When it comes to heavy equipment, having a clear understanding of the layout and functionality of various elements is crucial for effective maintenance and repair. A comprehensive visual representation serves as an essential guide for operators and technicians alike, enabling them to identify components quickly and accurately.

Familiarizing yourself with the arrangement of different parts can enhance your ability to troubleshoot issues efficiently. By studying the organization of key elements, one can gain insights into the machinery’s operational processes and the role each component plays in its overall functionality.

Moreover, recognizing the interconnectivity between various segments can streamline repair procedures and reduce downtime. This knowledge empowers users to make informed decisions when it comes to servicing their equipment, ultimately leading to improved performance and longevity.

Understanding Bobcat T300 Parts Diagram

This section provides insight into the essential components of a compact loader and how they are organized within a visual representation. Grasping the layout of these elements is crucial for effective maintenance and repair. The schematic serves as a guide, illustrating how each piece interacts with others, ensuring optimal performance of the machinery.

Importance of Component Awareness

Recognizing individual elements within the assembly is vital for troubleshooting and servicing. Familiarity with the arrangement allows operators and technicians to identify potential issues quickly and address them effectively. Furthermore, understanding the function of each component enhances overall operational efficiency.

Utilizing Visual References

Visual aids are invaluable tools in the repair process. They simplify the identification of components and provide clarity on assembly relationships. By leveraging these resources, users can navigate the complexities of machinery more confidently, ensuring proper handling and longevity of the equipment.

Key Components of Bobcat T300

The essential elements of this machine play a vital role in its overall performance and efficiency. Understanding these key parts helps users to appreciate the functionality and capabilities that contribute to its versatility in various applications.

Hydraulic System: This critical system is responsible for powering various attachments and implements, enabling the equipment to perform a wide range of tasks. The hydraulic components ensure smooth operation and precise control.

Engine: The heart of the equipment, the engine provides the necessary power to drive all functions. Its performance directly impacts productivity and operational efficiency.

Tracks: These elements enhance traction and stability on uneven terrain, allowing for improved maneuverability. The design and quality of the tracks contribute significantly to the machine’s overall performance.

Cab: The operator’s compartment is designed for comfort and visibility. An ergonomic layout ensures that all controls are within reach, facilitating ease of operation during extended use.

Electrical System: This system manages power distribution and controls various electronic components. Proper functionality of the electrical elements is essential for the efficient operation of the machine.

