Piston – A critical moving part, it transfers force from expanding

Key Elements in the Maytag 92 Engine Design

The engine’s design showcases a balance between simplicity and efficiency, which was critical for its time. It was built to perform reliably under minimal maintenance, providing a long service life. With its compact structure, the engine offered robust functionality, incorporating features that maximized operational durability and ease of use.

Fuel and Ignition System

The fuel delivery system was designed for efficiency, utilizing gravity to feed the fuel directly into the combustion chamber. This straightforward approach reduced mechanical complexity and the likelihood of failure. The ignition system featured a magneto mechanism, ensuring consistent spark generation without external power, which made the engine self-sufficient in various conditions.

Cooling and Lubrication

Effective cooling was ensured through an air-cooled system, eliminating the need for liquid coolant, which could lead to additional maintenance challenges. The lubrication method relied on a splash system, whi

Common Issues with Maytag 92 Parts

Like any mechanical device, older engines tend to face a range of recurring problems over time. These issues often arise due to wear, poor maintenance, or the natural aging of individual elements within the machine. Identifying these trouble spots early can help prevent more significant malfunctions and extend the overall lifespan of the equipment.

One common concern involves engine components that have either corroded or deteriorated due to moisture exposure. Rust can affect the performance, causing certain parts to stick or seize. Additionally, improper storage or lack of regular cleaning may lead to the buildup of debris, further impairing the smooth operation of the system.

Another frequent issue is related

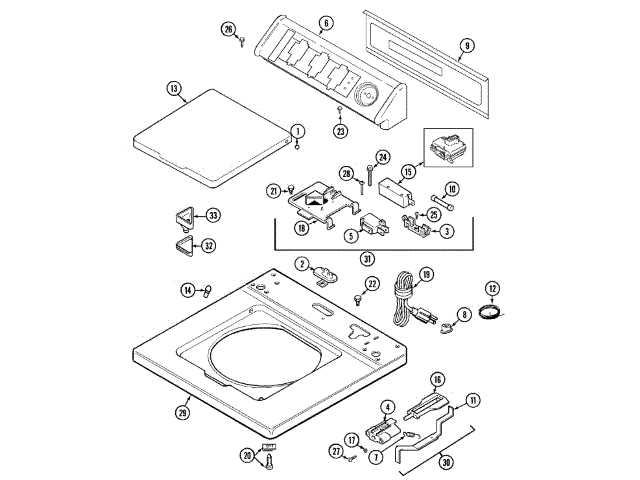

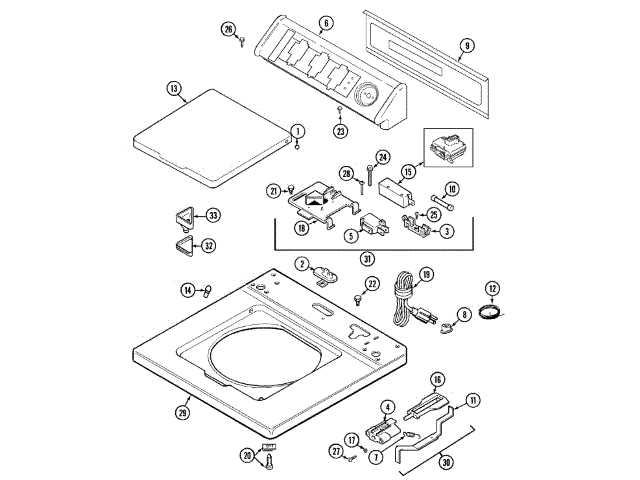

How to Identify Maytag 92 Components

Understanding the individual elements of this vintage engine is essential for proper maintenance and restoration. Each component plays a vital role in the operation, and recognizing them correctly ensures smooth functioning and longevity. In this guide, we’ll walk through the key elements to help identify and differentiate between various parts, ensuring clarity and ease when working on the unit.

Recognizing Key Engine Elements

The power source in this machine consists of several distinguishable sections. First, locate the cylinder, which typically features cooling fins and connects to the crankshaft. The crankshaft itself is central, often positioned near the base and linked to the flywheel. The flywheel, a large, heavy disk, is crucial for maintaining momentum during operation. Attached to the crankshaft, the connecting rod moves in sync with the piston

Guide to Locating Specific Maytag 92 Parts

Identifying specific components for household appliances can be a challenging task, particularly when it comes to older or unique models. This guide aims to simplify the process of finding these essential elements, ensuring you can maintain and repair your appliance effectively. Whether you’re a DIY enthusiast or a professional technician, knowing where to look for accurate information is crucial.

Start by gathering information about the appliance, including its serial number and any unique identifiers. This information will significantly enhance your search for the right components. Here are several reliable sources to consider when looking for the necessary elements:

| Source |

Description |

Access Method |

| Manufacturer’s Website |

Official site often provides resources, including manuals and lists of available items. |

Visit the support or product section. |

| Authorized Retailers |

These sellers can offer authentic replacements and may provide additional assistance. |

Search online or visit local stores. |

| Online Marketplaces |

Platforms like eBay or Amazon may have listings from various sellers, including used components. |

Search by the specific part number. |

| Repair Forums |

Community-driven sites where users share experiences, solutions, and sometimes offer parts for sale. |

Join discussions related to your appliance. |

| Local Repair Shops |

Professionals often have spare parts or can help locate hard-to-find items. |

Contact nearby repair services for inquiries. |

By utilizing these resources, you can efficiently track down the components you need, ensuring your appliance remains in optimal working condition. Keep detailed records of any parts you replace to assist in future maintenance and repairs.

