In the intricate world of automotive engineering, the functionality of gear engagement systems plays a crucial role in ensuring seamless vehicle operation. This section delves into the essential components that facilitate the smooth transition between different driving modes, enabling drivers to optimize performance and enhance control.

By examining the arrangement and interaction of these essential elements, one can appreciate the complexity and precision involved in modern vehicle design. Each component contributes to the overall efficiency and responsiveness, underscoring the importance of understanding their layout and function.

Whether you are a seasoned mechanic or an enthusiastic novice, familiarizing yourself with these mechanisms can significantly improve maintenance practices and troubleshooting skills. This knowledge empowers individuals to identify issues and implement effective solutions, ensuring vehicles remain in peak condition.

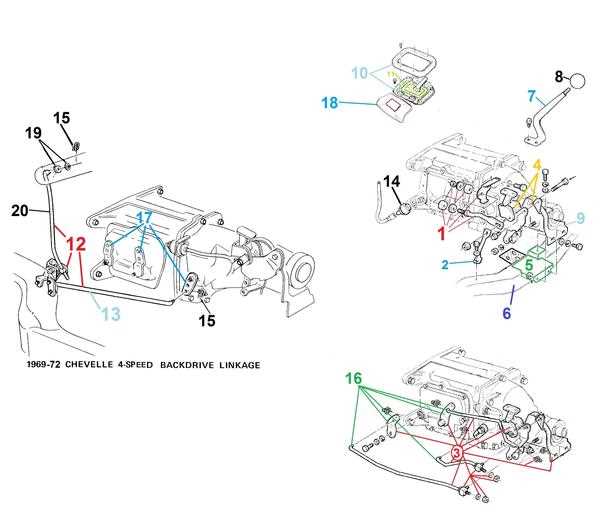

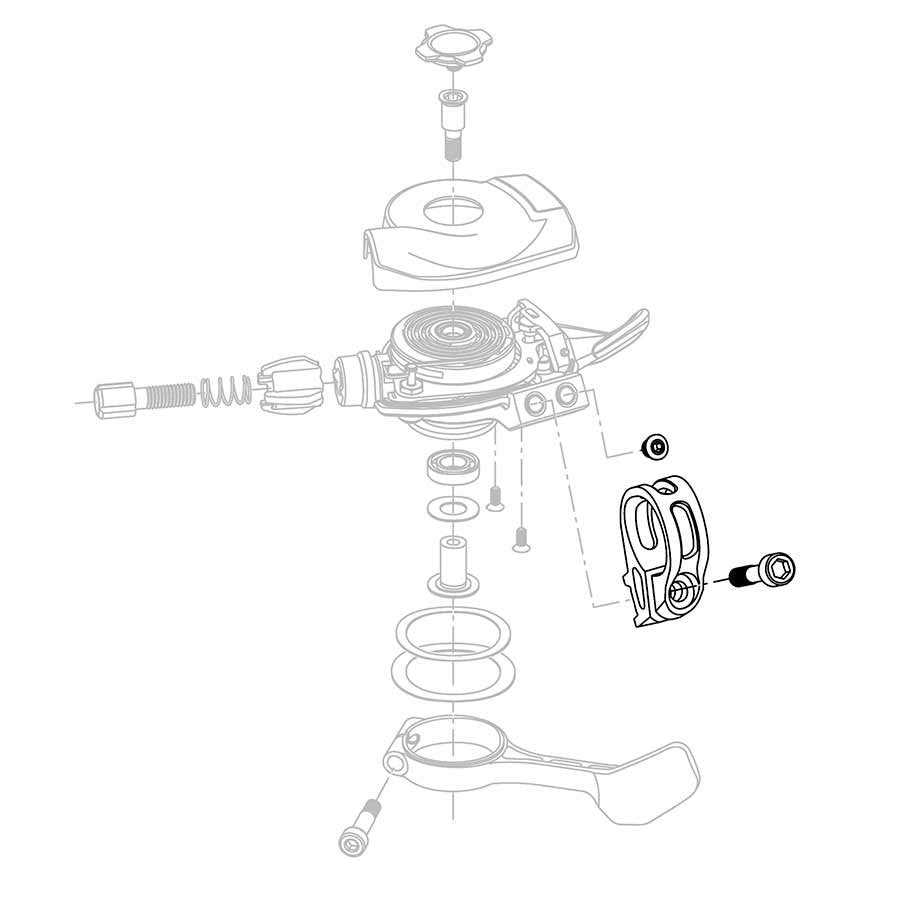

Understanding Shifter Parts Diagrams

Interpreting the visual representations of gear control mechanisms is essential for both enthusiasts and professionals. These illustrations provide crucial insights into the components and their relationships, aiding in effective maintenance and troubleshooting.

Key Components to Identify

- Control Levers

- Linkages

- Mounting Brackets

- Cables

- Adjustment Screws

Interpreting the Visuals

- Familiarize yourself with symbols used in the representation.

- Note the arrangement of elements and how they connect.

- Understand the functionality of each component depicted.

- Refer to the accompanying legends for clarification on terminology.

Mastering the comprehension of these visual guides not only enhances your ability to work on the mechanisms but also deepens your appreciation for their intricate design and functionality.

