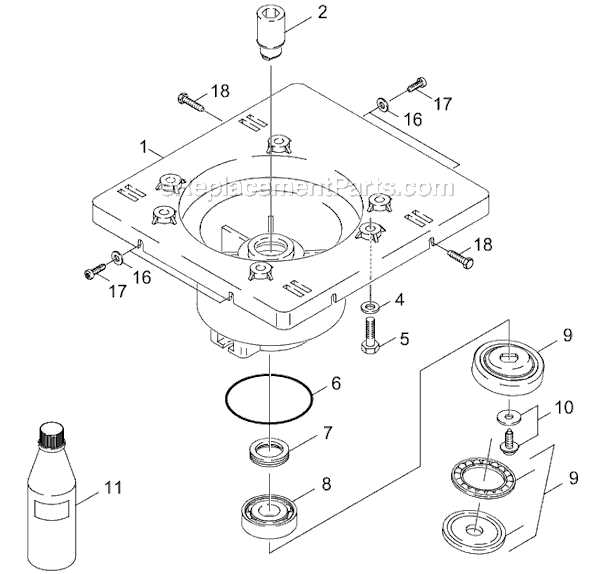

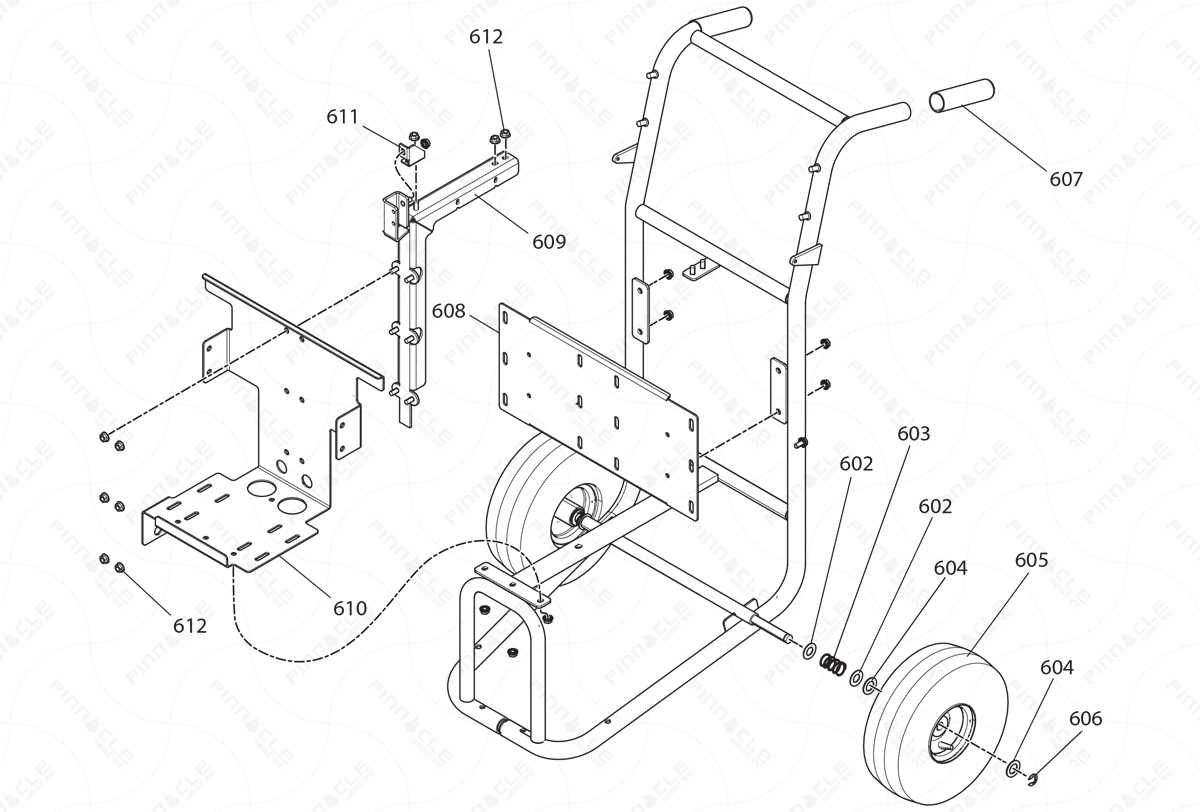

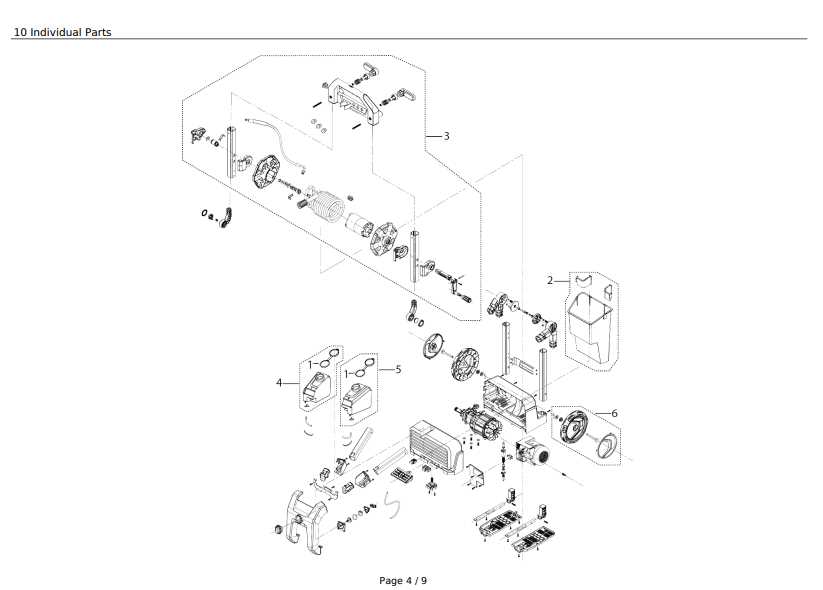

Understanding the Parts Diagram

Grasping the visual representation of components is crucial for effective maintenance and repair. This overview will enhance your ability to identify and comprehend each element’s role within the system.

- Each section illustrates various items.

- Labels clarify the function of each component.

- Connections between elements showcase how they interact.

By familiarizing yourself with this visual guide, you can streamline your repair process and ensure your equipment operates at its best.

- Start by identifying the main components.

- Note any specific annotations or notes.

- Use the guide as a reference during repairs.

Common Issues and Solutions

When operating a pressure cleaning unit, users may encounter various challenges that can affect performance. Understanding these common problems and their solutions can help maintain efficiency and extend the lifespan of the equipment.

| Issue | Possible Cause | Solution |

|---|---|---|

| Low Water Pressure | Clogged nozzle or filter | Clean or replace the nozzle and filter. |

| Engine Won’t Start | Empty fuel tank or faulty spark plug | Refill the tank and check the spark plug for damage. |

| Excessive Vibration | Unbalanced motor or loose components | Tighten all connections and inspect for imbalances. |

| Water Leakage | Damaged seals or hoses | Inspect seals and hoses for wear; replace if necessary. |

| Strange Noises | Foreign objects in the pump | Turn off the unit and remove any debris. |

How to Identify Replacement Parts

Understanding how to pinpoint necessary components for your equipment is essential for effective maintenance and repair. Knowing the specific pieces that require attention helps ensure that your machine functions optimally and prolongs its lifespan. This guide outlines practical steps to identify and source these crucial elements.

Consult the User Manual

Your first resource should always be the user manual. It typically contains a detailed list of components along with their specifications. By reviewing this document, you can gain insights into which elements are interchangeable or need replacement. Additionally, manuals often include troubleshooting sections that highlight common issues and the respective parts involved.