Replacement Options for Maytag Model 92

When it comes to maintaining and restoring home appliances, ensuring the availability of appropriate components is crucial for optimal performance. Users often seek various alternatives to facilitate repairs or upgrades, thereby enhancing the longevity and efficiency of their equipment. This section explores several viable choices for sourcing replacements, focusing on compatibility, quality, and accessibility.

One effective option is to consider authorized retailers that specialize in appliance replacements. These establishments typically offer genuine components that guarantee compatibility with existing equipment. Additionally, exploring online marketplaces can yield a wide range of options, often at competitive prices. When opting for this route, it is essential to verify seller reliability and product authenticity to avoid potential issues.

For those seeking more cost-effective solutions, aftermarket alternatives can be an attractive choice. Many manufacturers produce compatible components that meet or exceed original specifications. However, thorough research is necessary to ensure that these substitutes provide the desired performance and durability. Reading customer reviews and checking warranty options can aid in making an informed decision.

Lastly, consider local repair shops or appliance service centers. These professionals often have access to a variety of components and can provide valuable guidance on the best options available. Engaging with experts not only facilitates the repair process but can also lead to recommendations for enhanced performance and efficiency.

Maintenance Tips for Maytag 92 Engine Parts

Ensuring the longevity and optimal performance of your machinery requires regular attention to its key components. By following a structured maintenance routine, you can prevent potential issues and extend the lifespan of your equipment. This guide outlines essential practices to keep your engine in peak condition.

Regular Inspection

Conducting frequent evaluations of critical elements is vital. Look for signs of wear, corrosion, or damage that could affect functionality. Here are some key areas to focus on:

- Check belts and hoses for cracks or fraying.

- Inspect gaskets and seals for leaks.

- Examine electrical connections for corrosion.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is crucial for smooth operation. Follow these steps:

- Remove debris and dirt from the engine surface regularly.

- Apply suitable lubricant to moving parts to reduce friction.

- Replace filters as recommended to ensure optimal airflow and fluid flow.

By implementing these maintenance strategies, you can enhance performance and reliability, ultimately saving time and resources in the long run.

Exploring Rare Parts of Maytag 92

In the world of vintage appliances, certain components become increasingly elusive as time passes. This section delves into the unique and hard-to-find elements that define a particular appliance from a renowned brand. Understanding these rare items not only enhances the restoration process but also adds depth to the appreciation of the craftsmanship involved.

Uncovering Unique Components

Among the most sought-after elements are those that are essential for functionality yet rarely available in the market. These unique items often require dedicated searching, as they are not typically produced in large quantities. Collectors and enthusiasts often share tips on where to find these elusive treasures, including specialty shops, online marketplaces, and vintage fairs.

Importance of Rarity in Restoration

The scarcity of certain elements can significantly impact the restoration journey. When rare components are successfully sourced, they not only ensure the appliance operates as intended but also contribute to its historical integrity. Maintaining the original specifications of the machine becomes a point of pride for restorers, highlighting the significance of preserving vintage engineering.

Restoration Process for Maytag 92 Engines

Restoring vintage engines is a rewarding endeavor that combines craftsmanship with historical appreciation. This process involves a series of meticulous steps designed to revive these classic machines, ensuring they operate as intended while preserving their original charm. A successful restoration not only enhances functionality but also contributes to the cultural legacy associated with these engines.

Assessment and Documentation: The first step in the restoration journey is a thorough evaluation of the engine’s current condition. Documenting its state through photographs and notes will help track progress and identify necessary repairs. Look for any signs of wear, damage, or corrosion that may affect performance.

Disassembly: Carefully disassemble the engine, ensuring that each component is removed in a systematic manner. Keep track of fasteners and small parts by organizing them in labeled containers. This will facilitate reassembly and minimize the risk of losing crucial components.

Cleaning: Once disassembled, thoroughly clean all parts using appropriate methods. This may involve soaking components in solvents, using brushes to remove grime, or employing ultrasonic cleaners for delicate pieces. Proper cleaning is essential to prepare surfaces for inspection and restoration.

Inspection: After cleaning, inspect each component for signs of damage or wear. Pay special attention to critical elements such as bearings, seals, and gaskets. Any worn or damaged parts should be noted for replacement or repair.

Repair and Replacement: Depending on the inspection results, proceed with necessary repairs or replacements. Some components may be repairable through welding or machining, while others might need to be sourced from specialty suppliers or fabricated. Maintain the original specifications as closely as possible to preserve authenticity.

Reassembly: Begin the reassembly process by carefully following the documentation created during disassembly. Use appropriate lubricants and sealing compounds to ensure smooth operation and prevent leaks. Double-check the orientation and fit of each component to avoid any issues later on.

Testing: After reassembly, it is crucial to conduct thorough testing to ensure that the engine functions correctly. Monitor for unusual noises, vibrations, or leaks during operation. Make any necessary adjustments and perform final checks to guarantee reliability and safety.

Final Touches: Once testing is complete, consider cosmetic enhancements such as repainting or polishing to restore the engine’s aesthetic appeal. A well-restored engine should not only perform reliably but also look great, showcasing the effort put into its revival.

This restoration process highlights the importance of attention to detail and a passion for preserving mechanical history. Each step plays a vital role in bringing these engines back to life, ensuring they can be enjoyed for generations to come.