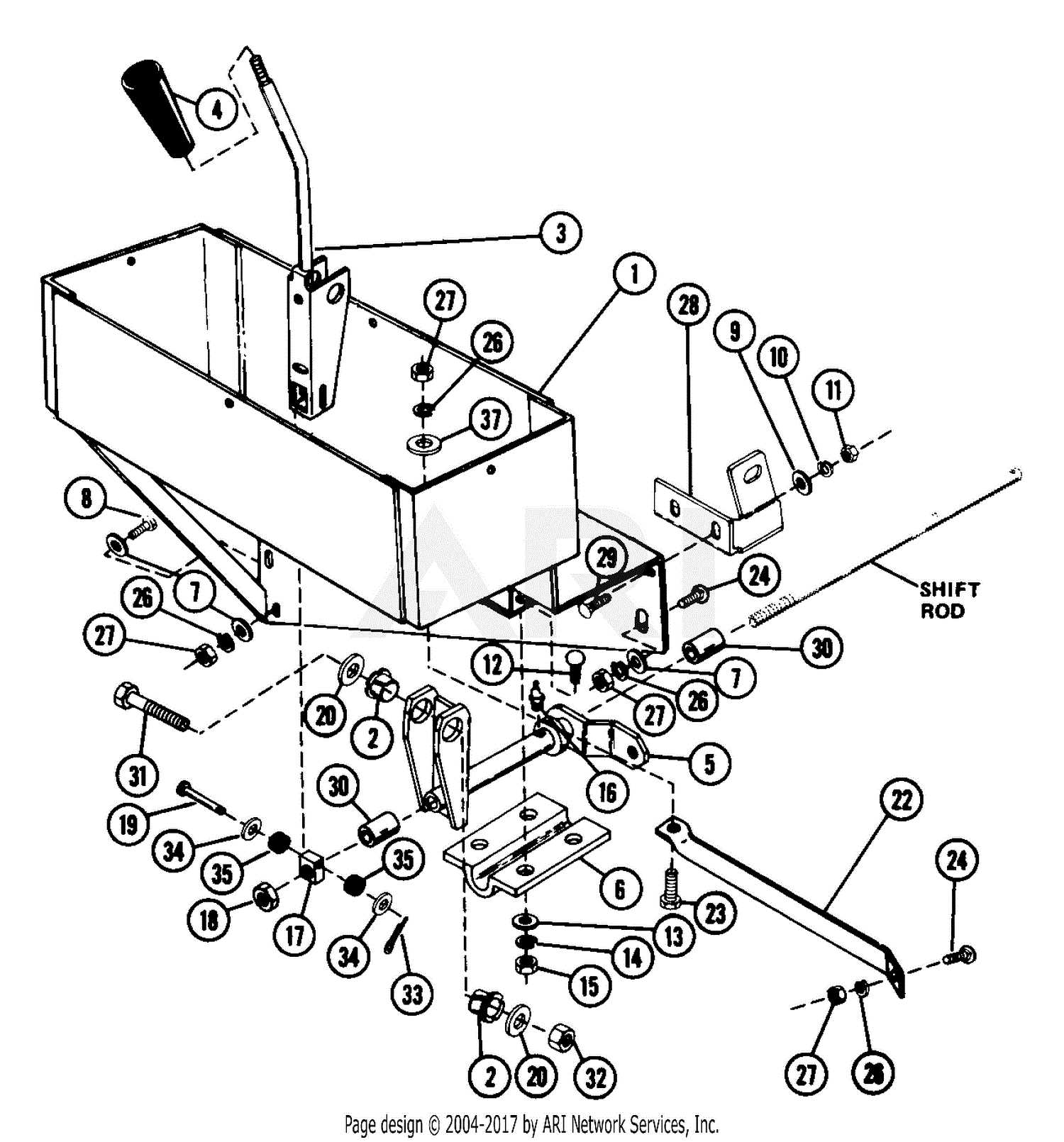

Components of a Shifter Assembly

The assembly responsible for gear selection in a vehicle comprises several essential elements that work in harmony to facilitate smooth operation. Each component plays a crucial role, contributing to the overall functionality and efficiency of the system.

Key Elements

Among the primary constituents are the mechanism itself, which provides the interface for user interaction, and the linkage that connects to the transmission. Additionally, a reliable return spring ensures the mechanism returns to its neutral position, promoting ease of use and enhancing user experience.

Supporting Components

Other notable features include the housing that protects internal mechanisms and the detent system that offers tactile feedback during gear changes. Wear-resistant materials are commonly utilized to ensure longevity and performance stability, highlighting the importance of durability in design. The proper functioning of these elements is vital for efficient vehicle operation, making understanding their roles essential for maintenance and repair.