Utilize Online Resources

The internet offers a wealth of information for identifying essential components. Manufacturer websites often feature interactive tools or databases where you can input your equipment’s model number. Online forums and communities can also be invaluable, as experienced users may provide insights and advice based on their own repair experiences.

Importance of Regular Maintenance

Routine upkeep is crucial for ensuring the longevity and efficiency of any equipment. By dedicating time to maintenance tasks, users can prevent minor issues from escalating into major problems, ultimately saving time and money.

Benefits of Regular Upkeep

- Enhanced Performance

- Increased Lifespan

- Cost Savings

- Improved Safety

Key Maintenance Practices

- Regular Cleaning

- Component Inspections

- Lubrication of Moving Parts

- Replacement of Worn Parts

By adopting these practices, users can delve into the ultimate efficiency of their machines, ensuring they operate at peak performance for years to come.

Where to Find K2000 Parts

Locating components for your high-pressure cleaning machine can be straightforward if you know where to look. Numerous resources, both online and offline, cater to the needs of users seeking specific replacements. Understanding the right places to search can save time and ensure that you get the quality items necessary for optimal performance.

Online Retailers

The internet is a treasure trove for those seeking replacement components. Websites specializing in home improvement and maintenance often have extensive inventories. Consider the following options:

| Website | Description |

|---|---|

| Amazon | Offers a wide variety of options with user reviews for informed choices. |

| eBay | A platform for both new and used components, often at competitive prices. |

| Manufacturer’s Site | The most reliable source for original items, often with detailed specifications. |

Local Hardware Stores

For those who prefer a hands-on approach, local retailers can be a great resource. Many hardware stores stock essential components or can order them for you. Establishments that focus on home and garden supplies often have knowledgeable staff who can assist in finding the right items for your equipment.