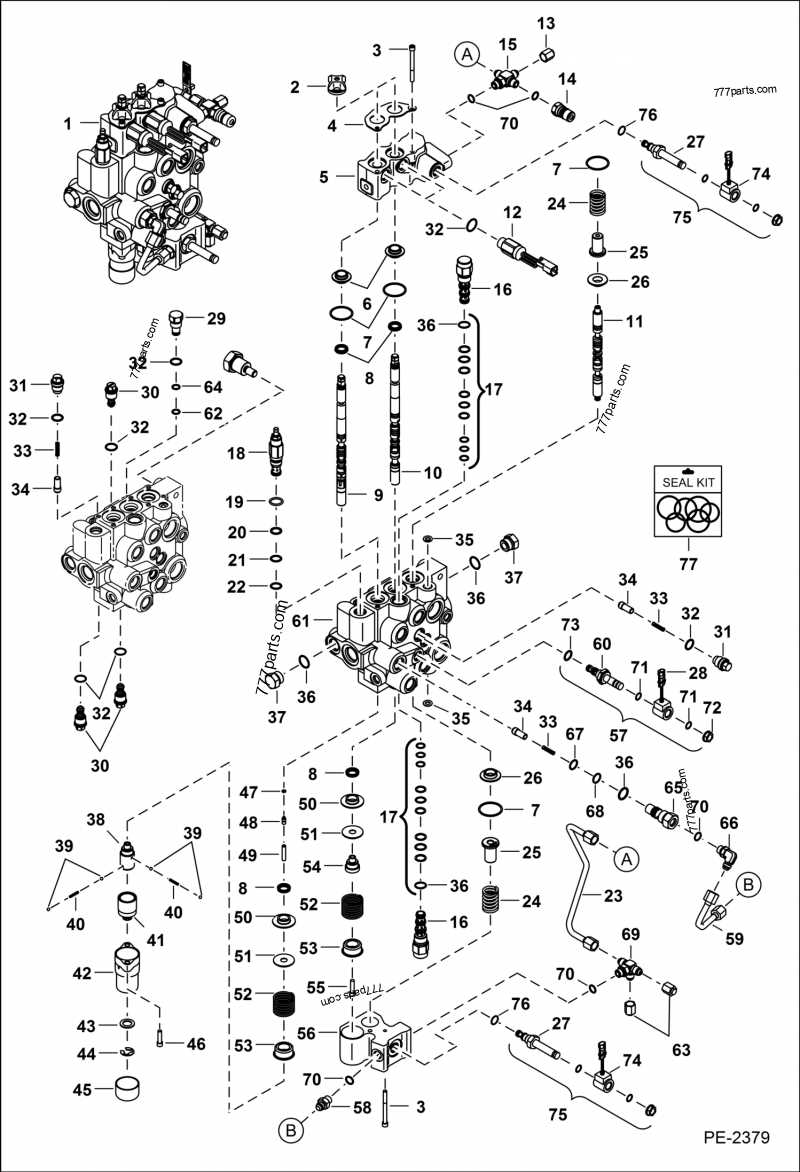

Hydraulic System Overview

The hydraulic system is a vital component that enables various machinery functions through fluid power. This system relies on the movement of hydraulic fluid to transfer force, allowing for efficient operation of different attachments and tools. Understanding its layout and components is essential for effective maintenance and troubleshooting.

Key Components

- Hydraulic Pump: Responsible for generating flow and pressure within the system.

- Actuators: Devices that convert hydraulic energy into mechanical movement.

- Valves: Control the direction and flow of hydraulic fluid.

- Reservoir: Stores hydraulic fluid and allows for thermal expansion.

- Hoses and Fittings: Facilitate the movement of fluid between components.

System Functionality

The hydraulic system operates by drawing fluid from the reservoir, which the pump then pressurizes. This pressurized fluid is directed through various valves to the actuators, enabling them to perform tasks such as lifting or pushing. Proper maintenance of each component ensures the system operates efficiently and prolongs the machinery’s lifespan.

Engine Specifications and Parts

This section provides an overview of the essential components and technical details related to the power unit of the machine. Understanding the specifications and individual elements is crucial for maintenance and performance optimization.

| Specification | Description |

|---|---|

| Engine Type | Diesel, 4-cylinder |

| Displacement | 2000 cc |

| Power Output | 75 HP |

| Torque | 250 Nm |

| Cooling System | Liquid-cooled |

| Fuel System | Direct injection |

Key components of the engine include the cylinder head, crankshaft, and fuel injectors. Each part plays a vital role in ensuring efficient operation and reliability.