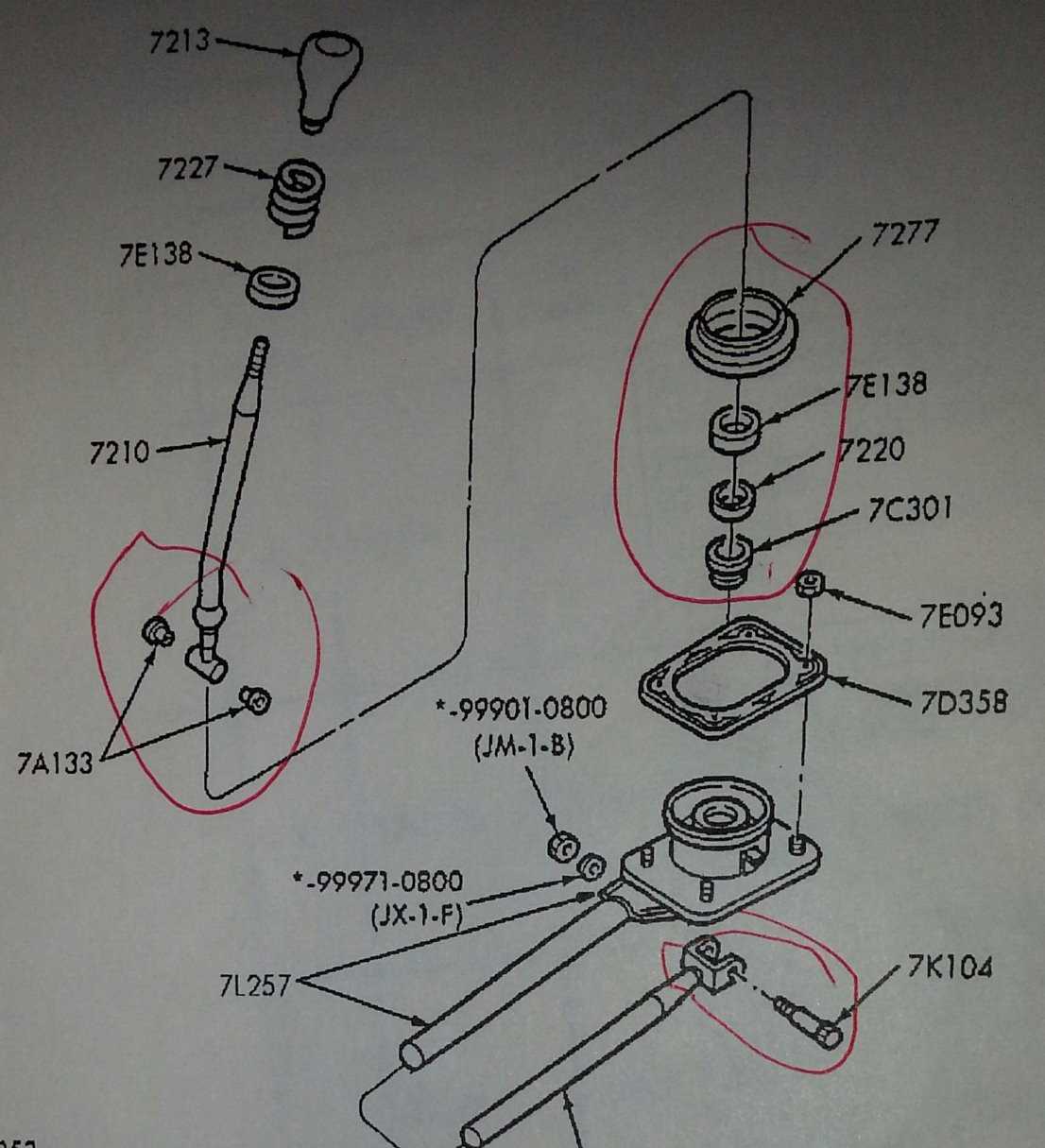

Importance of Accurate Diagrams

Clear and precise representations play a crucial role in various technical fields, facilitating understanding and effective communication. These visual aids provide essential guidance for both novices and experienced professionals, ensuring that tasks are completed efficiently and accurately.

Here are several reasons why precise illustrations are vital:

- Enhanced Clarity: Detailed visuals help in breaking down complex systems into easily understandable components.

- Improved Efficiency: Accurate representations enable quicker assembly and troubleshooting, saving time and resources.

- Reduced Errors: Clear guides minimize the chances of mistakes during installation or repairs, leading to safer operations.

- Standardization: Consistent visuals across different resources ensure that everyone follows the same guidelines, promoting uniformity in processes.

In summary, investing time in creating and utilizing accurate visuals is essential for achieving success and maintaining quality in any technical endeavor.

Common Issues with Shifter Parts

When dealing with the mechanism that controls gear selection in vehicles, several challenges can arise, impacting performance and user experience. Understanding these common problems is crucial for effective maintenance and timely resolution.

Frequent Problems Encountered

One of the most prevalent issues involves misalignment, which can prevent smooth transitions between gears. Additionally, wear and tear on the internal components often leads to unresponsiveness or unexpected gear changes. Furthermore, a lack of lubrication can exacerbate friction, causing further complications.