Comparison with Other Models

This section aims to explore how this specific power washer stacks up against its competitors in the market. By examining key features, performance metrics, and user feedback, we can gain insights into its relative strengths and weaknesses.

| Feature | This Model | Competitor A | Competitor B |

|---|---|---|---|

| Power Output | 2000 PSI | 1800 PSI | 2300 PSI |

| Water Flow Rate | 1.3 GPM | 1.5 GPM | 1.2 GPM |

| Weight | 25 lbs | 30 lbs | 22 lbs |

| Warranty | 2 years | 1 year | 3 years |

Ultimately, the choice of a power washer depends on individual needs and preferences, making it essential to delve into these comparisons before making a purchase decision.

Tools Needed for Repairs

When it comes to maintenance and fixing various equipment, having the right tools is essential for achieving efficient and effective results. Proper instruments not only streamline the repair process but also enhance safety and accuracy. Below is a list of commonly required tools that can assist in carrying out necessary repairs.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening or tightening nuts and bolts. |

| Screwdriver Set | Essential for removing and securing screws of various types. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures that fasteners are tightened to the specified torque. |

| Multimeter | Used for measuring voltage, current, and resistance. |

| Utility Knife | Handy for cutting through materials or stripping wires. |

| Work Gloves | Provides protection for hands while working on equipment. |

| Safety Glasses | Protects eyes from debris and harmful substances during repairs. |

Equipping yourself with these tools will prepare you for a wide range of repair tasks, ensuring that you can address issues efficiently and safely.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your cleaning device. Follow the outlined steps carefully to ensure effective repairs and optimal performance.

- Identify the Problem

- Listen for unusual sounds during operation.

- Check for leaks or diminished pressure.

- Assess the power supply and connections.

- Gather Necessary Tools

- Screwdriver set

- Wrench

- Replacement components

- Disassemble the Unit

- Turn off the device and unplug it.

- Carefully remove outer casing.

- Document the placement of screws and parts.

- Inspect and Replace Damaged Components

- Check hoses, filters, and seals for wear.

- Replace any damaged items with new ones.

- Clean any debris that may obstruct functionality.

- Reassemble the Device

- Follow your documentation for correct part placement.

- Tighten screws securely without over-tightening.

- Test the Device

- Reconnect to power and conduct a trial run.

- Monitor for any remaining issues.

By adhering to these steps, you can effectively tackle common problems and ensure your equipment remains in peak condition.

Benefits of Genuine Parts

Using authentic components for your equipment ensures superior performance and longevity. These parts are specifically designed to fit your machine perfectly, providing optimal functionality. Unlike generic alternatives, genuine components are rigorously tested and engineered to meet the highest standards of quality and reliability.

Quality Assurance is one of the main advantages of choosing original components. Each piece is made with precision and care, ensuring that it lasts longer and functions more efficiently. This means fewer replacements and repairs, saving you time and money in the long run.

Enhanced Safety is another key benefit. Genuine parts are built with safety in mind, reducing the risk of accidents caused by faulty or incompatible components. This is especially important when working with high-powered machinery where safety should always be a priority.

Optimal Efficiency is ensured when you use parts specifically made for your equipment. Genuine components are engineered to work seamlessly with the rest of the machine, resulting in better performance, improved energy efficiency, and fewer maintenance needs.

By opting for authentic pieces, you not only protect the longevity of your equipment but also ensure a smoother, more reliable user experience, free from the complications that come with inferior alternatives.

Tips for Extending Equipment Life

Maintaining the longevity of your machinery is crucial for ensuring optimal performance and avoiding costly repairs. Regular care and attention to specific maintenance tasks can significantly extend the useful life of your equipment. Whether it’s cleaning, lubrication, or periodic inspections, small efforts can prevent bigger issues down the road.

Regular Cleaning and Maintenance

One of the simplest yet most effective ways to prolong the lifespan of your equipment is by keeping it clean. Dirt, dust, and debris can accumulate and cause unnecessary wear on moving parts. Regularly wiping down surfaces and checking for blockages will help maintain smooth operation. Additionally, ensure that any filters or screens are cleared of obstructions to avoid overheating or inefficient performance.

Proper Lubrication and Storage

Lubricating components such as motors, gears, and other mechanical parts can significantly reduce friction and wear. Always follow the manufacturer’s recommendations for lubricants and intervals between applications. Moreover, when not in use, store the equipment in a dry and protected environment to prevent rust and corrosion, which can drastically reduce its effectiveness and lifespan.