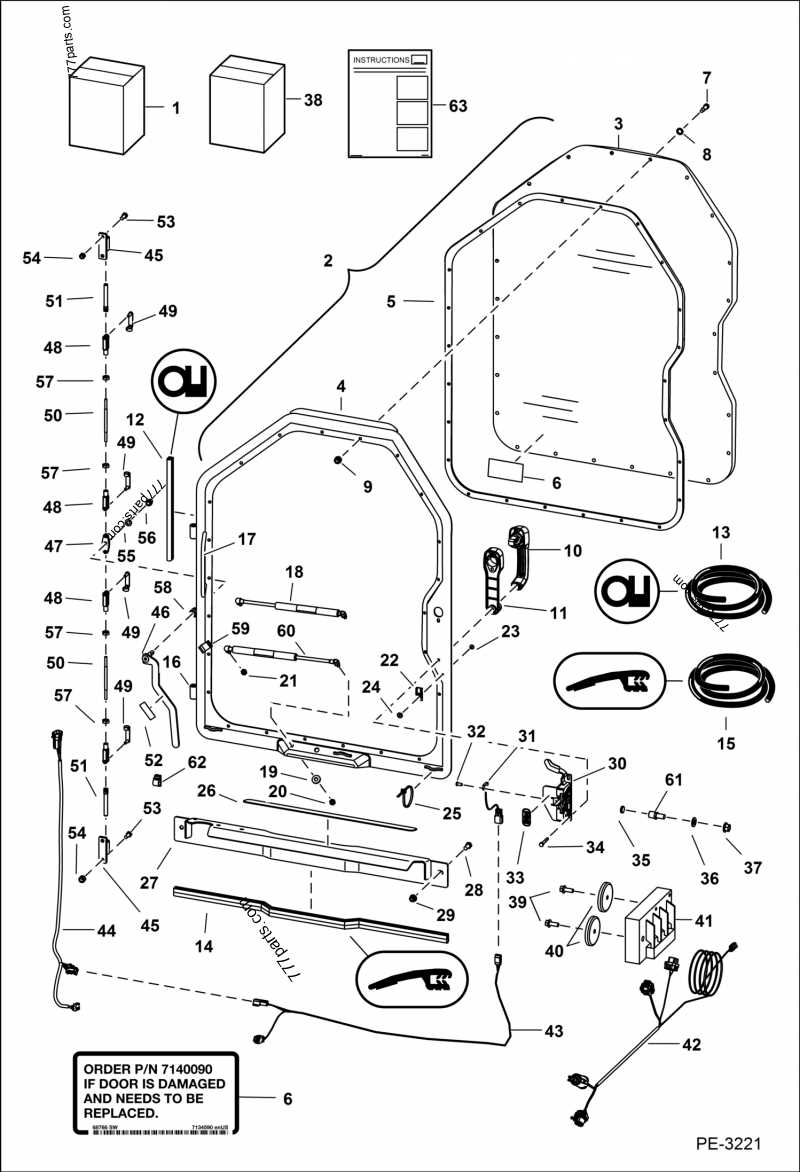

Electrical System Breakdown

The electrical network of machinery plays a crucial role in its overall functionality and performance. Understanding the various components and their interactions within this system is essential for effective maintenance and troubleshooting. This section delves into the key elements that comprise the electrical system, highlighting their functions and significance.

- Power Supply: The primary source of electricity that energizes all components.

- Wiring Harness: A collection of wires and connectors that facilitate the transmission of electrical signals.

- Fuses and Relays: Protective devices that prevent overloads and control the flow of electricity.

- Control Modules: Central units that manage the operation of various electrical components.

- Sensors: Devices that monitor specific conditions and provide feedback to the control modules.

- Actuators: Mechanisms that convert electrical signals into physical movement or actions.

Regular inspections and maintenance of these elements are vital to ensure the electrical system operates smoothly. Addressing any issues promptly can prevent more significant problems and extend the lifespan of the equipment.

Tracks and Undercarriage Details

The undercarriage system plays a crucial role in the performance and stability of compact machinery. This section delves into the key components that ensure efficient operation and durability, providing insight into the essential features that enhance traction and mobility on various terrains.

Key Components of the Undercarriage

The undercarriage is comprised of several vital elements, each contributing to the overall functionality of the equipment. Understanding these components aids in maintenance and troubleshooting.

| Component | Description |

|---|---|

| Tracks | Designed for optimal grip and wear resistance, tracks enable smooth movement over different surfaces. |

| Sprockets | These components engage with the tracks, facilitating movement and power transfer from the drive system. |

| Rollers | Rollers support the weight of the machine and assist in distributing pressure, ensuring stability and reducing wear. |

| Idlers | Idlers help maintain proper tension in the track system, allowing for smooth operation and preventing slippage. |

Maintenance Tips for Longevity

Regular inspections and timely maintenance are essential for extending the life of the undercarriage. Key practices include checking track tension, cleaning debris from components, and replacing worn parts to prevent further damage.

Attachment Compatibility and Options

The versatility of the machine allows it to handle a wide variety of attachments, making it suitable for different tasks across industries. The key to its adaptability lies in its hydraulic capabilities and the quick-connect system, which streamlines the process of switching between implements.

Hydraulic Attachments

Many attachments require hydraulic power to function effectively. These include equipment for excavation, material handling, and landscaping, among others. The hydraulic system provides the necessary pressure and flow to ensure optimal performance across different attachment types.

Non-Hydraulic Options

There are also non-hydraulic attachments available that can be used for simpler tasks. These options are typically used for applications like transporting materials or light grading work.

| Attachment Type | Function |

|---|---|

| Buckets | Digging, loading, and carrying materials |

| Pallet Forks | Lifting and transporting pallets |

| Augers | Drilling holes in various soil types |

Routine Maintenance and Spare Parts

Regular upkeep is essential for optimal performance and longevity of your machinery. Consistent checks and timely replacements of essential components can prevent unexpected failures and enhance operational efficiency.

Scheduled Servicing: Establish a routine maintenance schedule to inspect vital systems. This includes lubricating moving parts, checking fluid levels, and replacing filters as necessary.

Component Replacement: Utilizing high-quality replacements is crucial for maintaining functionality. Familiarize yourself with the most commonly worn components and ensure they are readily available.

Inspection Procedures: Conduct visual inspections to identify any signs of wear or damage. Pay special attention to hoses, belts, and electrical connections, as these are often prone to degradation.

Documentation: Keep a detailed record of maintenance activities and part replacements. This not only aids in tracking performance but also assists in planning future servicing needs.