Symptoms and Solutions

| Symptoms | Potential Solutions |

|---|---|

| Difficulty in changing gears | Check alignment and adjust as necessary |

| Unintended gear shifts | Inspect for wear and replace damaged components |

| Excessive resistance | Apply appropriate lubricant to moving parts |

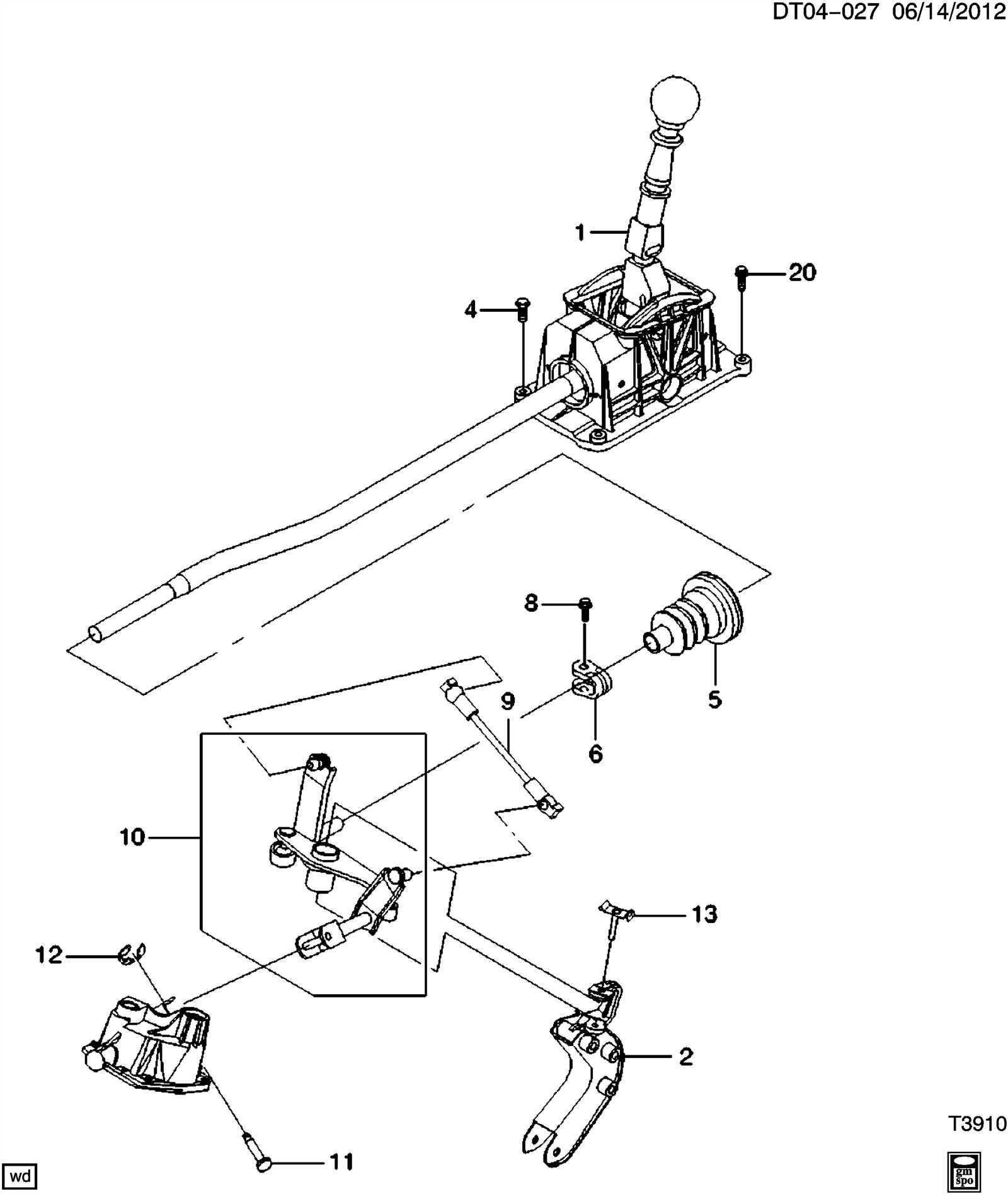

How to Read a Shifter Diagram

Understanding the visual representation of components and their relationships is essential for effective troubleshooting and maintenance. A well-organized illustration provides clarity, allowing users to identify individual elements and comprehend how they interact within the system. This guide will help you navigate the complexities of such representations and enhance your mechanical skills.

Identifying Key Elements

The first step in interpreting the illustration is to recognize the various components depicted. Each element typically corresponds to a specific function or mechanism. Look for labels and symbols that indicate what each part does. Familiarity with common nomenclature will aid in quickly grasping the overall layout.

Understanding Connections

Once you have identified the components, the next focus should be on the connections between them. These links often indicate how forces are transmitted or how movements are coordinated. Pay attention to lines and arrows; they usually illustrate the direction of movement or the flow of energy. Analyzing these connections can provide insights into potential issues and repair strategies.

| Component | Description | Function |

|---|---|---|

| Lever | Control mechanism | Initiates action |

| Cable | Flexible connector | Transmits movement |

| Linkage | Joint or connector | Transfers motion |

| Housing | Protective enclosure | Encases components |

Identifying Shifter Components Easily

Understanding the various elements of a transmission control mechanism is crucial for effective maintenance and operation. Familiarity with each component not only simplifies repairs but also enhances the overall driving experience. Here, we will explore how to easily recognize and differentiate these essential pieces.

Common Elements

Several key components play a vital role in the functionality of the system. Below is a list of the most frequently encountered elements:

- Selector Lever: The primary interface for the driver to engage different modes.

- Linkage: Connects the lever to the transmission, facilitating movement.

- Cables: Often used in automatic systems to transfer motion efficiently.

- Indicator Lights: Provide feedback on the current mode selected.

- Detents: Mechanical stops that provide tactile feedback during mode selection.

Recognizing Specific Features

When examining these components, pay attention to specific characteristics that help in identification:

- Material: Observe the construction material, whether plastic, metal, or rubber.

- Shape: Note the design–some levers may be elongated, while others are compact.

- Color: Many mechanisms utilize color coding for quick reference.

- Labeling: Look for markings or labels that indicate functionality or mode.

By understanding these elements and their unique features, recognizing each part becomes a straightforward task, paving the way for more informed decisions in vehicle operation and maintenance.

Comparing Manual vs. Automatic Shifters

When it comes to selecting the right transmission for a vehicle, drivers often find themselves weighing the advantages and disadvantages of two distinct types. Each option offers a unique driving experience and caters to different preferences, making the choice significant for both performance and comfort.

Driving Experience

The engagement level and control over the vehicle’s power delivery vary greatly between the two options. Enthusiasts often prefer one for its direct connection to the driving dynamics, while others appreciate the convenience of the alternative.

Maintenance and Reliability

Different mechanisms can lead to variations in maintenance requirements and reliability over time. Understanding these factors can help potential buyers make an informed decision.

| Feature | Manual Transmission | Automatic Transmission |

|---|---|---|

| Driver Engagement | High | Low |

| Ease of Use | Requires skill | User-friendly |

| Fuel Efficiency | Generally better | Varies |

| Maintenance Cost | Lower | Higher |

| Performance | More responsive | Smoother shifts |

Repairing vs. Replacing Shifter Parts

When it comes to maintaining your vehicle’s transmission control system, one of the key decisions is whether to fix existing components or opt for new replacements. Each choice comes with its own set of advantages and considerations, affecting both performance and cost. Understanding these options can help you make a more informed decision based on your specific needs and circumstances.

Benefits of Repairing

Choosing to repair components can often be a cost-effective solution. In many cases, a simple fix can restore functionality without the need for extensive investment. Additionally, repairing can reduce waste, contributing to a more sustainable approach to vehicle maintenance. Here are some advantages:

| Advantages | Considerations |

|---|---|

| Lower costs | Potential for recurring issues |

| Environmentally friendly | Requires skilled labor |

| Quick turnaround | Limited warranty |

Advantages of Replacing

On the other hand, opting for new components can provide peace of mind and potentially enhance overall performance. New components are typically designed to meet modern standards, ensuring reliability and efficiency. Here are some benefits:

| Advantages | Considerations |

|---|---|

| Improved reliability | Higher upfront costs |

| Warranty protection | Longer installation time |

| Modern technology | Possible compatibility issues |

Tools Needed for Shifter Maintenance

Proper upkeep of your vehicle’s control mechanisms is essential for ensuring smooth operation and longevity. To perform maintenance effectively, it’s important to have the right tools at hand. This section outlines the necessary equipment to carry out routine inspections and repairs, helping you maintain optimal performance.