Common Repairs and Solutions

In the realm of machinery maintenance, understanding frequent issues and their corresponding fixes is essential for optimal performance. Many operators encounter typical challenges that can arise from wear and tear, operational misuse, or environmental factors. This section aims to highlight some prevalent repairs along with practical solutions that can enhance the longevity and efficiency of the equipment.

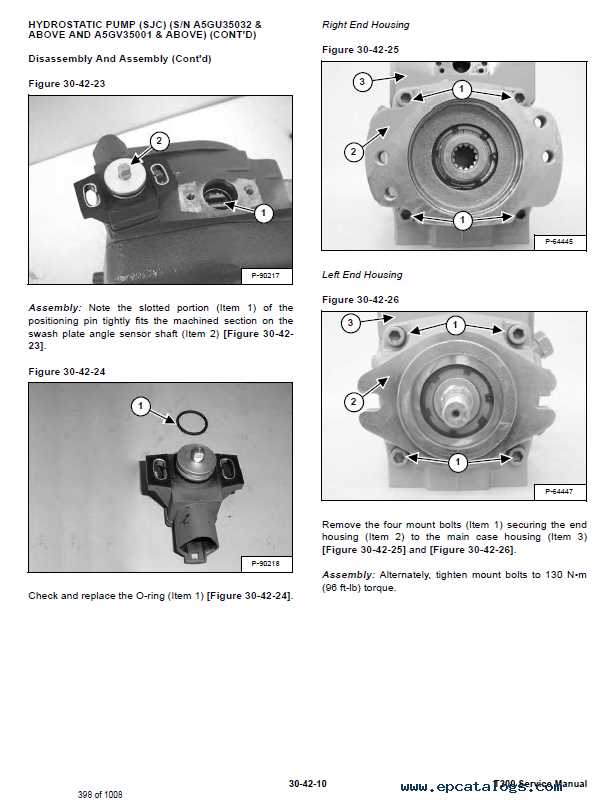

Hydraulic System Troubleshooting

Hydraulic issues are often among the most common problems faced by operators. Leaks, reduced power, and erratic movements can indicate faults within the hydraulic system. Regularly checking hydraulic fluid levels and inspecting hoses for signs of damage can help prevent more serious complications. If a leak is identified, promptly replacing the damaged hose or sealing the leak can restore functionality.

Engine Performance Enhancements

Another frequent concern involves engine performance. Symptoms such as rough idling, difficulty starting, or reduced power output may suggest that routine maintenance tasks, like oil changes or filter replacements, have been neglected. Ensuring that air filters are clean and fuel systems are free from blockages can significantly improve engine performance. Additionally, regularly scheduled maintenance checks can catch issues before they escalate.

Parts Ordering and Availability

When it comes to acquiring components for heavy machinery, understanding the ordering process and ensuring the availability of necessary items is essential. Having access to a reliable source for these essential elements can significantly impact operational efficiency and maintenance routines.

Ordering Process

The procedure for obtaining essential components typically involves identifying the specific requirements and consulting a trustworthy supplier. Many suppliers offer online platforms where users can search for components based on equipment specifications. It’s crucial to verify compatibility before placing an order to avoid any delays in maintenance.

Availability Considerations

Availability of components can vary based on demand, supplier stock levels, and shipping times. To ensure timely access to required items, it’s advisable to establish a relationship with a reputable distributor. Regular communication can provide insights into stock levels and help in planning for future needs.

Diagram Interpretation Tips

Understanding technical illustrations can significantly enhance your ability to maintain and repair machinery. Familiarizing yourself with the various components and their interactions will facilitate a smoother troubleshooting process. Here are some essential tips to improve your interpretation skills.

- Familiarize with Symbols: Take time to learn common symbols and notations used in technical illustrations. Recognizing these can provide quick insights into the functions and relationships of different parts.

- Study the Layout: Pay attention to the overall layout of the illustration. Understanding how components are organized can help you visualize the assembly and disassembly processes.

- Follow the Sequence: Look for numbered sequences or arrows that indicate the order of assembly or disassembly. Following these steps can prevent mistakes during maintenance.

- Cross-reference Information: Use accompanying manuals or guides to cross-reference information. This can provide additional context that aids in understanding complex systems.

- Take Notes: While interpreting, jot down key observations or questions that arise. This can help clarify your understanding and guide further research.

By applying these strategies, you can enhance your ability to analyze technical illustrations effectively, leading to improved repair and maintenance outcomes.