Essential Equipment

First and foremost, a reliable set of wrenches and sockets is crucial. These will allow you to tighten or loosen components as needed. Additionally, a screwdriver set with various head types ensures that you can access screws of different shapes and sizes. A pair of pliers can also be invaluable for gripping and twisting small parts during adjustments.

Maintenance Accessories

For thorough cleaning, a soft cloth and a suitable cleaner will help remove dirt and grime. Lubricants are vital for ensuring that moving elements function smoothly; choose one designed for mechanical systems. Lastly, having a torque wrench is beneficial for ensuring that all components are secured to the manufacturer’s specifications, preventing future issues.

By gathering these tools, you will be well-equipped to maintain and enhance the performance of your vehicle’s control mechanisms.

Upgrading Your Shifting System

Enhancing your transmission mechanism can significantly improve the overall performance of your bicycle or vehicle. By focusing on the components that facilitate gear changes, you can achieve smoother transitions, increased responsiveness, and a more enjoyable riding experience.

Assessing Compatibility is the first step in this enhancement journey. Before acquiring new elements, it’s essential to evaluate how they will integrate with your existing setup. Consider the brand, model, and specifications to ensure optimal compatibility.

Next, choosing Quality Components is crucial. Investing in high-quality materials can lead to better durability and reliability. Look for options that are known for their performance in various conditions, as this can make a noticeable difference during your rides.

Additionally, installation and adjustment play a significant role in functionality. Properly installing and tuning the new elements can maximize their potential. If you’re uncertain about the process, seeking professional assistance can save time and avoid potential issues.

Finally, regular maintenance will help sustain the enhancements made. Keeping components clean and well-lubricated ensures long-lasting performance and prevents premature wear. By following these steps, you can transform your shifting experience into a seamless and enjoyable part of your journey.

Finding Quality Replacement Parts

When seeking to restore or enhance the functionality of your vehicle, locating high-quality components is essential. The right selections not only ensure optimal performance but also contribute to the longevity of your equipment. This section outlines key considerations and sources for obtaining reliable replacements.

Key Considerations

- Compatibility: Always verify that the item is suitable for your specific model to avoid fitting issues.

- Material Quality: Look for durable materials that can withstand wear and tear, ensuring longer usage.

- Brand Reputation: Research brands known for their reliability; user reviews can provide insight into their performance.

Where to Find Quality Components

- Authorized Dealers: Purchasing from official dealers guarantees authenticity and quality assurance.

- Specialty Retailers: These shops often carry a wider selection and can offer expert advice tailored to your needs.

- Online Marketplaces: Websites dedicated to automotive supplies can provide competitive pricing, but ensure to check seller ratings.

- Local Workshops: Mechanics can recommend trusted sources based on their experiences and customer feedback.

Tips for DIY Shifter Repairs

When tackling repairs related to your vehicle’s gear mechanism, understanding the common issues and knowing how to approach them can save both time and money. Whether it’s a minor adjustment or a more involved fix, having a clear plan and the right tools will make the process smoother.

Here are some practical suggestions to guide you through your repair journey:

- Identify the Problem: Before you start, carefully assess what’s wrong. Common issues might include difficulty in changing gears or unusual noises.

- Gather Your Tools: Make sure you have the necessary tools on hand, such as wrenches, screwdrivers, and pliers. A detailed tool list can help you avoid interruptions.

- Consult a Manual: Having a repair manual or online resources specific to your vehicle model can provide valuable insights and step-by-step instructions.

- Check for Wear: Inspect all components for signs of wear or damage. Replacing worn elements early can prevent further issues.

- Keep it Clean: Ensure the work area and the components are clean. Dirt and debris can cause complications during repairs.

Following these guidelines will help you effectively address issues related to your vehicle’s gear mechanism. Taking the time to understand the process will not only enhance your skills but also improve your vehicle’s performance.